This thesis investigates the torsional behavior of single cell box girder bridges through finite element analysis. The author develops a finite element computer program to analyze orthotropic steel box girder bridges under uniform torsional loads. The program is verified by comparing results to theoretical solutions. The program is then used to study the stresses in several example bridges with different geometry and boundary conditions. The results demonstrate that torsional bending stresses, which are often ignored in design, are important to consider. The author makes recommendations for accounting for torsional deformations in bridge design based on the parametric studies.

![•

17

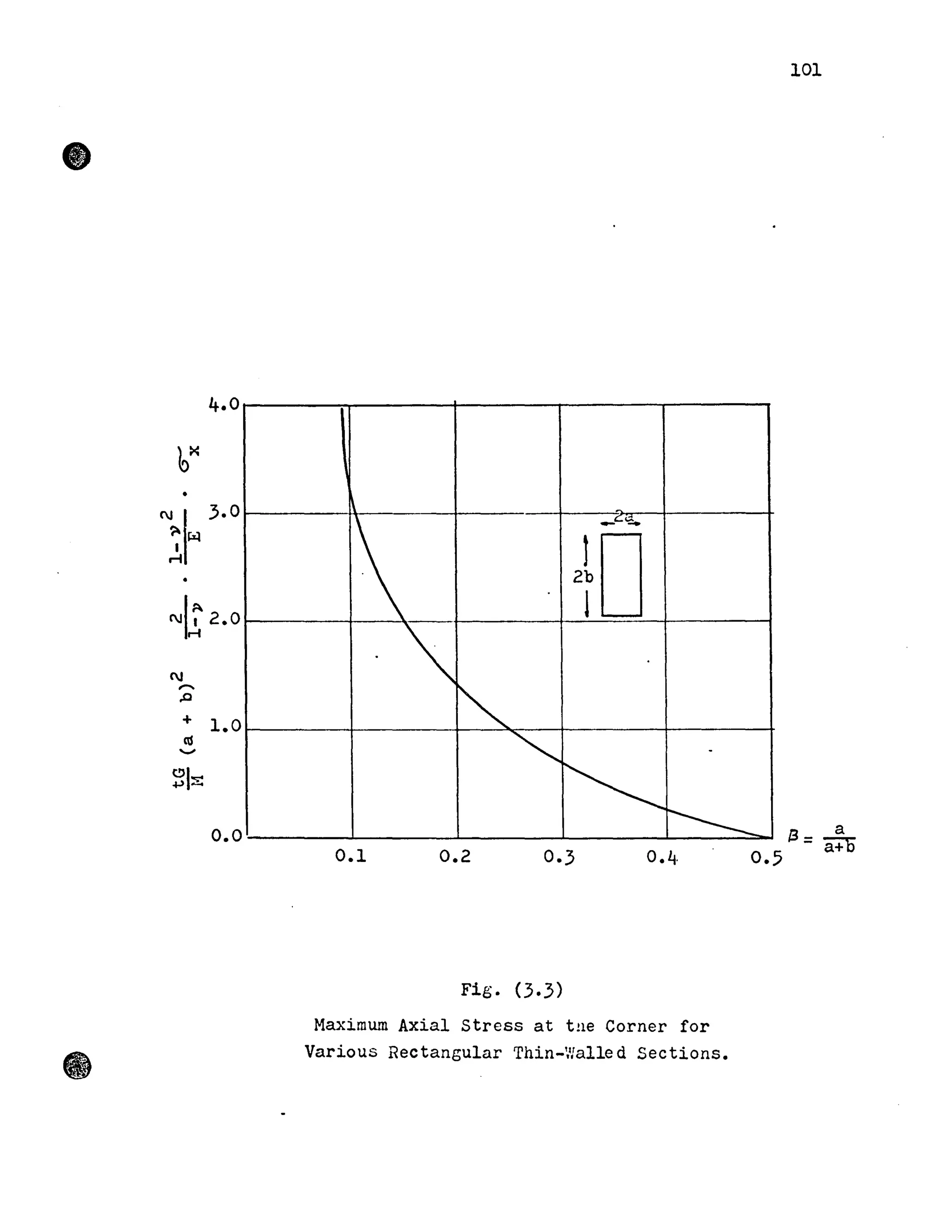

being on the unsafe side.

Using the formulas of the refined approximate theory

derived by Dabrowsky for the values of the maximum torsion bending

stress in an eccentrically loaded simply supported beam, the

writer inspected the effect of shape ratio on the increase of

axial stresses due to eccentricity of load on box girder bridges.

