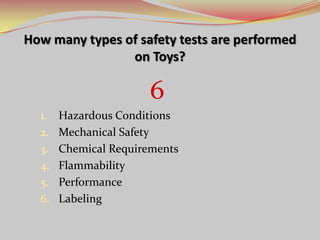

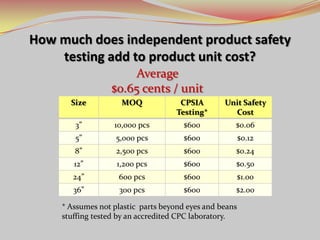

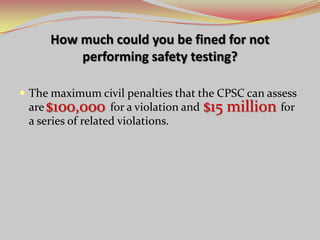

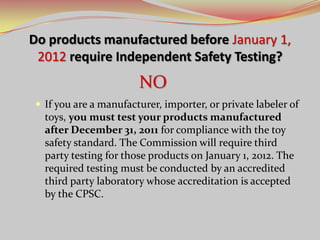

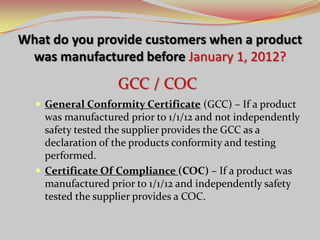

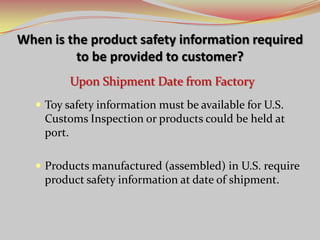

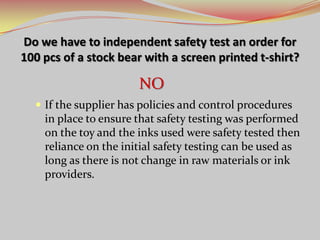

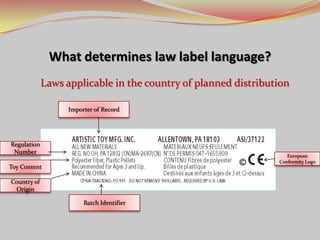

The document outlines essential information for artistic toy employees and distributors, including types of safety tests required for toys and their associated costs. It specifies that products manufactured post-January 1, 2012 must undergo independent safety testing conducted by accredited laboratories, with significant penalties for non-compliance. Additionally, it details requirements for product safety information and certification for imported toys and emphasizes the importance of maintaining compliance with safety standards.