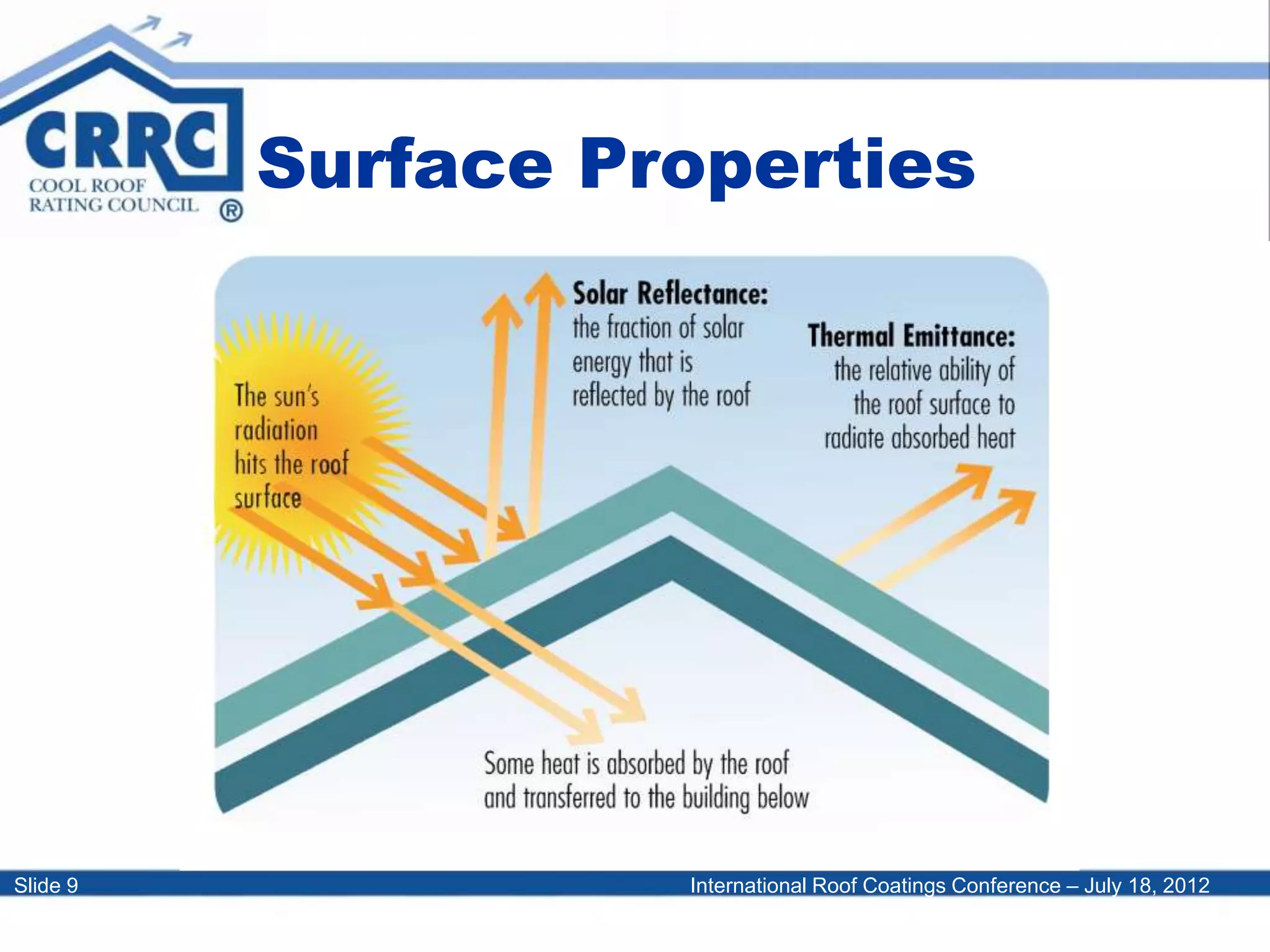

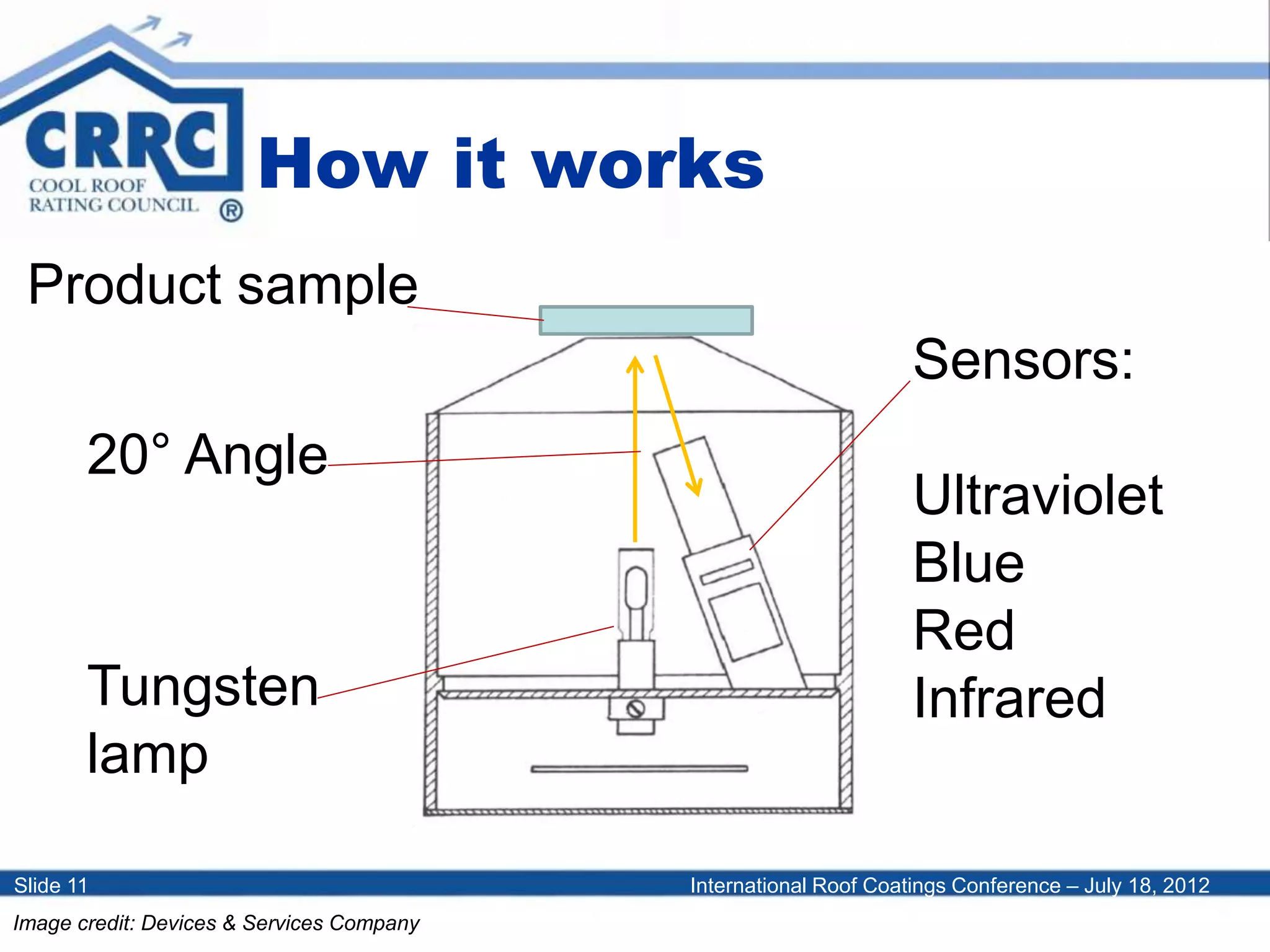

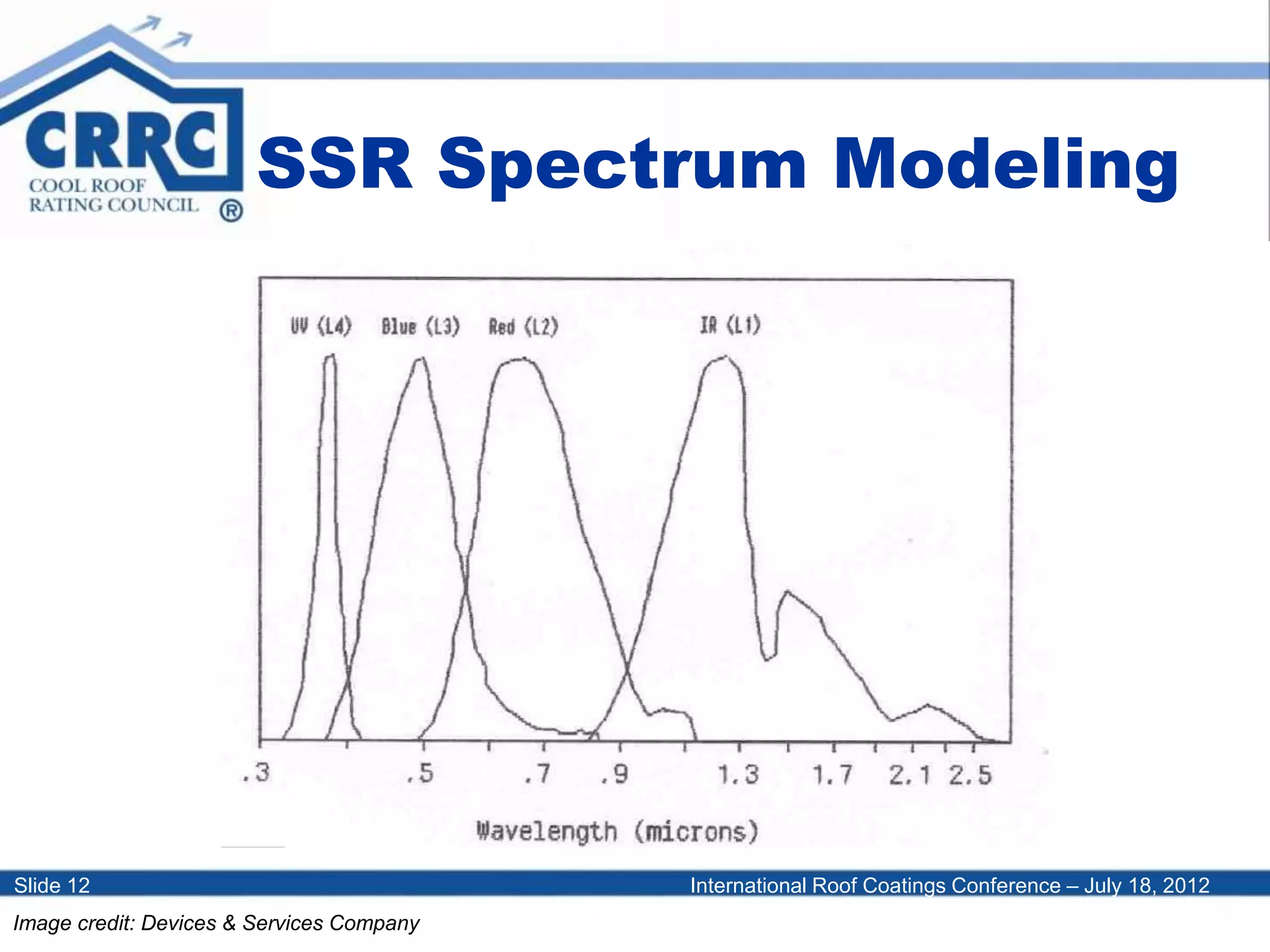

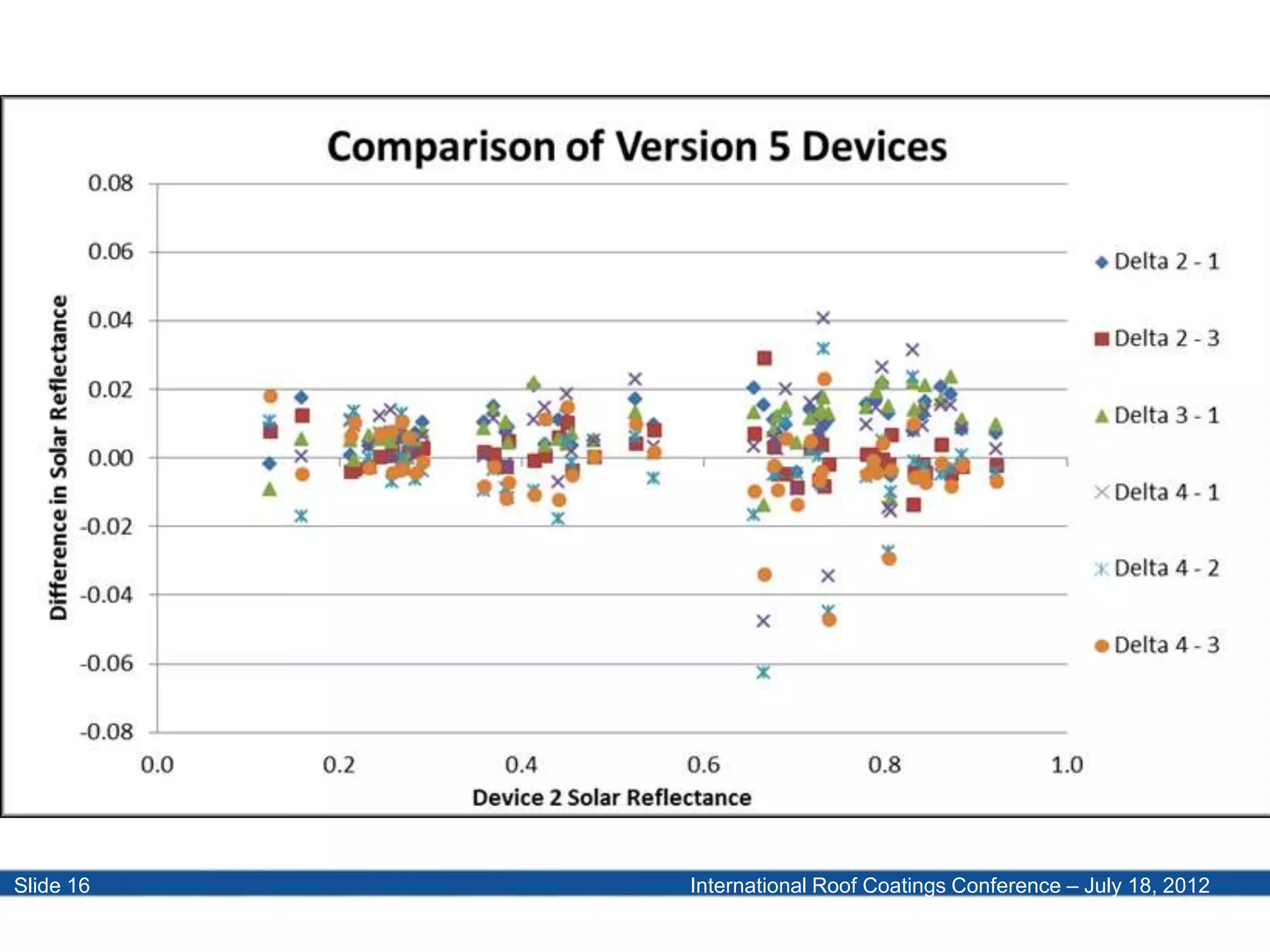