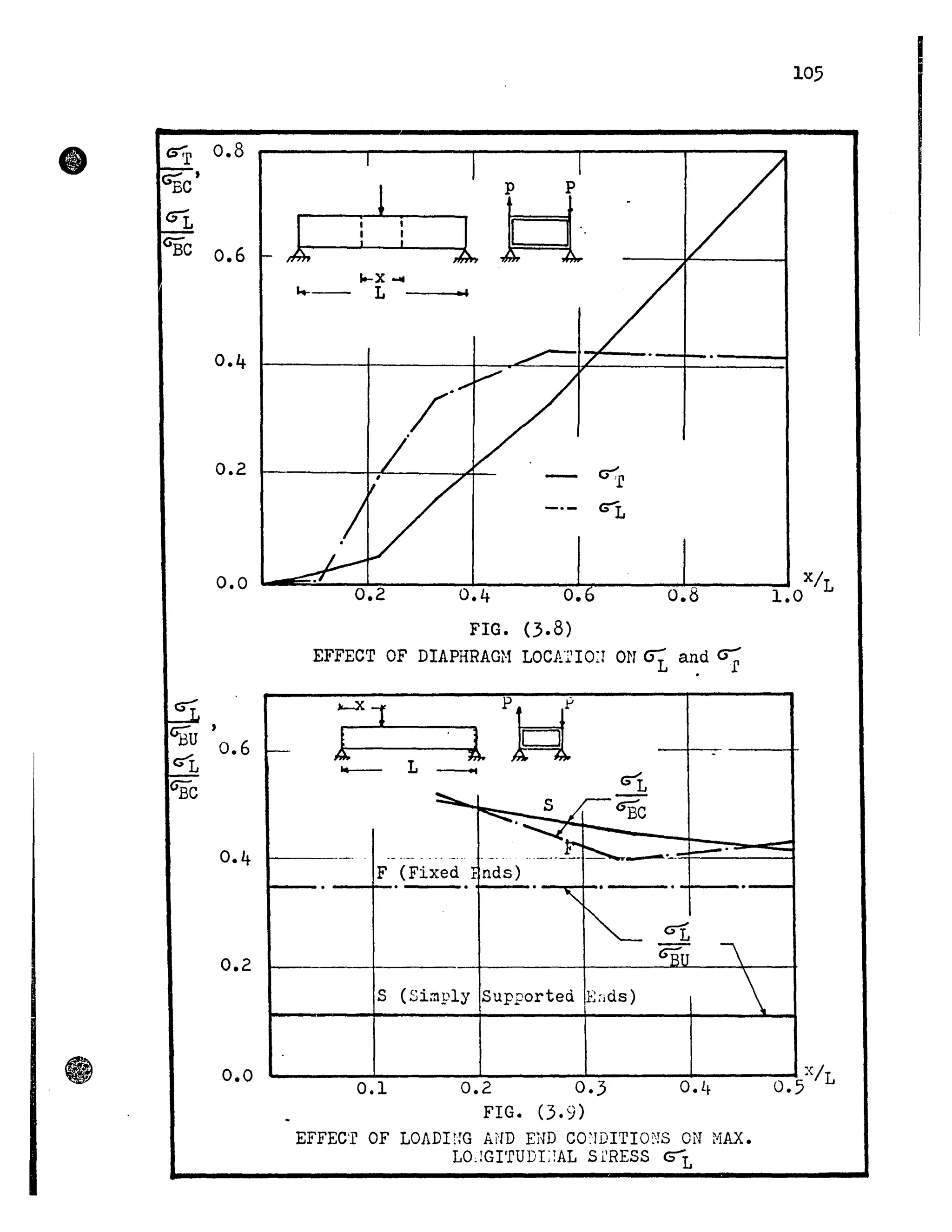

The results presented in Figures (3.6) and (].7) show the trans-

verse influence lines of the maximum axial stress ( ~ ) at mid-

span, for the cases of concentrated and uniformly distributed load.

The stresses are made dimensionless by dividing by the bending

stress (9;uor~) at midspan. The practical range of width to length

ratios, for box girder bridges, has been chosen for the case of

uniformly distributed load. It can be seen that the stress in-

crease is greater in the case of concentrated load and for the

worst practical conditions this increase May reach approximately

50%. However, the corresponding increase for uniformly distributed

loads is about 20%.

3.3 WORK DO~ΠFOR DEFORMABLE CROSS SEC.i.'ION

A considerable body of the early literature was devoted

to problems in aircraft field. 'l'he MOSt important of this is the

work of Reissner (Ref. 14) and Ebner (Ref. 15). The idealization

mentioned in Section 3.2 for aircraft structures was also the

basis of this Vlork. Ebner showed hoVl doubly symmetrical boxes

could be solved by the hlethod of influence coefficients ( ~ik).

His method is based on the principle of virtual forces and is

applicable to problems of two dimensional elasticity. Argyris](https://image.slidesharecdn.com/torsionalbehaviourofsinglecellboxgirderbridges-140613171733-phpapp01/75/Torsional-behaviour-of-single-cell-box-girder-bridges-34-2048.jpg)

