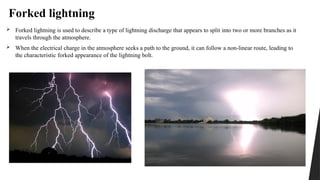

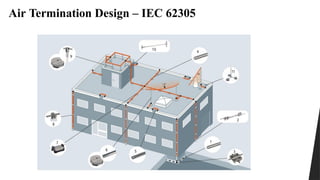

The document provides a comprehensive introduction to lightning phenomena, detailing the stages of lightning formation and its effects, including physical damage and electromagnetic impacts. It discusses the design and components of lightning protection systems, such as air terminals and down conductors, along with methods for risk assessment and air termination design. Additionally, it covers various methods for protecting structures, emphasizing the importance of proper installation to mitigate lightning risks.