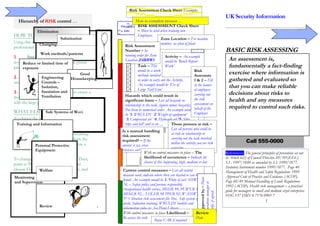

1. This document provides examples of how to complete a risk assessment check sheet. It includes information on identifying hazards, those at risk, current control measures, the likelihood of risks occurring, and reviewing risk assessments.

2. The document lists the key elements to include in a risk assessment such as the location, activity, task, hazards, persons at risk, current controls, likelihood of risks, and review date. It also notes that additional control actions may be required.

3. Instructions are provided on filling out a risk assessment form, including attaching additional documents like a manual handling assessment if required. Overall approval of the risk assessment is also part of the process.

![Risk Assessment Procedure’s –Flow Chart

1 CHEP. A Suitable and Sufficient Key Words and Meanings

Info

Risk Assessment as Hazard Is anything source or situation that has potential to 1. HAZARD Identification

recommended by the HSE cause harm

2. Persons at

Identify the Significant RISKS Risk The chance it is that a hazard will cause actual 3. Evaluate the level of

RISK

harm, based on the degree of exposure, the likelihood RISK

And Ignore the of the hazard-event and the severity of the

Trivial Ones … consequences

Identify and Priorities the 4. RISK Controls

Measures required complying Harm When harm is defined in terms of human injury or ill

with - health, damage to property, damage to the environment, (Existing and Additional)

Any Relevant Statutory business loss etc or a combination

Provisions 5. Record RISK

Hazard- The interaction of a person with a hazard that could Assessment

Remain appropriate to the nature event start an accident sequence findings

of work

Accident The sequence of events that begins with a person

6. Monitor and Review

And valid over a reasonable

sequence interacting with a hazard a subsequent loss of control,

period of time

and ends with the consequences of an accident.

Regulations Requiring Risk How to use the ‘Risk Nomogram’ Principles of Prevention …

Assessments [H.A.S.A.W.Act

1974] Managemen

t of H&SAW Regulations 1999 Step One ~ Assess the Probability of occurrence

1. Avoid the ™

Noise at Work Regulations 1989 (2005)

Step Two ~ Assess the Exposure Time RISK

PUWER 1998, H&S 2. Evaluating the RISKS

(DSE) Regulations 1992, Fire which cannot be avoided

Precautions Regulations 1997 (as amended), COSHH Step Three ~ At the intersection of the two lines draw

a left diagonal line, parallel with the guidelines, up until 3. Combating

Regulations 2002, Manual the RISK at source

it meets the edge of the grid.

Handling Regulations 1992

4. Adapting

Other Regulations under the Enabling Act

Step Four ~ Draw a horizontal line parallel with the the work to 5. Adapting to technical

include – Health and Safety (Consultation with Employees) guidelines until it intersects at the degree of injury line process

the

Regulations 1996, Safety Representatives and Safety that you have established. Individual

Committees Regulations 1977, Workplace (Health, Safety and

Welfare) Regulations 1992, The Health and Safety (Safety Step Five ~ Draw a right diagonal line from the injury 6. Replacing the dangerous by

Signs & Signals )Regulation 1998, Personal Protective line, parallel with the guidelines, until you arrive at your non-dangerous or less

Equipment Regulations 1992, Lifting Operations and Lifting 7. Developing

degree of risk. Step Five dangerous

Equipment Regulations 1998, Electricity at Work a coherent

8. Giving collective

Regulations 1989, Supply of Machinery Safety Regulations overall

Step One Risk line protective measures

1992 (as amended 1994), Confined Spaces Regulations 1997, prevention

priority over

Pressure Systems Safety Regulations 2000, Dangerous policy

Step Four individual

Substances and Explosive Atmospheres Regulations 2002, protective measures appropriate

9. Giving

Reporting of Injuries and Dangerous Occurrences Regulations Step Two Step Three instruction to employees Info

1 CHEP.

1995 – These can also be applied as controlling measures …](https://image.slidesharecdn.com/uksbrochurebasicriskassessing20102a-111112014359-phpapp02/85/Uks-brochure-basic-risk-assessing-2010-2a-2-320.jpg)