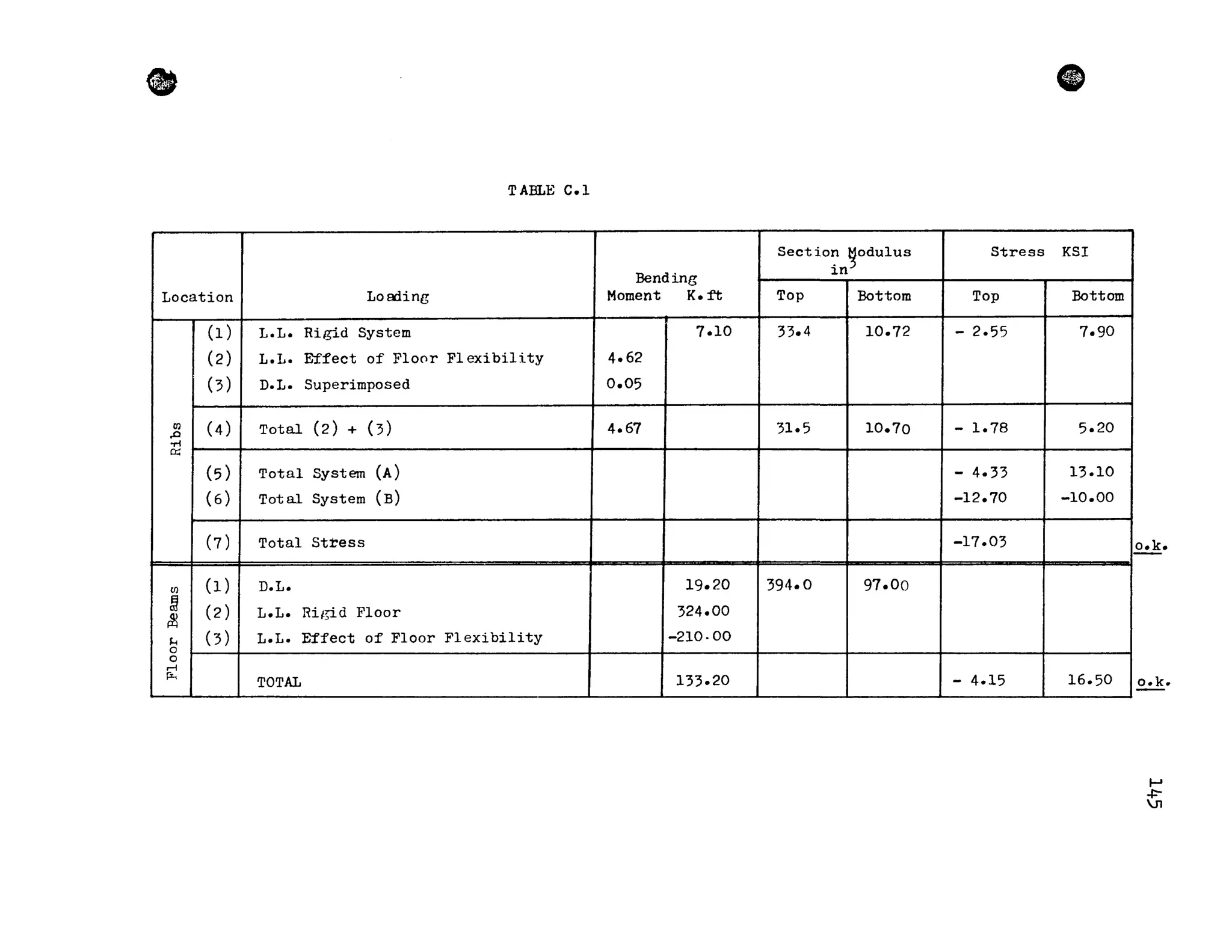

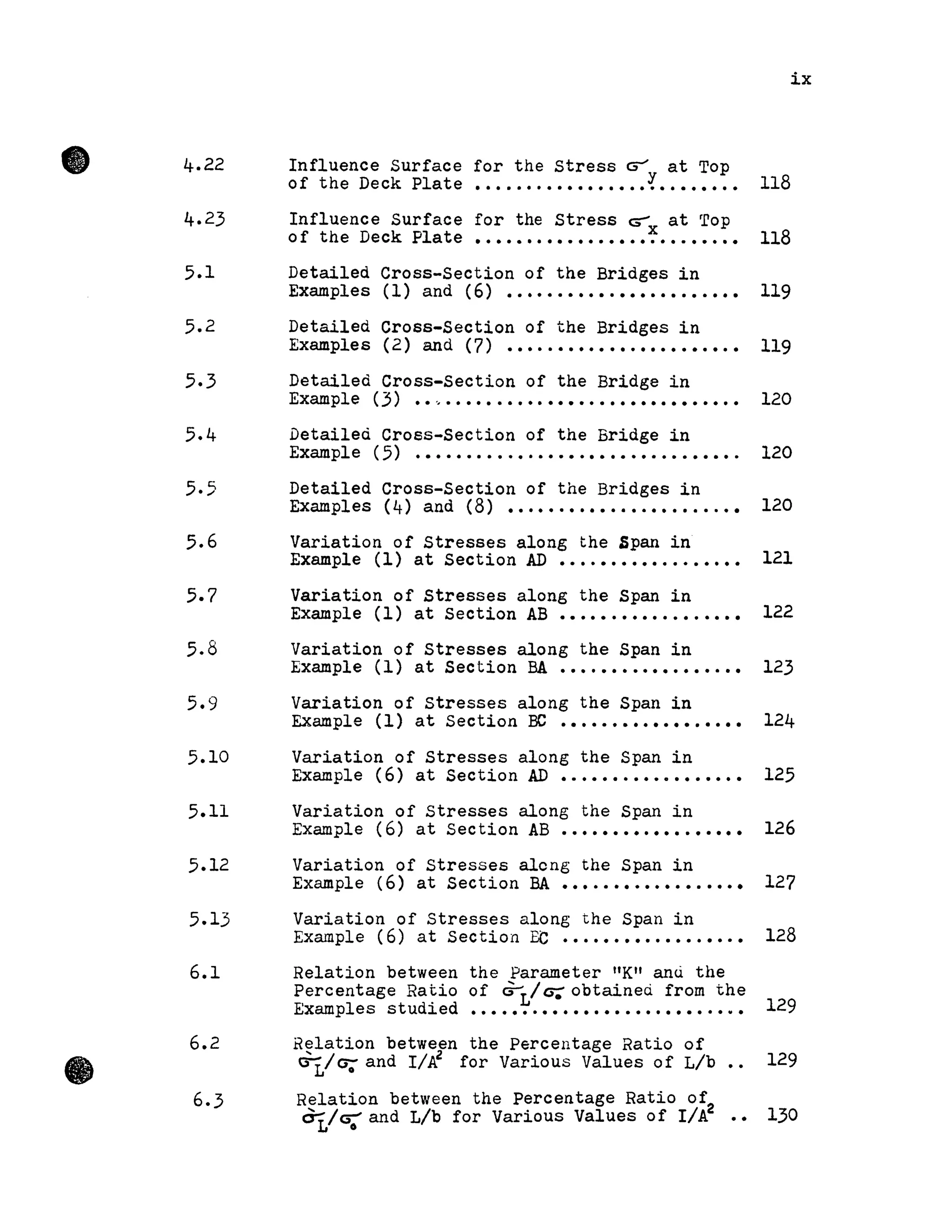

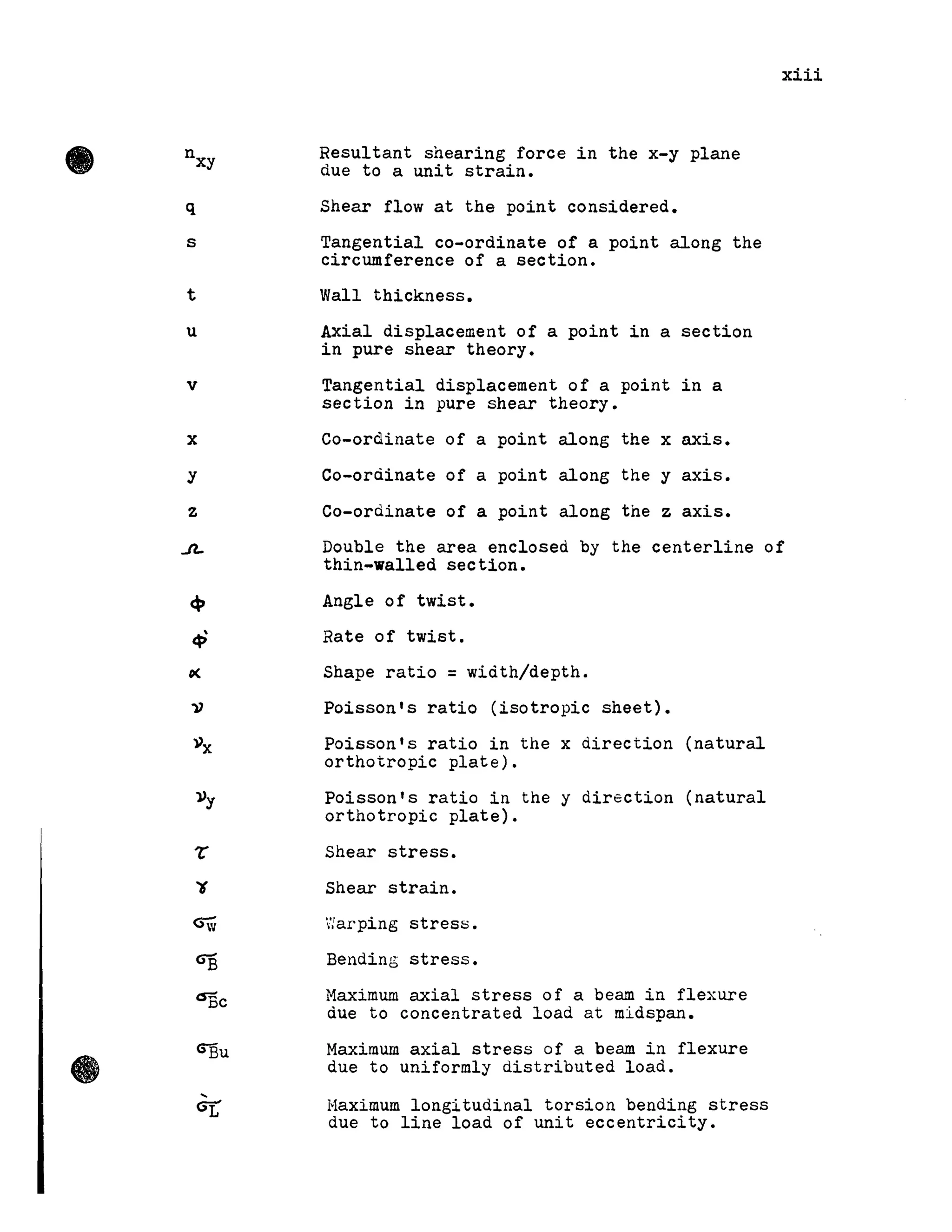

