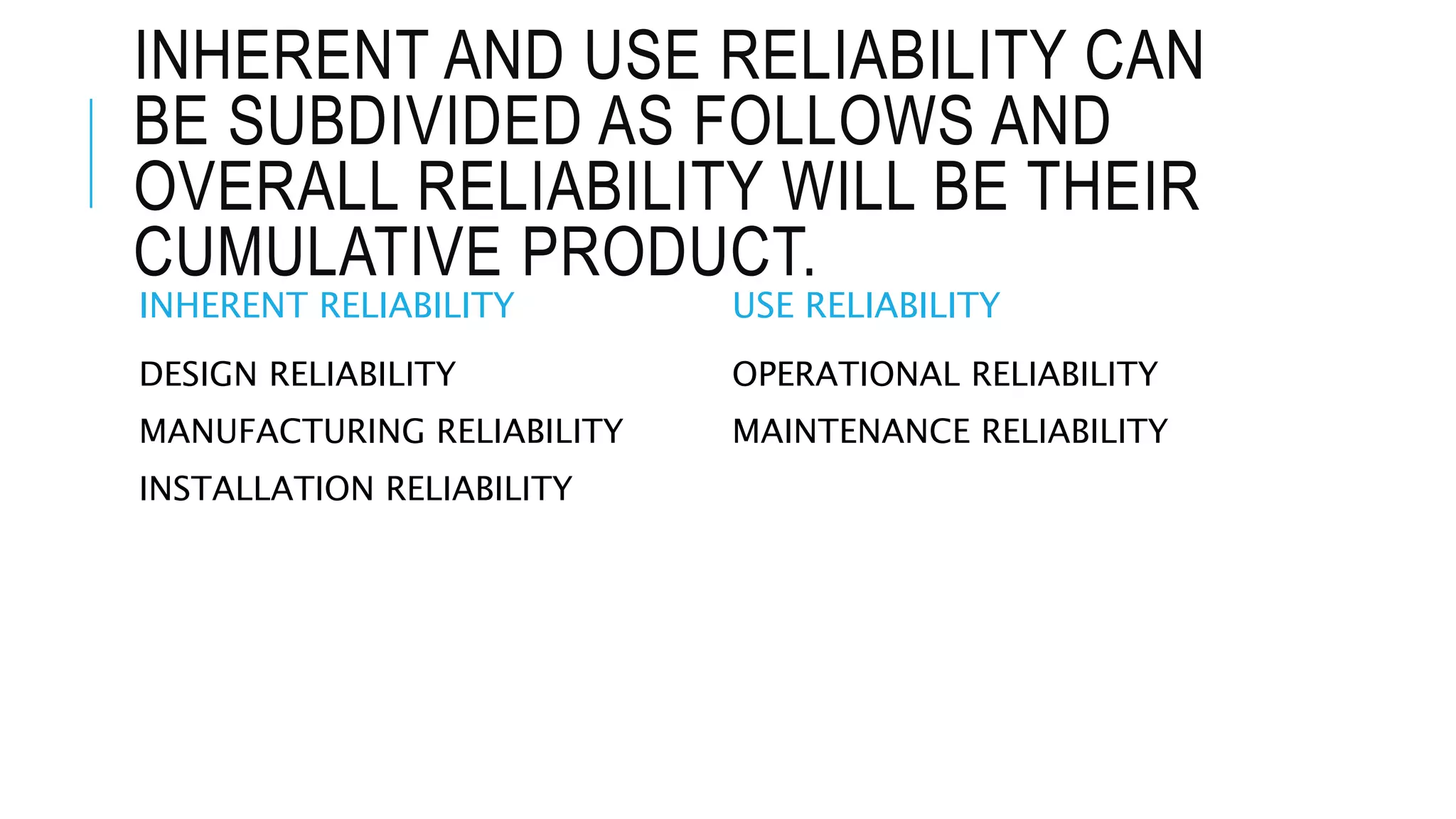

This document discusses equipment reliability engineering and ways to improve it. It defines reliability as the probability that equipment will function as required without defects or breakdowns. Low reliability leads to chronic equipment losses due to frequent failures. Reliability consists of inherent reliability from design and manufacturing and use reliability from operation and maintenance. Five factors that affect inherent reliability are identified: design, manufacturing, installation, operation, and maintenance. Improving use reliability requires studying optimal equipment usage, operator skills, and ensuring equipment and operators are well-matched. Both high operator capability and good equipment condition are needed for overall efficiency.