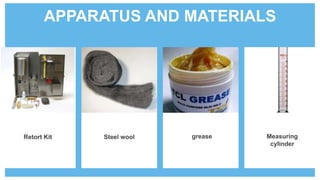

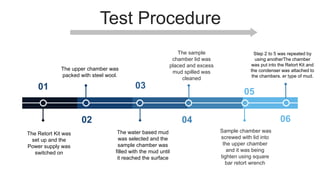

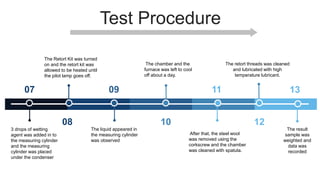

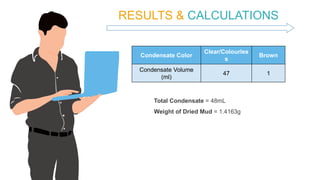

This document describes a laboratory experiment to determine the water content of drilling fluid samples. The objective is to determine the water content of each sample. The test procedure involves packing a retort kit with steel wool and mud samples, heating it to evaporate the water, and collecting and measuring the condensed water volume. For one brown mud sample, the procedure yielded 47 ml of condensed water and the dried mud weighed 1.4163 grams. The results and calculations are recorded. In summary, the document outlines a lab experiment to measure water content of drilling fluids by evaporating samples and collecting the condensed water.