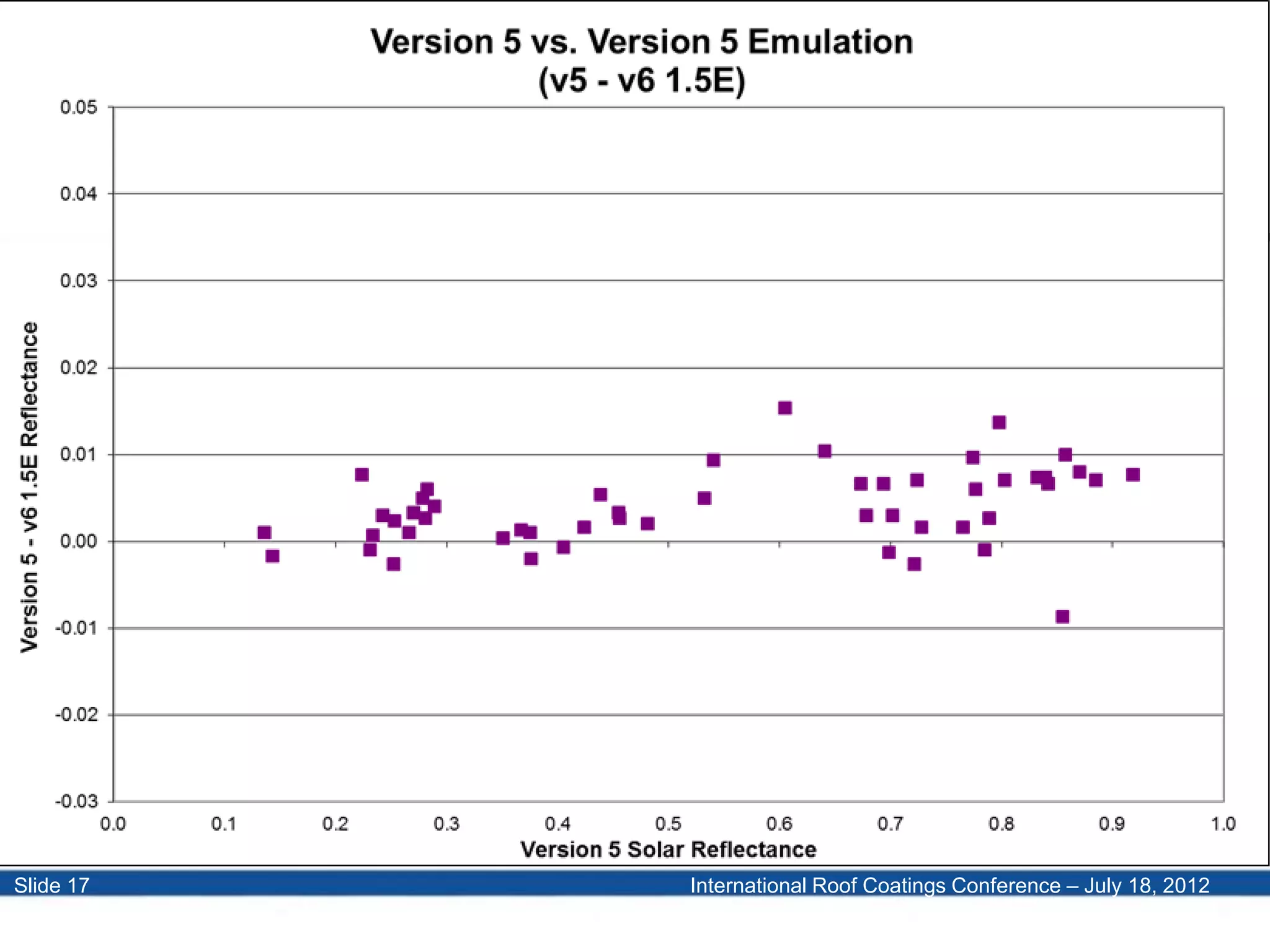

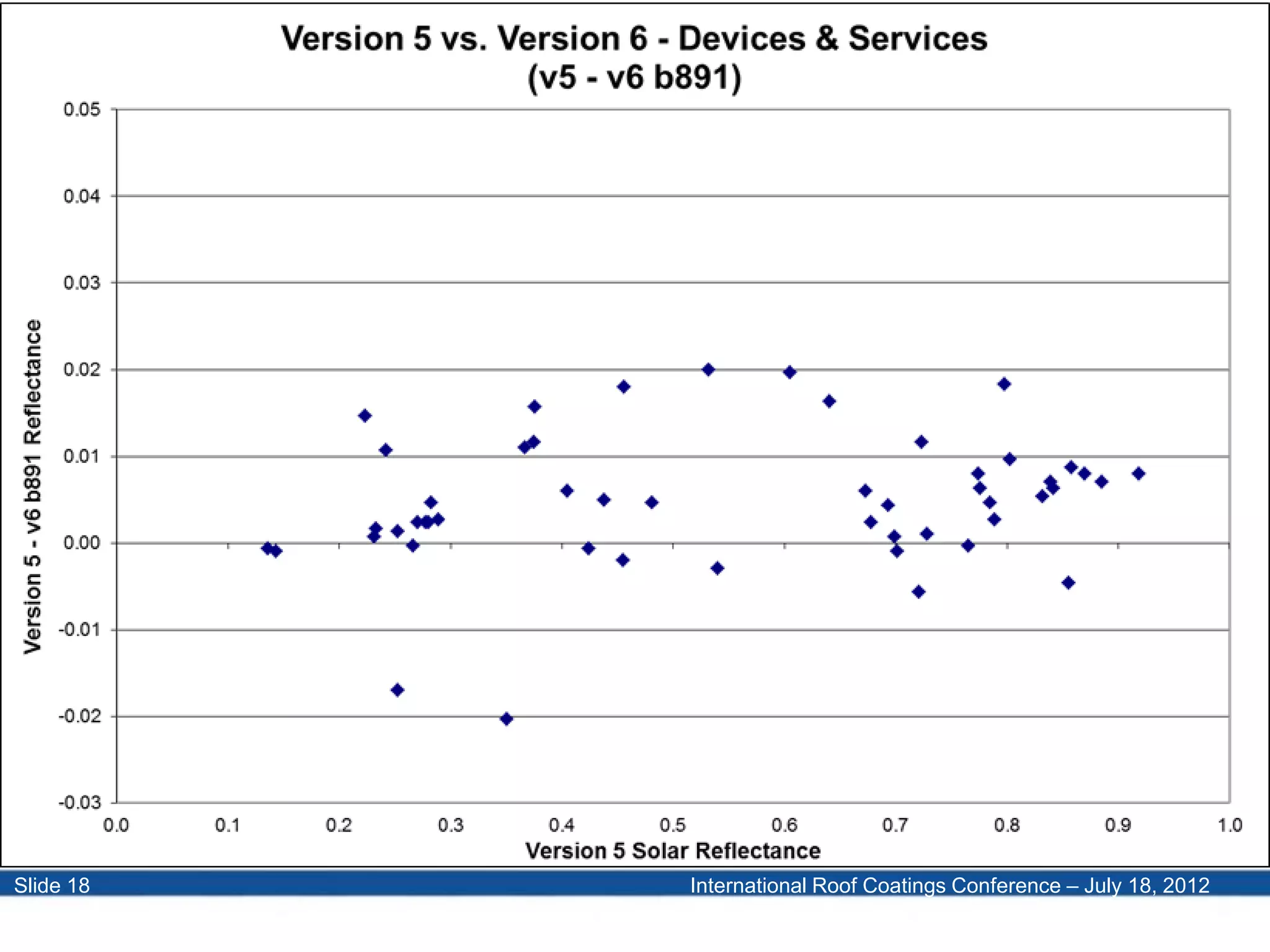

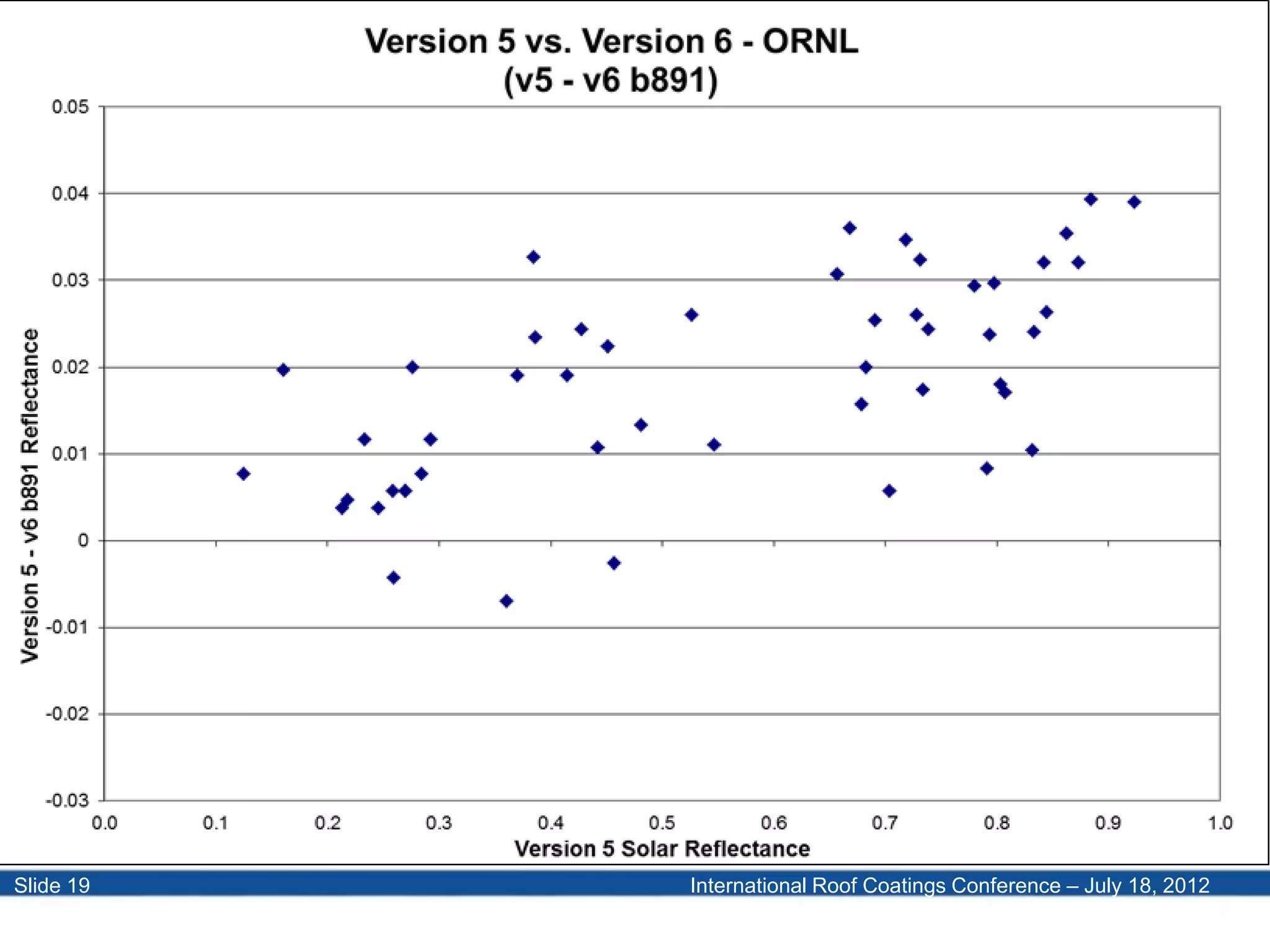

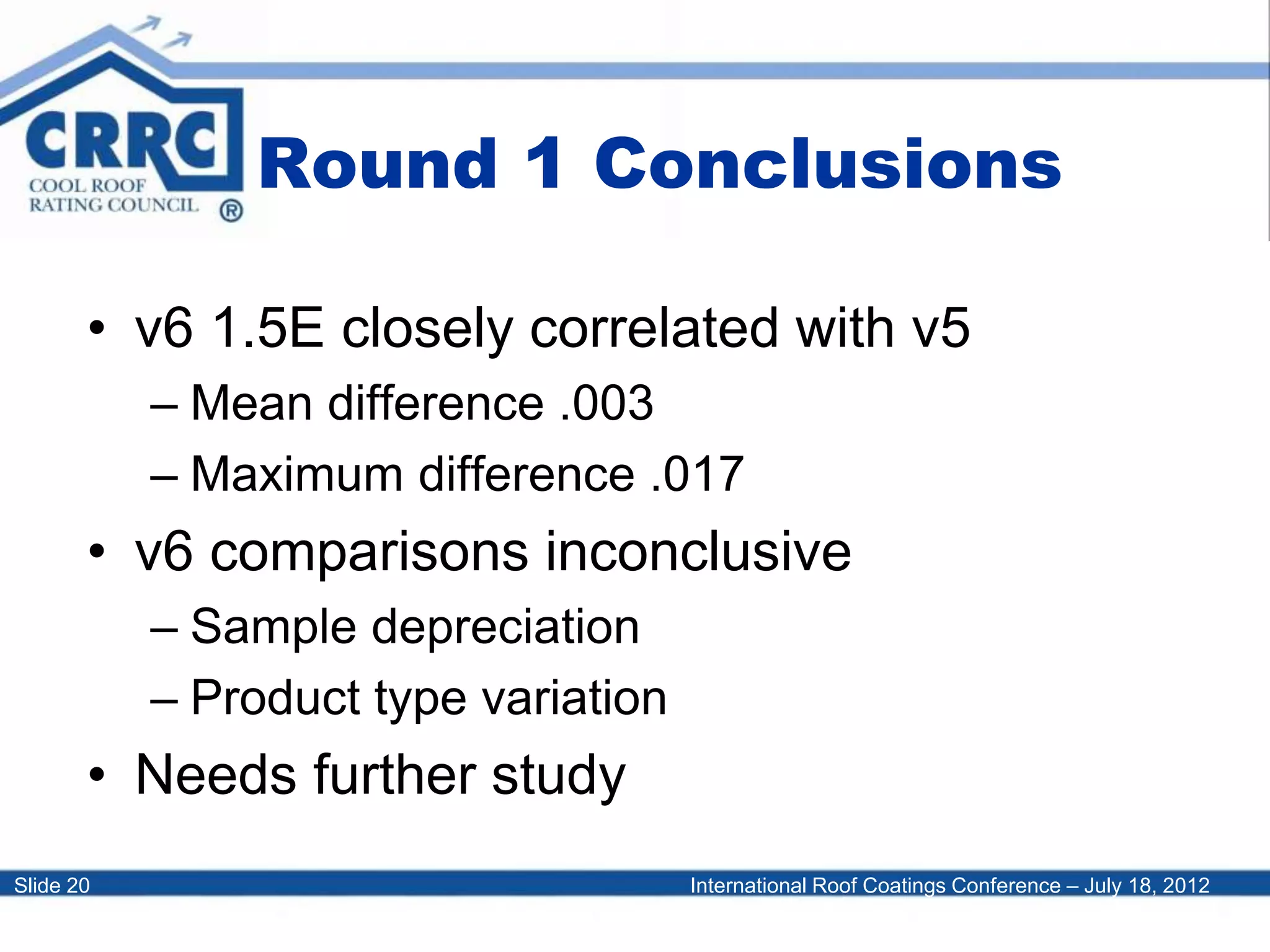

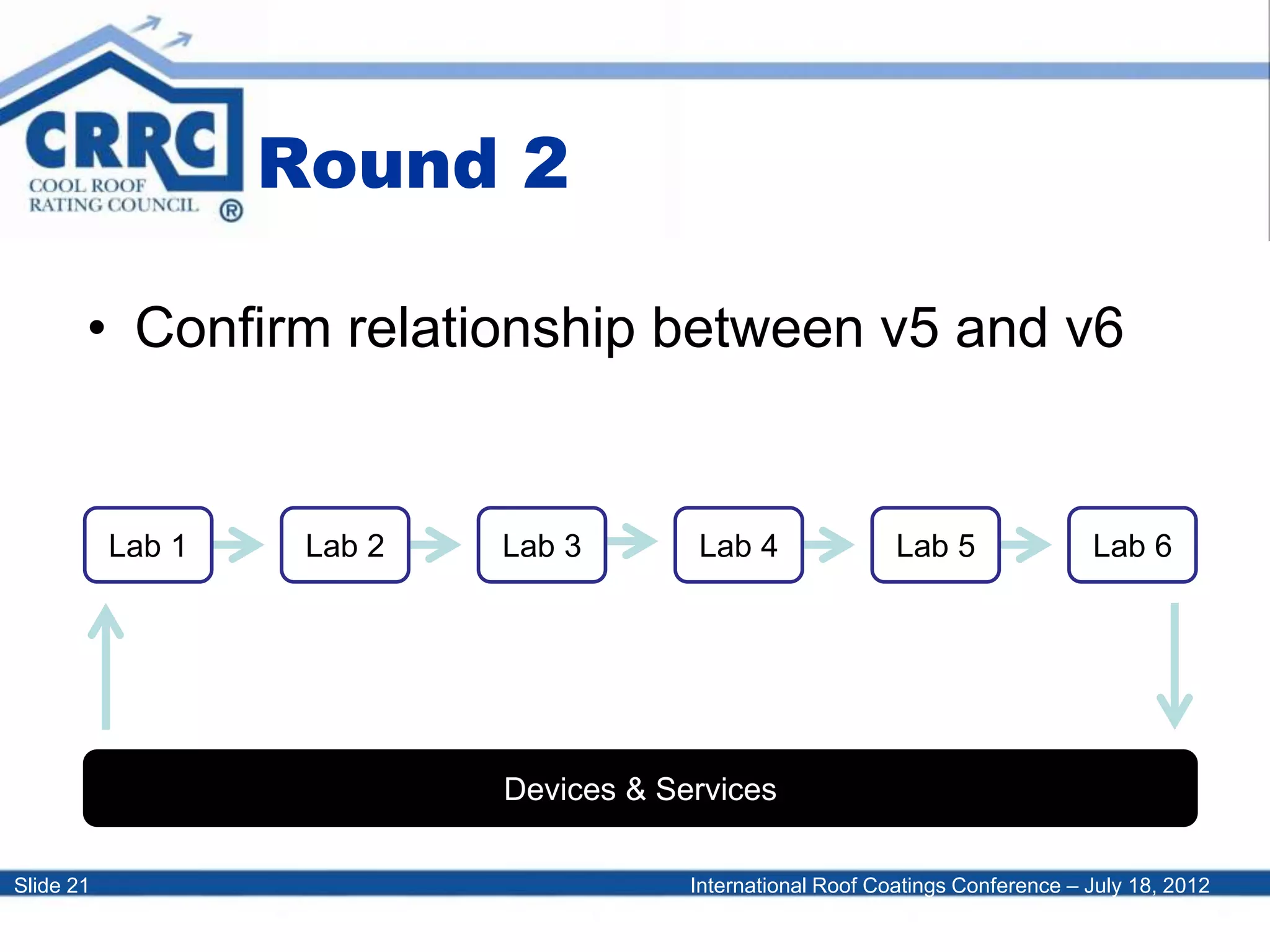

