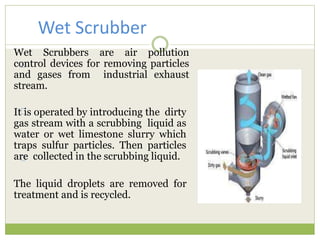

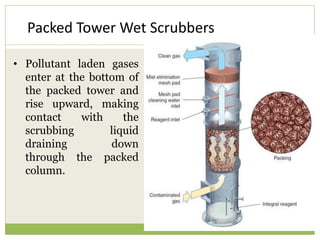

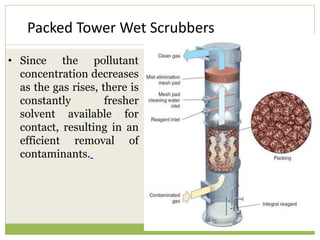

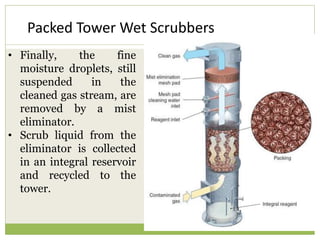

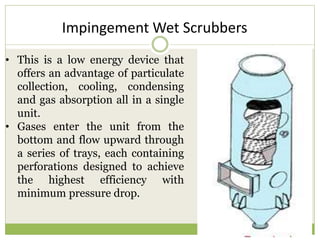

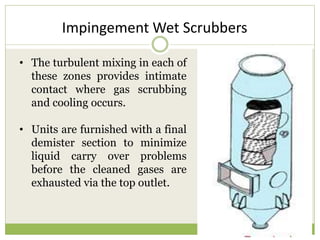

Wet scrubbers and dry scrubbers are two main types of particulate scrubbers used to remove particulates and gases from industrial exhaust streams. Wet scrubbers introduce a scrubbing liquid like water or slurry to trap pollutants, while dry scrubbers spray dry reagents to chemically react and neutralize or transform pollutants. The key variables that impact scrubber design include the nature and size of particulates, required removal efficiency, gas temperature and flow rate, and location. Common wet scrubber types are packed tower, impingement, and venturi scrubbers.