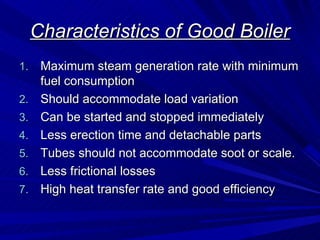

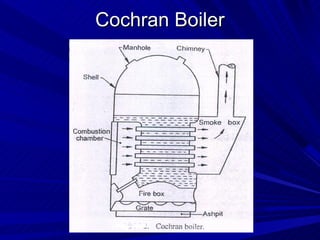

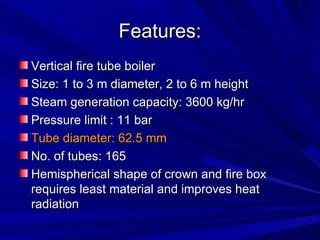

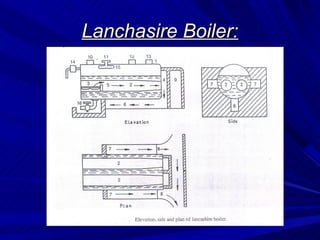

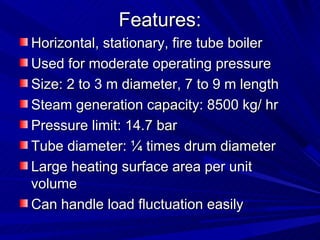

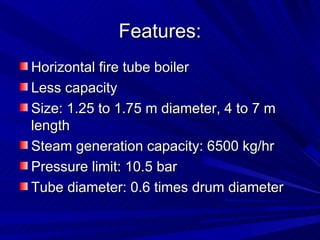

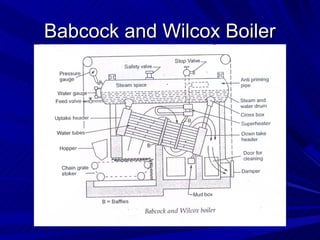

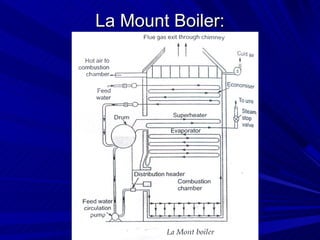

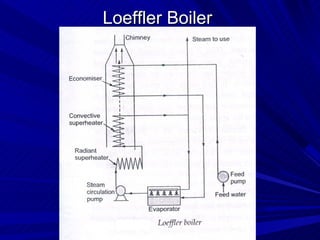

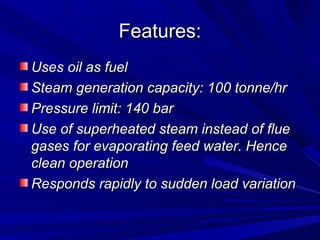

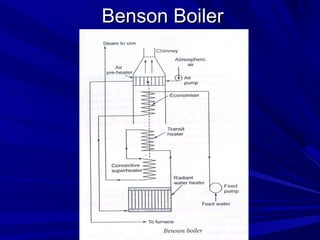

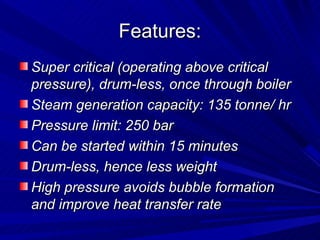

The document discusses steam boilers according to the Indian Boiler Regulation (IBR), defining them as closed vessels for generating steam under pressure. It describes characteristics of good boilers, factors affecting their selection, and various classifications and types of boilers, including fire tube and water tube designs. Additionally, it highlights specific examples of different boiler types, their features, steam generation capacities, and operating pressures.