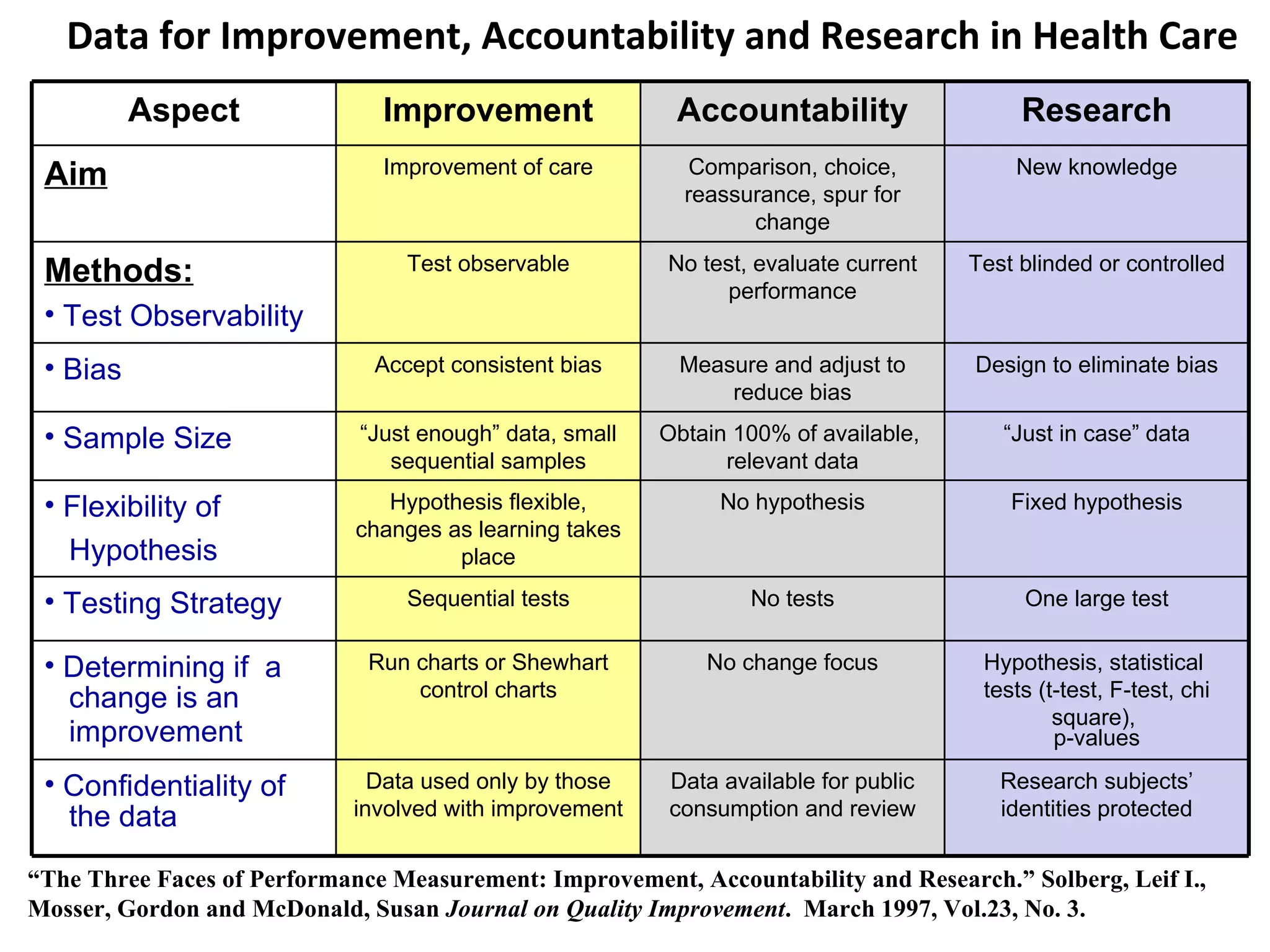

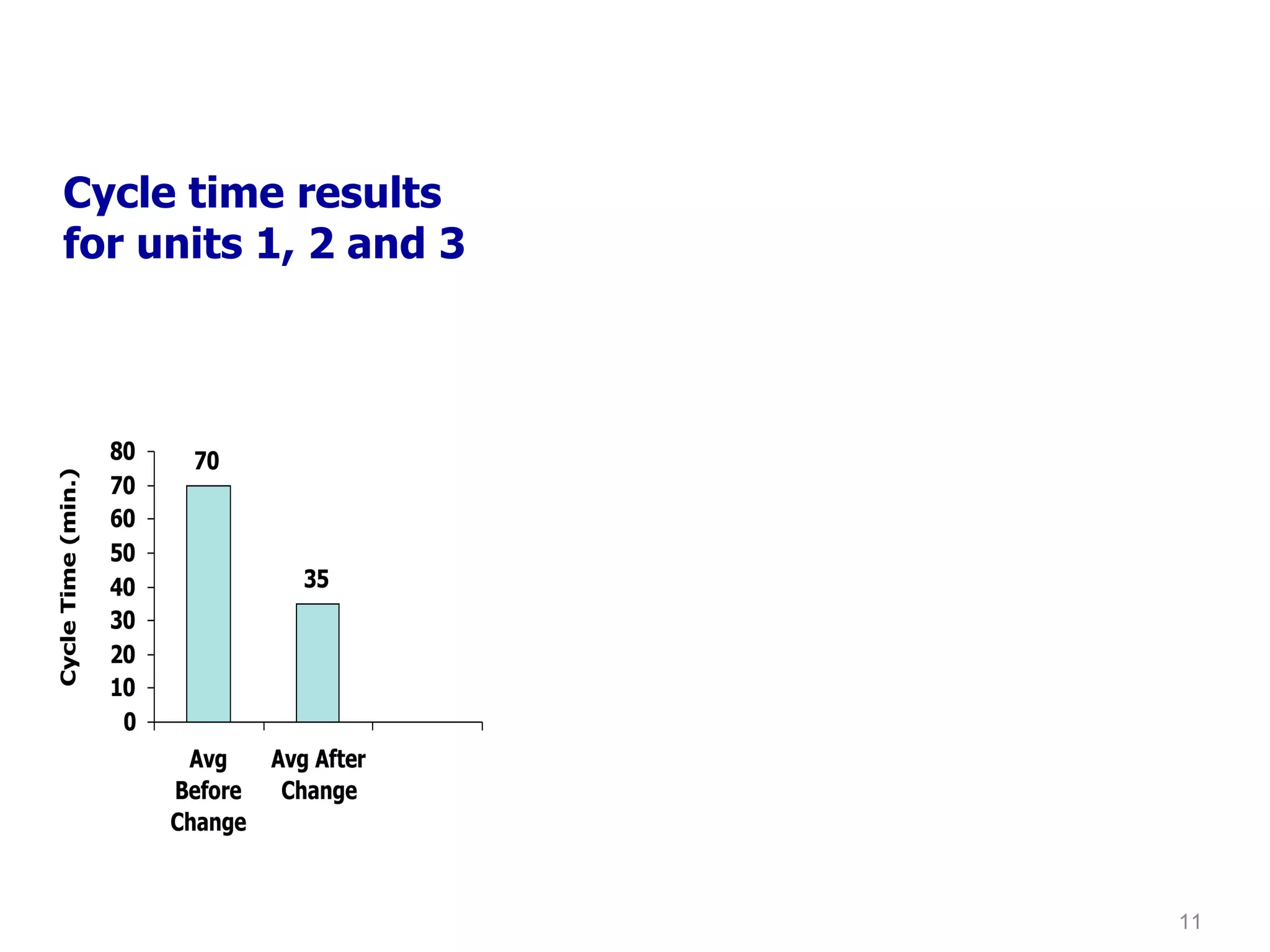

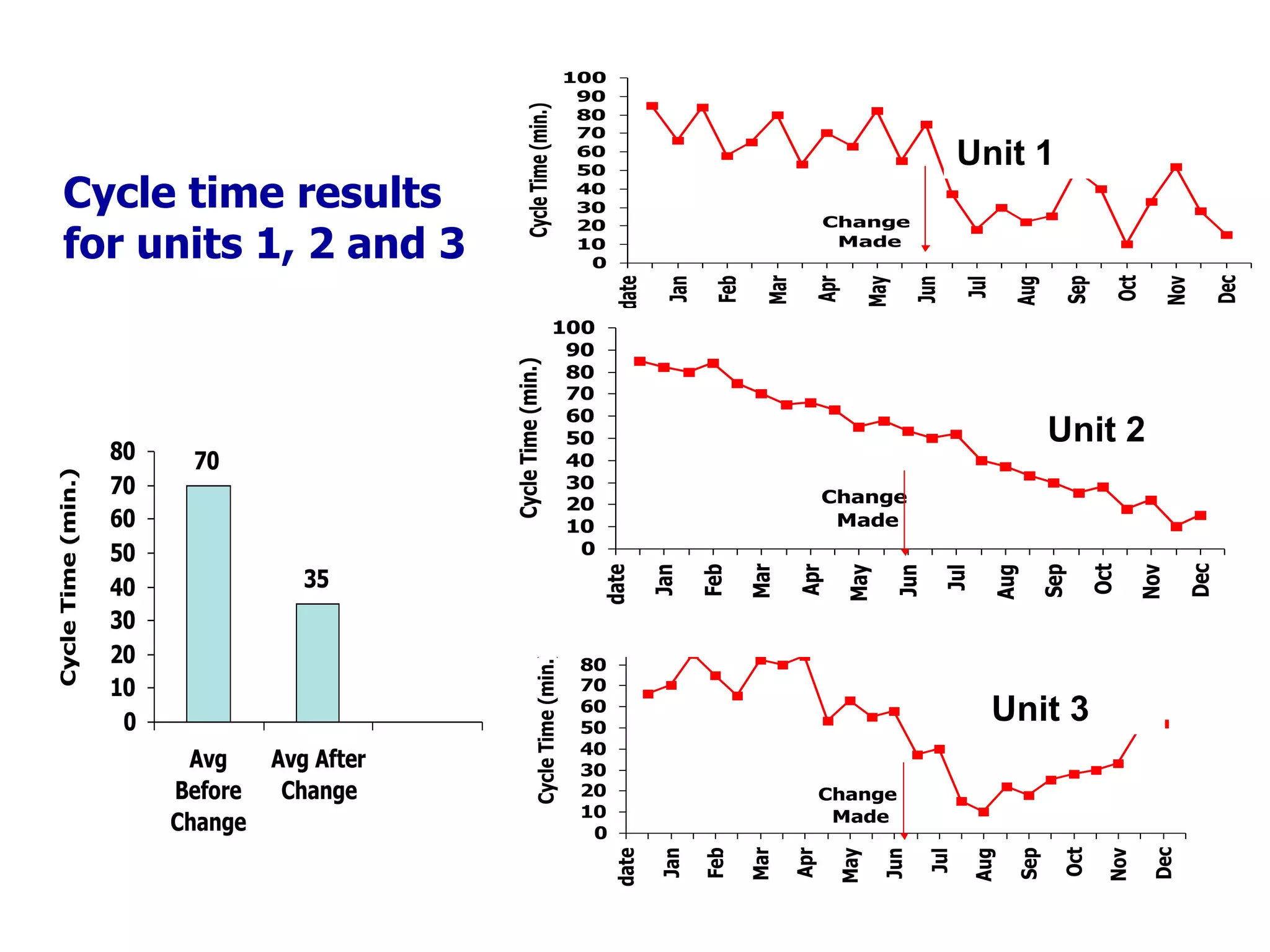

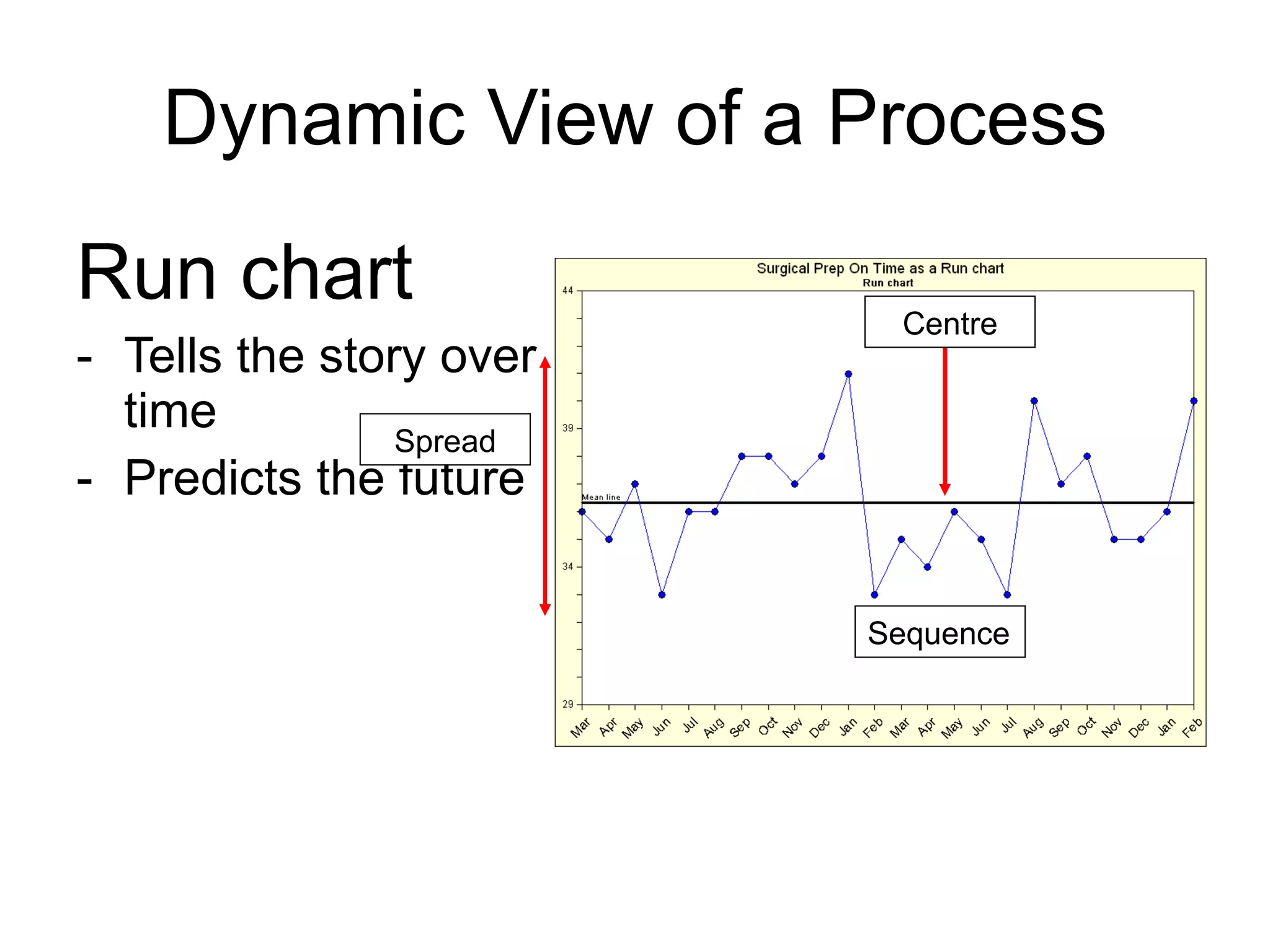

