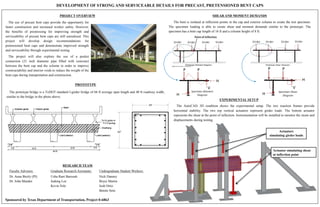

The document provides an overview of a research project to develop pretensioned precast bent caps that improve strength and constructability. The project team will experimentally test several bent cap specimens under simulated bridge loads and connections. The specimens include reinforced concrete, pretensioned solid and hollow designs, and a pocket connection using a corrugated pipe between the bent cap and column for improved construction tolerances.