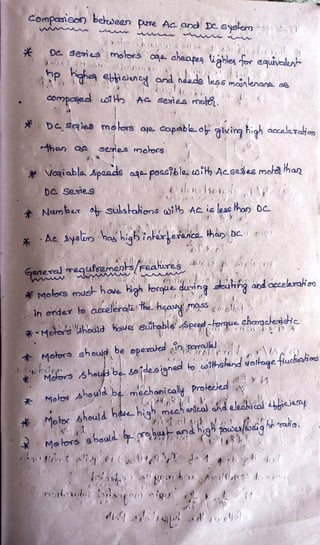

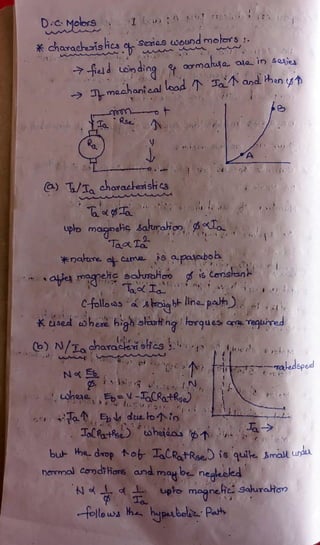

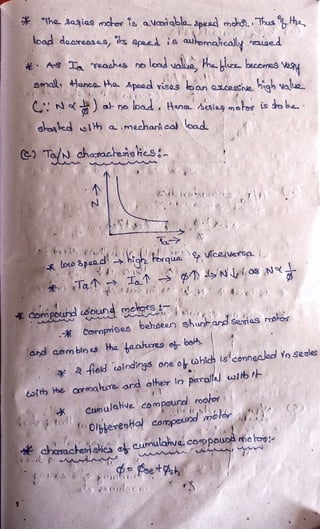

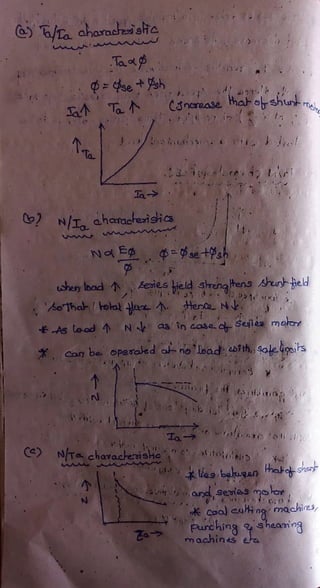

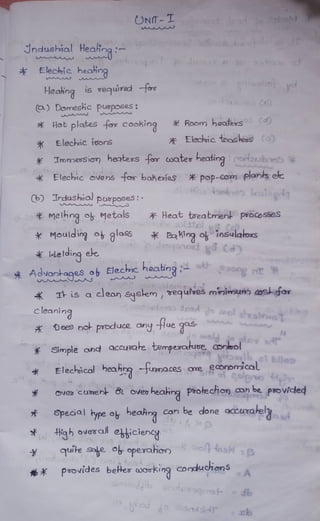

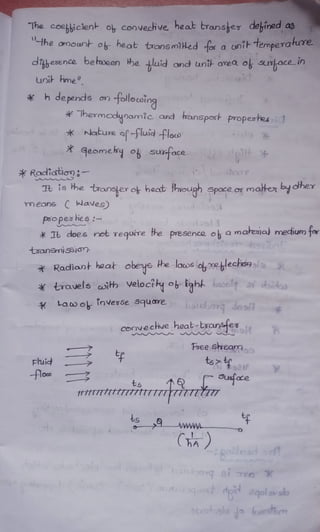

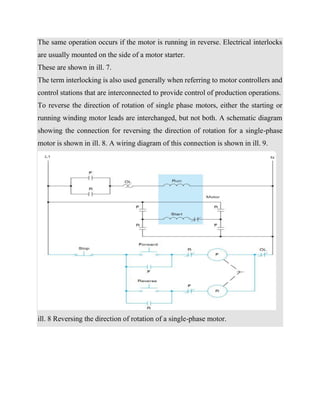

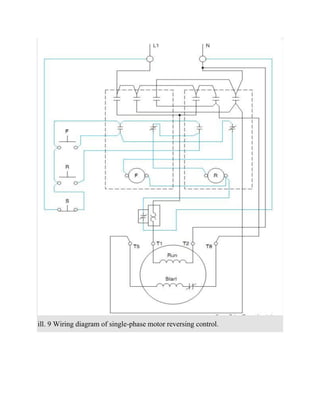

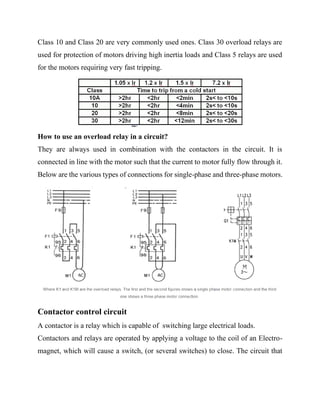

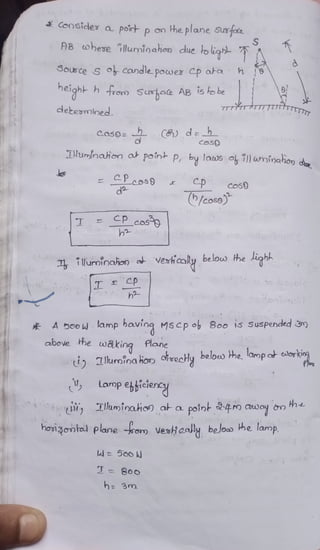

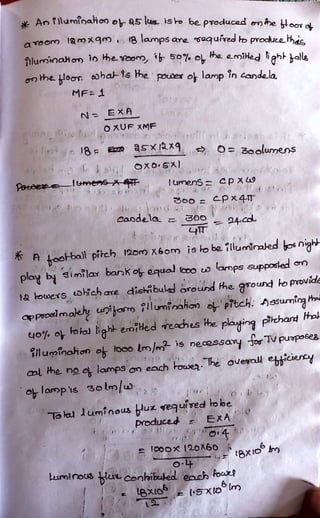

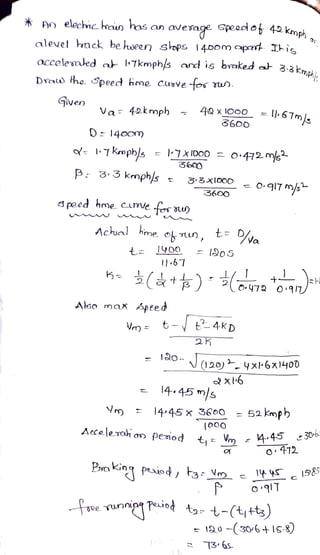

This document discusses several topics related to three-phase induction motors and their speed and direction control. It describes two methods for speed control using separate stator windings, and also discusses direct reversing and jogging control by interchanging motor leads. Interlocking methods like mechanical, push-button, and auxiliary contact interlocks are covered for reversing motor starters. Overload relays, their types and uses are also summarized. Finally, the document discusses contactor control circuits and their operation using start and stop pushbuttons.