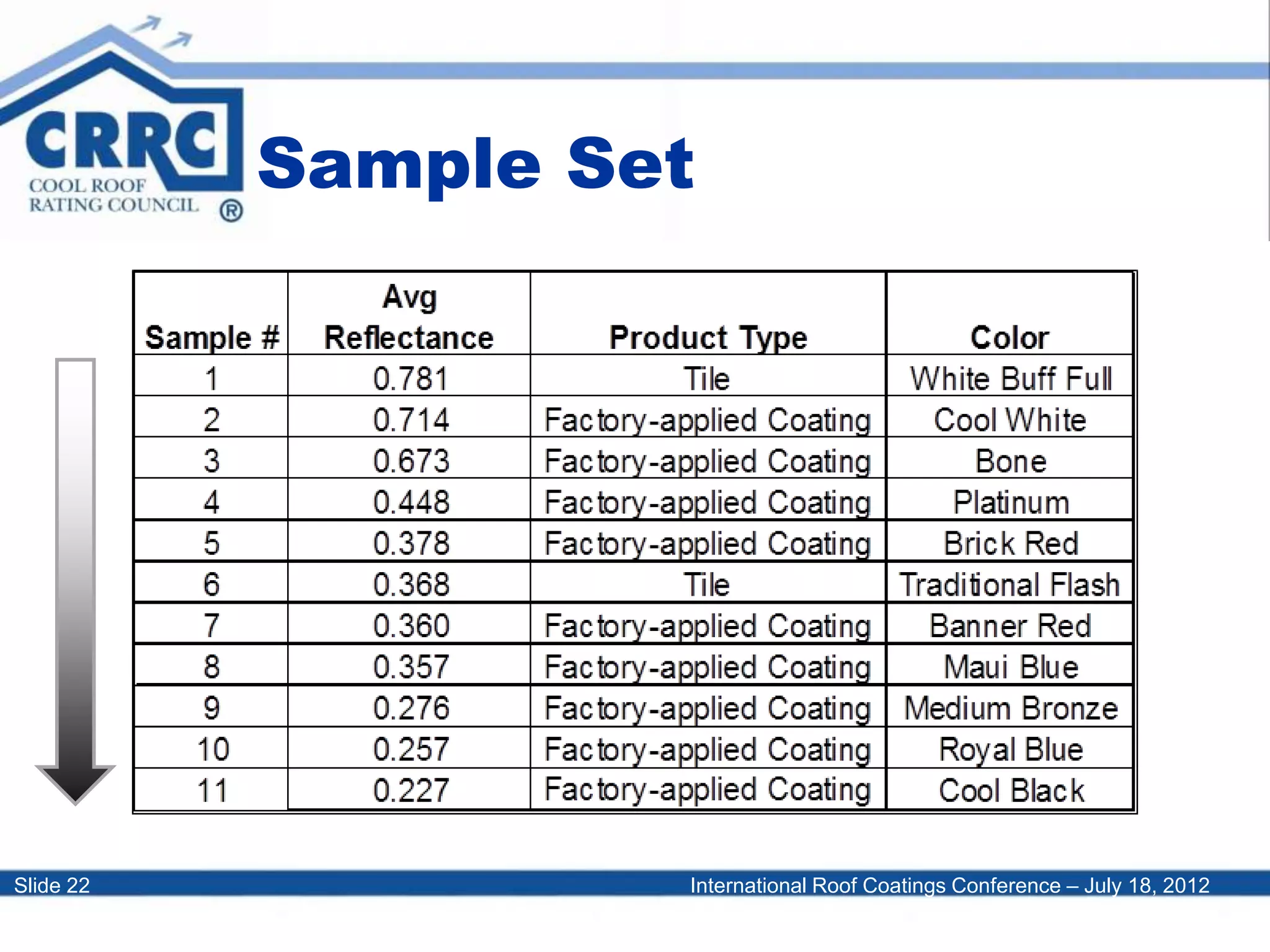

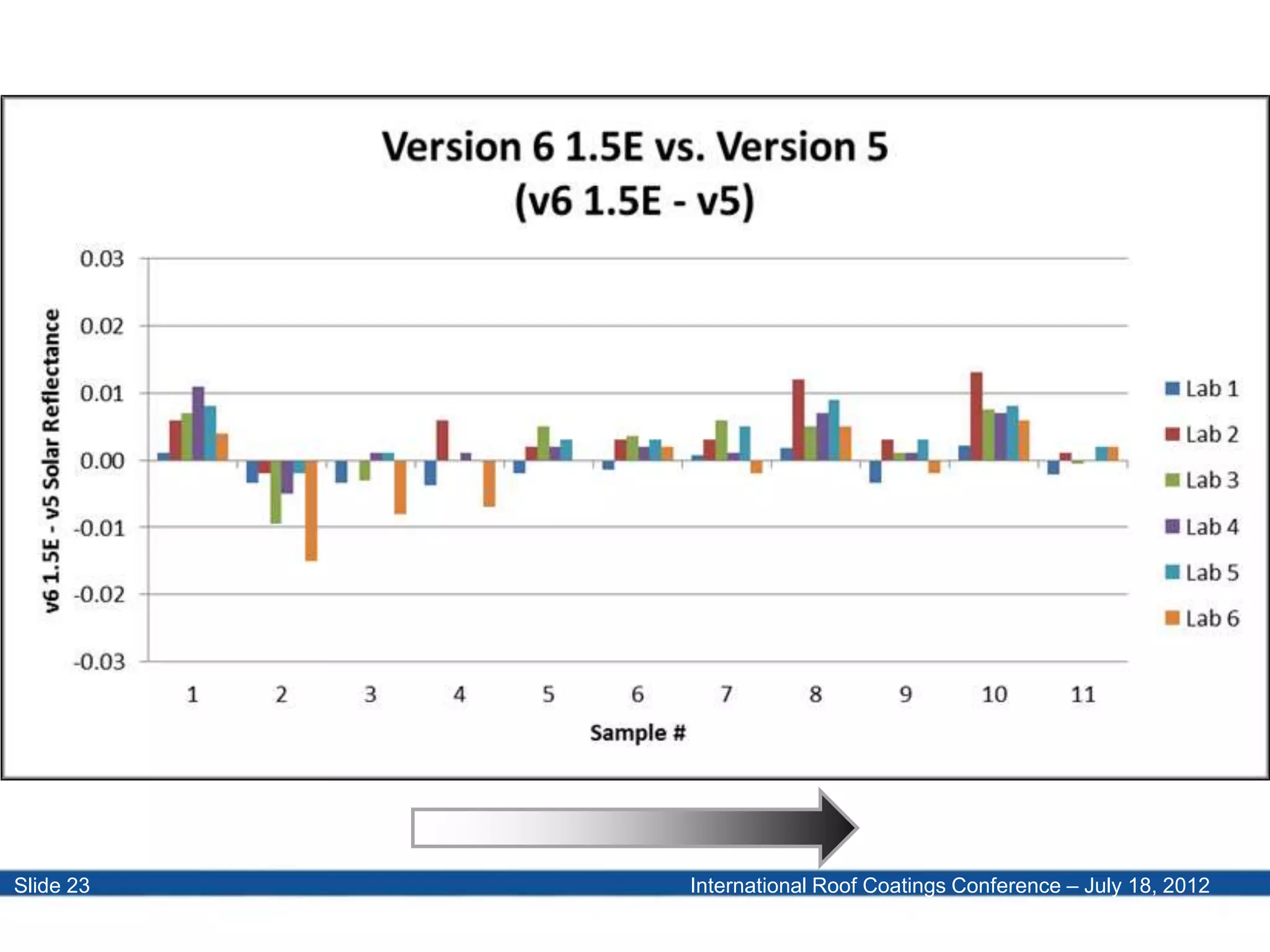

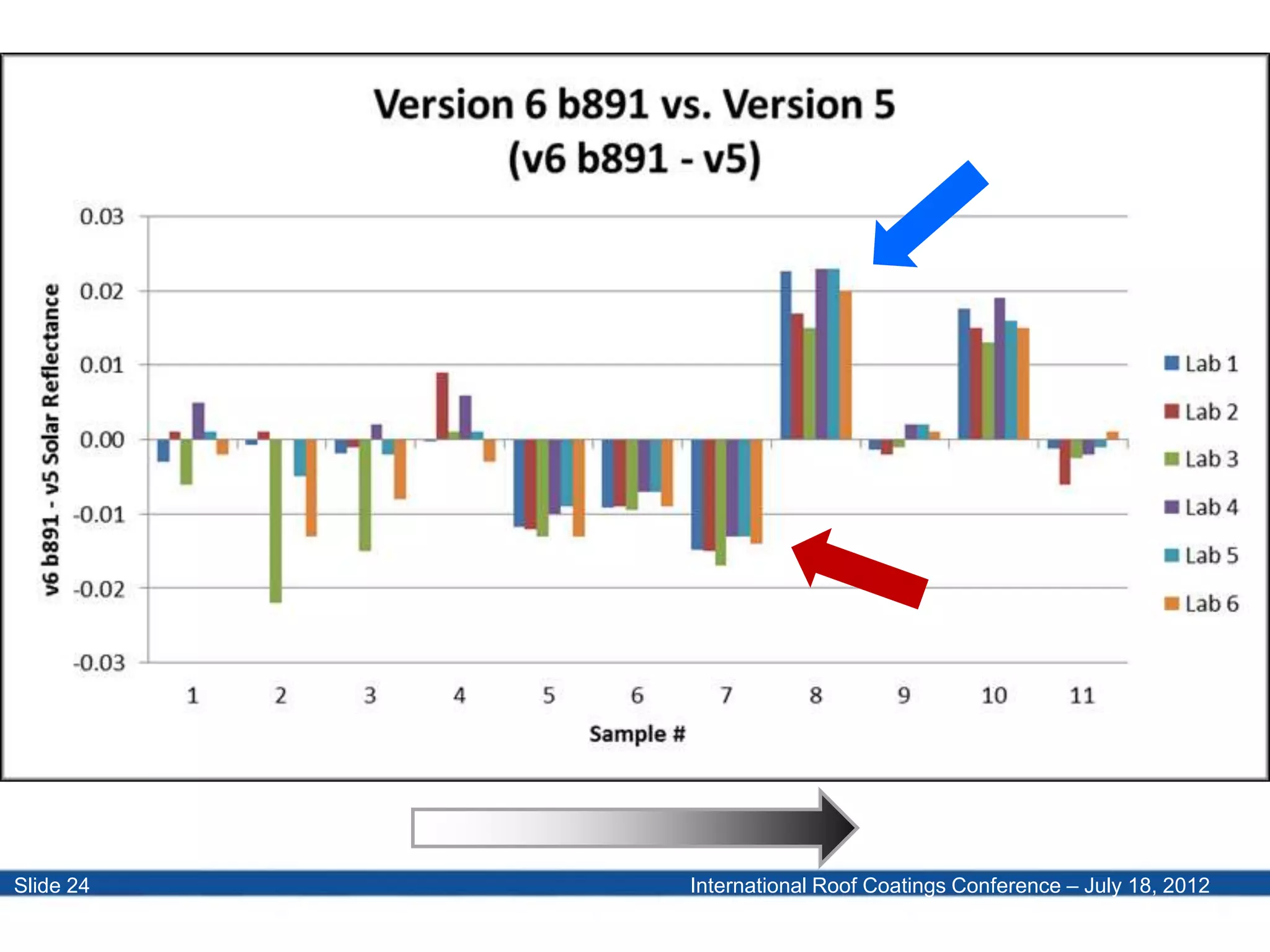

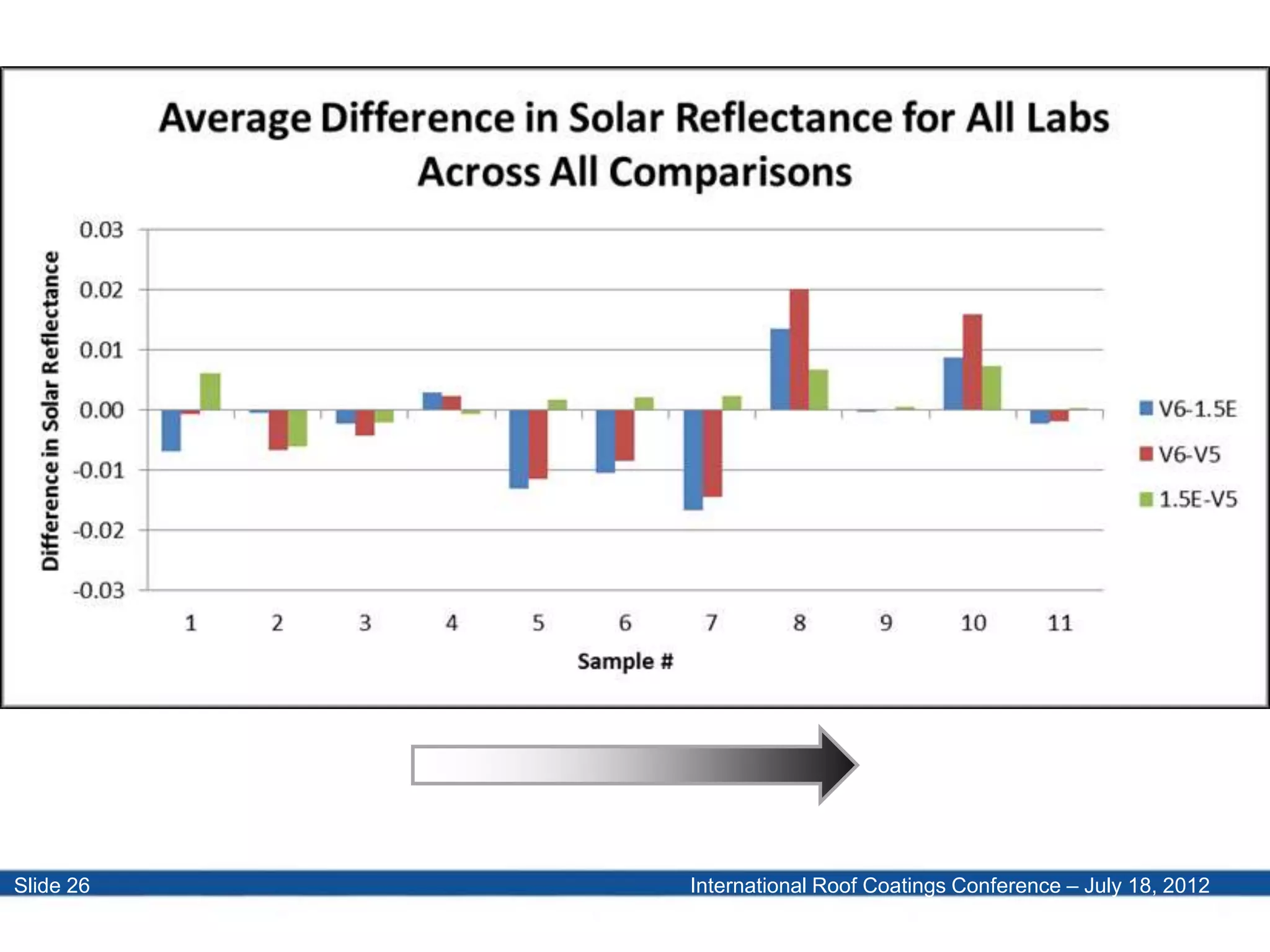

