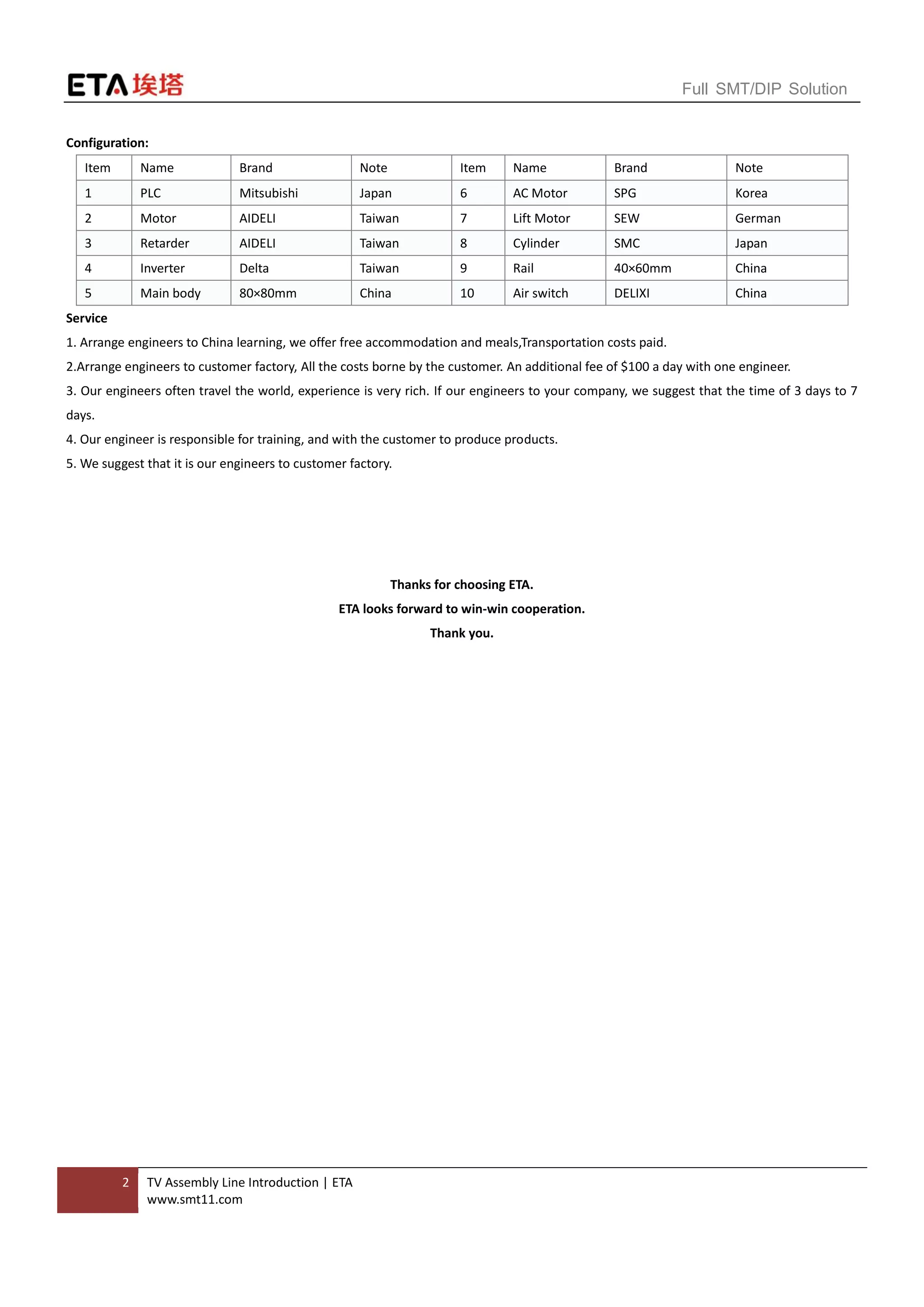

The document details the specifications and configuration of an ETA TV assembly line, including dimensions, materials used, and components like motors and PLCs. It also outlines service offerings, including engineer training and the potential for on-site support for customers. ETA aims for a collaborative partnership with clients, emphasizing rich experience and comprehensive assistance.