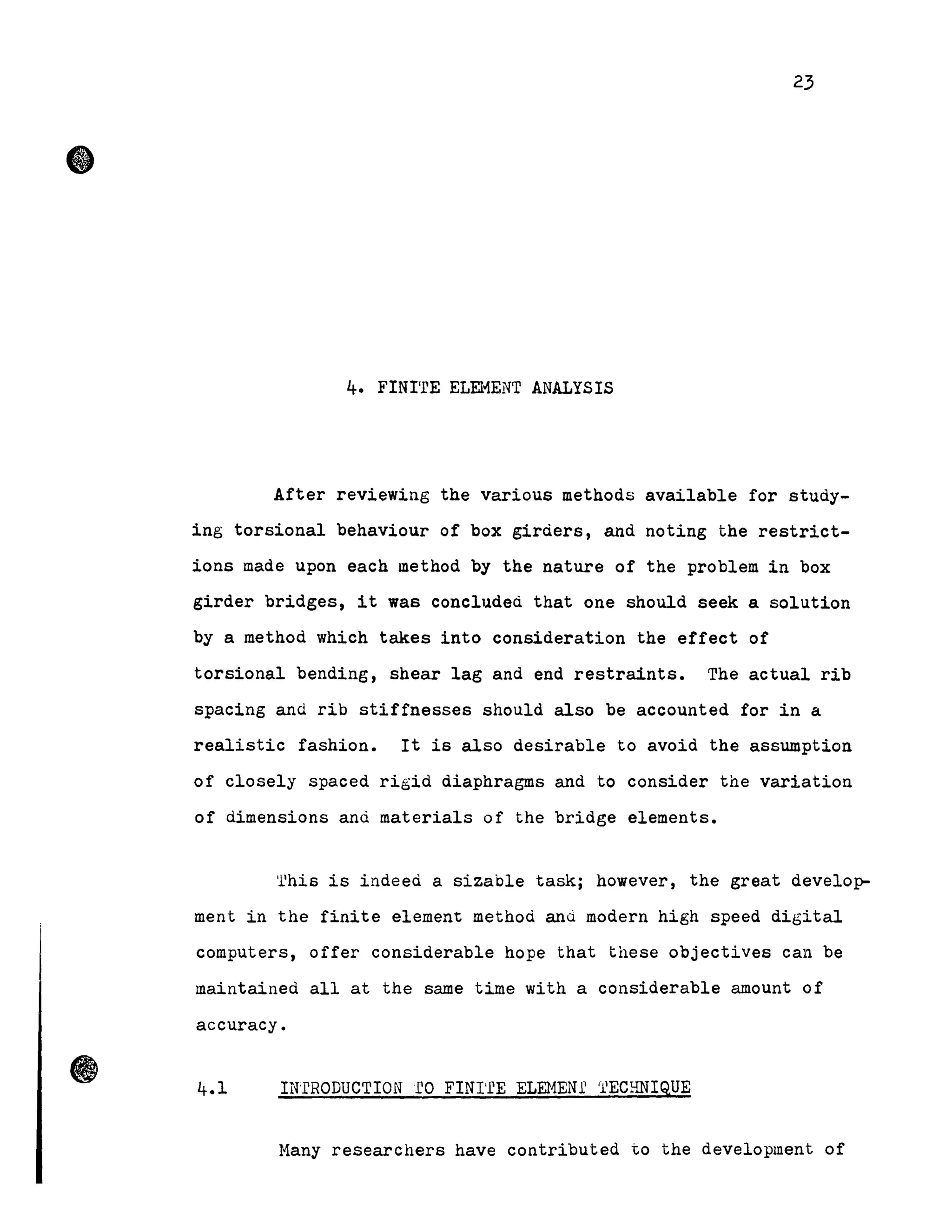

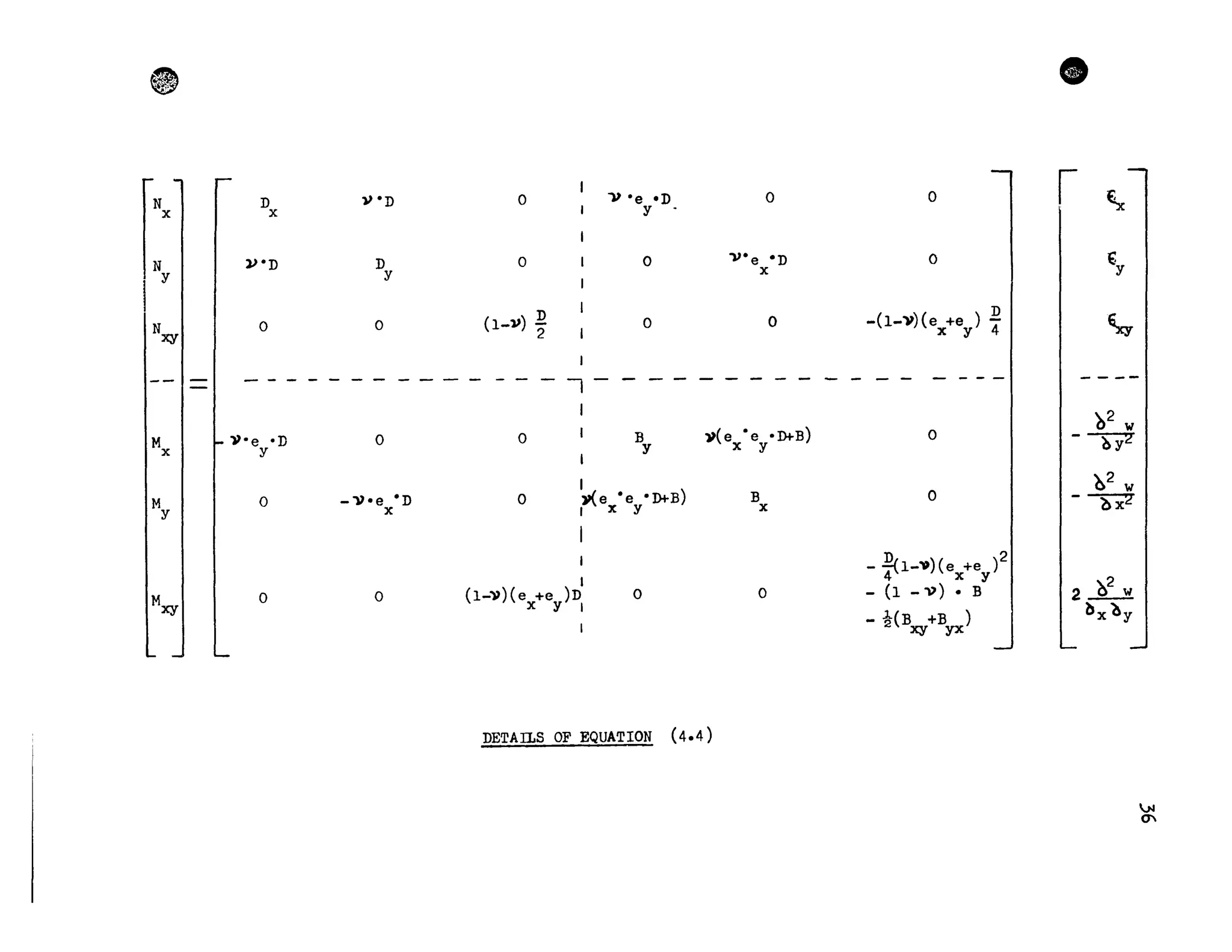

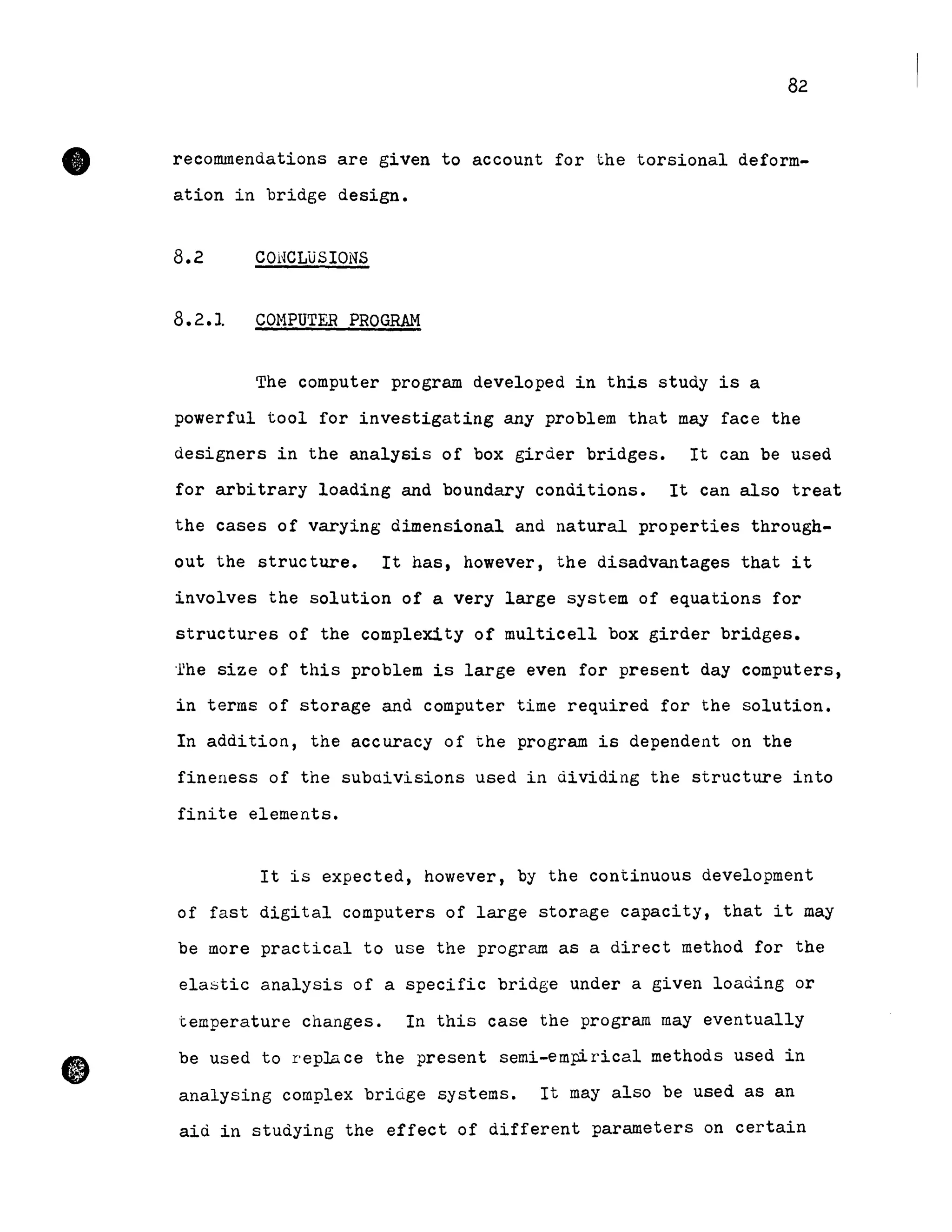

