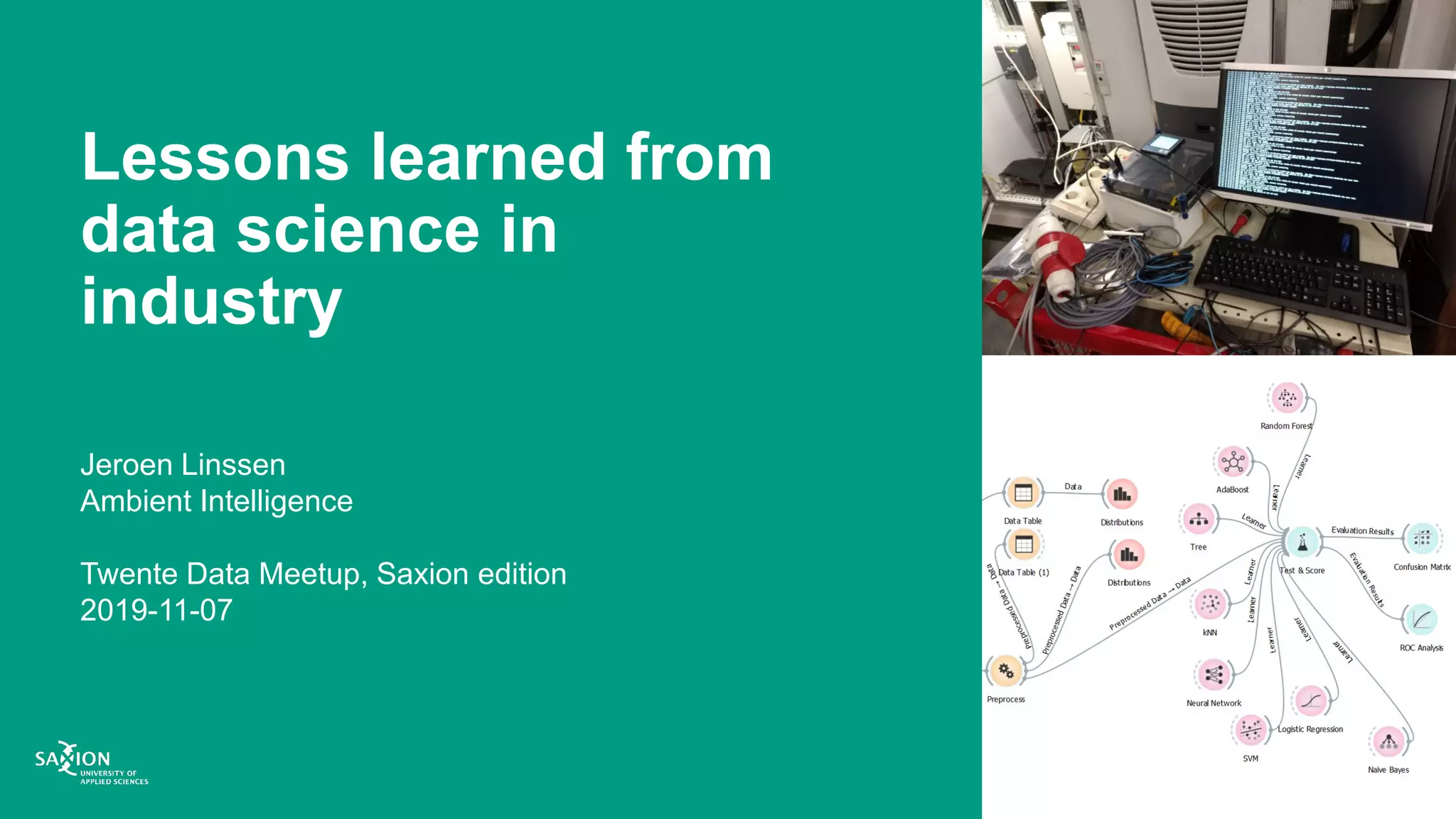

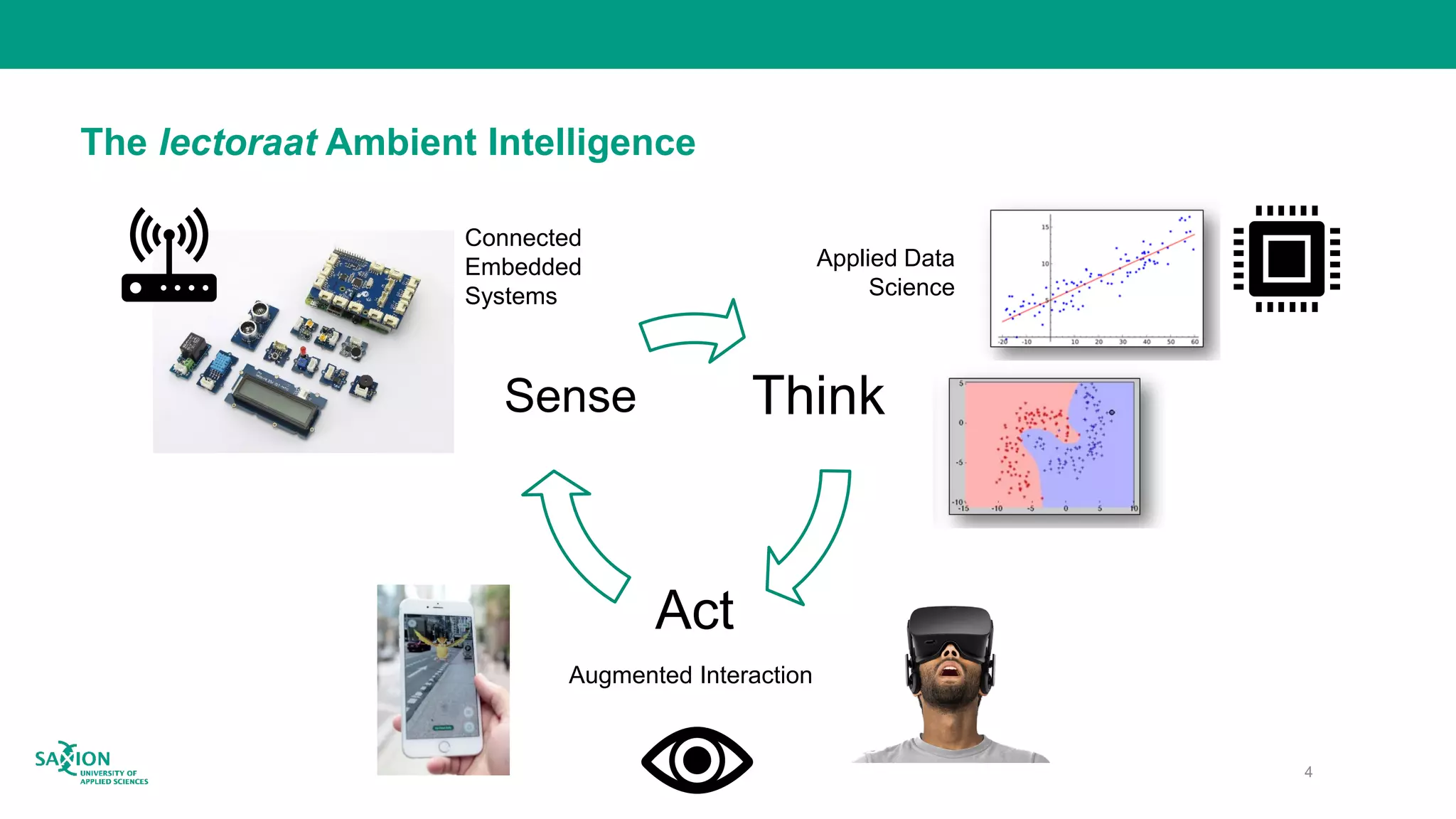

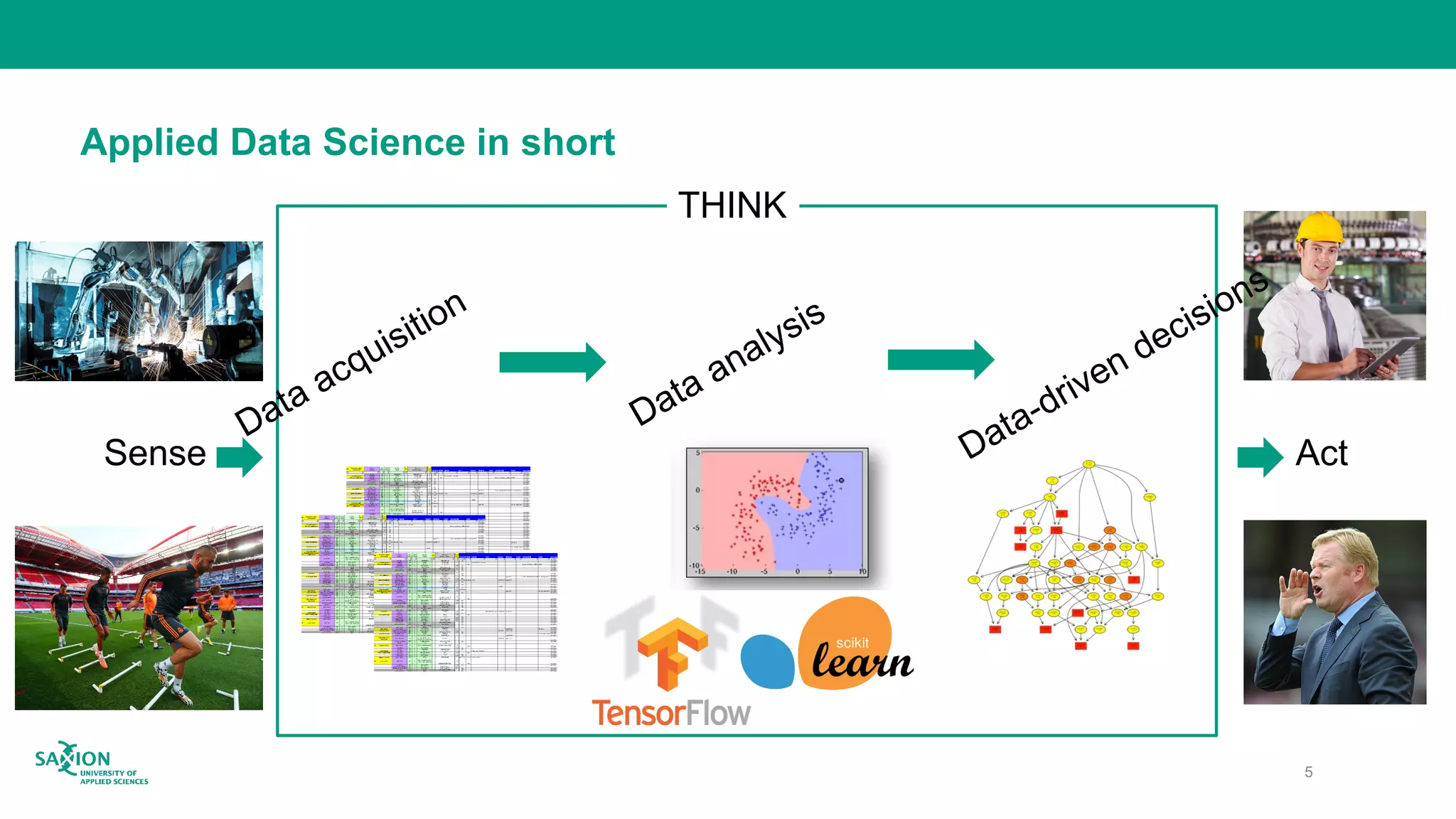

