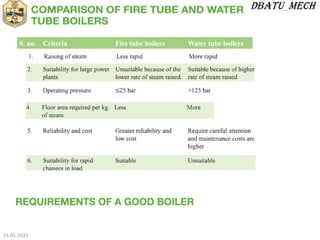

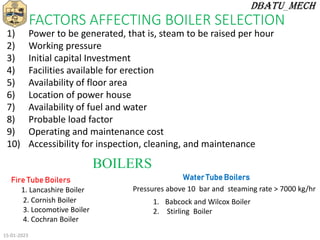

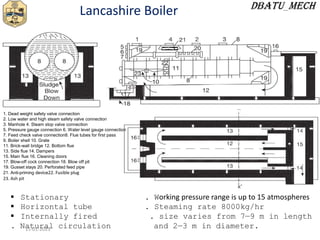

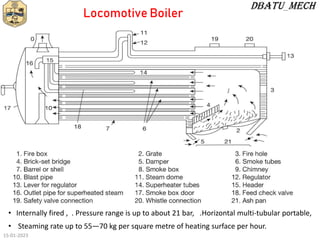

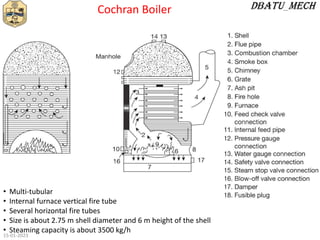

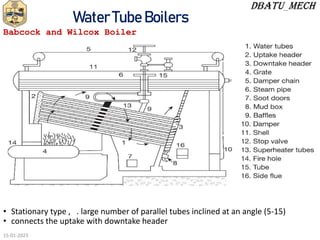

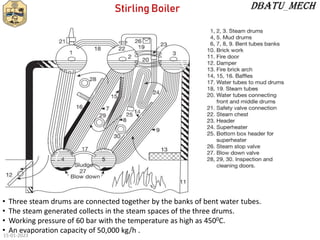

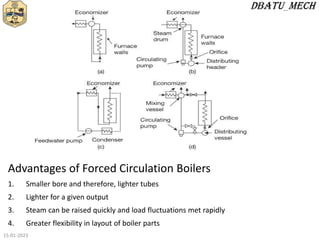

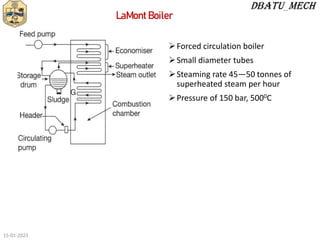

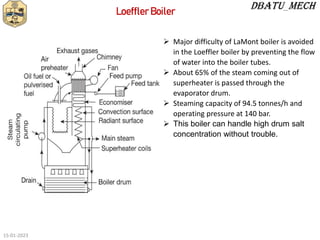

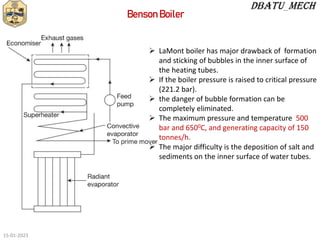

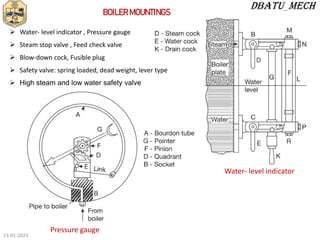

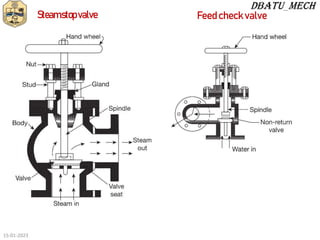

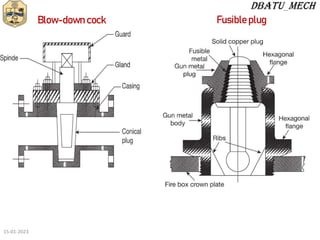

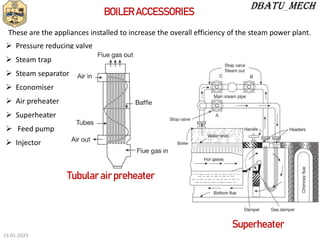

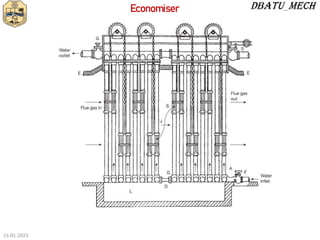

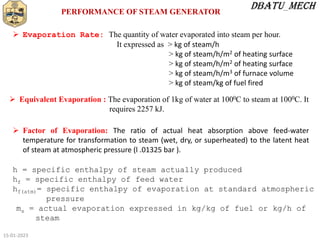

The document discusses factors affecting boiler selection and types of boilers. It describes key factors like steam output required, working pressure, fuel availability, and cost. Fire tube boilers discussed include Lancashire, Cornish, locomotive, and Cochran. Water tube boilers mentioned are suitable for pressures above 10 bar and output over 7000 kg/hr, such as Babcock & Wilcox and Stirling. Details are provided on Lancashire, locomotive, B&W, and Stirling boiler designs. Mountings, accessories, circulation methods, and high pressure boilers are also covered.