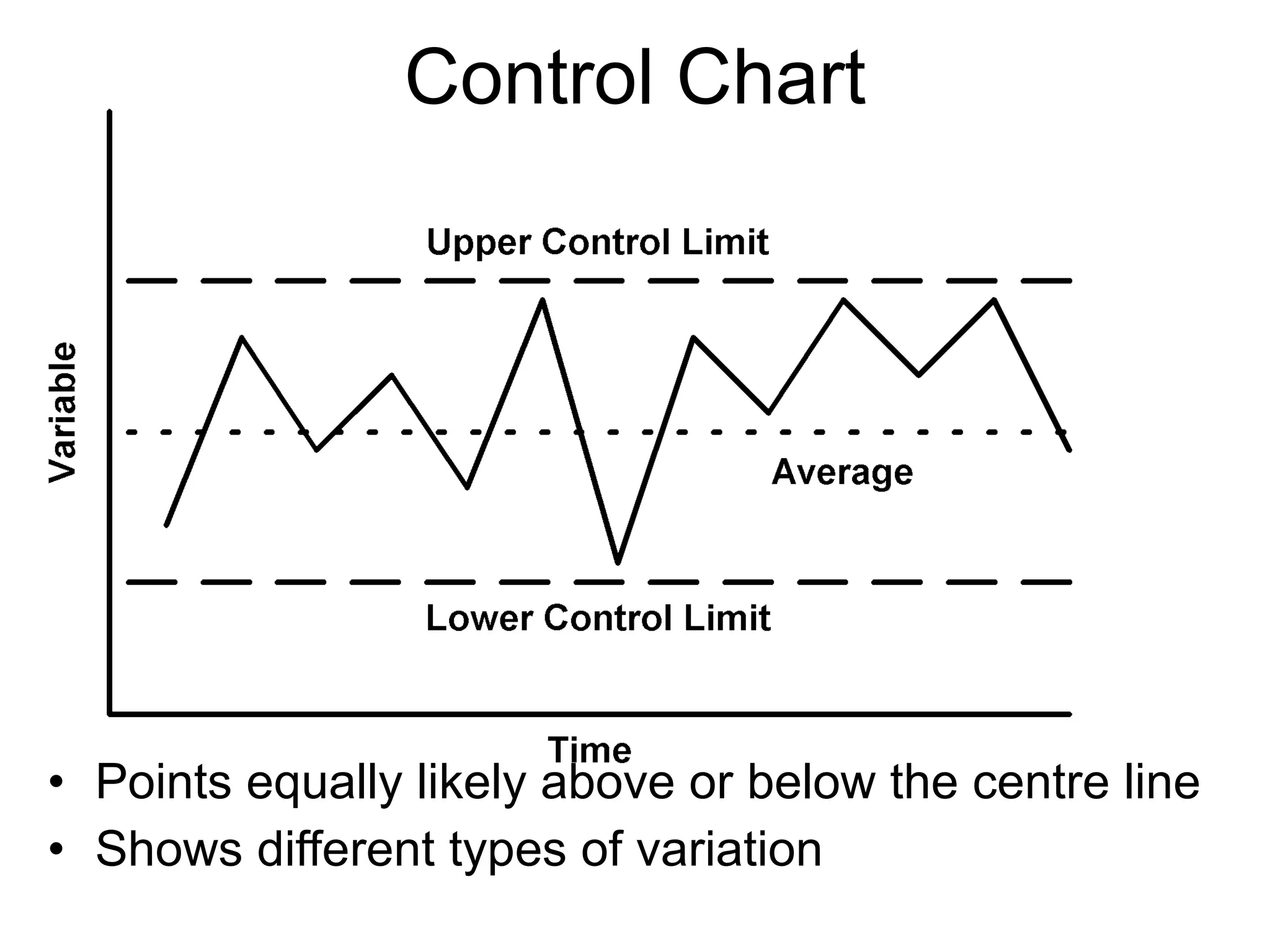

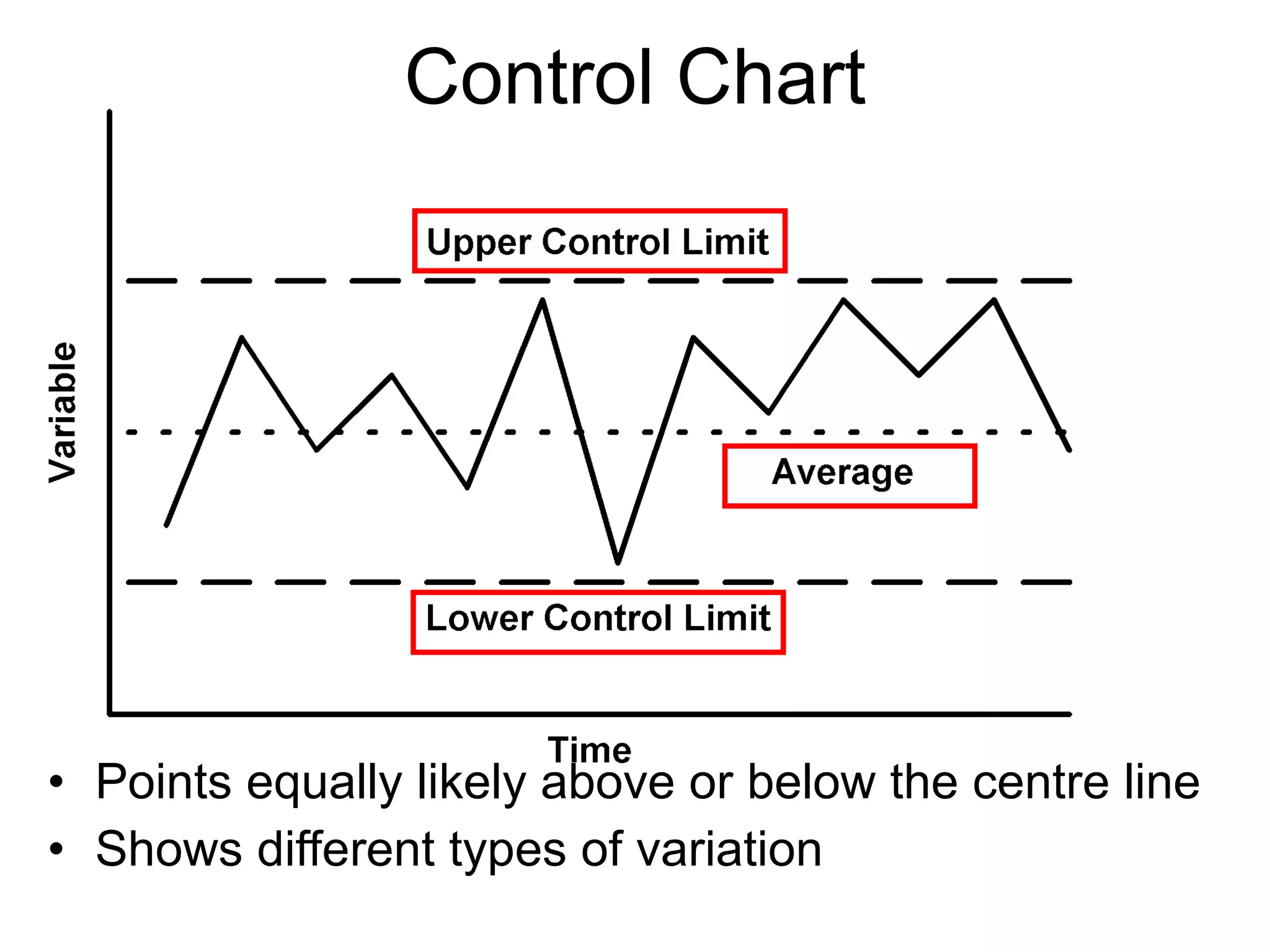

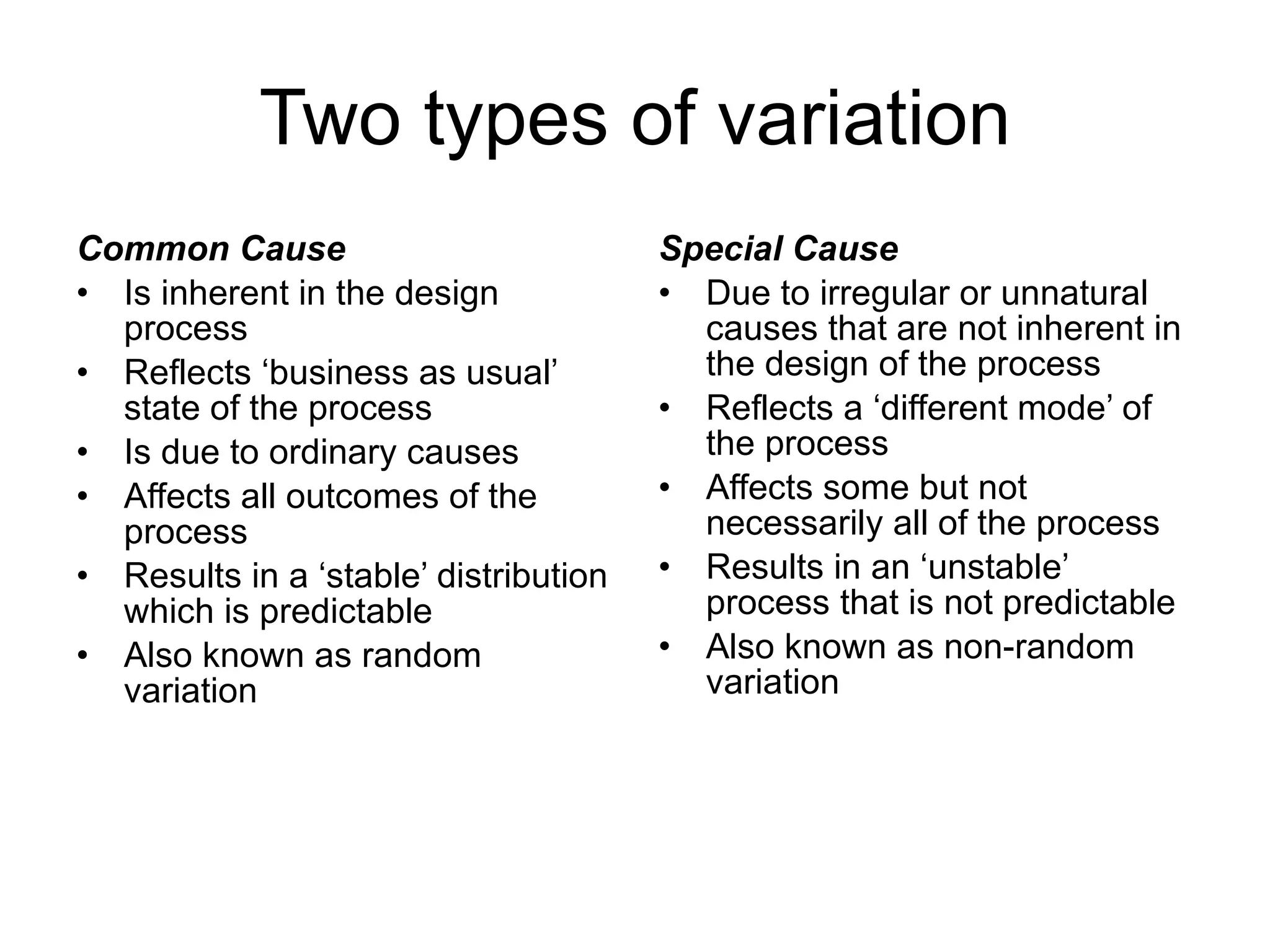

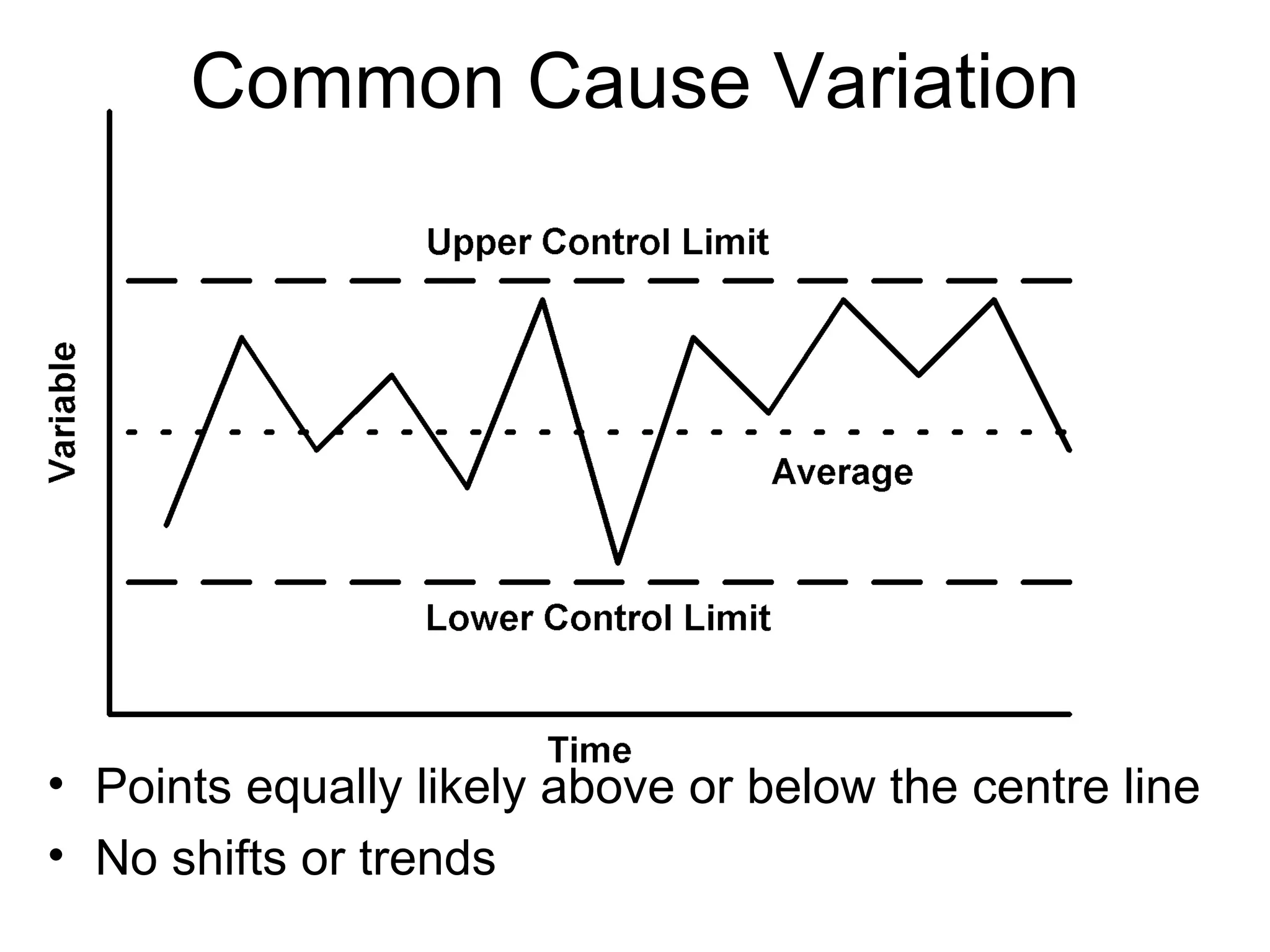

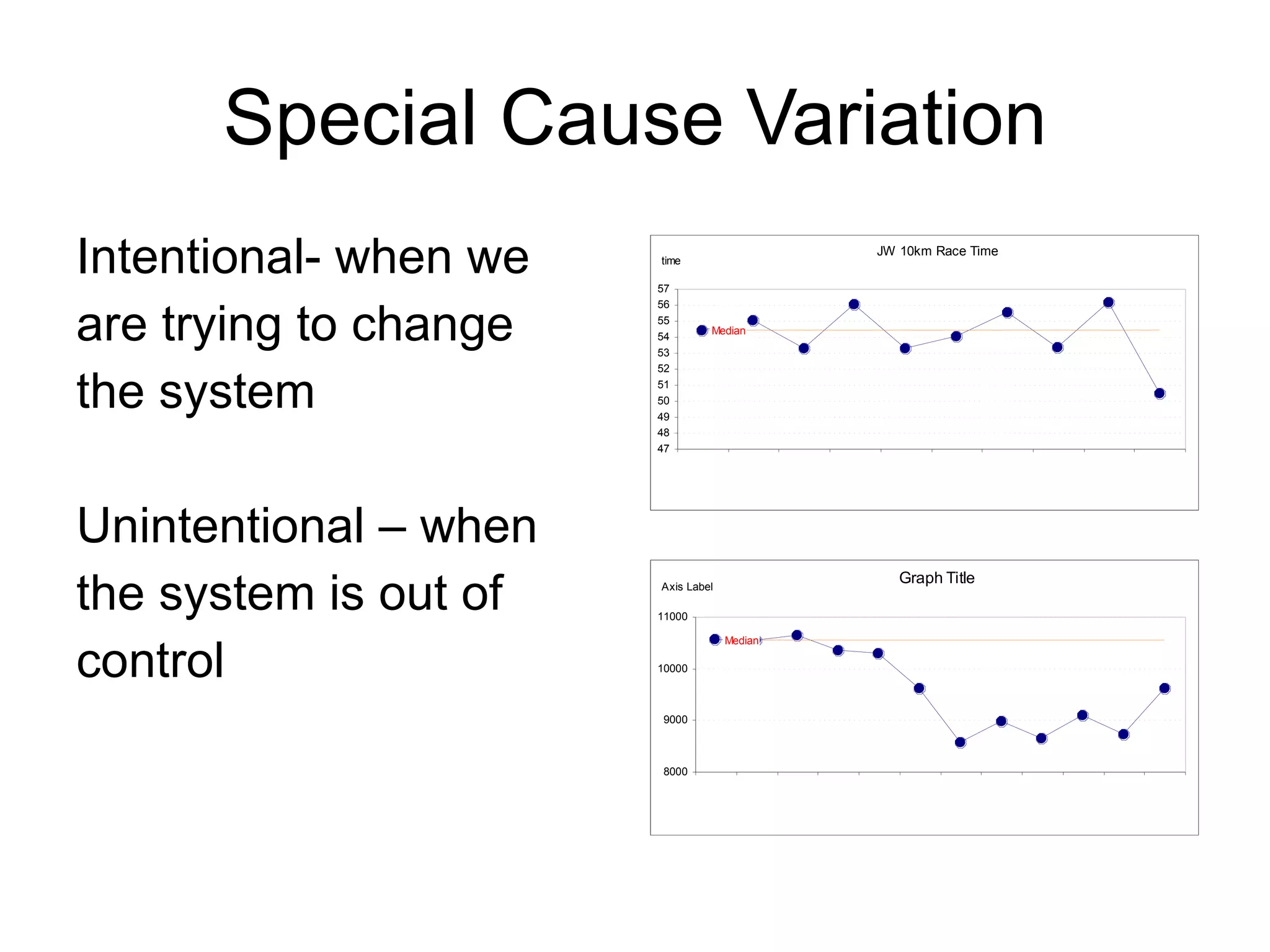