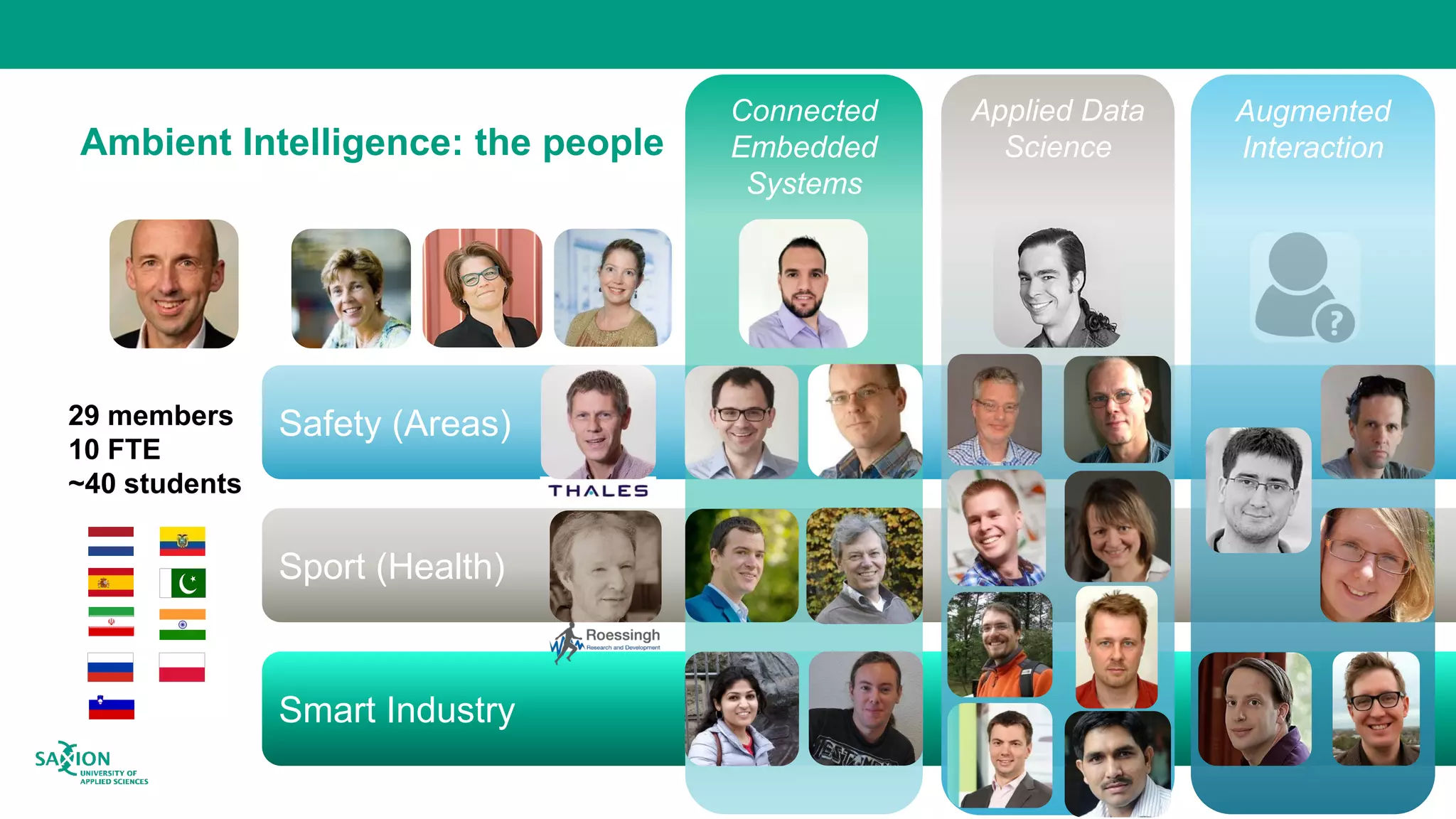

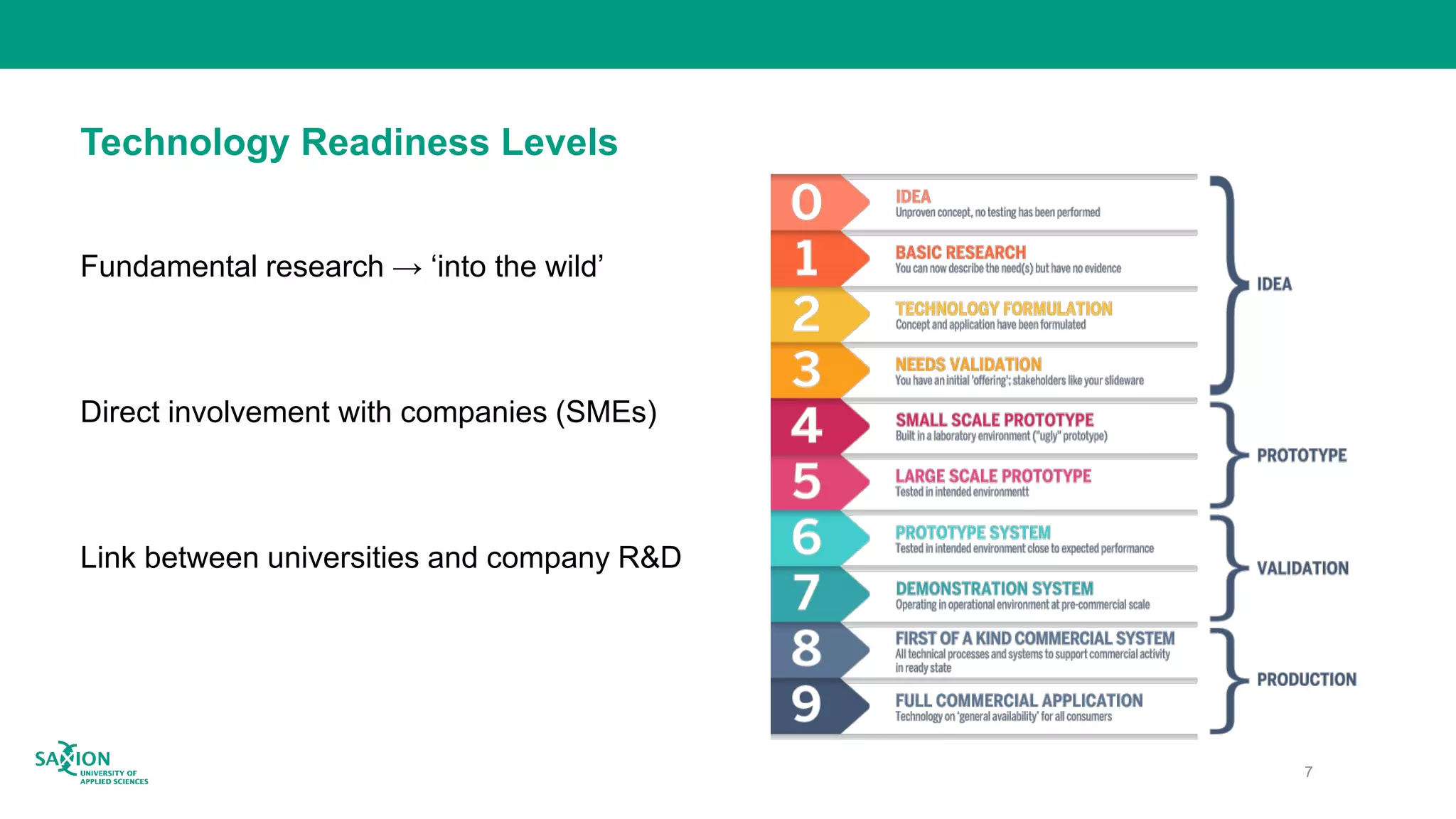

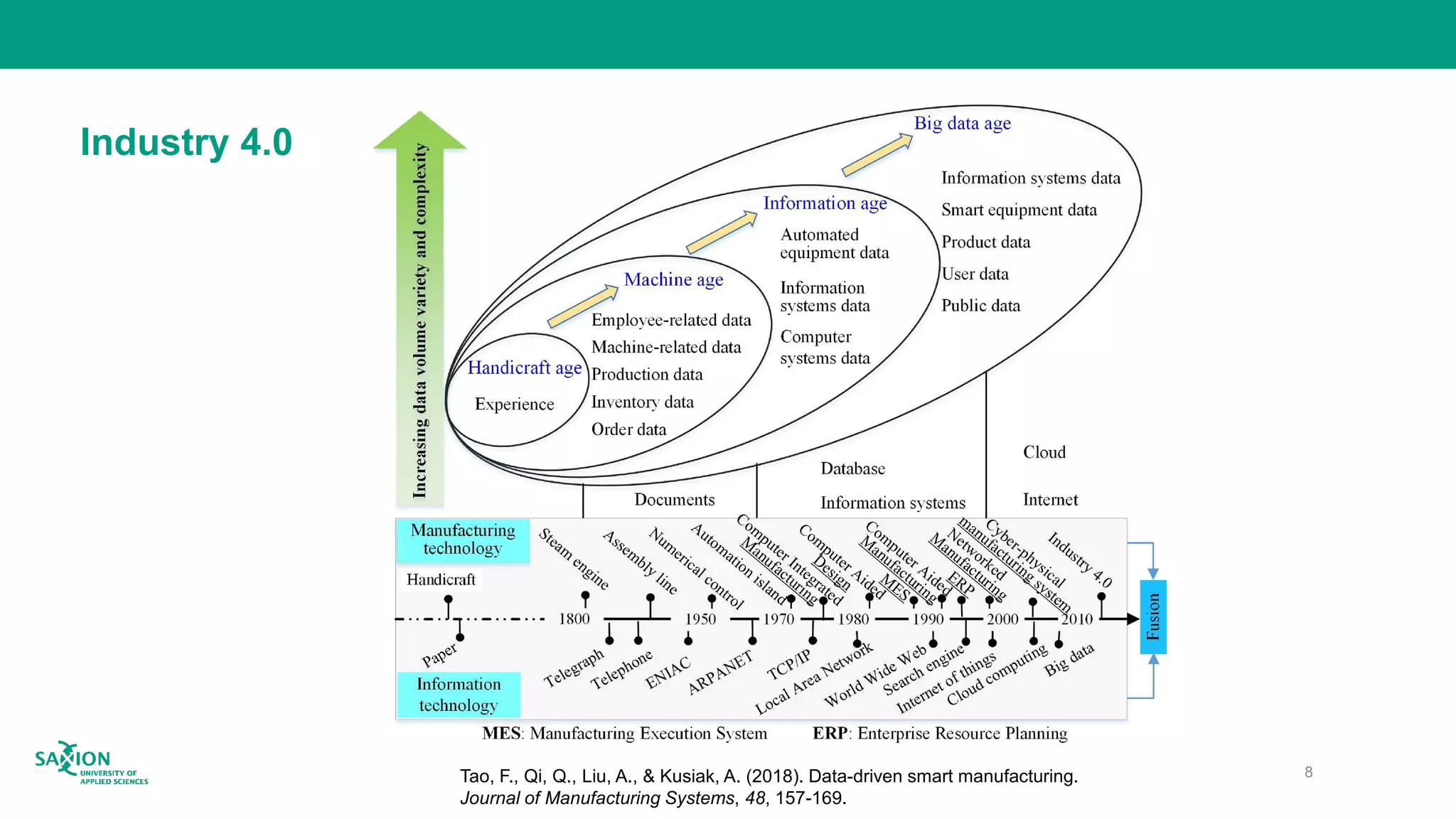

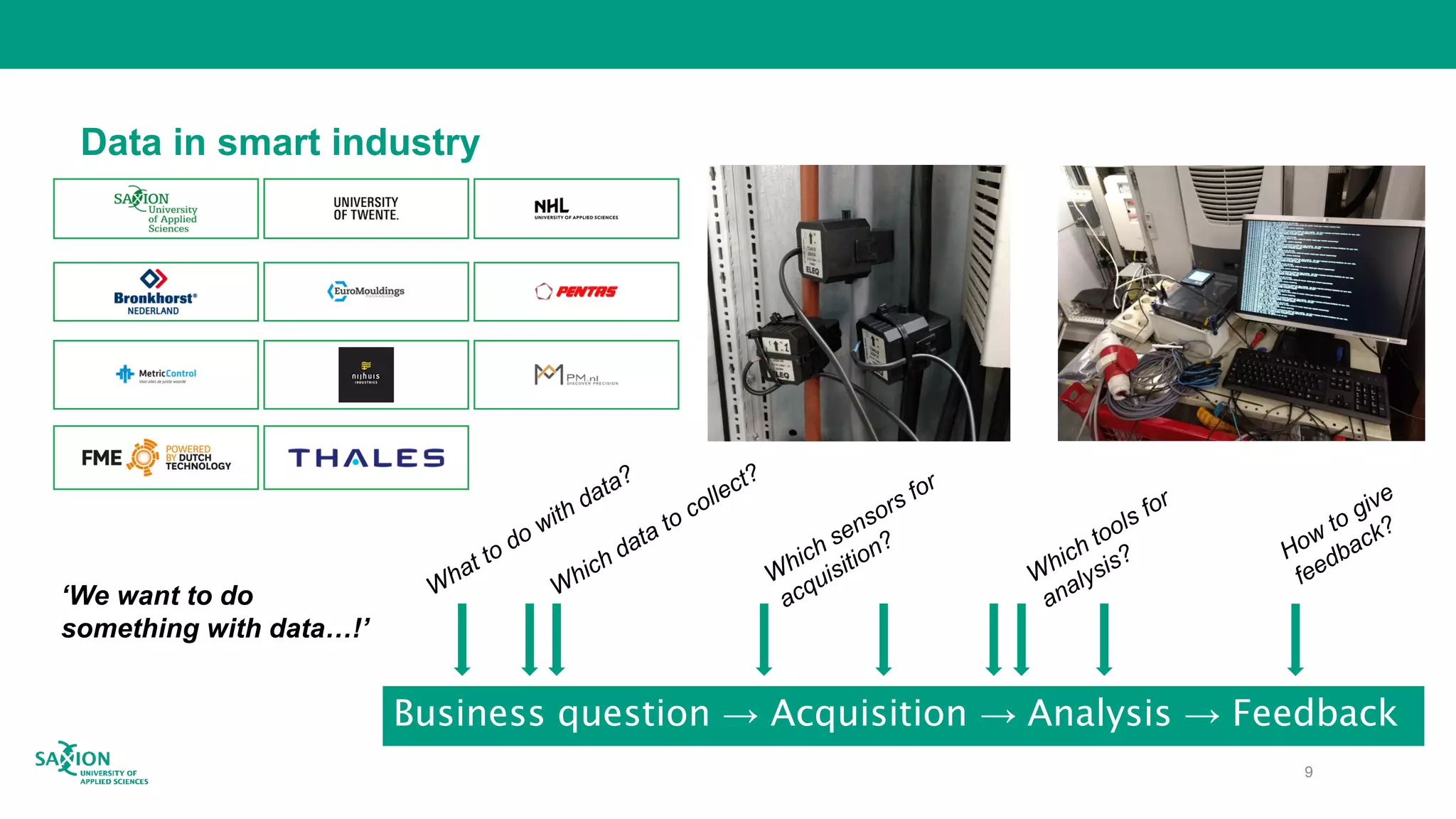