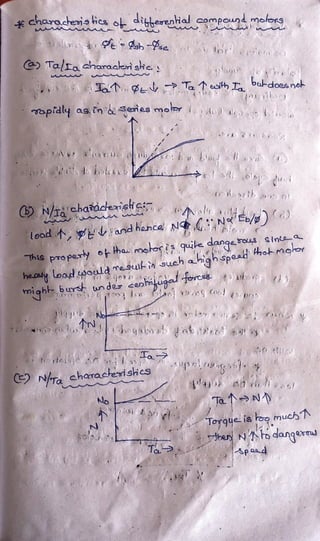

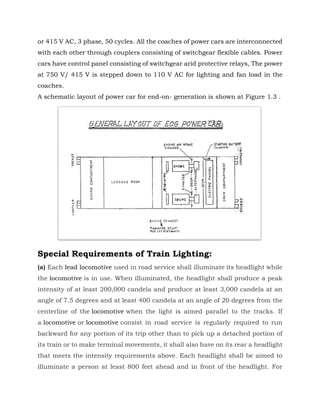

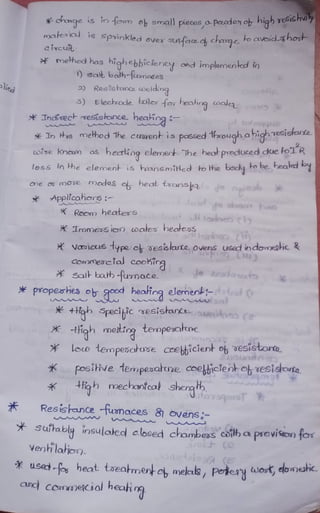

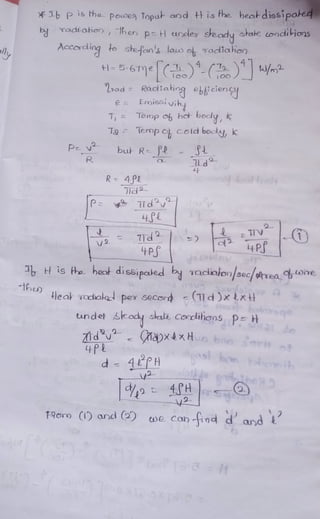

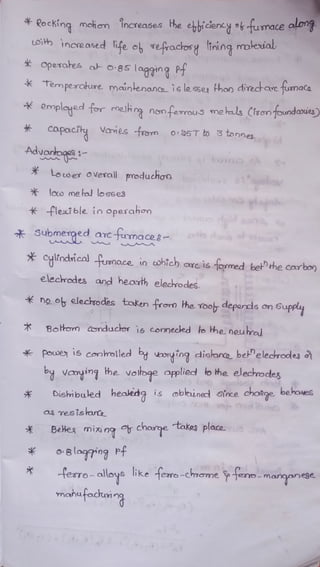

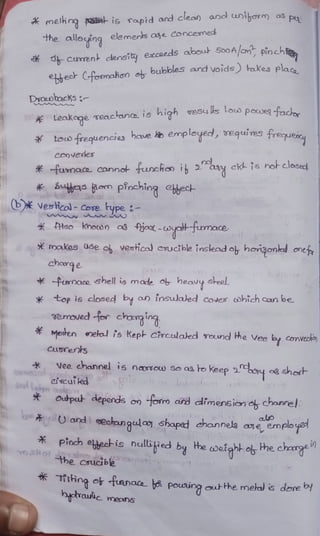

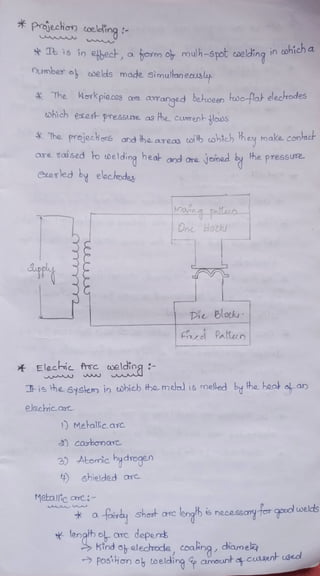

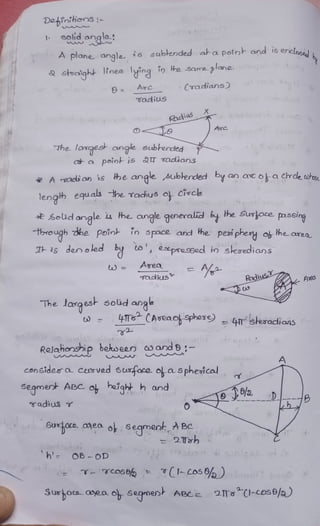

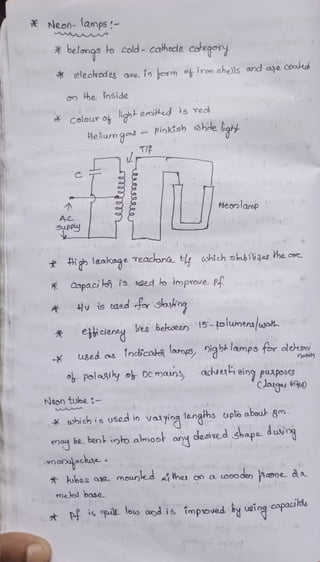

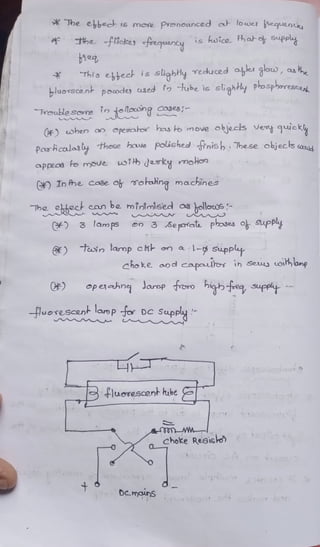

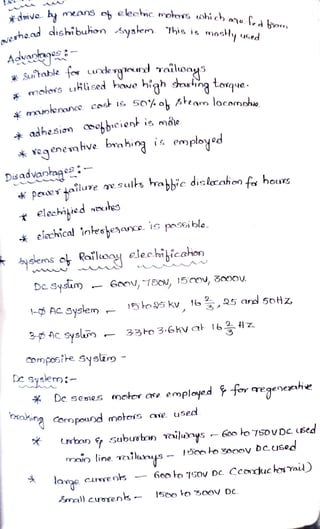