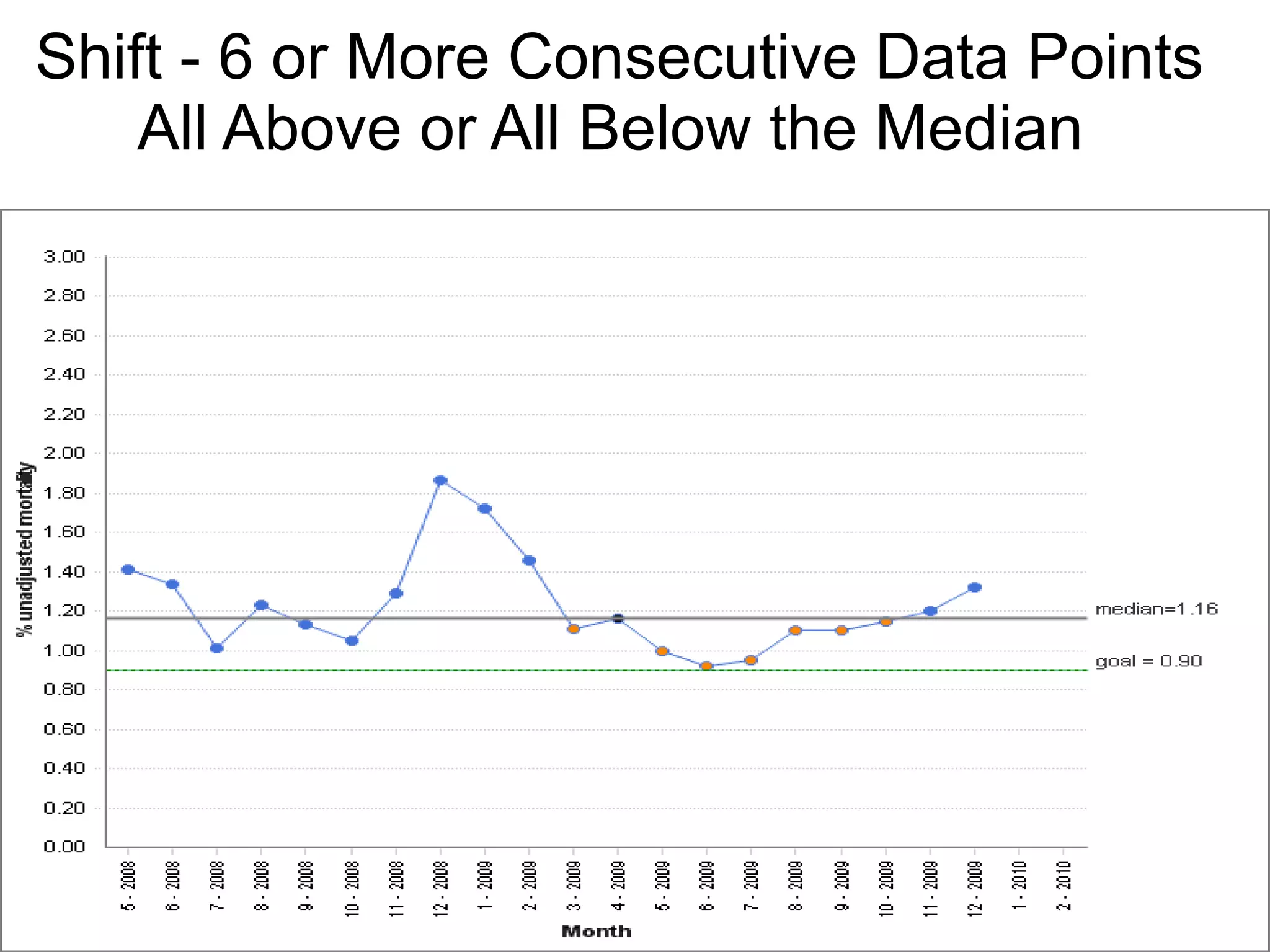

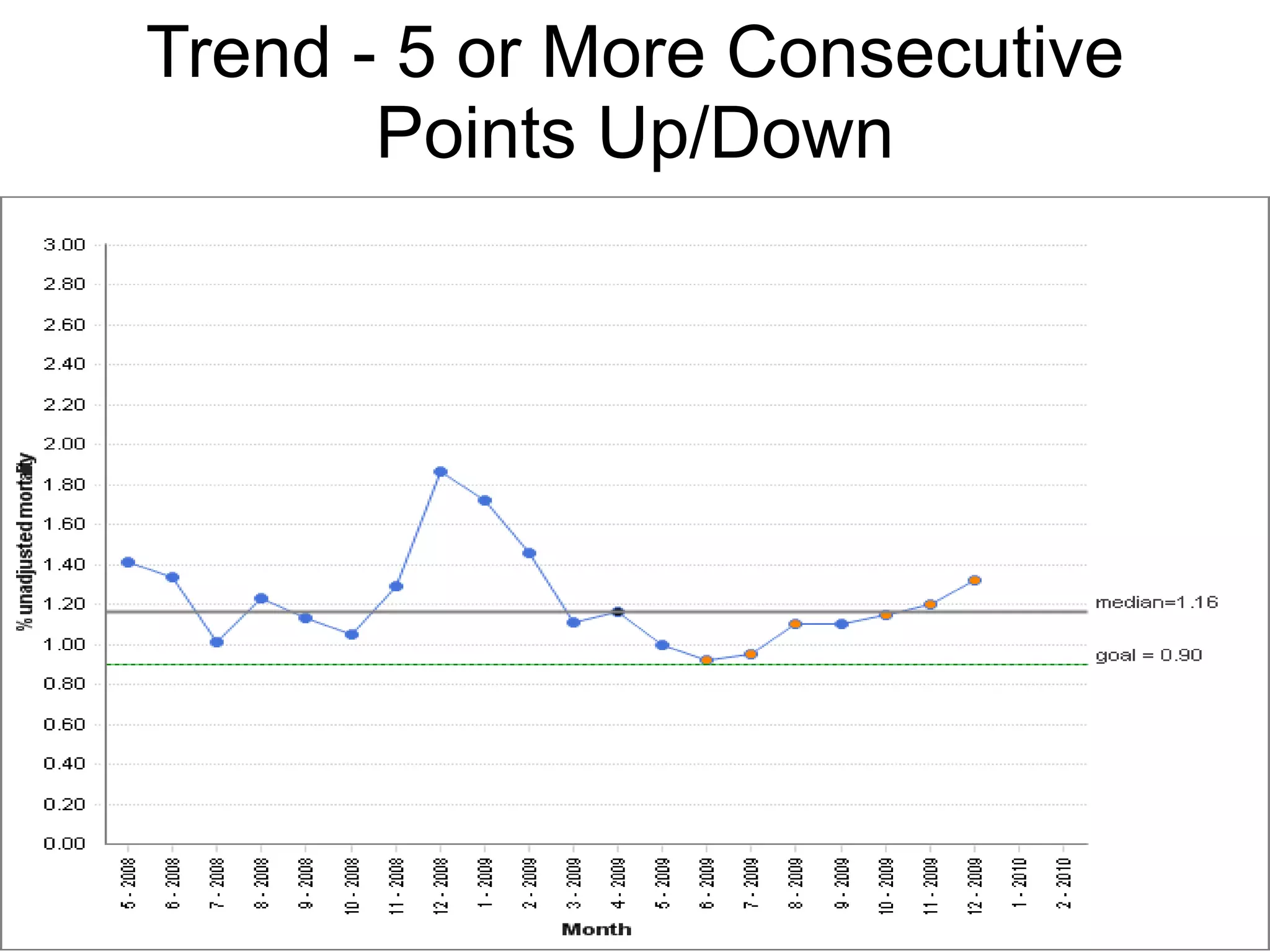

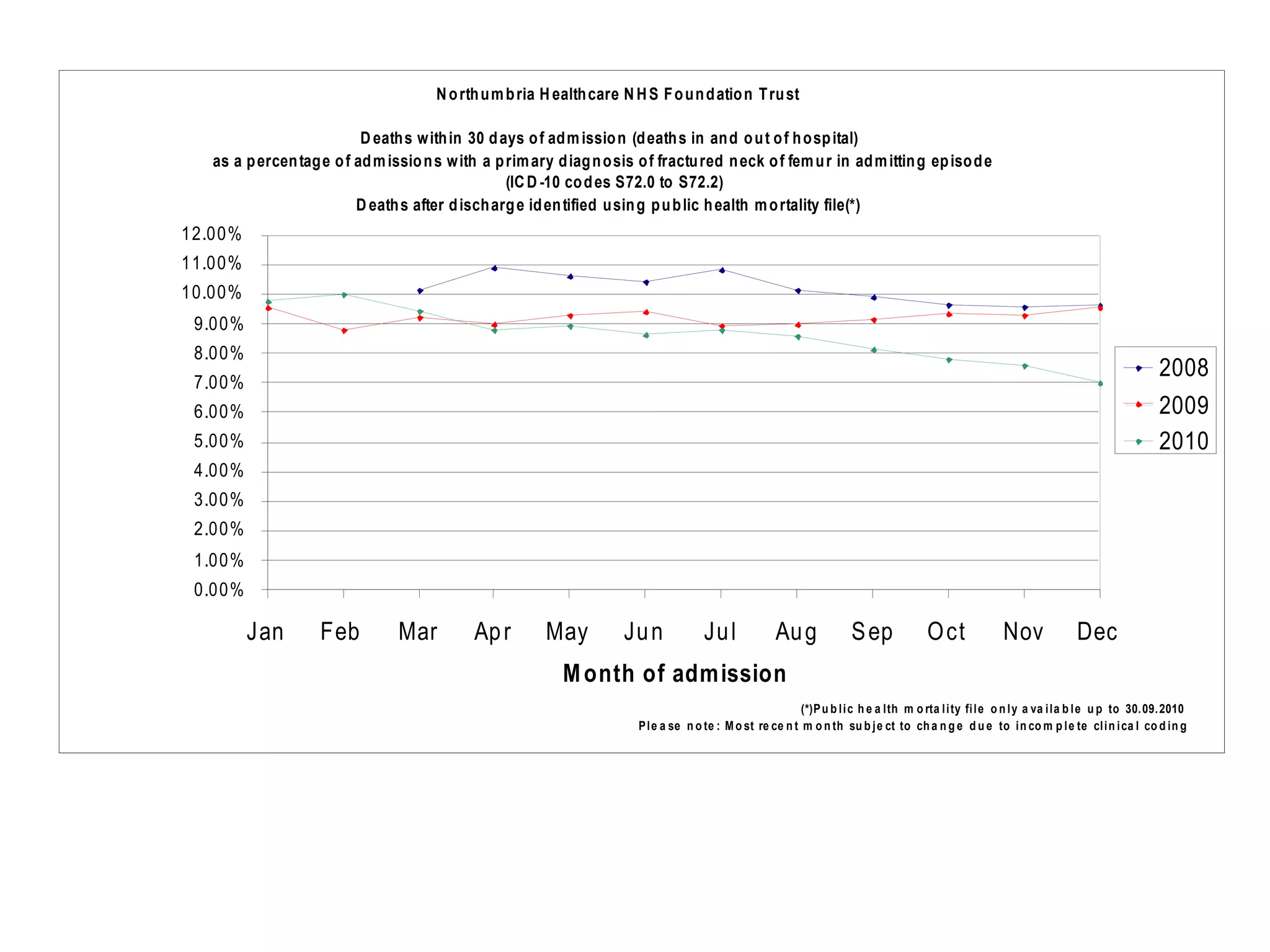

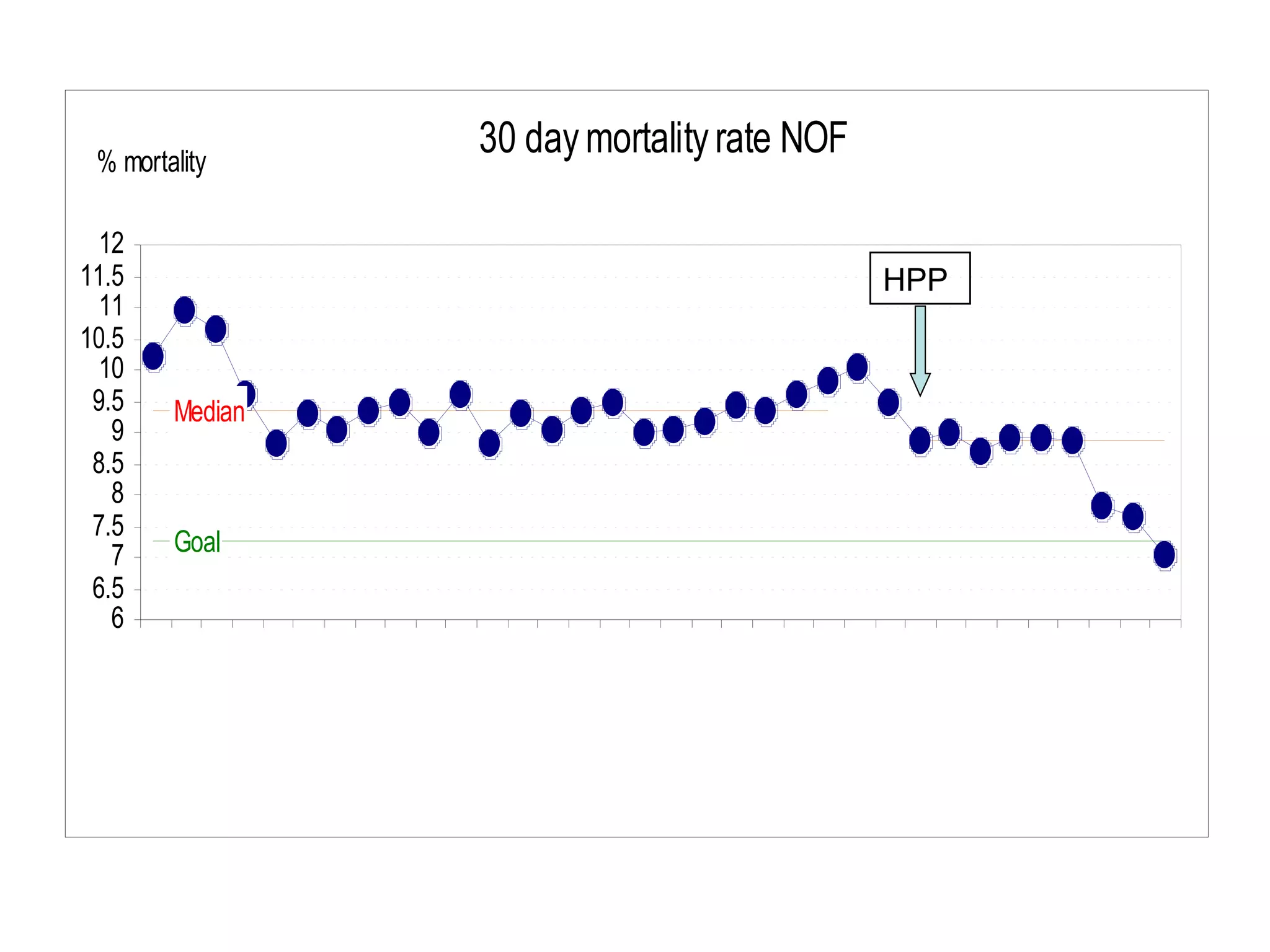