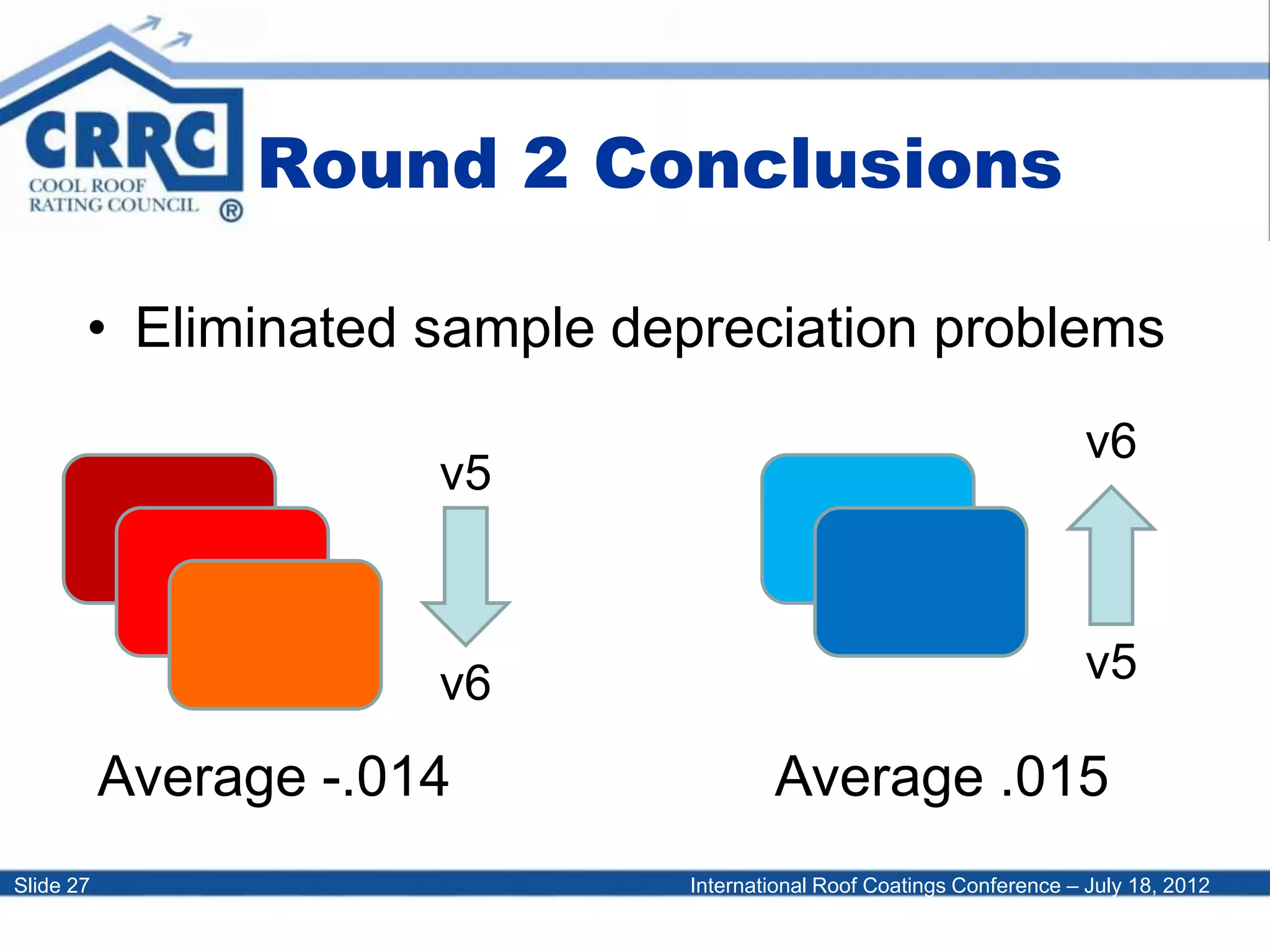

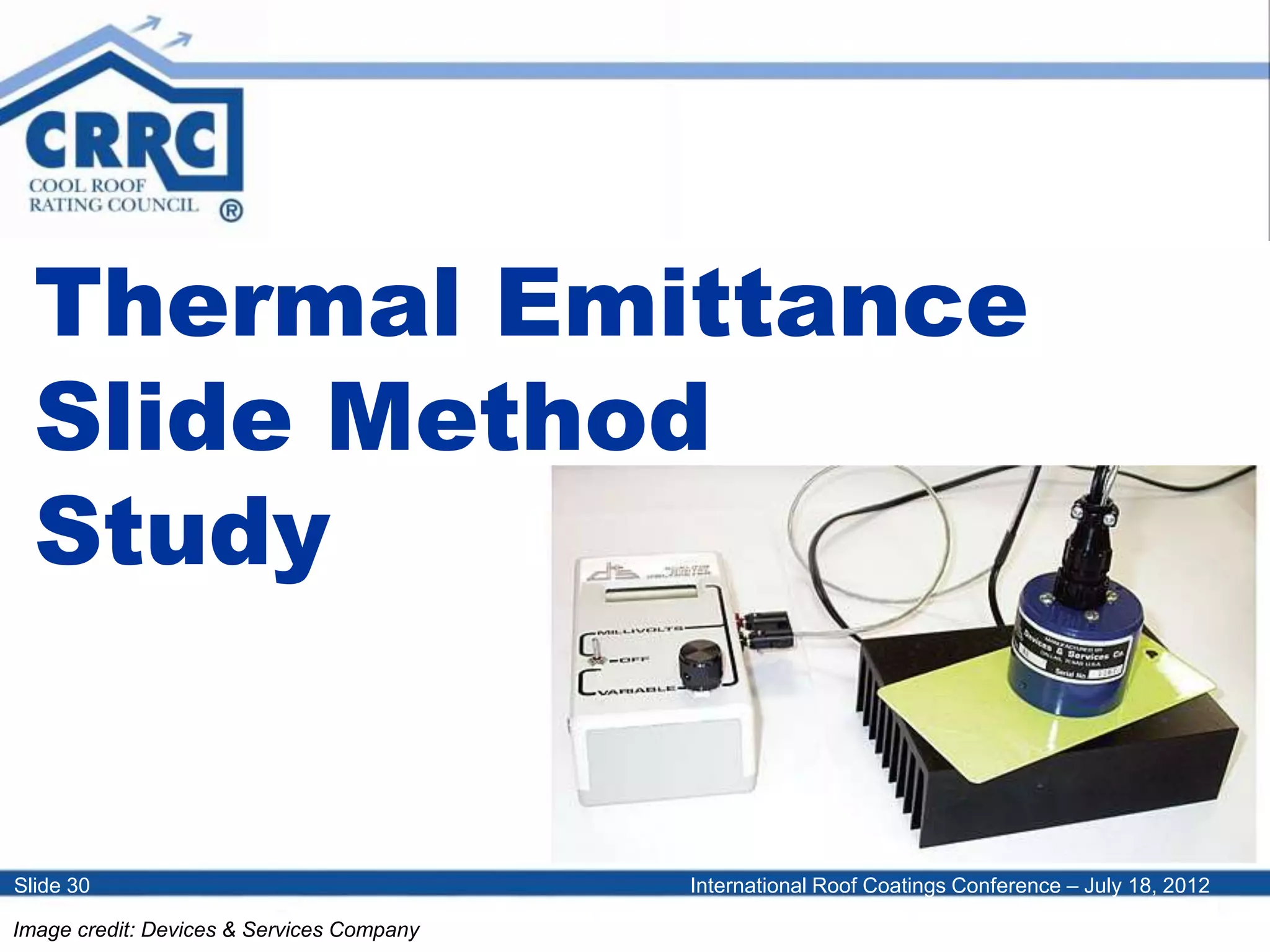

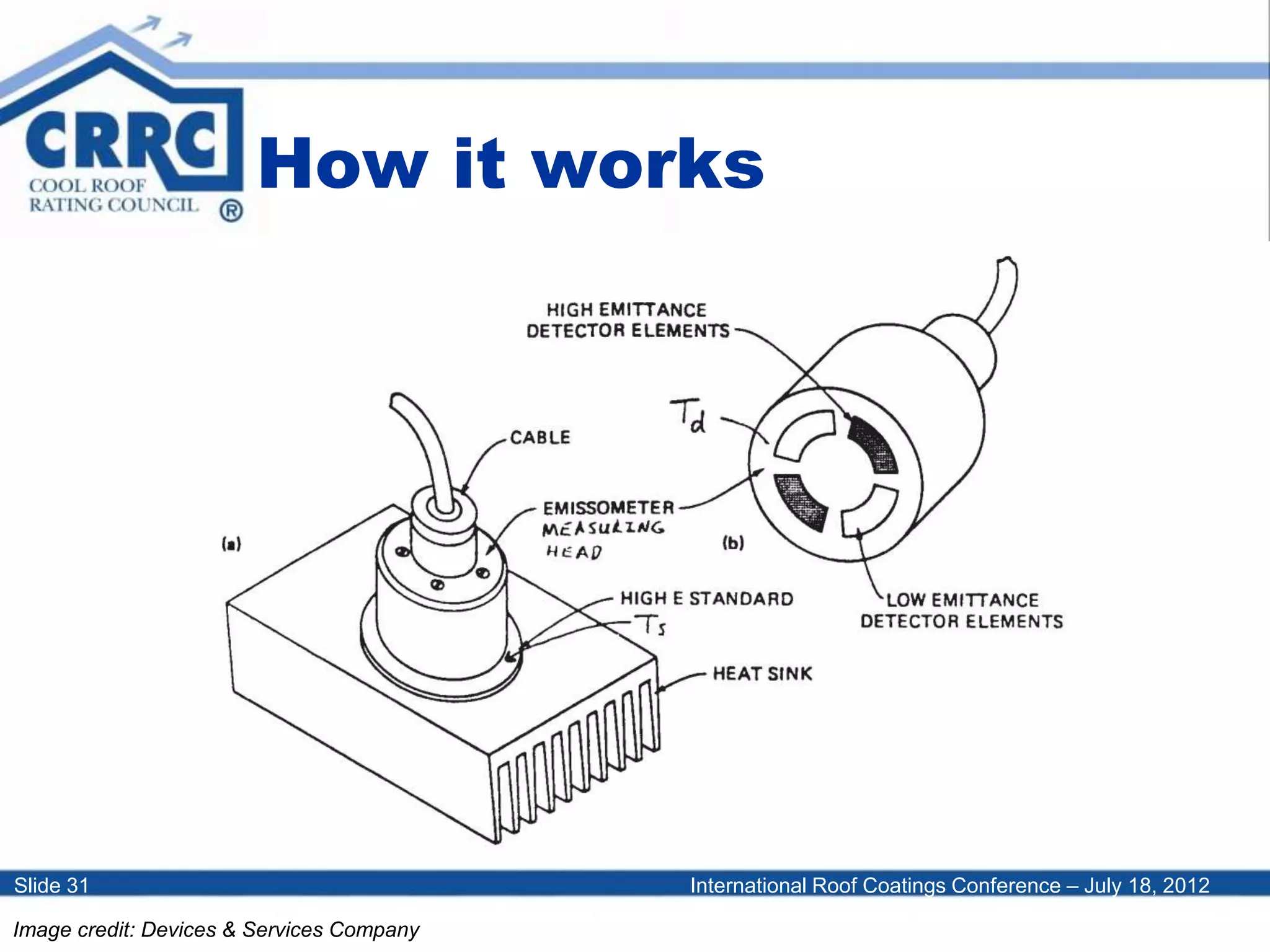

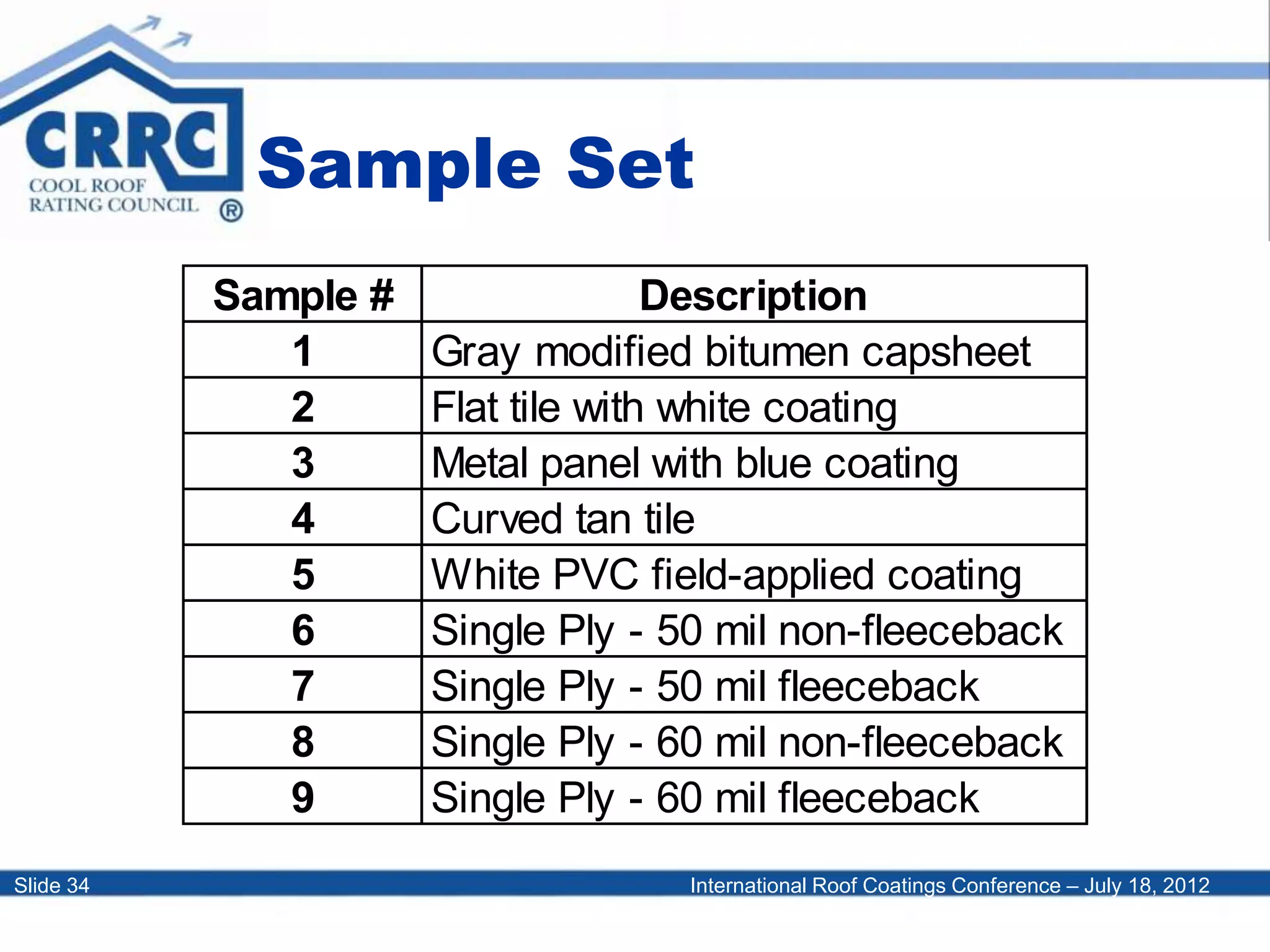

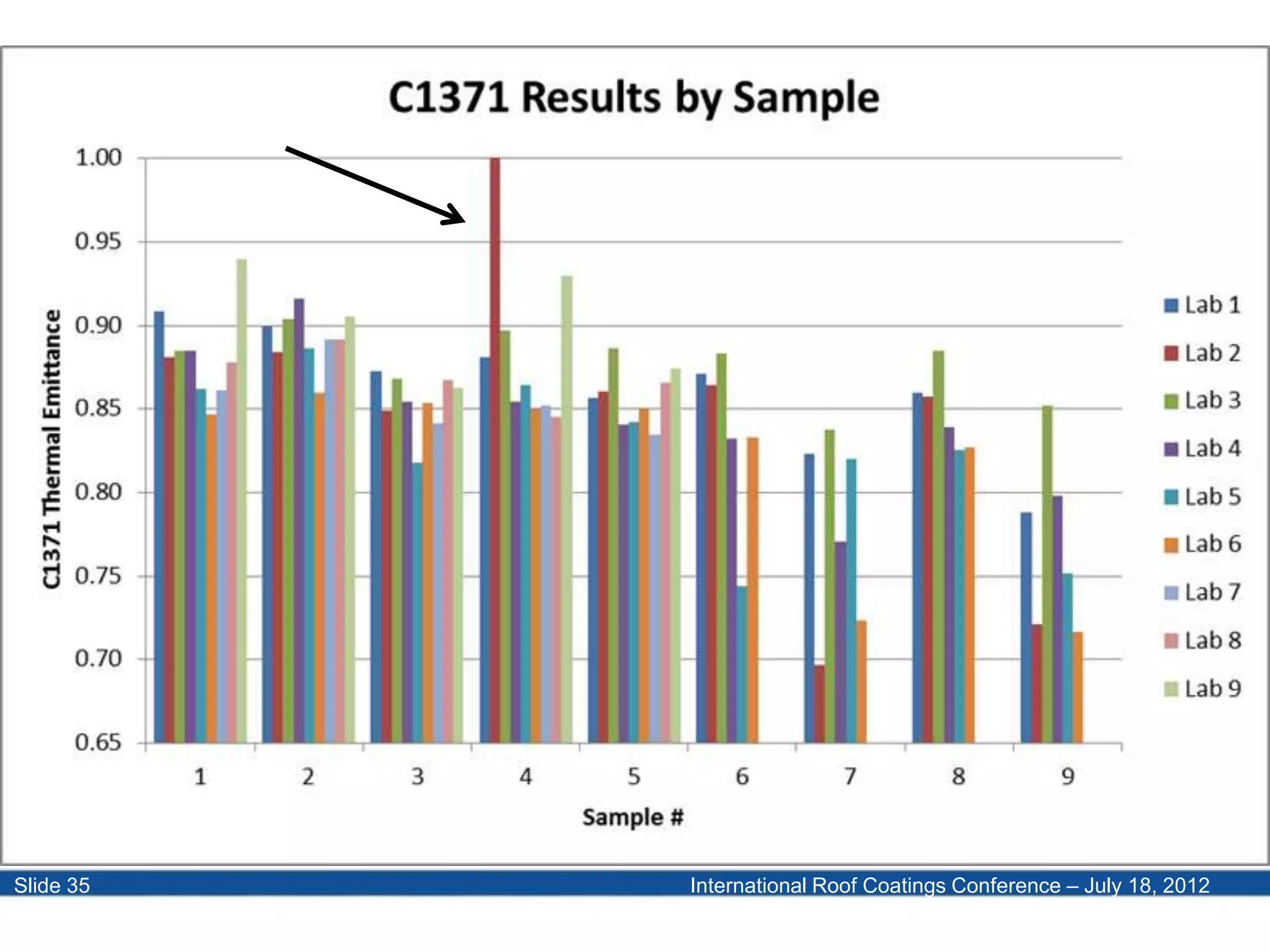