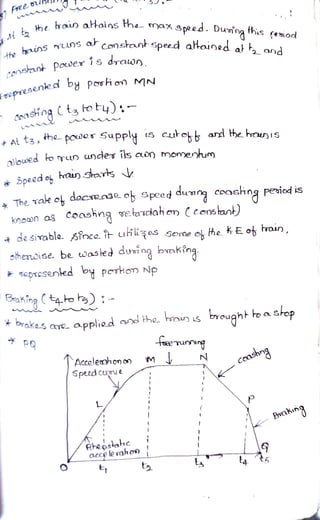

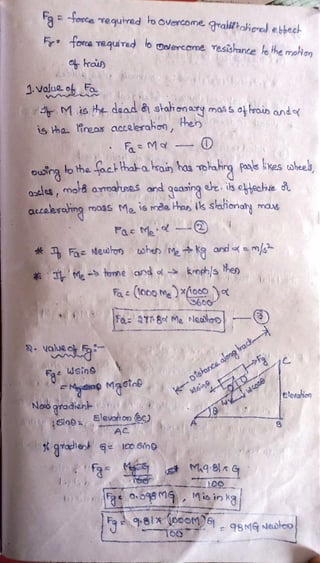

![l

I

I

J

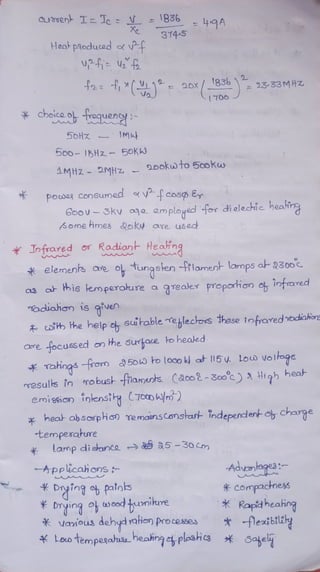

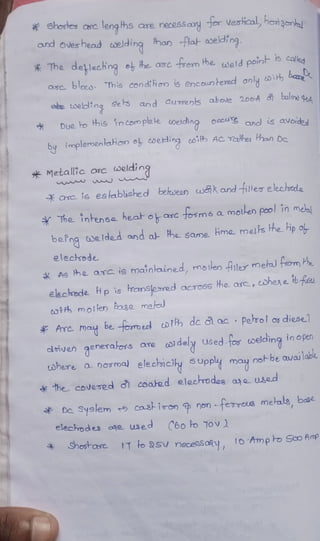

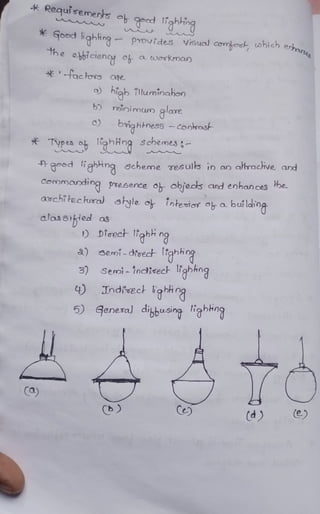

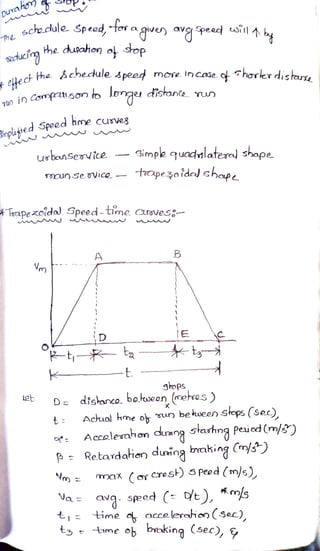

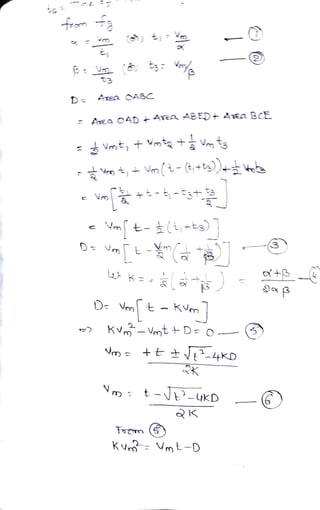

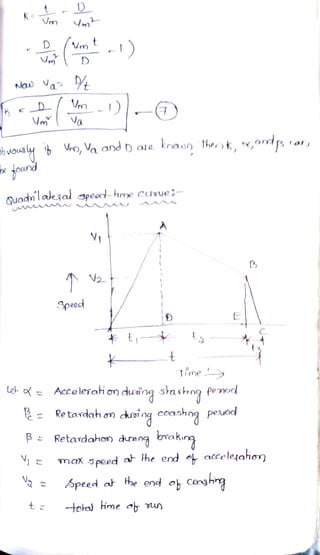

¾ qe~ ~n8 ~

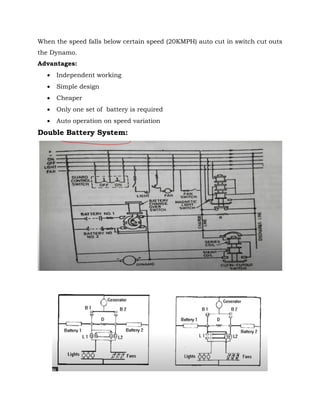

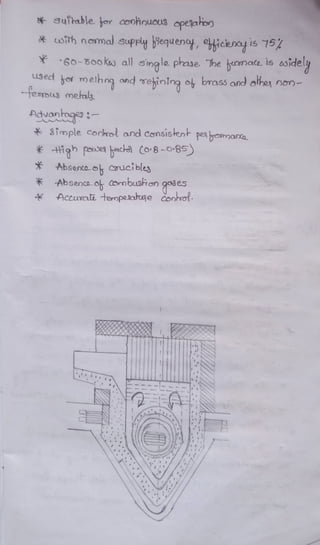