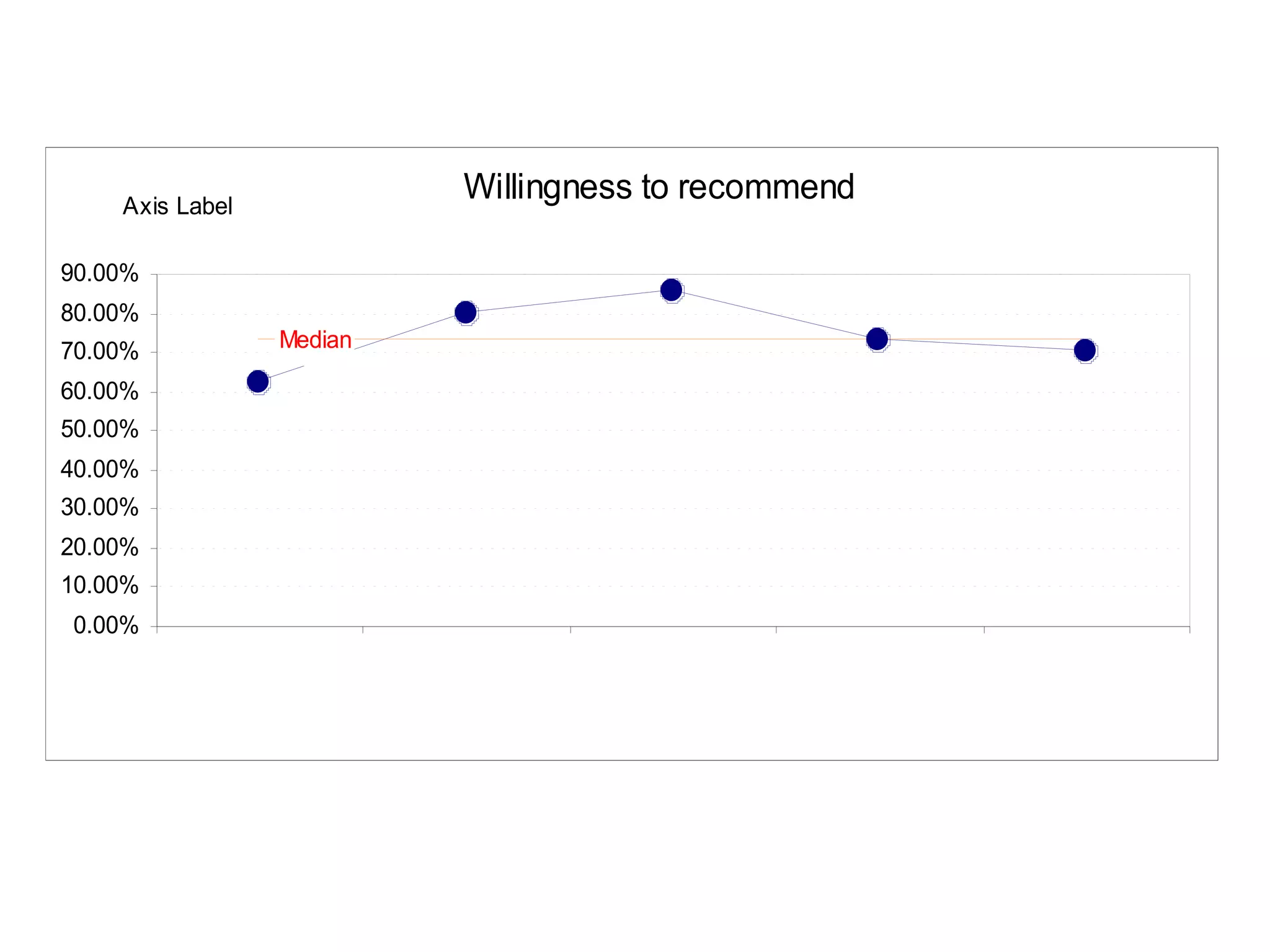

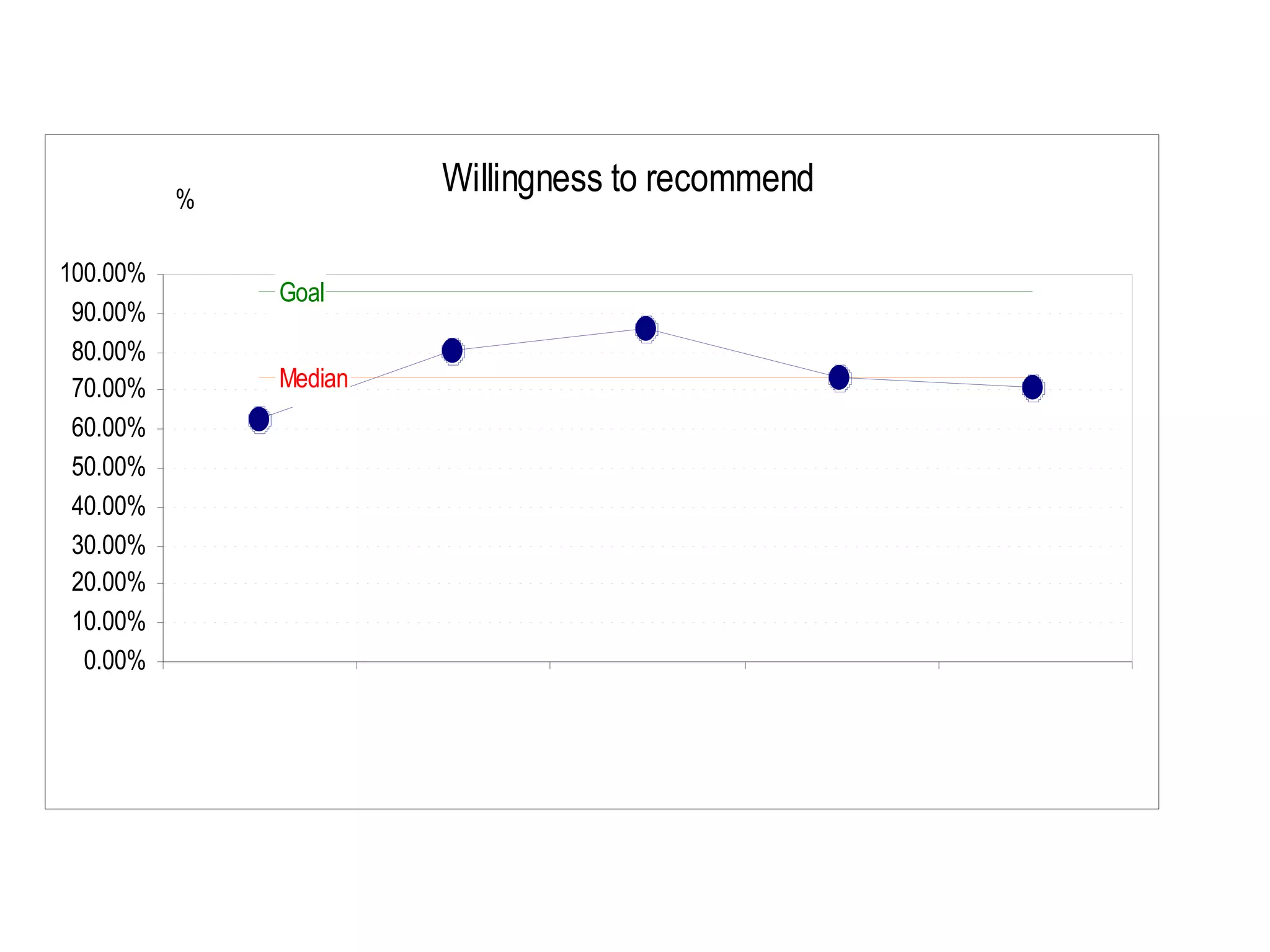

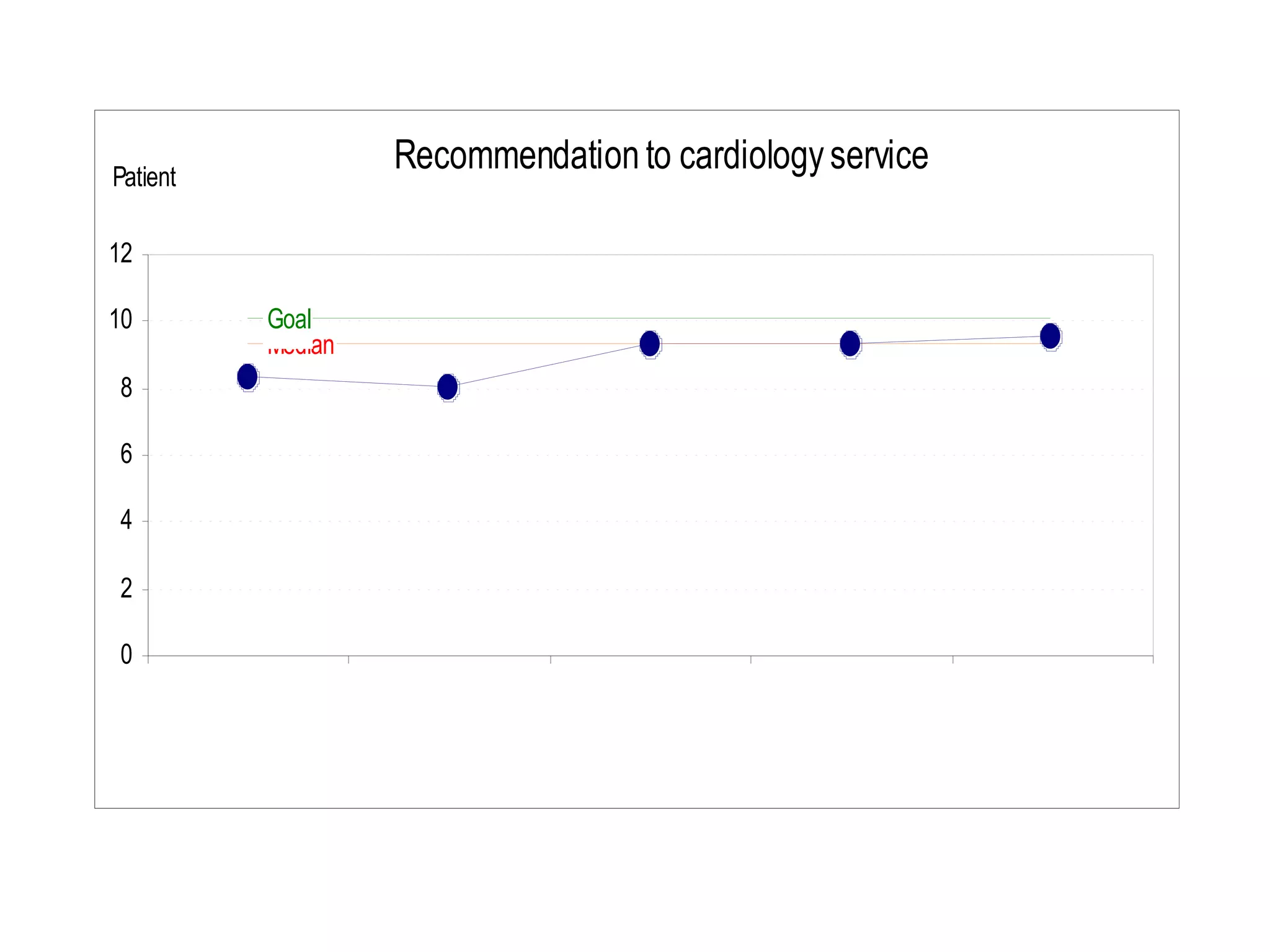

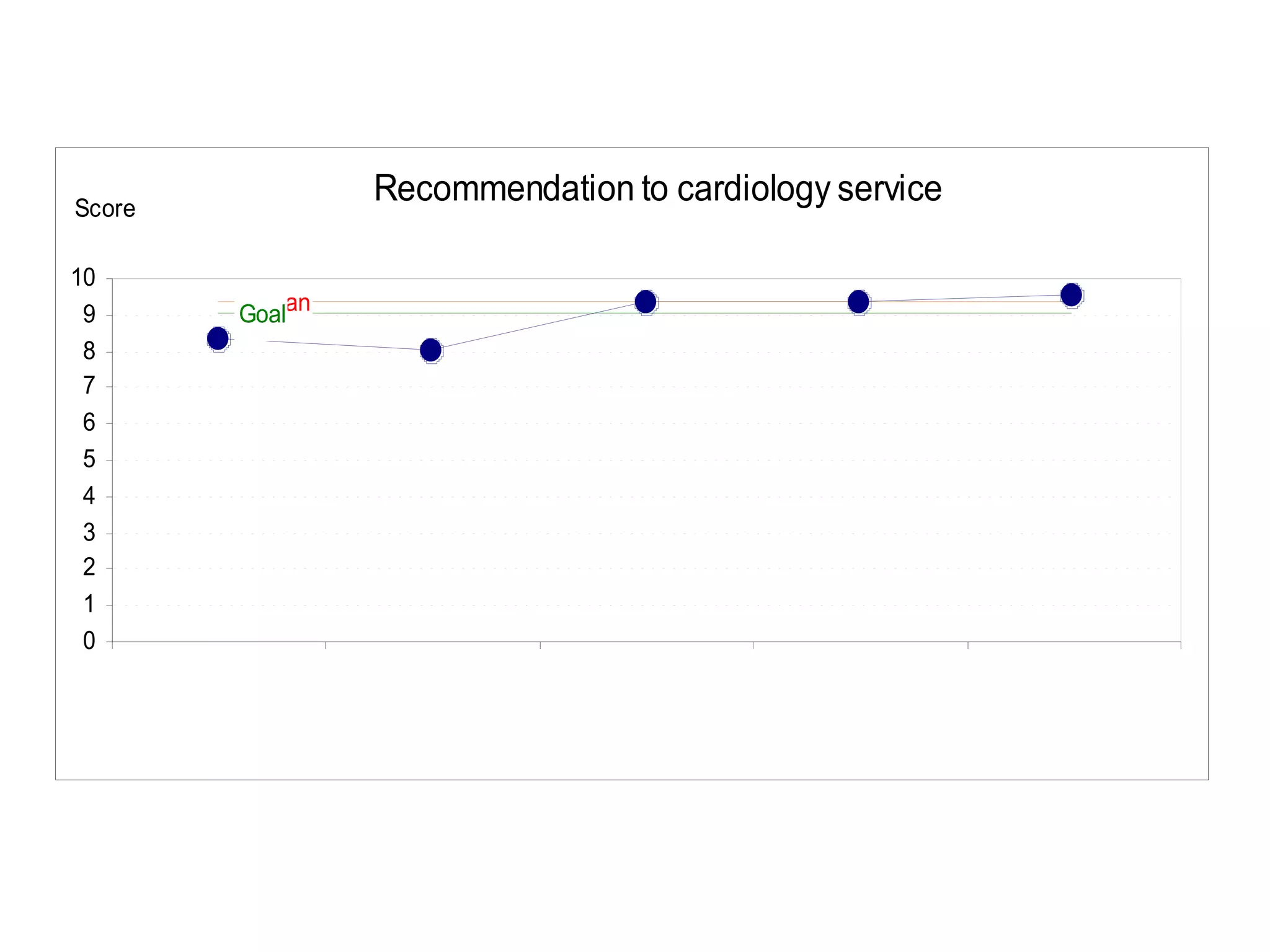

