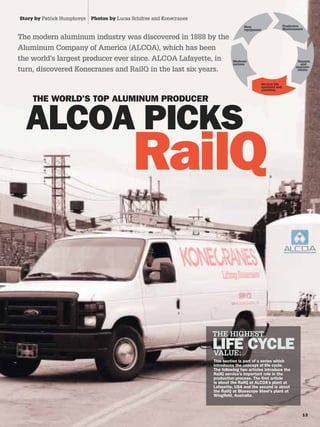

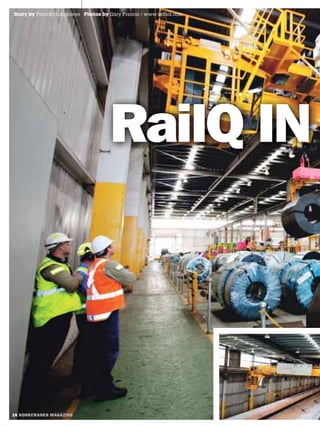

Konecranes' RailQ system has helped improve the reliability of cranes at ALCOA's plant in Lafayette, Indiana. Since implementing RailQ six years ago, ALCOA has seen significant reductions in unscheduled crane downtime and costs for replacing worn crane wheels and other parts. RailQ inspections identified issues with crane rails that were addressed, improving rail quality and reducing stress on crane components. ALCOA now works closely with Konecranes on crane maintenance and modernization efforts through predictive analytics to maximize equipment lifespan.