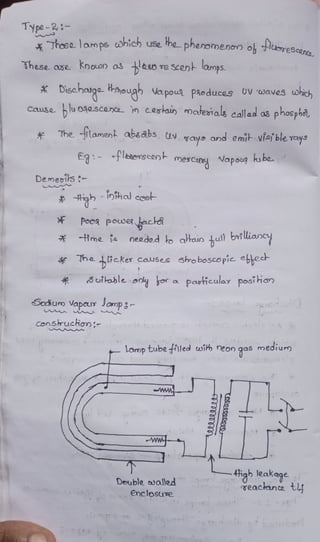

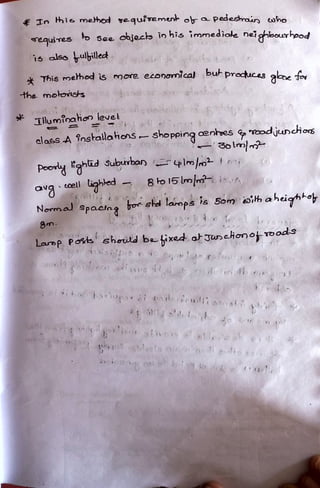

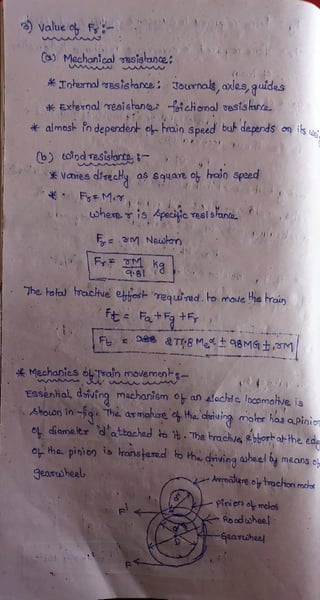

~ ¼hhl)'t -6ys/:iro lo.mps made- ol,- d,bffisi""d 0-~ ,

used t.0hic.h ~N~ near1'd e_qual ilu.ur)rnoJior> .tf) o.JJ

di'lfe.cHo-ns

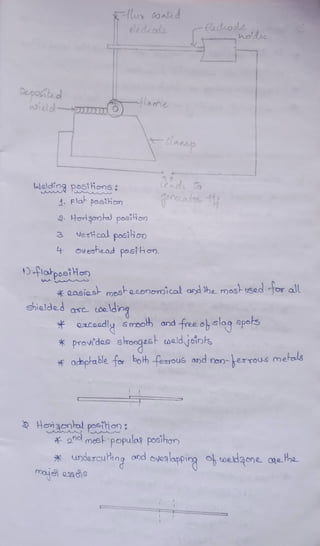

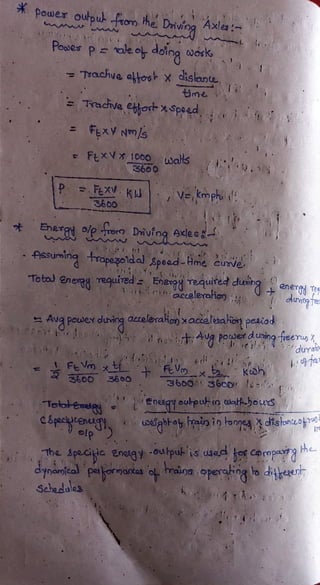

0~~8 .~ -

~, c ~ ~~ITcJ~6~

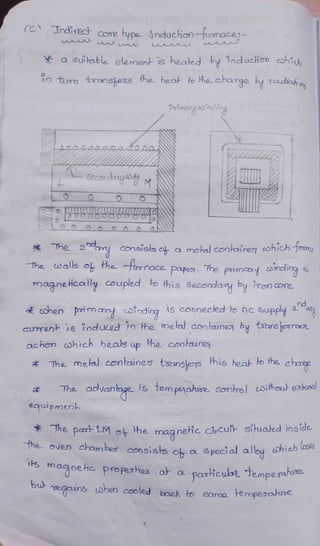

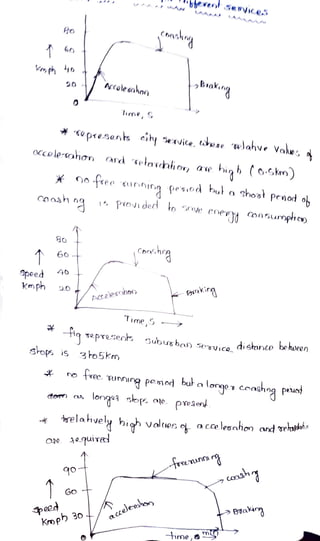

.' . .

