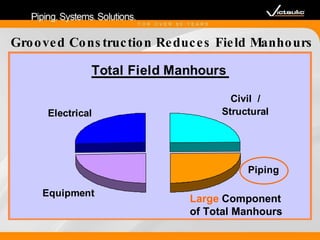

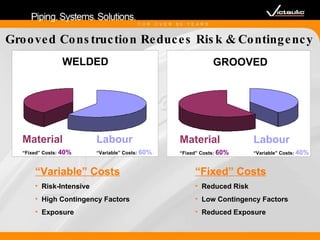

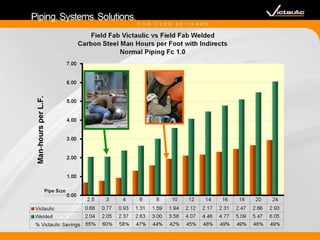

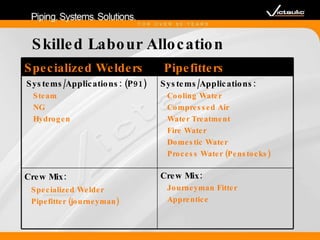

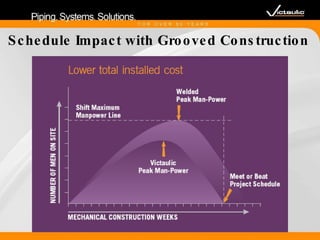

This document discusses the benefits of using grooved piping over welded piping for workforce management. Grooved piping reduces field manhours and risks compared to welded piping since it has lower variable labor costs and contingency factors. A case study of a power plant project in Toronto found that allocating welders to critical welded systems and pipefitters to grooved systems, using a two-person grooved crew instead of three, allowed the plant to be delivered ahead of schedule.

![John MacFarland Power Market Manager [email_address] 416-580-3007 Resources: www.victaulic.com www.compressedschedule.com](https://image.slidesharecdn.com/victaulicgroovedpipingimplicationsforworkforcemanagement-12863761169435-phpapp01/85/Victaulic-Grooved-Piping-Implications-For-Workforce-Management-20-320.jpg)