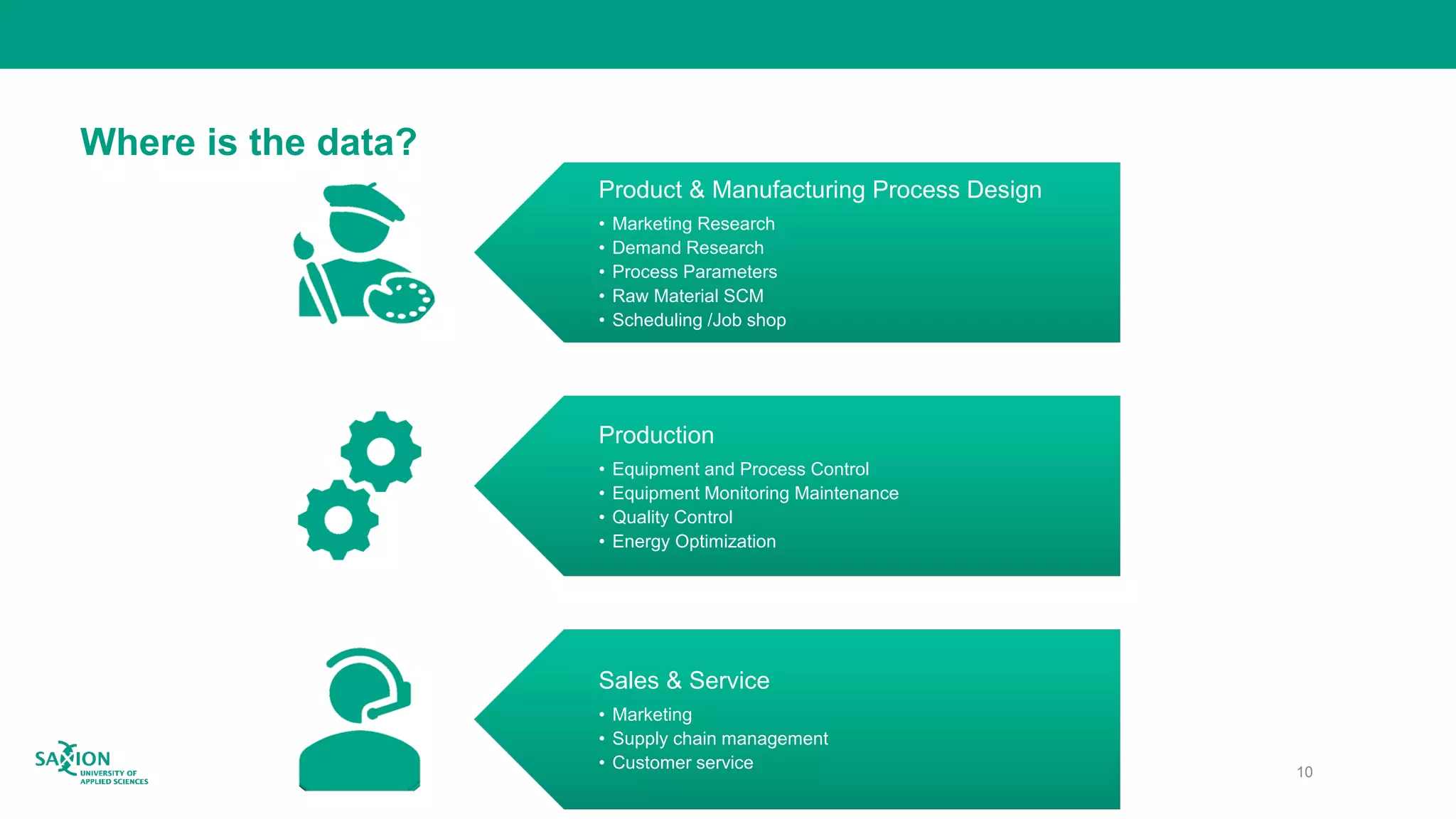

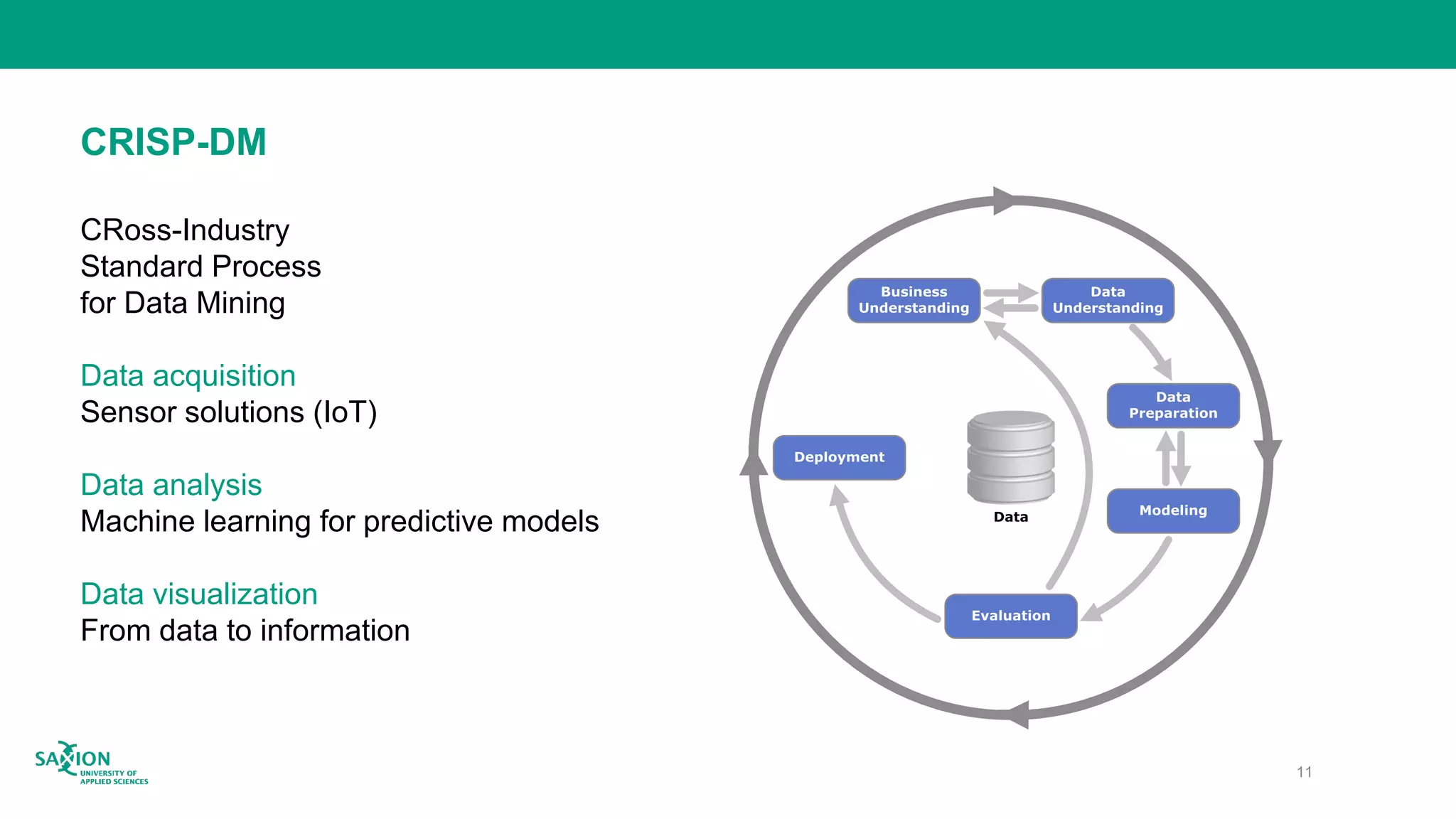

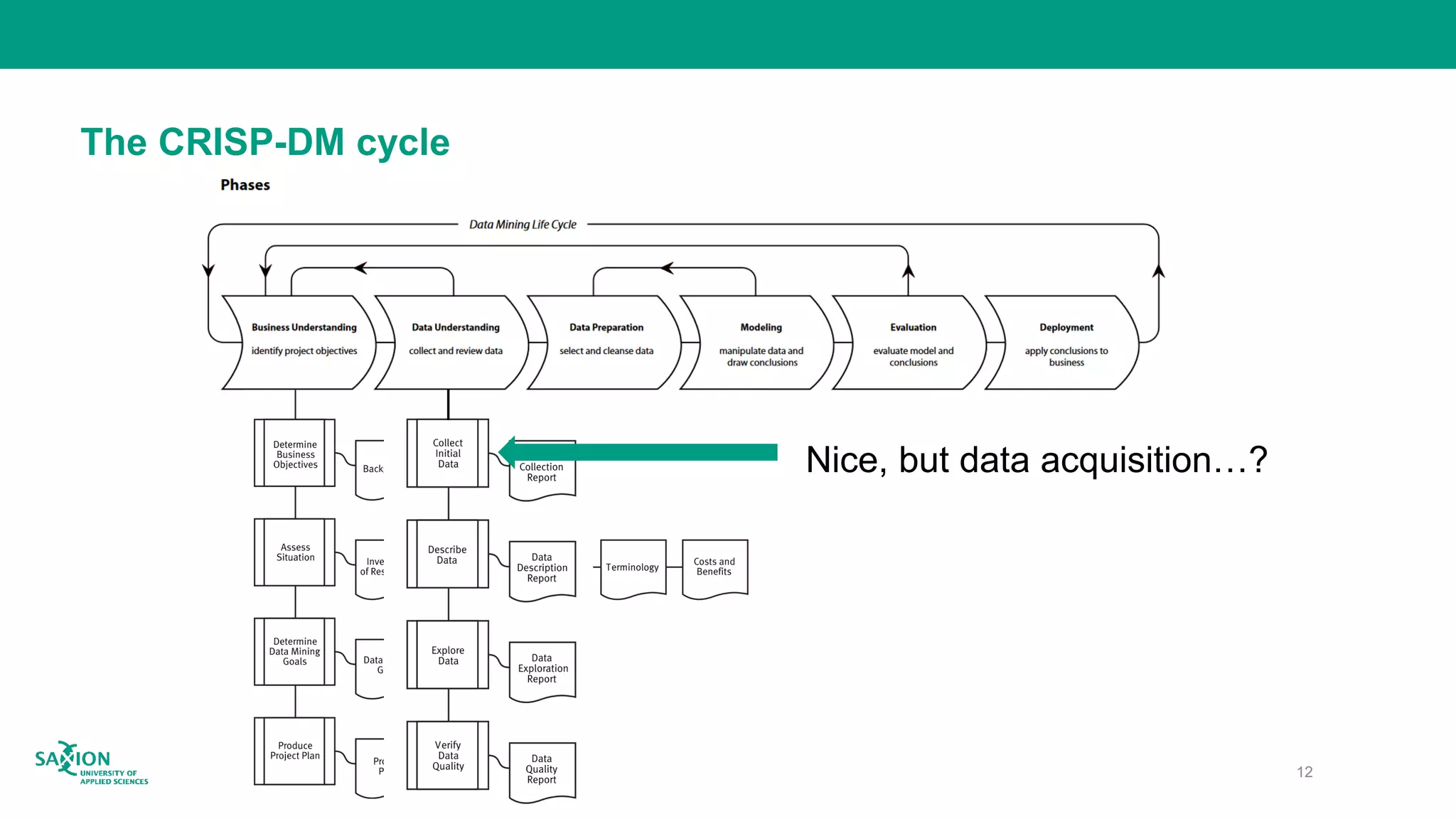