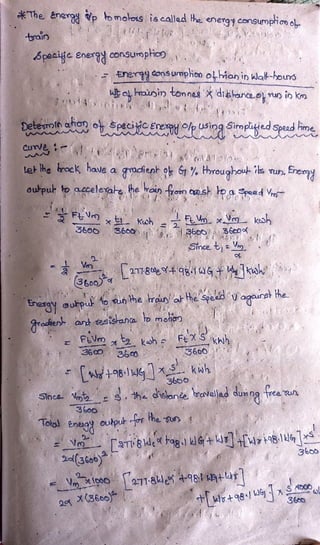

1) p-rovid~ a.de.quati- ~ lluroinQh071

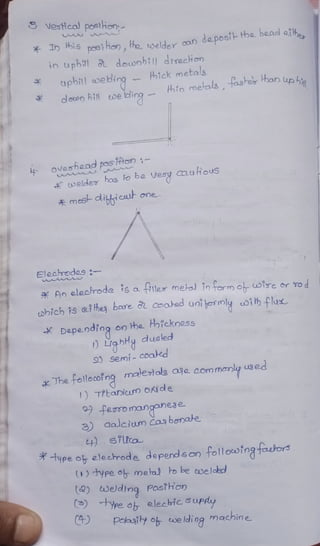

~) ltl)i~ro ~1-,I- dis~bu,~e,ry

'3) avoid

01a.Ye QJ)cf ho:rd -shadcws

., .. : ...Lt) f>rovide.s ti'<thl- ob St/ilnble. cdcx.tv-

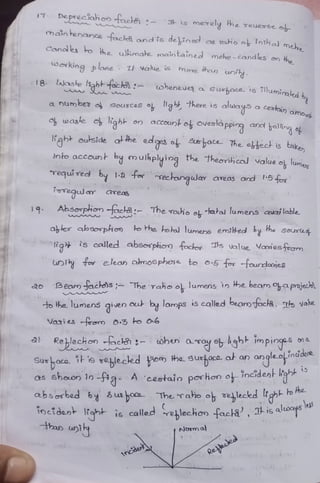

•

.·····,~

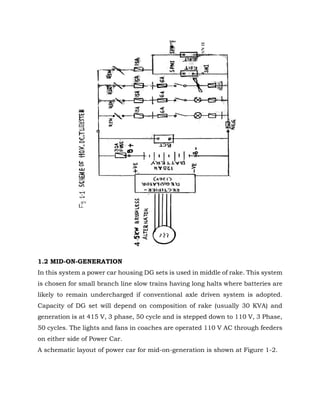

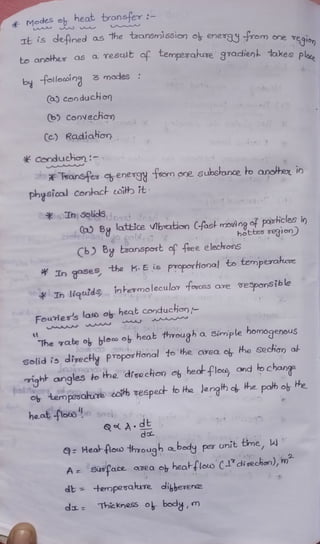

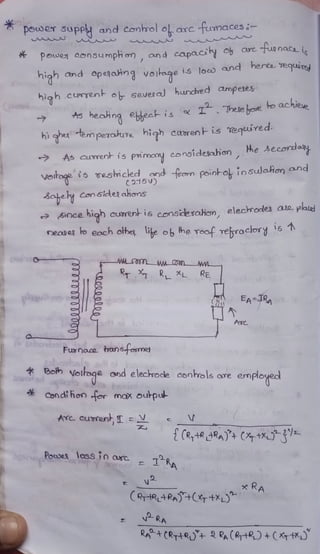

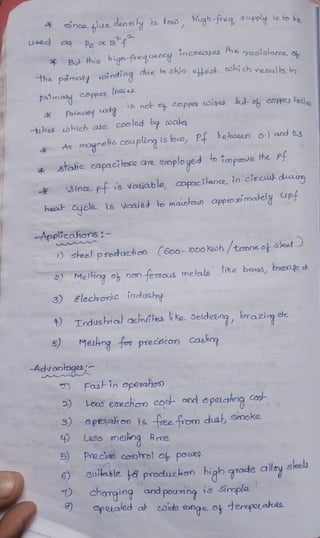

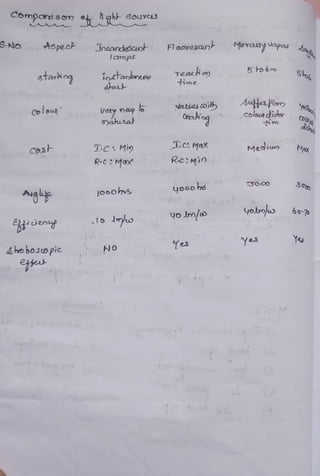

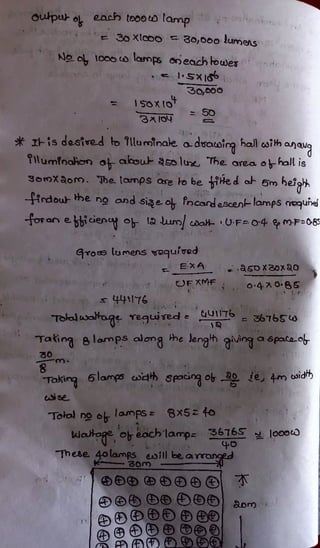

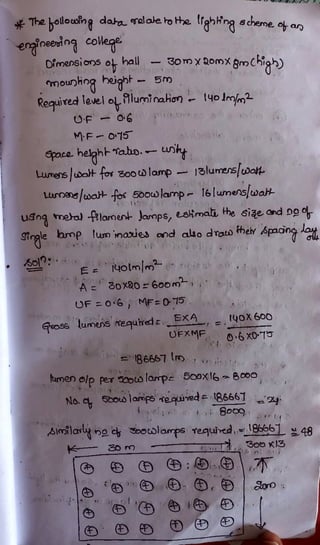

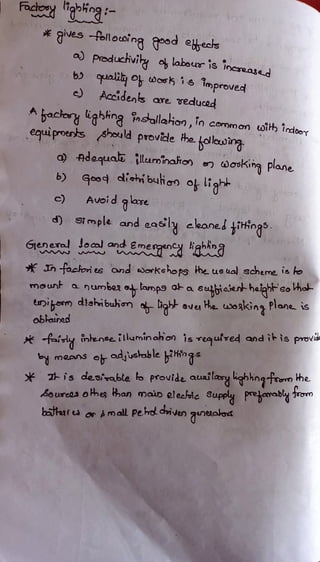

~?--~=--·~ ~ ~06" de.~i8nio51 ~

s ~ - . ~

,, :.tl")kn$r'cJ otr 'fff1.un;naJioY)

$ele.e-Jiem o~ lumfnoJres

6) Gf~e.. Dt"b"bOn')

4) ~W')H'"'r] ~r~'"° ard ~fl=la'"'3 °6- f11)Hi~

5) eooct;~ ~ u~

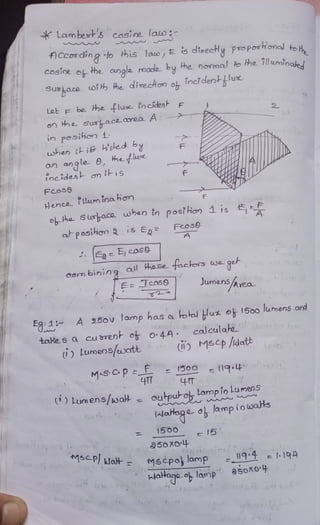

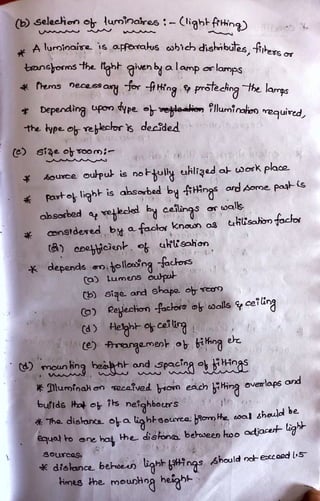

Oj J:')~Ob-~~:-

*""fQ..9uT~e,s p d;'~tre.rl- illuM~r">ctho,')

~()J.ef)6~~ ~ di~enJ- ou~~

(.a.) {ach:,.ie_s- ~ wos~~ps ..::;> 50 - ISoO

Po wez hous~ ~ 100 - aoo

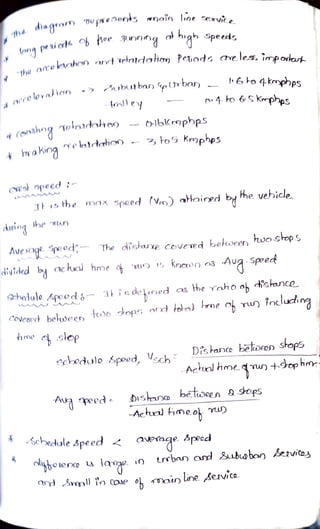

ol,-biciu](https://image.slidesharecdn.com/ueetotalnotes-240217014714-b5c16e47/85/Utilization-of-Electrical-Energy-notes-pdf-95-320.jpg)