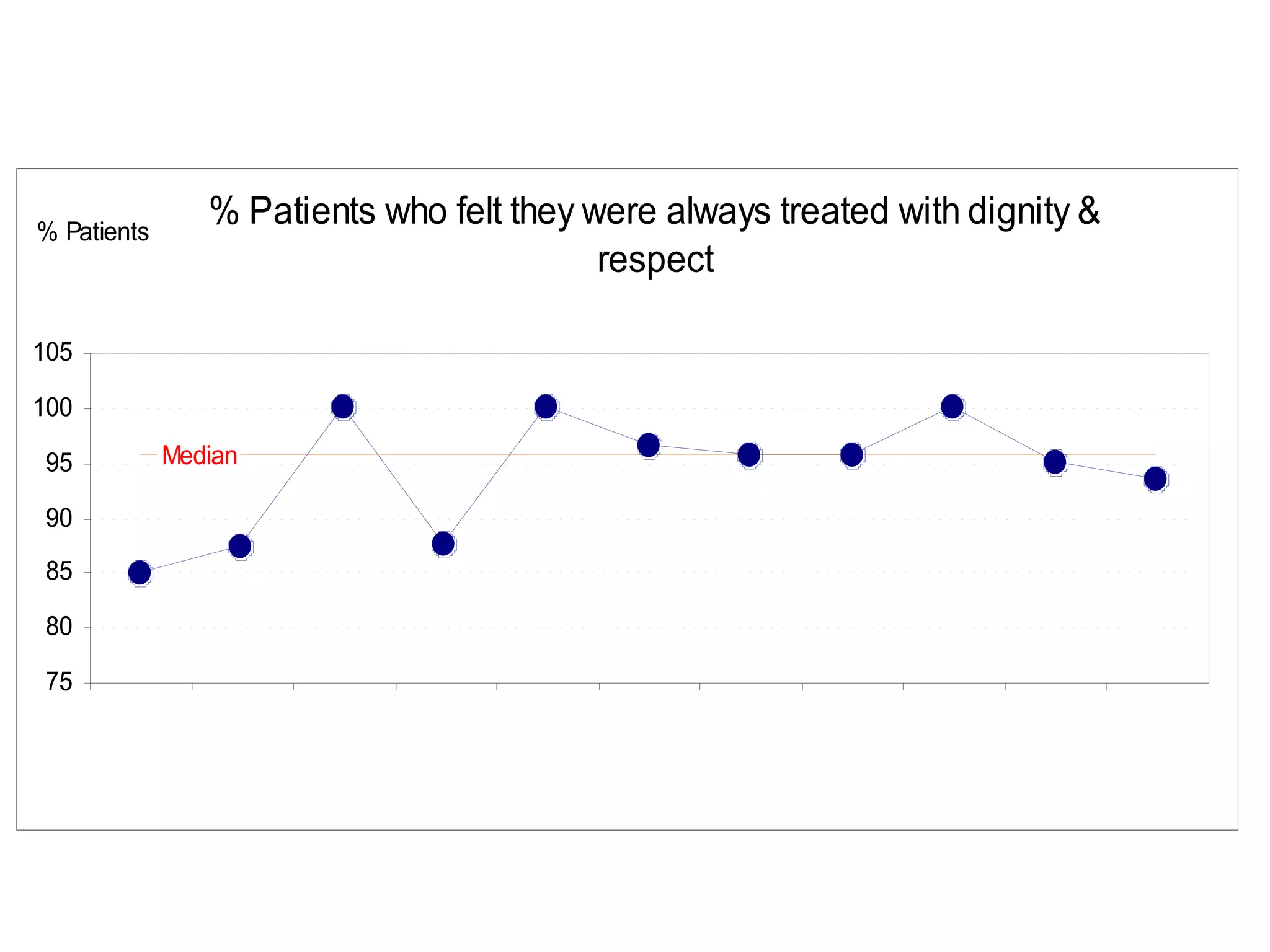

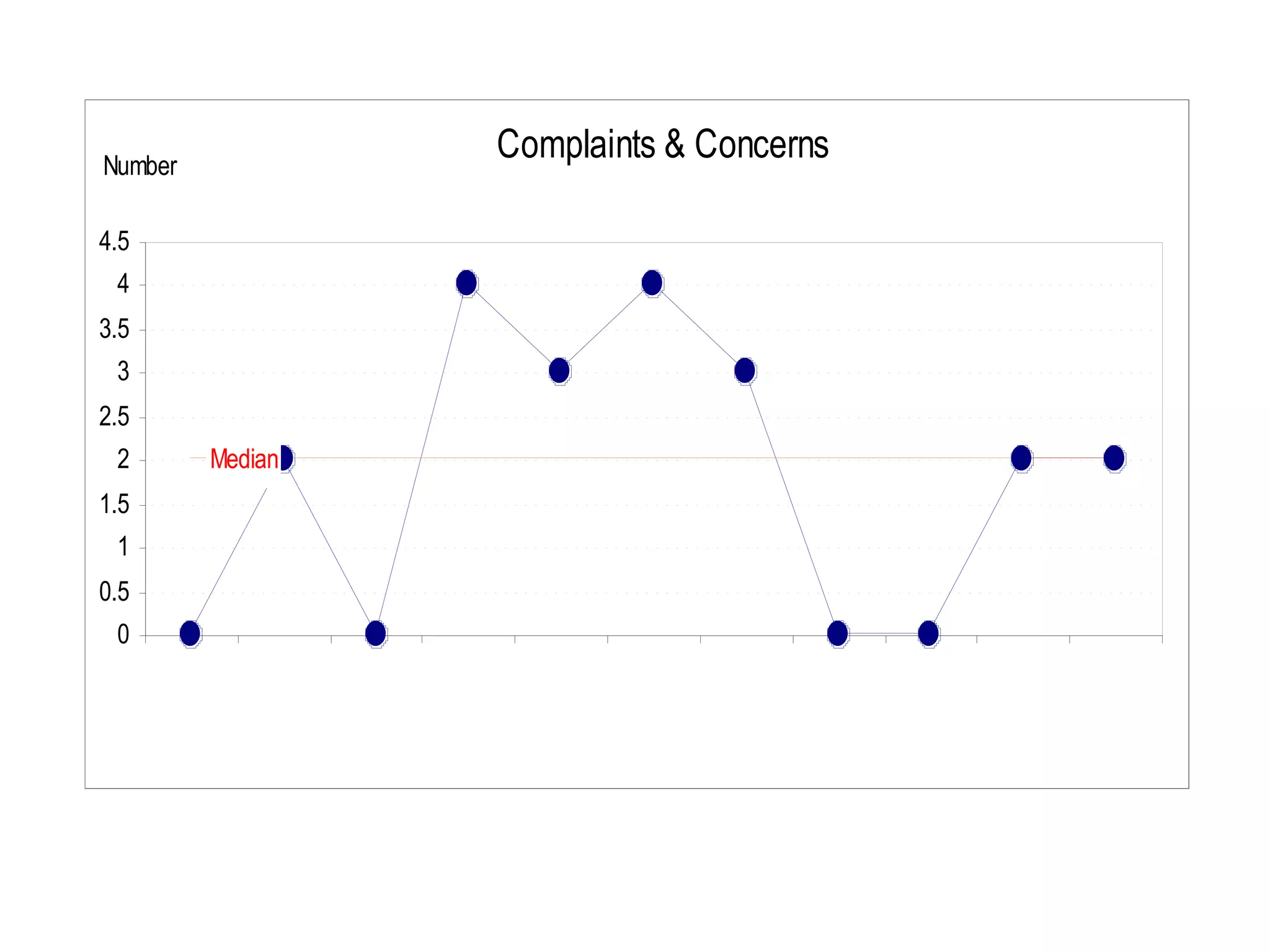

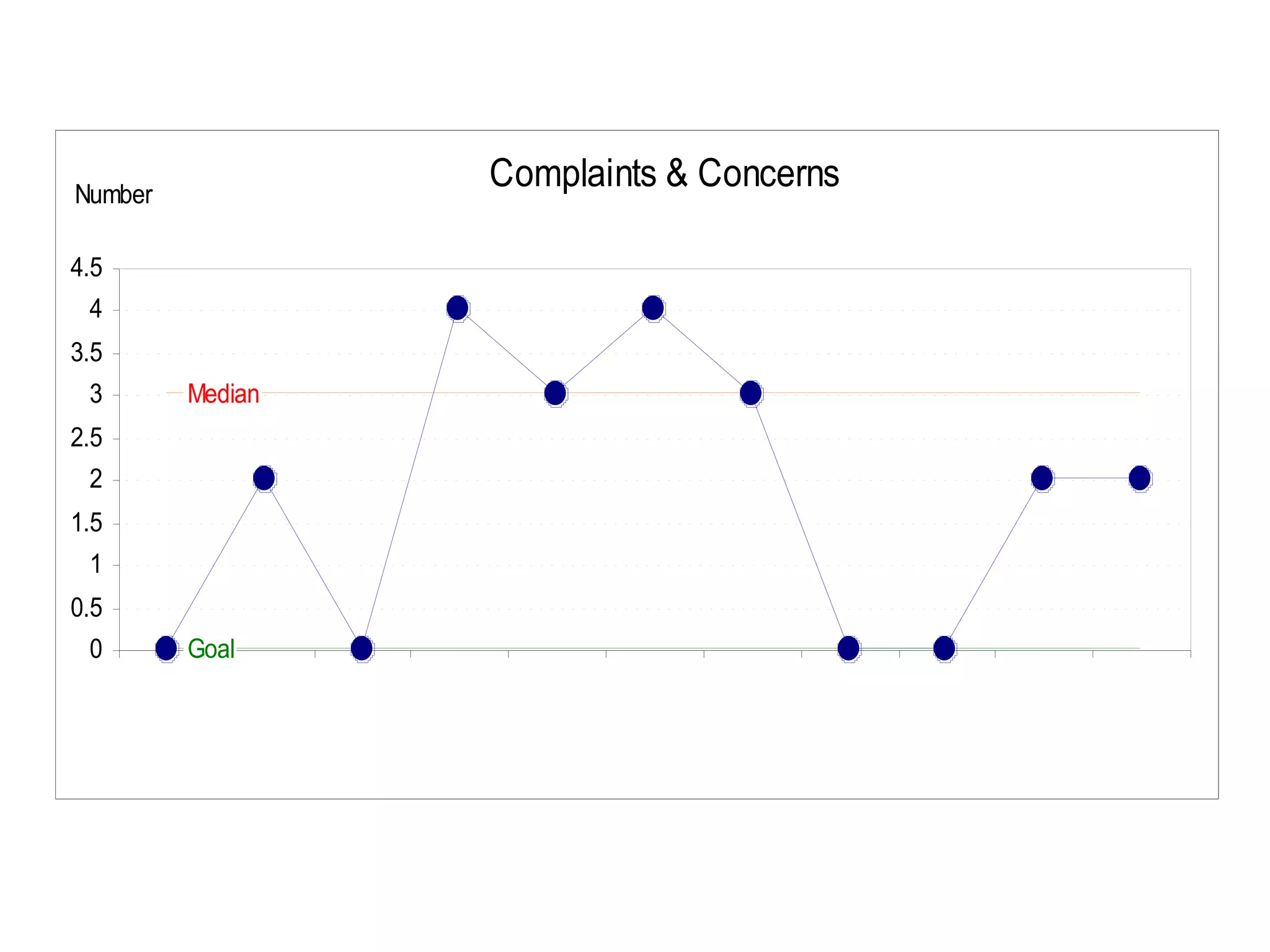

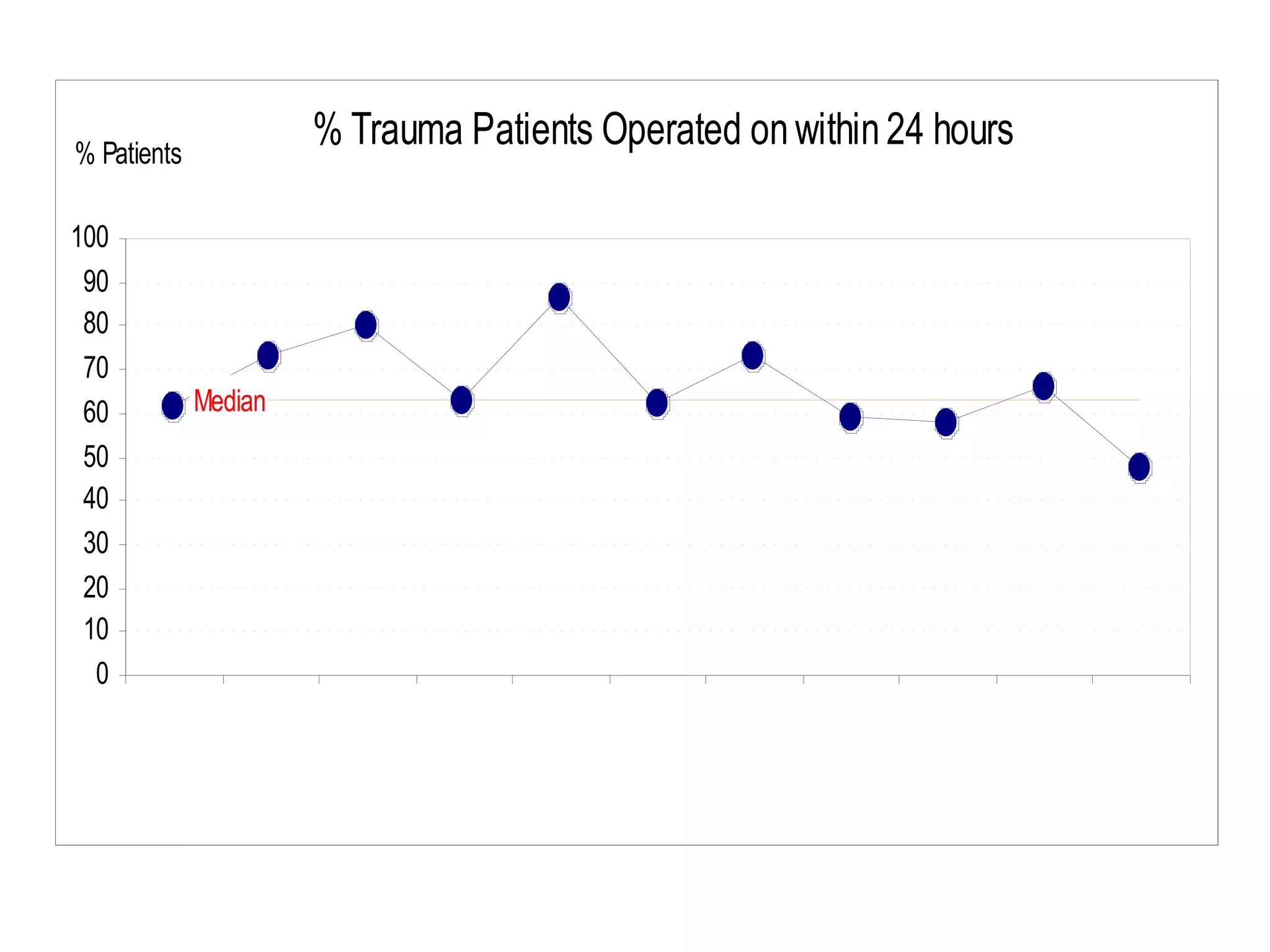

