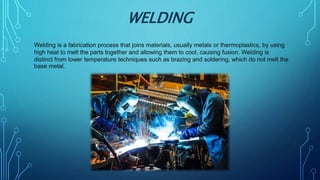

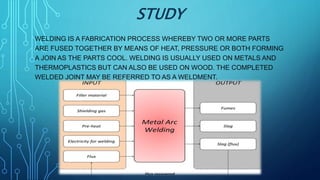

This document discusses different types of welding technology used in manufacturing industries. It introduces welding and defines it as a process of joining similar or dissimilar metals by applying heat with or without pressure. It then describes several common types of welding including arc welding, gas welding, plastic welding, fusion welding, and cold welding. The document provides details on arc welding and gas welding processes. It discusses the objectives of learning welding, studies welding as a fabrication process, and outlines the future scope and trends affecting the welding industry. The conclusion emphasizes that modern welding guarantees higher efficiency and quality.