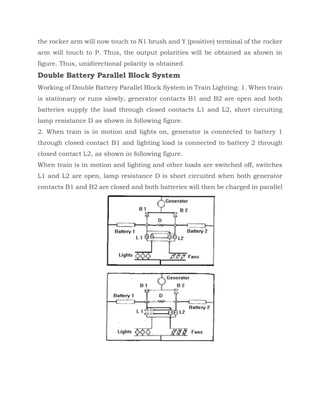

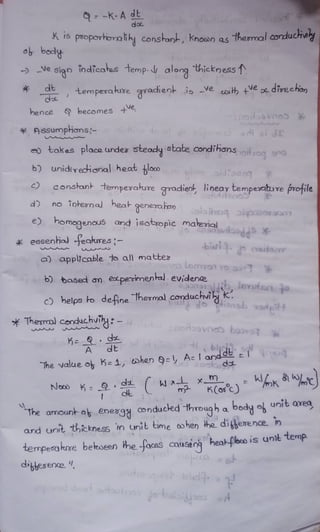

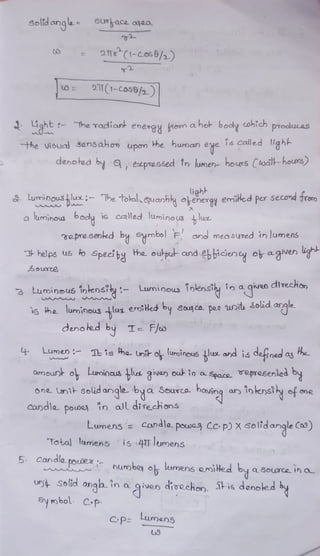

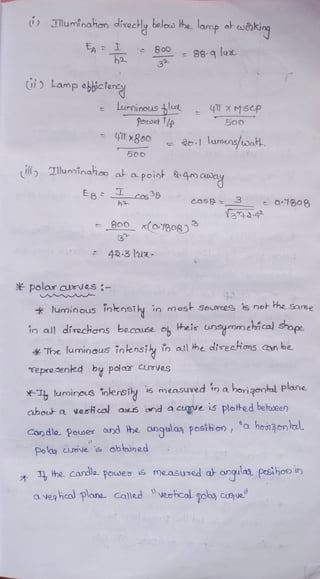

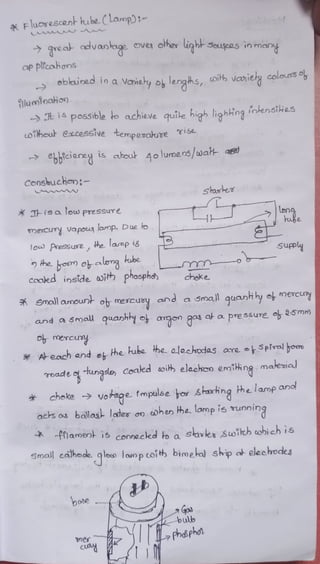

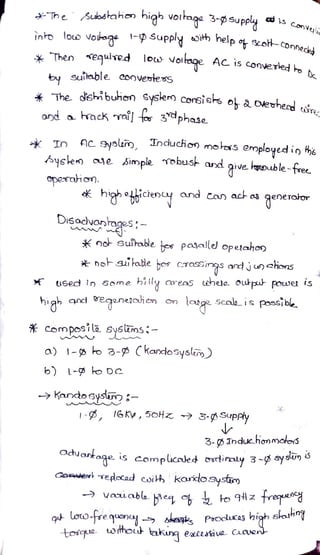

![s~~-!:}it:]:-

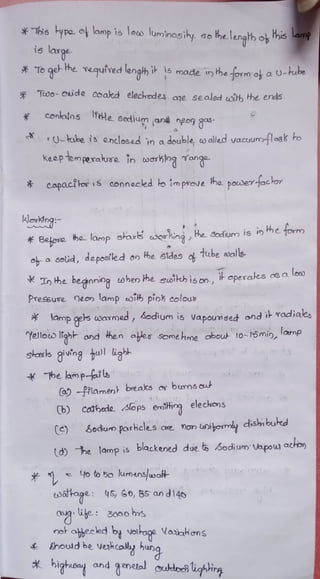

o~~"~ :-

~

{!J co.o:z,-~ Jis,,L 0~nuc.ka')5 on y~ 1r-,a,d~ ~

-o)J~ ~~ OJ"'ld c00v~ni~ ,

@ enho.n~I+~ cot'l'ln'W1 i1 valuct. o}r.skeJ-

© rn'"1?. olhoclive..

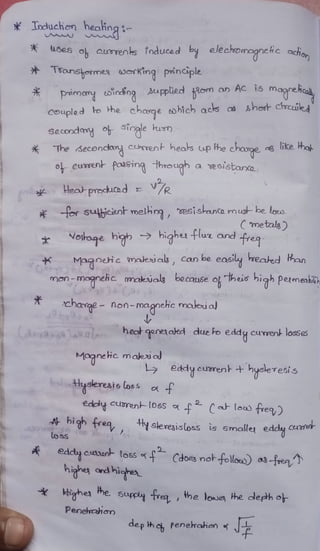

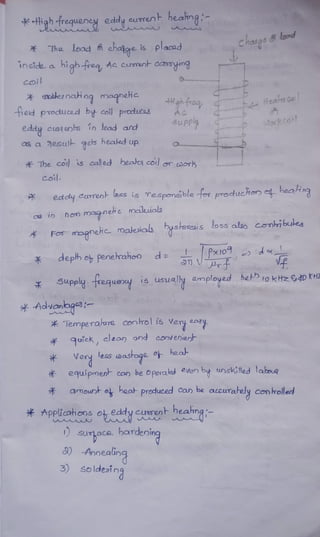

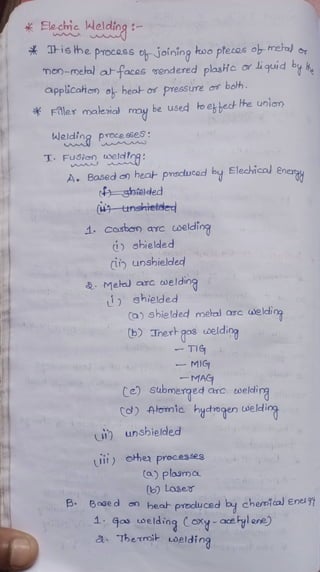

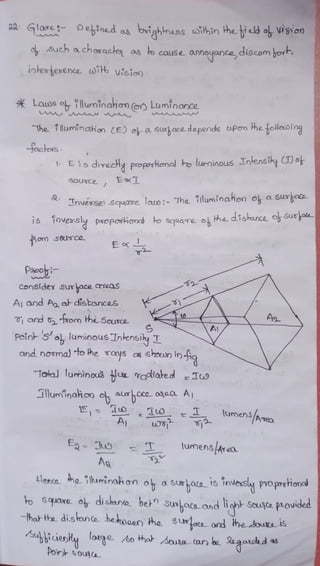

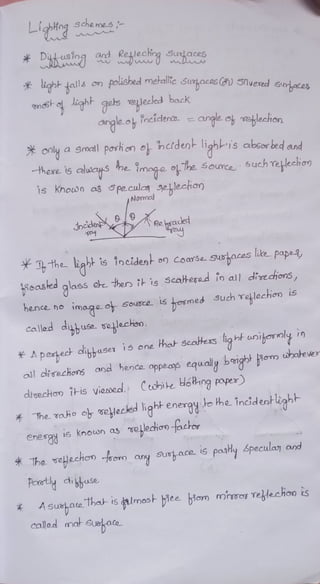

~ p,rfnciple..s f"vot"ed : -

t • 0,nt,-us~crr>

a. . /4pe.cul~ 'l"e.~ledio-o

~ : -

* lhe. lo.~p.!> ~H-e-d (J)jH) sull--a.bte. 'lfel,-e.~~ ~e.