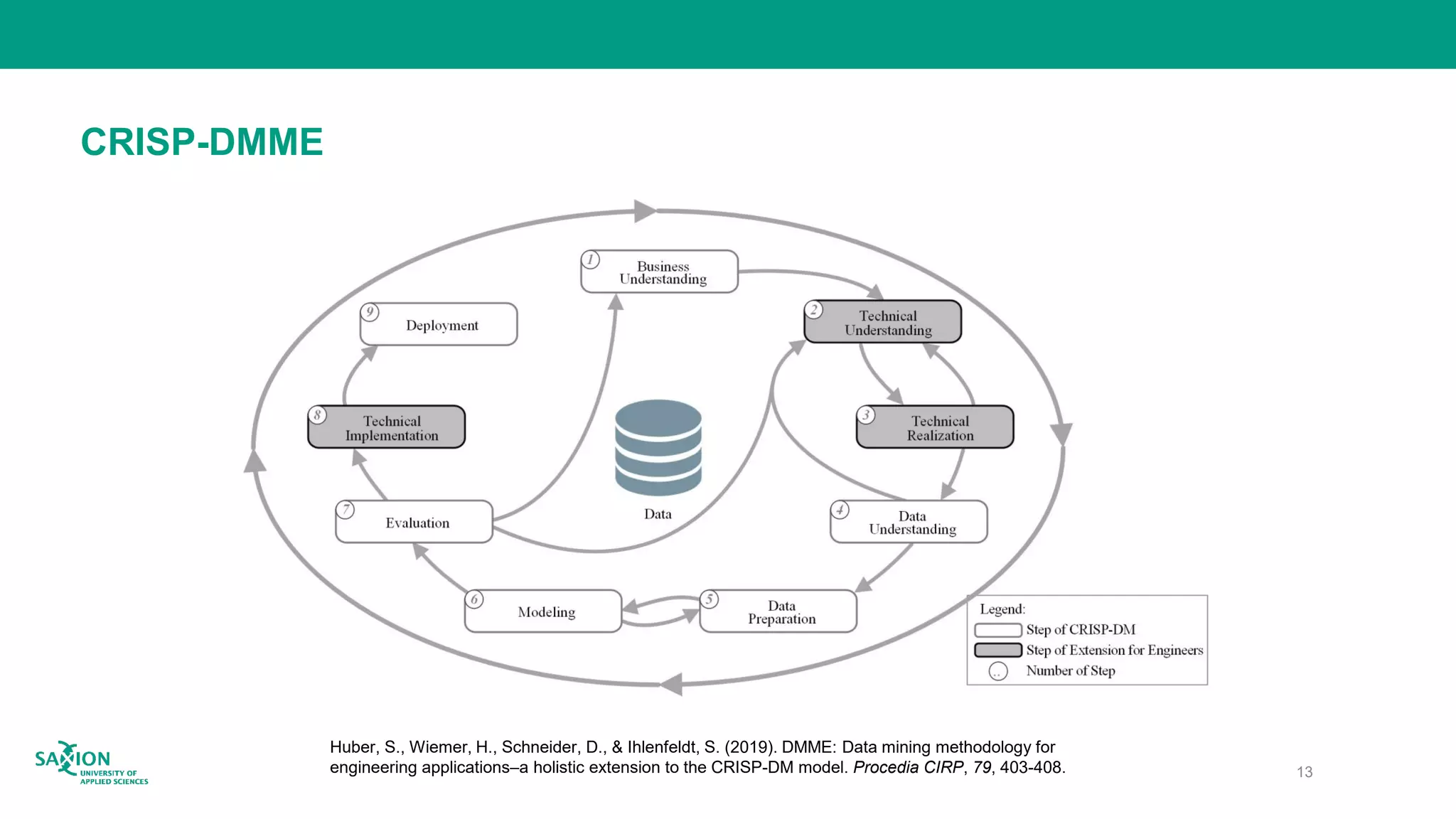

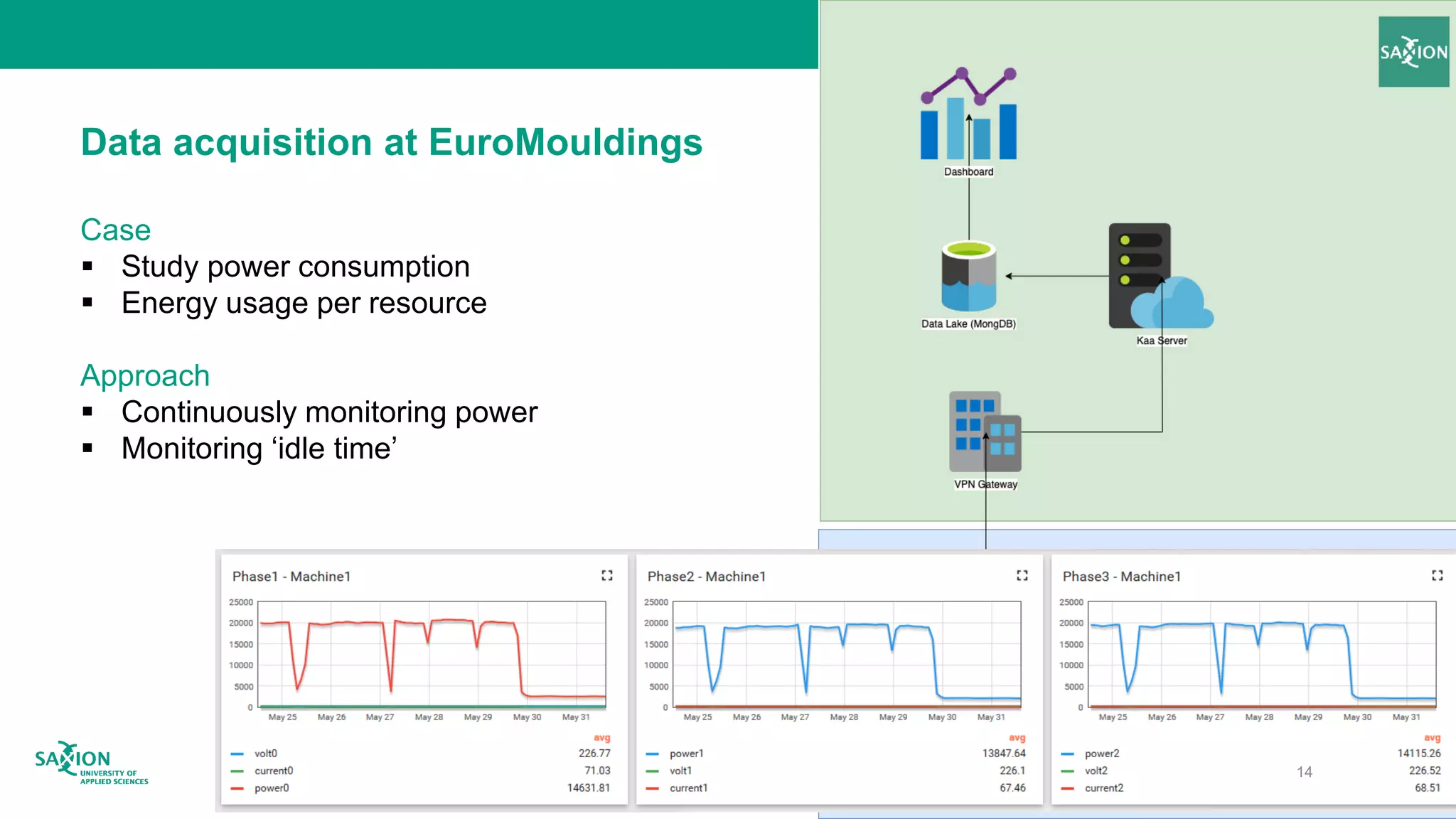

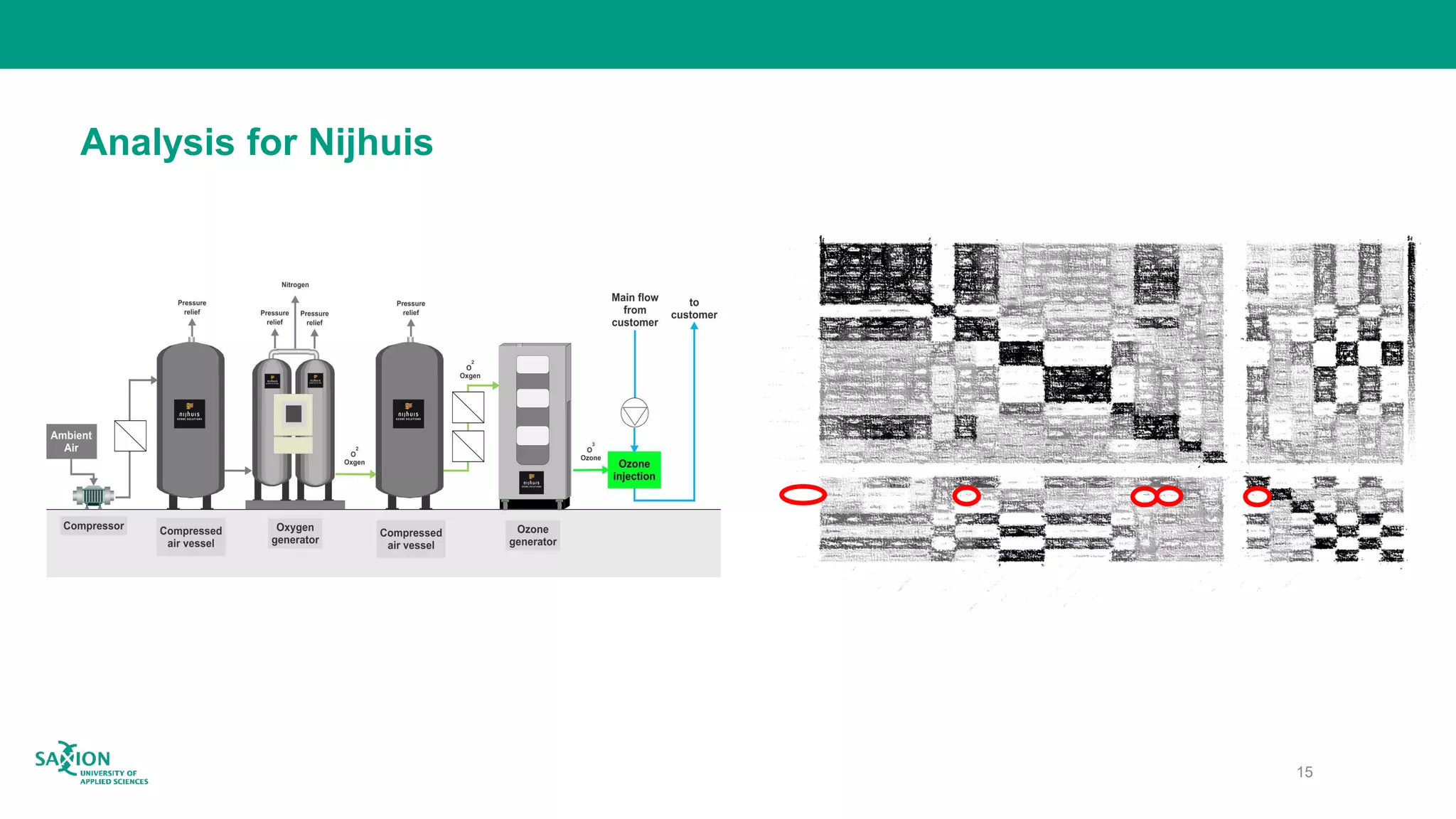

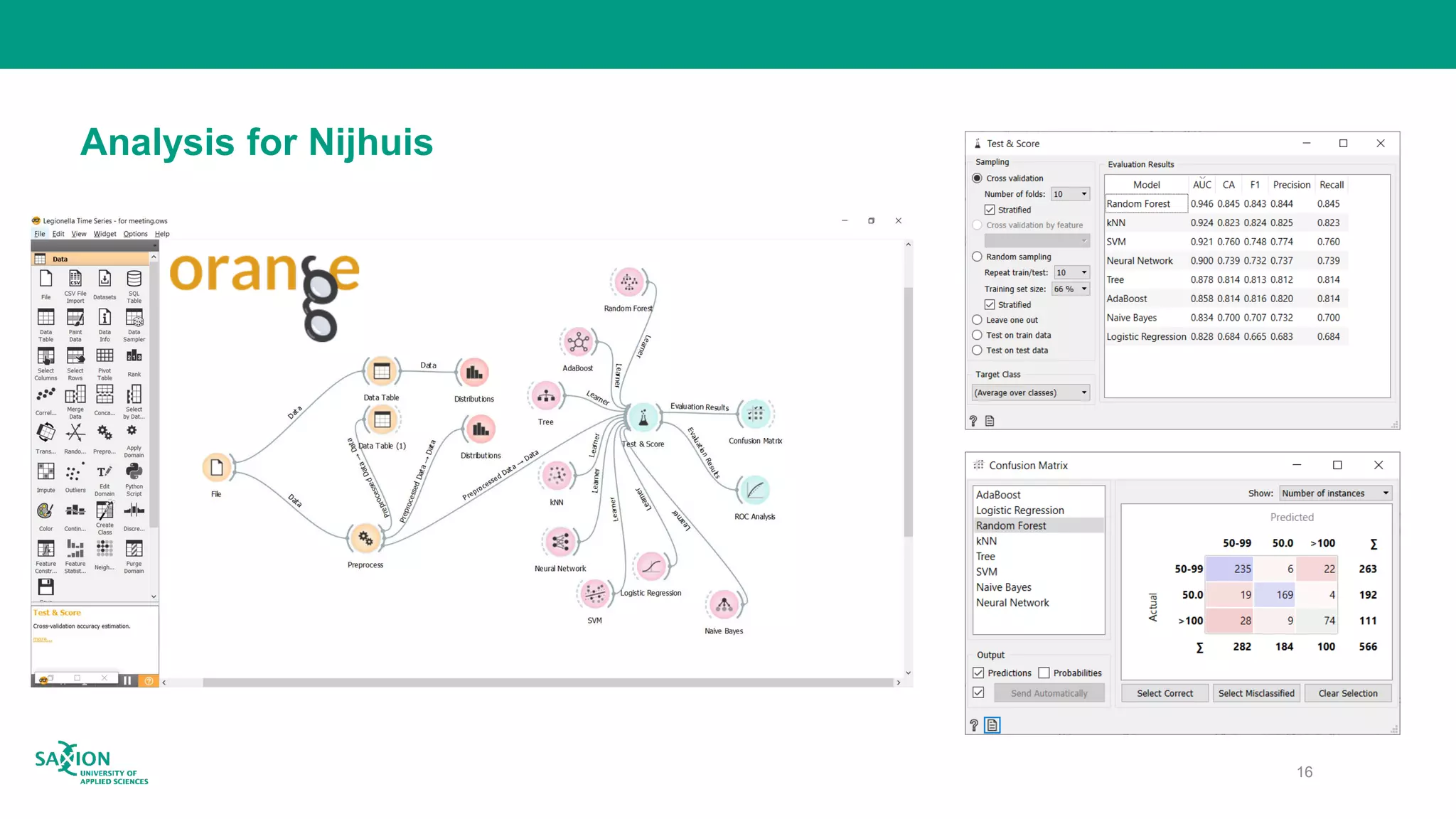

