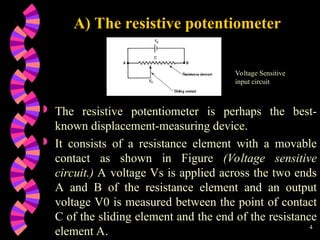

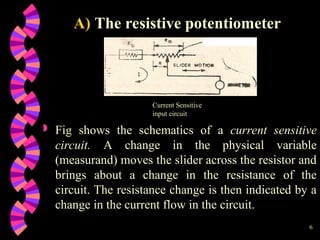

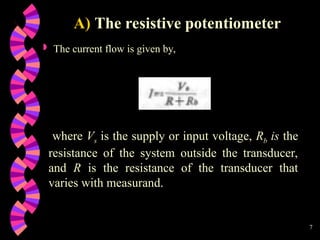

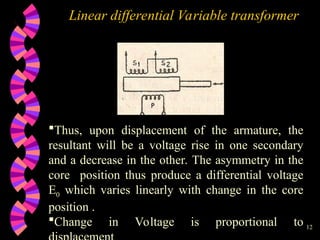

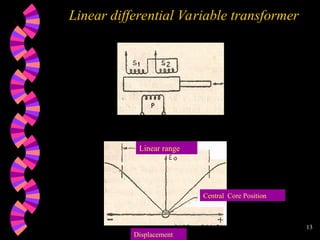

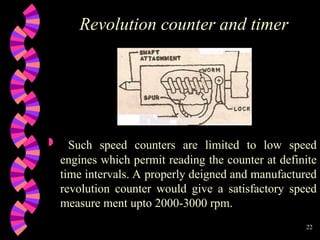

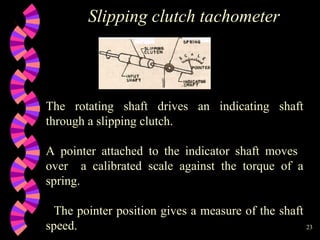

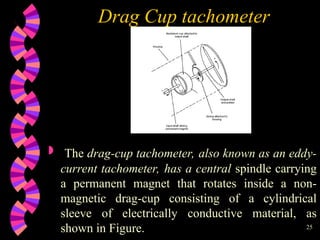

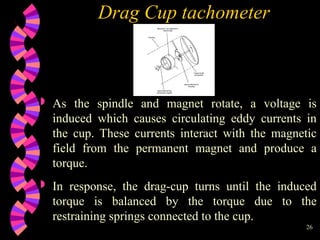

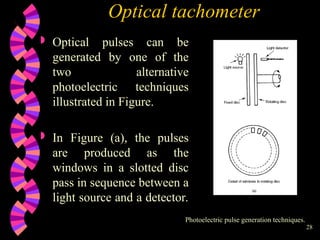

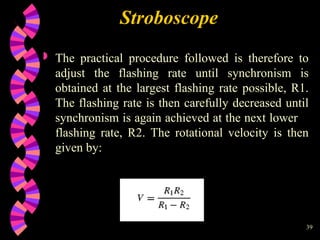

The document provides an overview of various displacement transducers used for measuring linear and rotational motion, including resistive potentiometers, linear differential variable transformers (LVDTs), and different types of tachometers. It discusses their operational principles, advantages, and applications, highlighting the techniques used for translating motion into electrical signals. The summary covers key concepts and device functionalities essential for understanding displacement measurement technologies.