'¾

I

I

ernplo~d ,the- des,ca.., ot,- 14)e. ve&,le.c."°"..s is. soc.h H-xd- H-ey

"Q dT~ I-he tiijhl- dotbn/Jlo,1'4s and sp-reo4 ~ uni!,mm~

cu p~asthl~ ttvex .h-Ubo-OLol,- rrocc4

.:f Ih o-fd.eJ h, a'-'~id ala-re · H->e. ~eh-lee~°"~ modei..,

~e ~o.-04-S°

* tJie ~tr~ao p~'"" o-n Ho)~ CftJl~fnc.ide.n~ SUJi~01J

"1"lalCU thL --a,ocl b~t~_

l-o o~"~ .

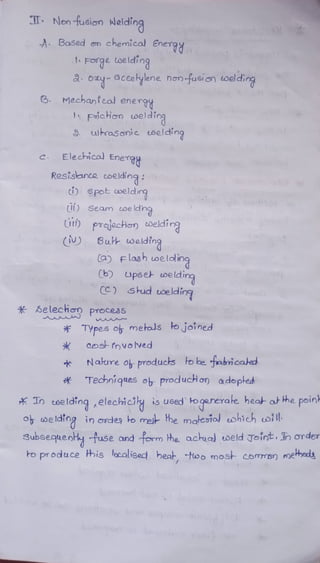

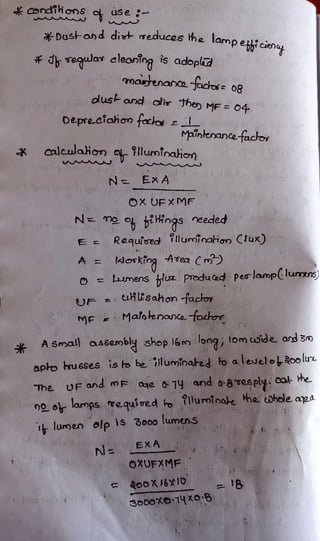

~~c.olcr.J~nca ~llw-r,ir,oh~ por~1-opei,.,~ ~ fn"e-rse

s9u01t"e lo.t&l me.l+,cx:t ·,.ei emplor · .

~ ..-e.sullonl- 'rllurw,To~at) te ~e.. ,SUll) ~,-.~ ilh.1Mt~ ~

dua. ~ Q..OV') ICIN'lp.

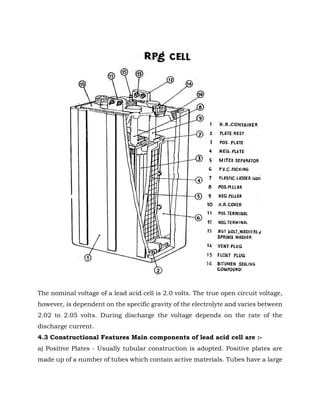

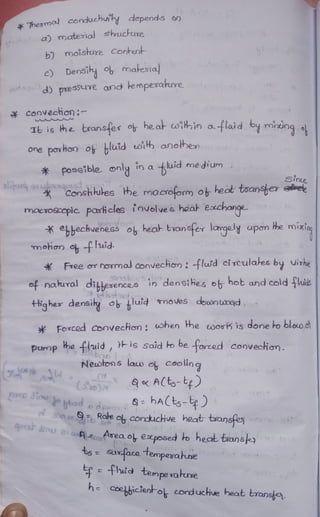

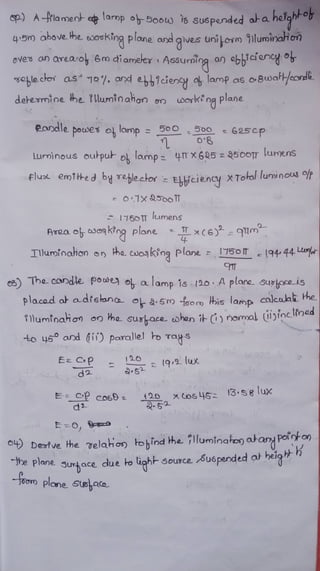

Cop Q..CO.}~ ~~~c:H :-,

~ --.,, ......,

* ~e.t,-ie..c.h:,is o.Te. c.u,rve..cl u f'W~Tes /4~ ~l+it- lif

; 5 H1'Y'otu0 c,f) Yo~ ~ a. ~e.,t J°(1e,~e.0 ~i,..,dcfeJU-](https://image.slidesharecdn.com/ueetotalnotes-240217014714-b5c16e47/85/Utilization-of-Electrical-Energy-notes-pdf-101-320.jpg)

