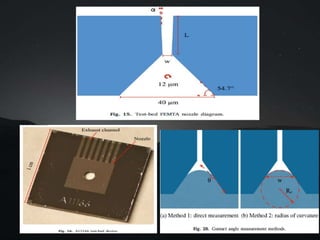

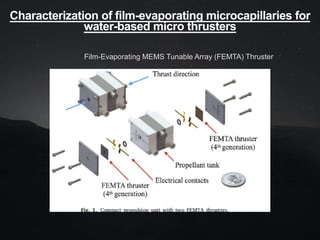

The document discusses water-based film-evaporation microthrusters.

1. They utilize the film evaporation principle to expel water propellant through micro-nozzles using efficient thermal valving, allowing for precise maneuvering of small satellites with low power.

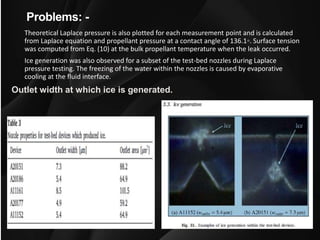

2. Testing showed maximum thrust occurs at nozzle throats less than 1.5 μm wide, but widths below 1 μm are needed to prevent leaking and ice generation issues.

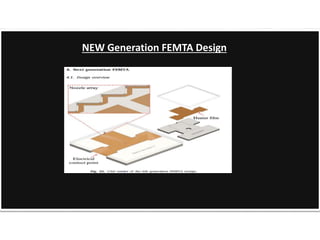

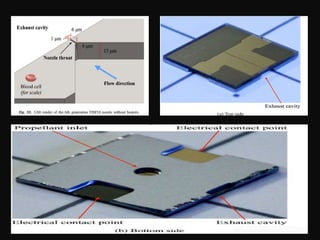

3. An improved design was proposed with an array of 1 μm wide nozzles that is expected to resolve prior reliability problems.

![Water-Based Microthrusters

or

Film-Evaporation Microthruster

Film-evaporation micro thrusters are a type of

propulsion system used in small satellites for precise

maneuvering in space. They utilize the film evaporation

principle to expel a propellant through a micro-nozzle,

allowing for efficient and controlled movement.

The use of water as a propellant offers environmental

and safety advantages, making it an attractive solution

for a wide range of emerging technologies.

by ROHAN SHARMA

[ Aeronautical ]](https://image.slidesharecdn.com/water-based-microthrusters-240222110436-256cf321/75/Water-Based-Micro-thrusters-for-nano-satellite-pptx-1-2048.jpg)

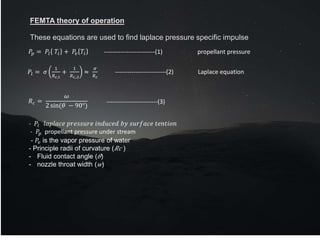

![FEMTA nozzle have shown that the flow is sonic at the exit of the throat. As a result, the

isentropic temperature and pressure at the nozzle throat exit are defined by Eqs. (4) and (5)

where 𝐶𝑝 is the specific heat and 𝑅 is the specific gas constant of water vapor.

DESIGN OF THRUSTER

𝑇𝑒=𝑇𝑖 1 −

𝑅

2𝐶𝑝−𝑅

-------------------------(4)

𝑃𝑒 = 𝑃𝑣 1 −

𝑅

2𝐶𝑝 − 𝑅

𝐶𝑝

𝑅

𝑢𝑒 = [2𝐶𝑝(𝑇𝑖 − 𝑇𝑒)]

1

2

𝑚 = 𝐴𝑒𝑢𝑒

𝑃𝑒

𝑅𝑇𝑒

𝐹 = 𝑚𝑢𝑒 + 𝑃𝑒𝐴𝑒

-------------------------(5)

-------------------------(6)

-------------------------(7)

-------------------------(8)](https://image.slidesharecdn.com/water-based-microthrusters-240222110436-256cf321/85/Water-Based-Micro-thrusters-for-nano-satellite-pptx-16-320.jpg)