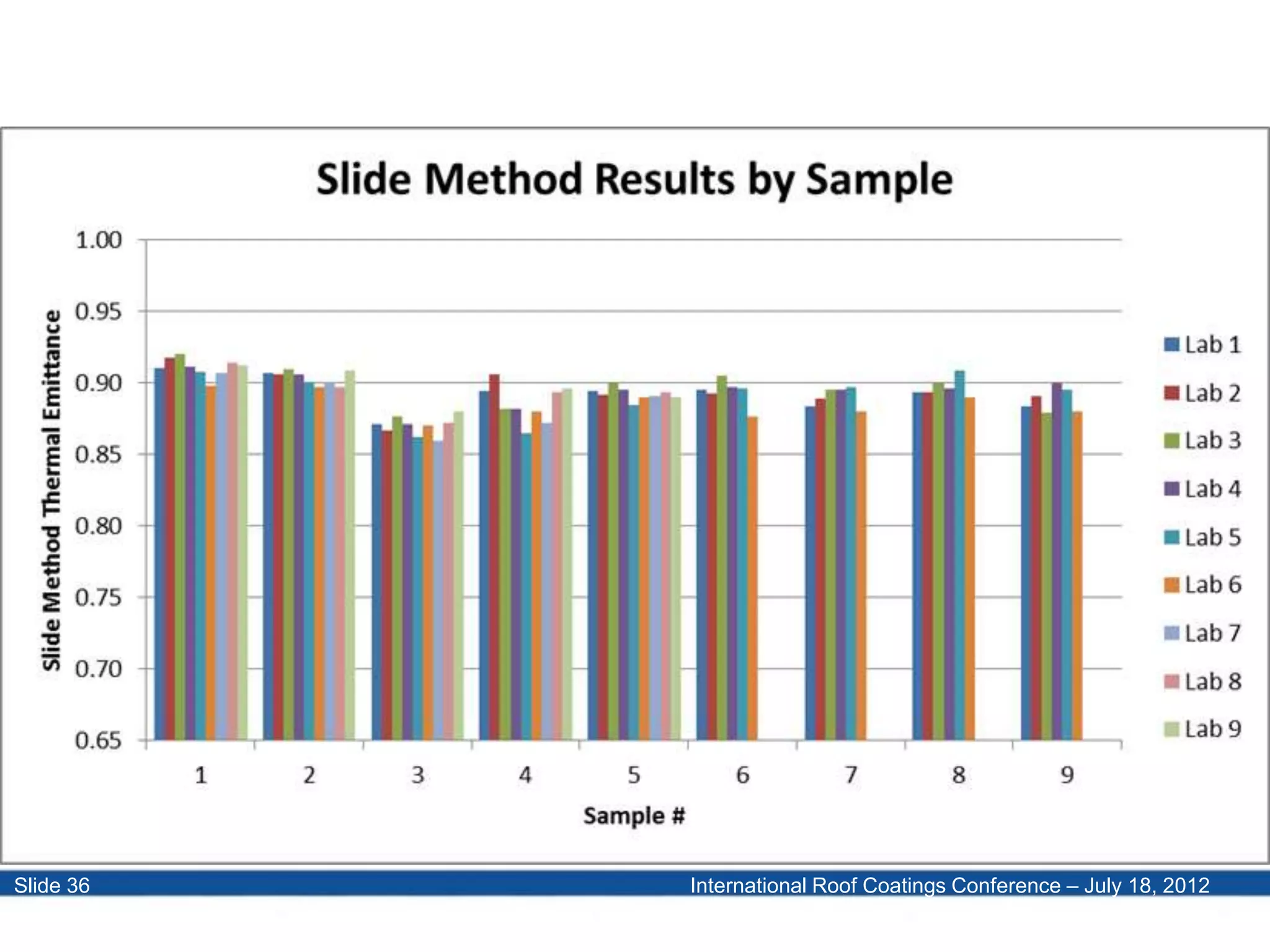

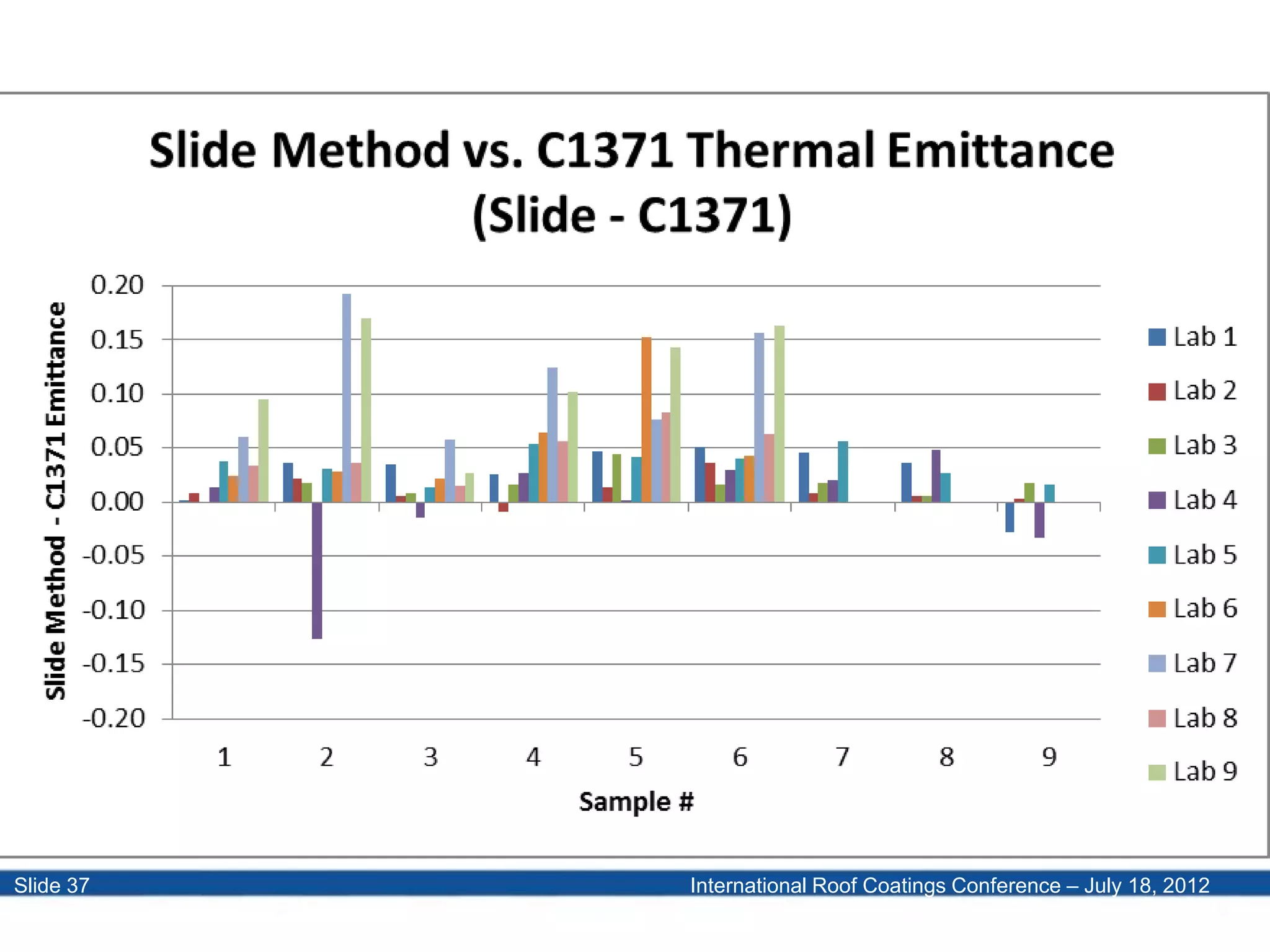

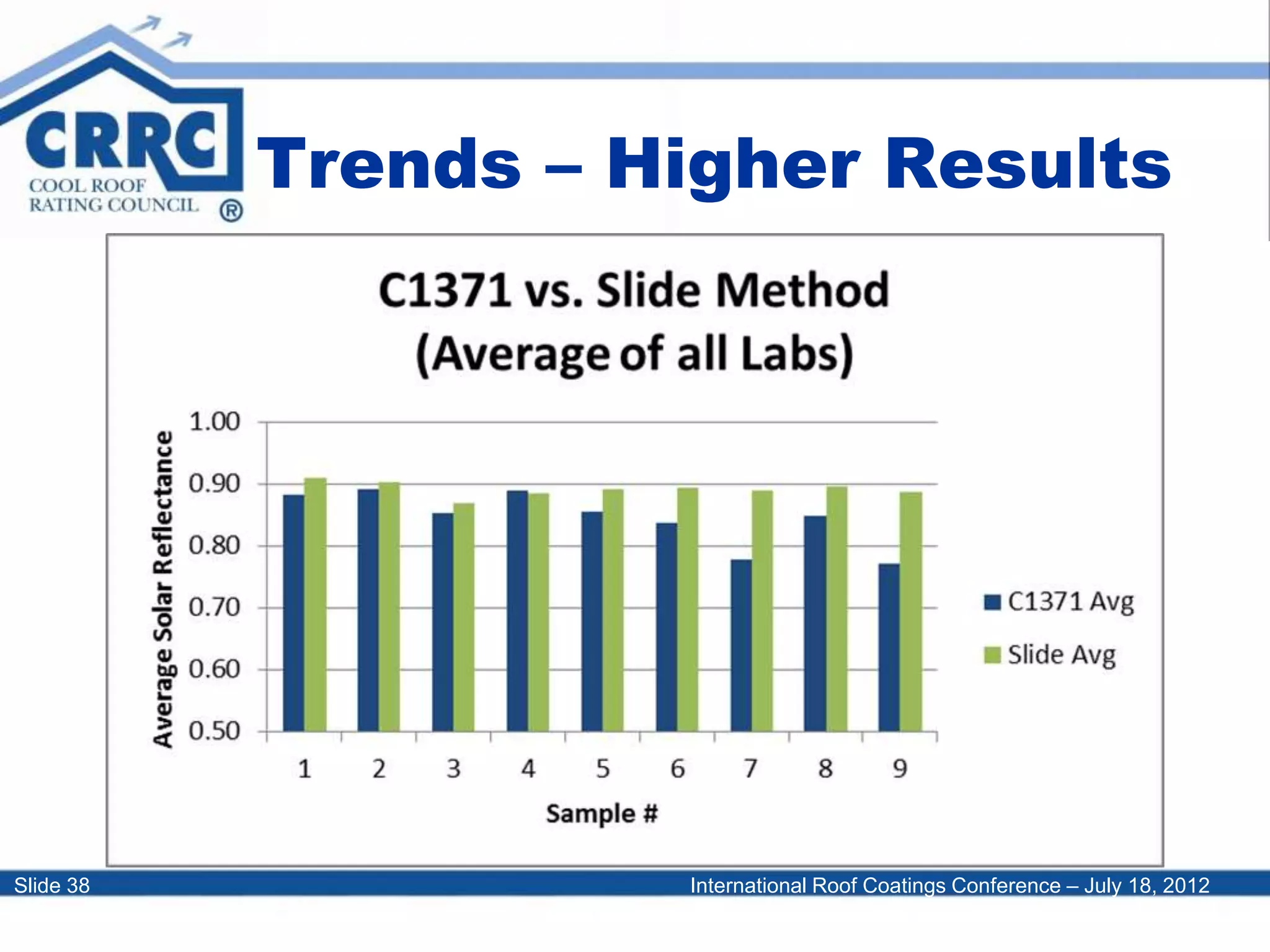

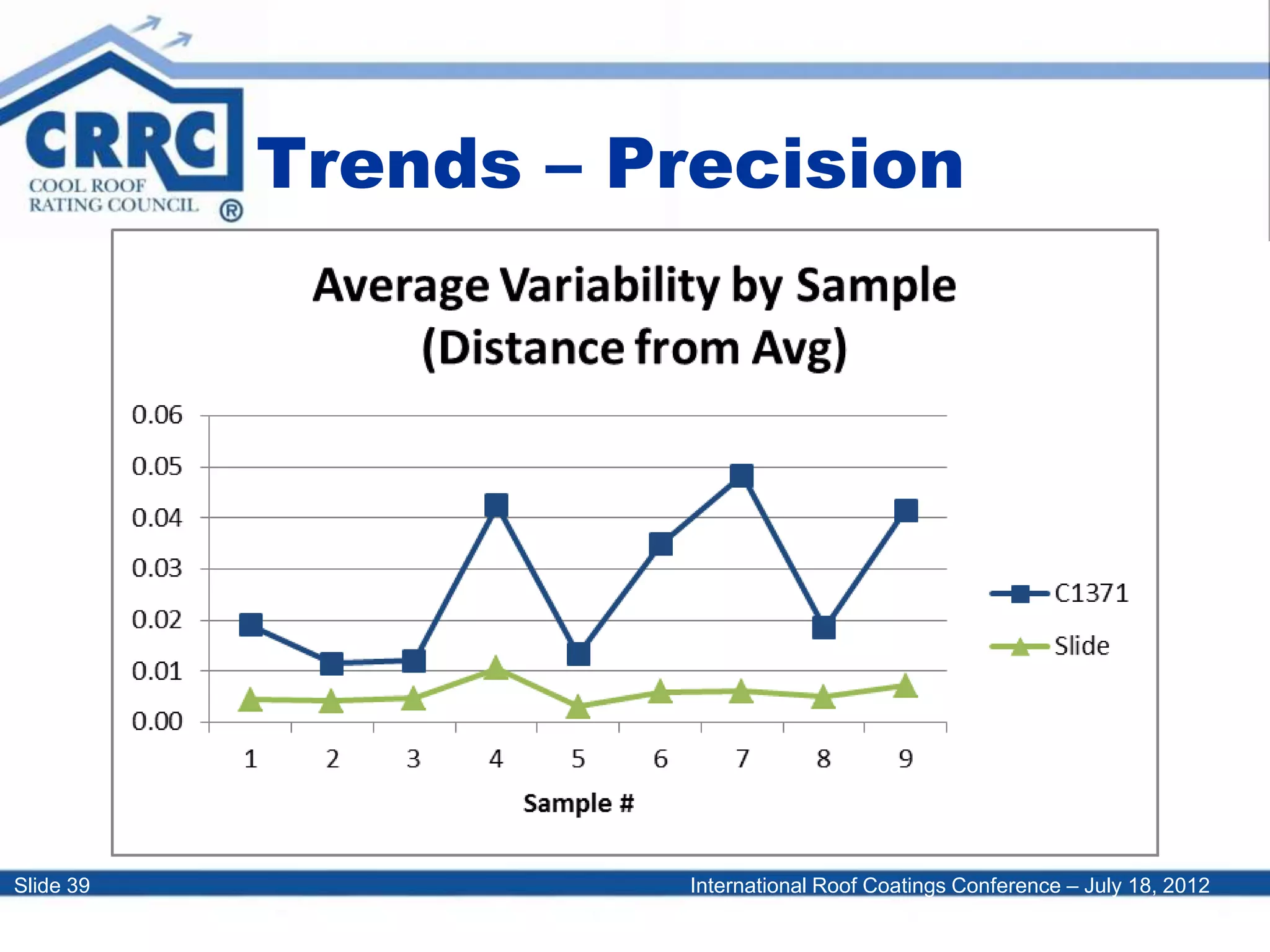

The document summarizes changes to test methods used by the Cool Roof Rating Council (CRRC) to rate solar reflectance and thermal emittance of roofing products. It describes two studies conducted to examine the impact of upgrading the Solar Spectrum Reflectometer device and adopting the Slide Method for thermal emittance testing. The studies found the test method changes resulted in small differences that did not warrant adoption of the new reflectometer version or extrapolation of slide test data, but some product types may be tested using the new methods going forward.