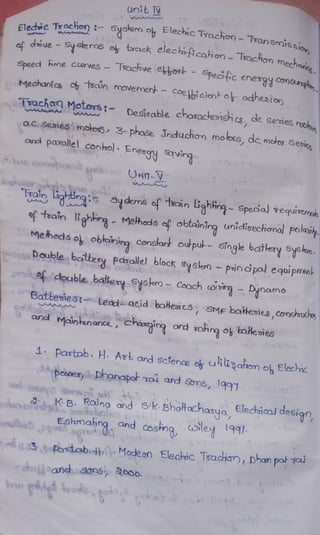

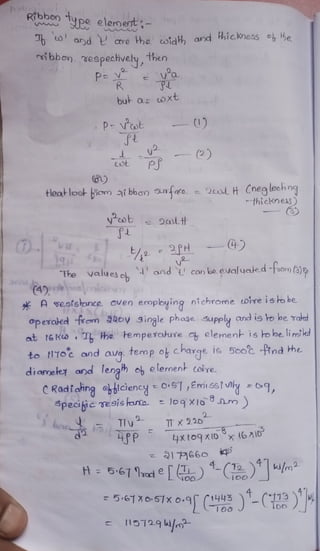

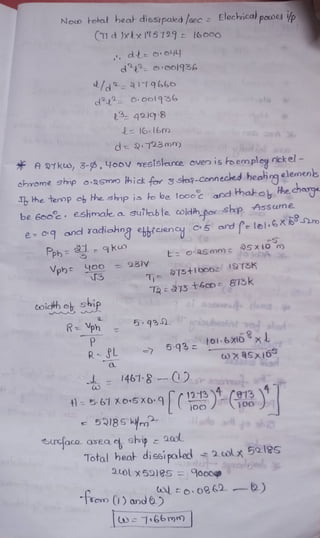

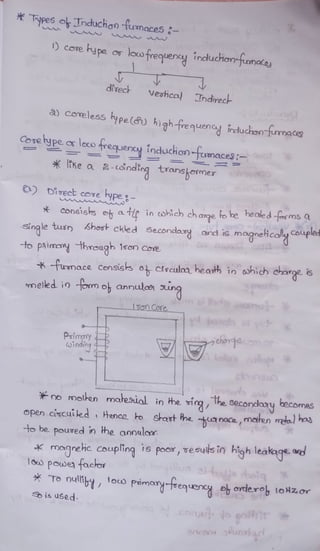

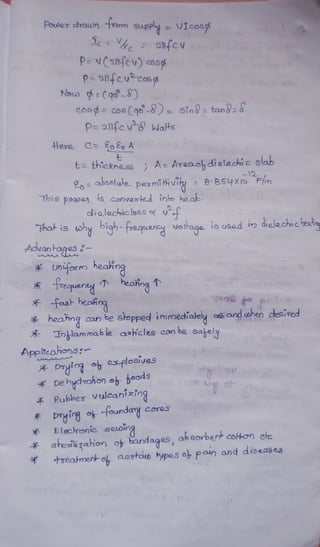

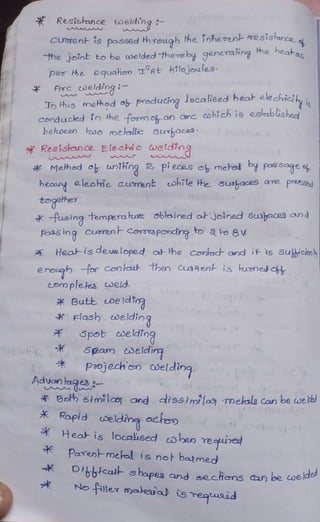

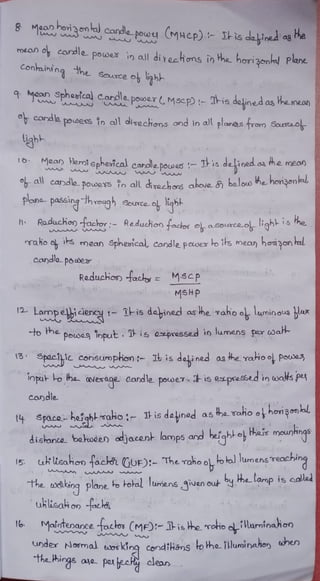

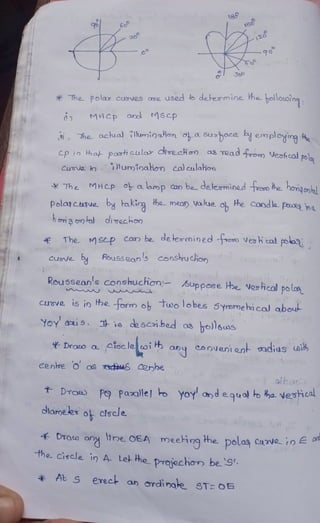

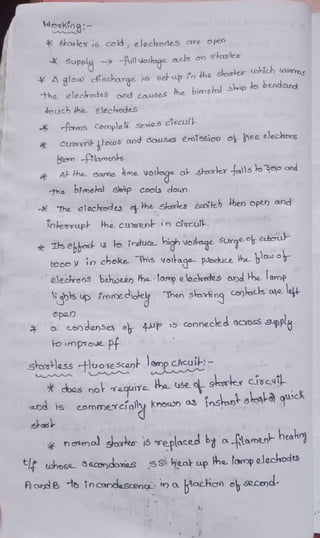

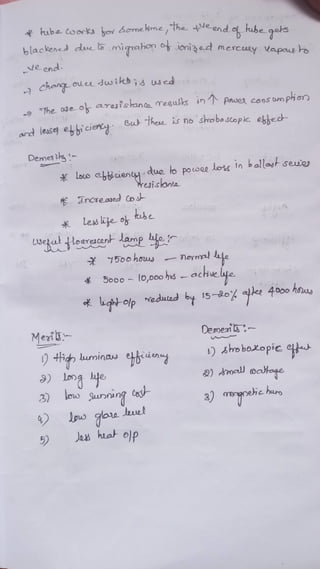

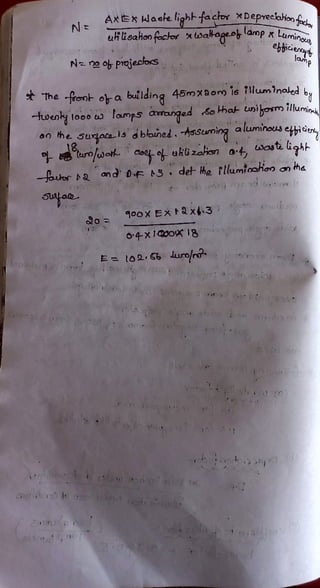

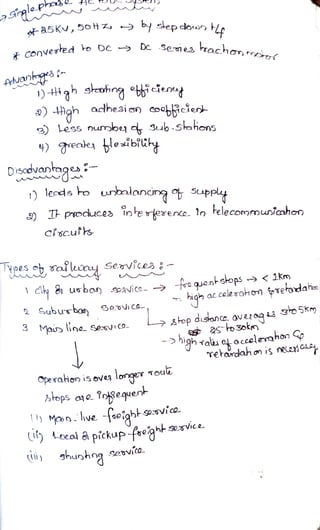

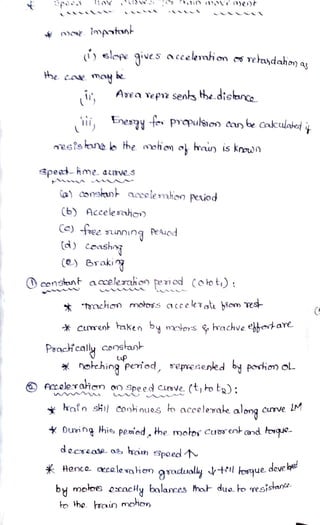

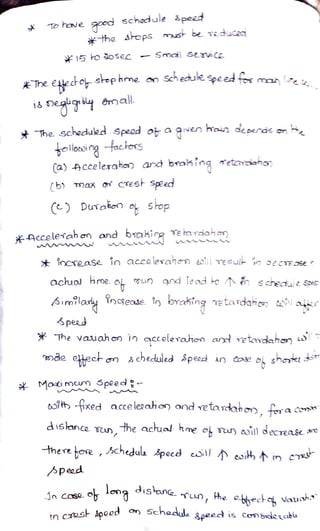

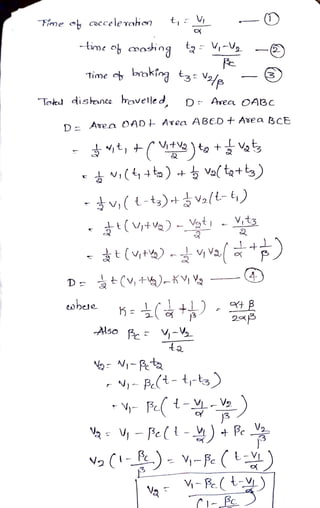

![ooley Me-loco e-l lG Hl] Ls'+s]

3600

he

usl atu a3600

Speciie enexgy oupo

Enegy oukpu- or he munin wal-hours

y etobhoftraip in omes dishard.ouiok

o-ol 6727o +0-778l981WG+r)S

l

WxS

olo72vxa oTR SL(81 4T

lh pesreorne-kn

She soackislevel ene GEo

6pari eneia ostmprio

Colo2V7He o218x h/enne.b](https://image.slidesharecdn.com/ueetotalnotes-240217014714-b5c16e47/85/Utilization-of-Electrical-Energy-notes-pdf-133-320.jpg)