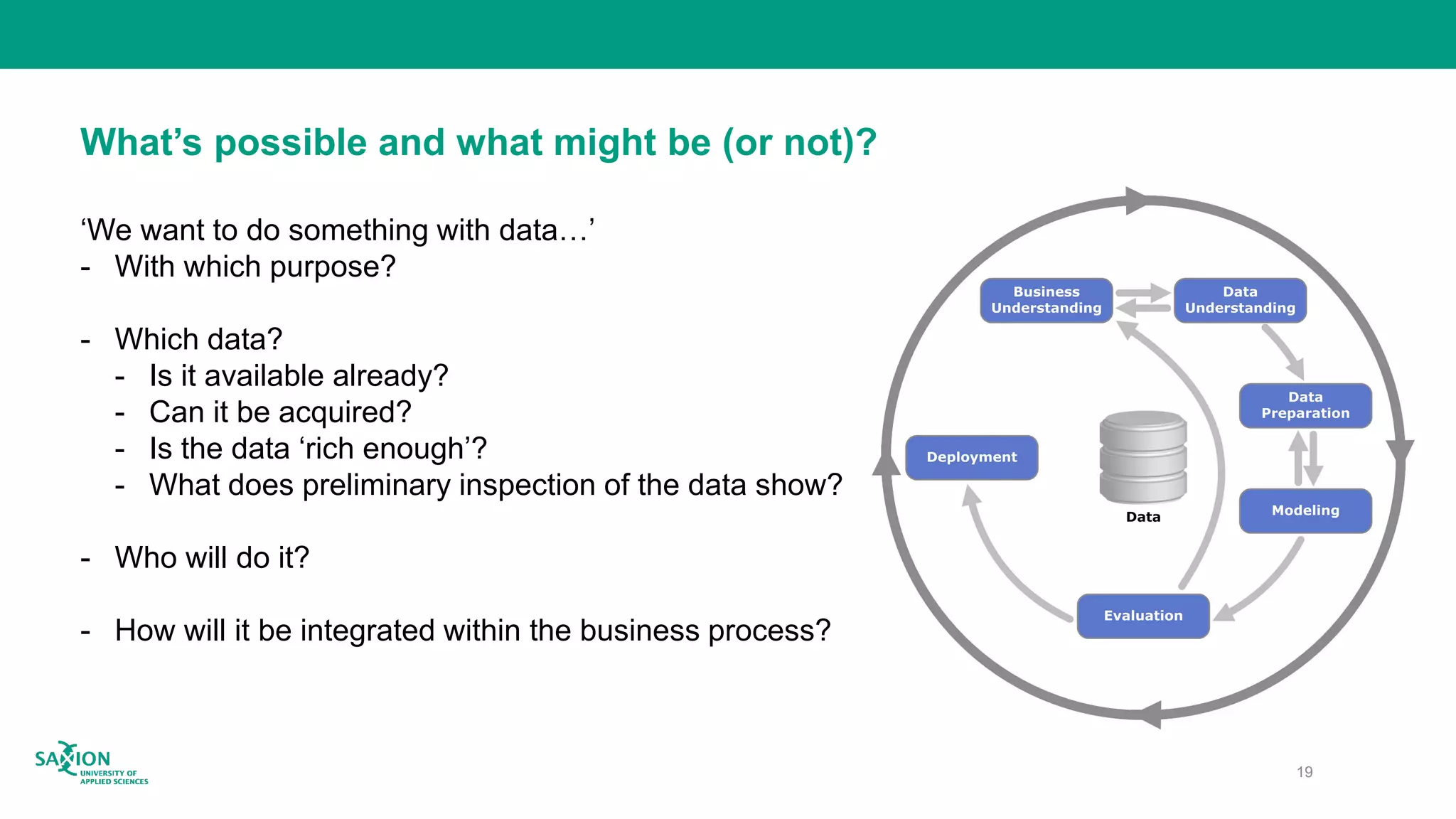

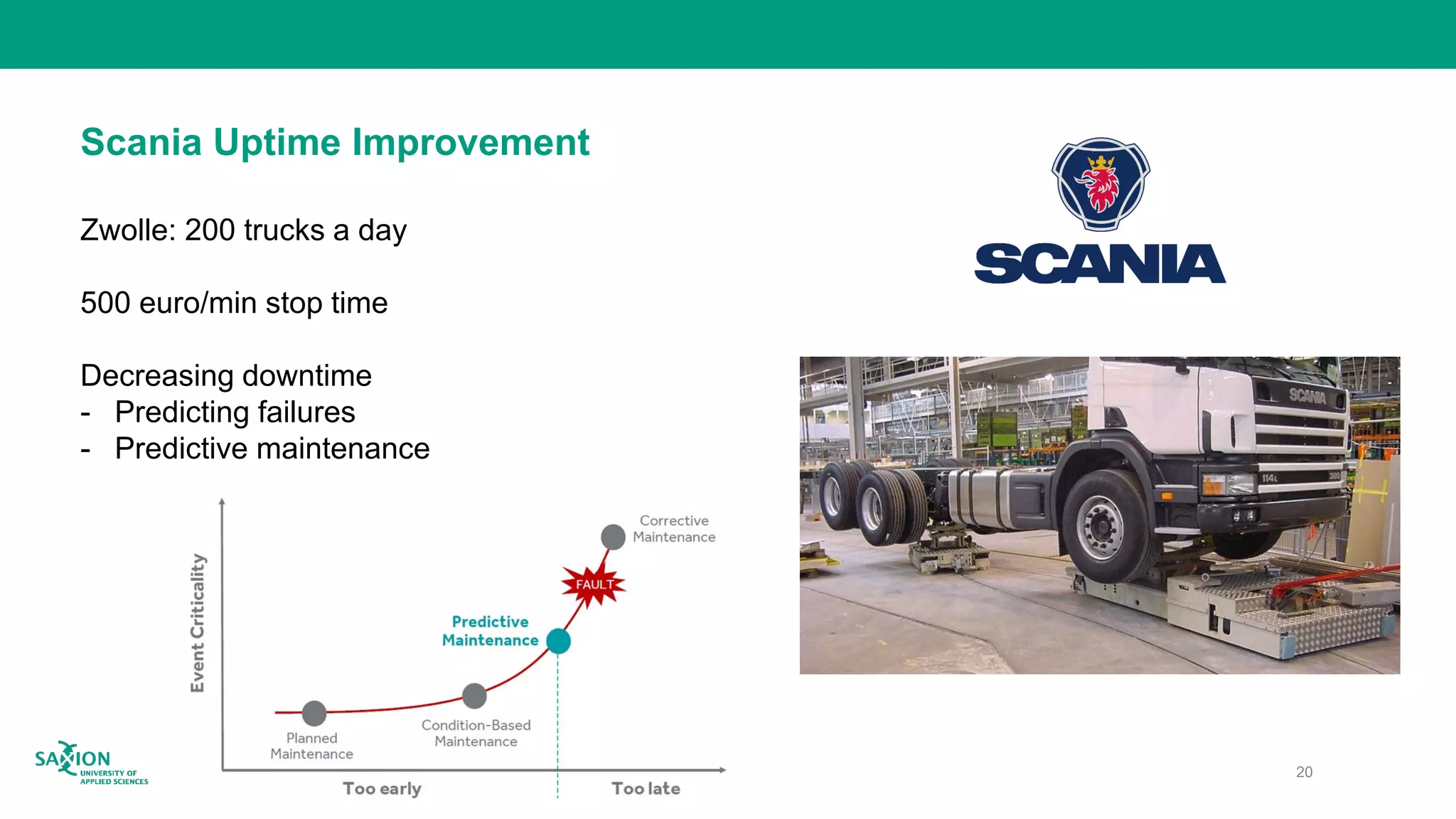

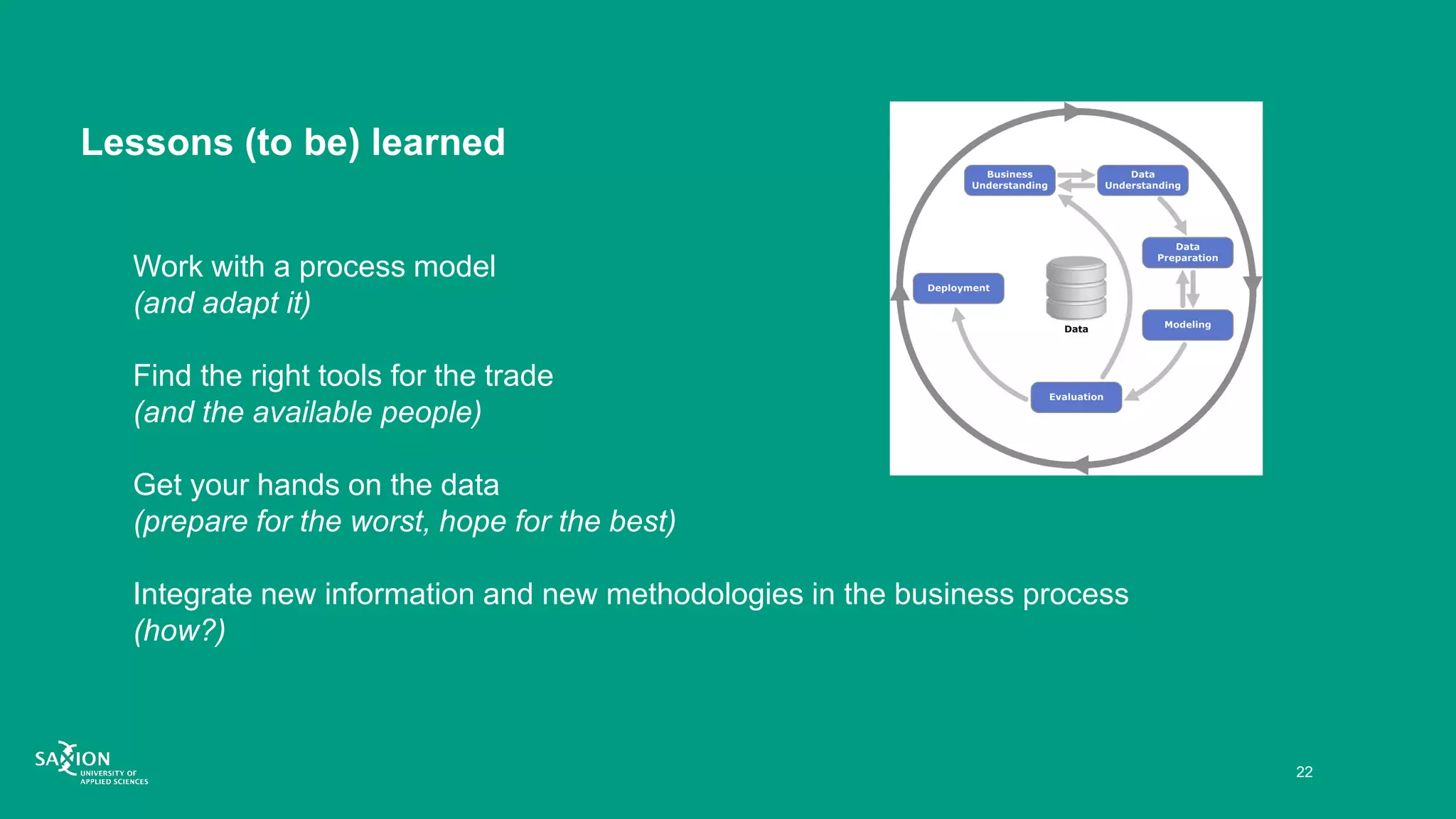

The presentation discusses the application of data science in ambient intelligence and industry, focusing on methodologies like CRISP-DM and the importance of data acquisition. It emphasizes lessons learned from case studies, including predictive maintenance and the connection between research institutions and companies. The presenter encourages adapting processes, finding the right tools, and integrating data-driven methodologies into business operations.