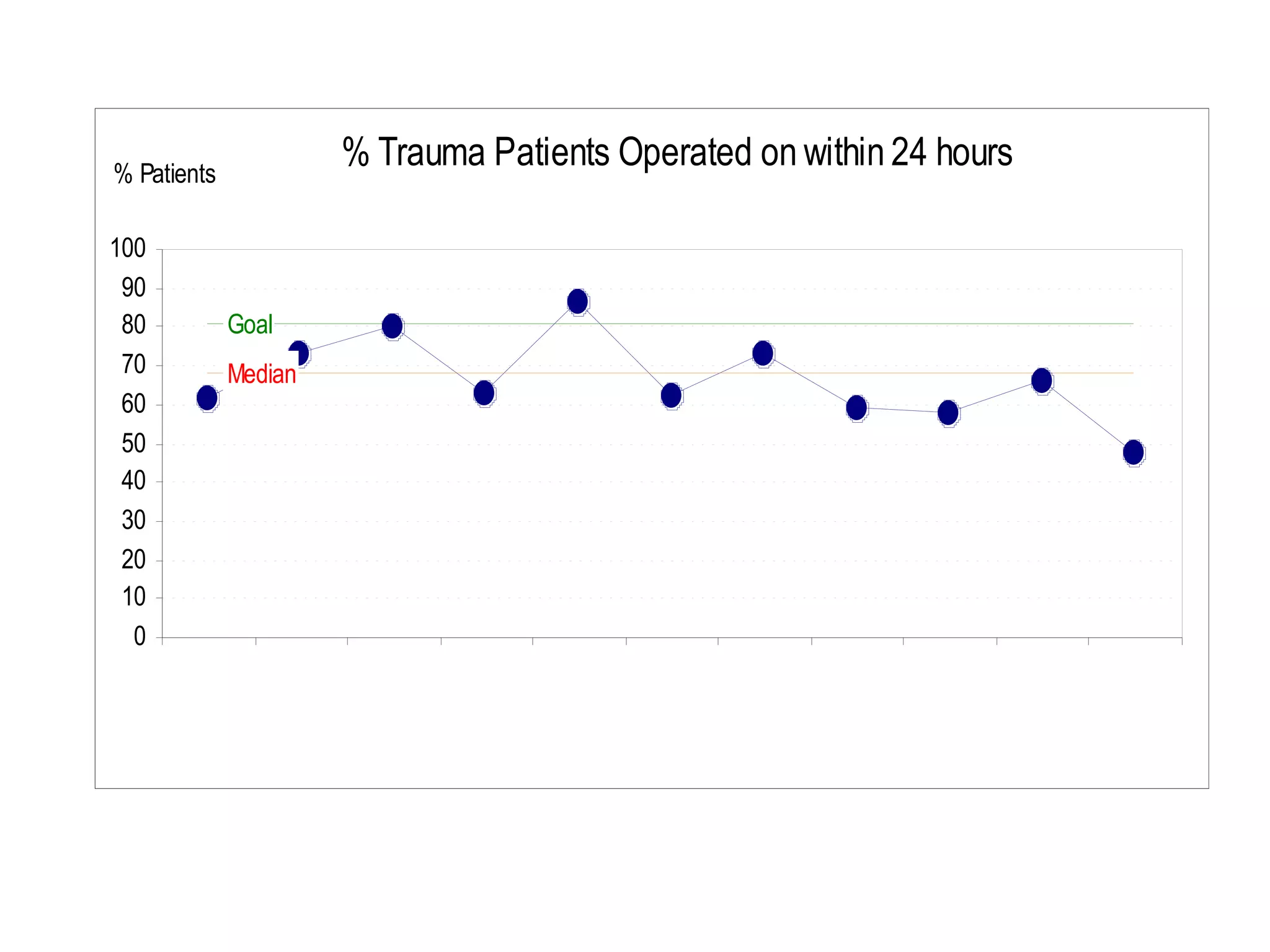

The document discusses using data for improvement, accountability, and research in healthcare. It outlines three aspects of using data: improvement aims to improve care through testing changes, accountability focuses on comparison and evaluation of current performance, and research aims to generate new knowledge through controlled testing and hypothesis testing. The document also discusses run charts and control charts as tools to analyze data over time and distinguish common and special cause variation.