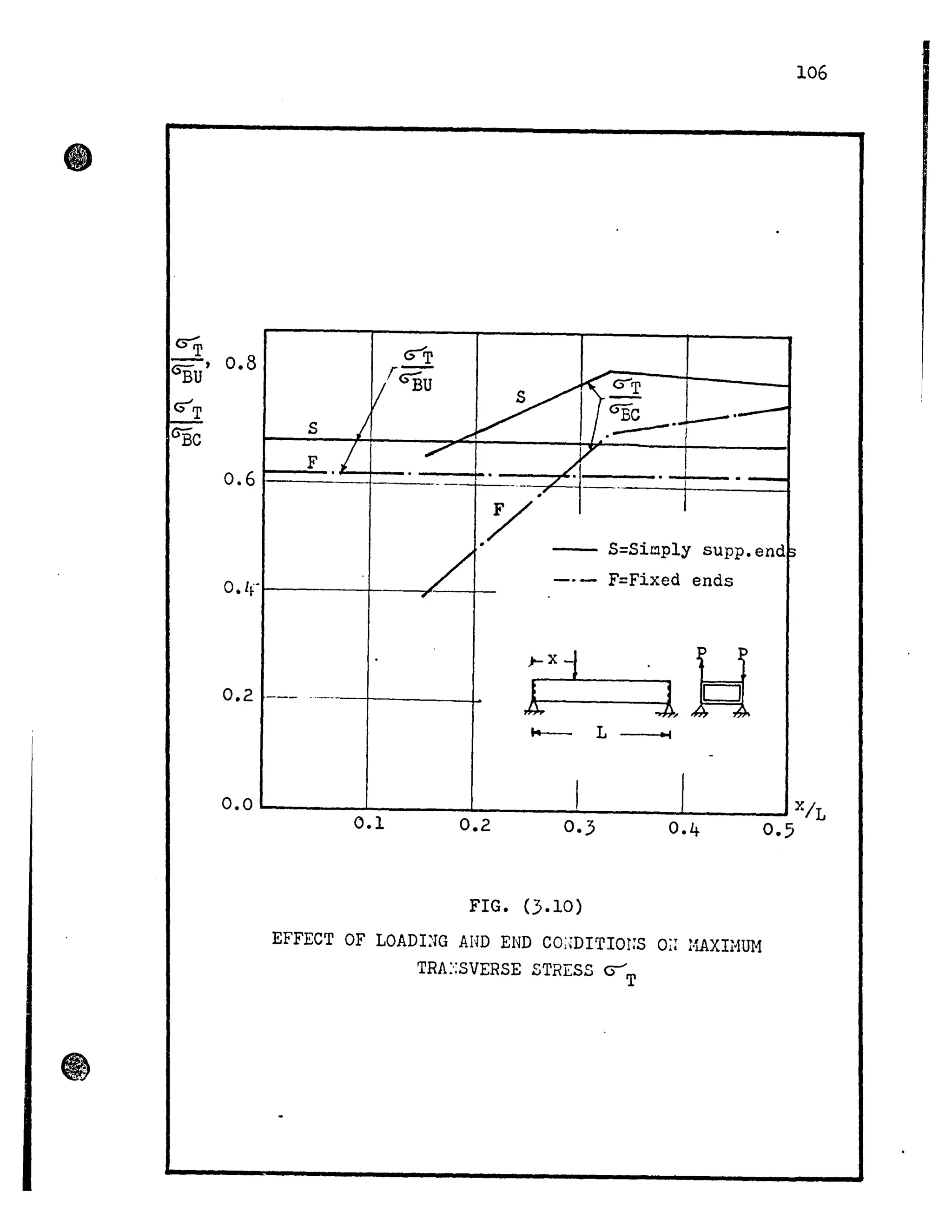

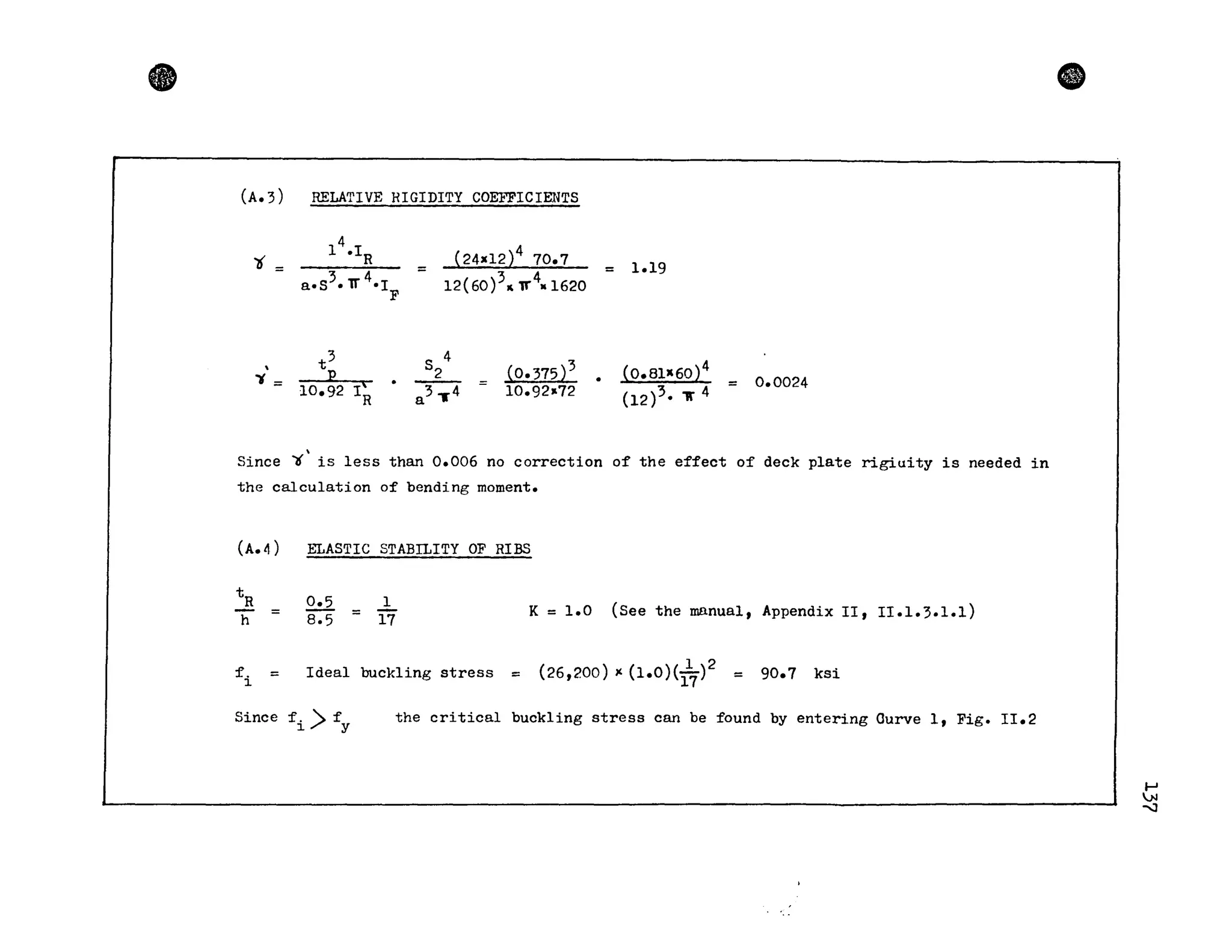

![Rigid Joints

e.

107

Bearn

Hembers

Triangular Plane

stress Elements

x~

Vi

VI !z

e~z

FIG. (4.1)

IDEALIZArrON OF A BOX GI~DE:::! BRIDGE B1 EQUIVALE:;T

GR ID~JOJK MW PLA::E STRESS TRIA;~GULA] ELEME~'irrS

"ex](https://image.slidesharecdn.com/torsionalbehaviourofsinglecellboxgirderbridges-140613171733-phpapp01/75/Torsional-behaviour-of-single-cell-box-girder-bridges-124-2048.jpg)

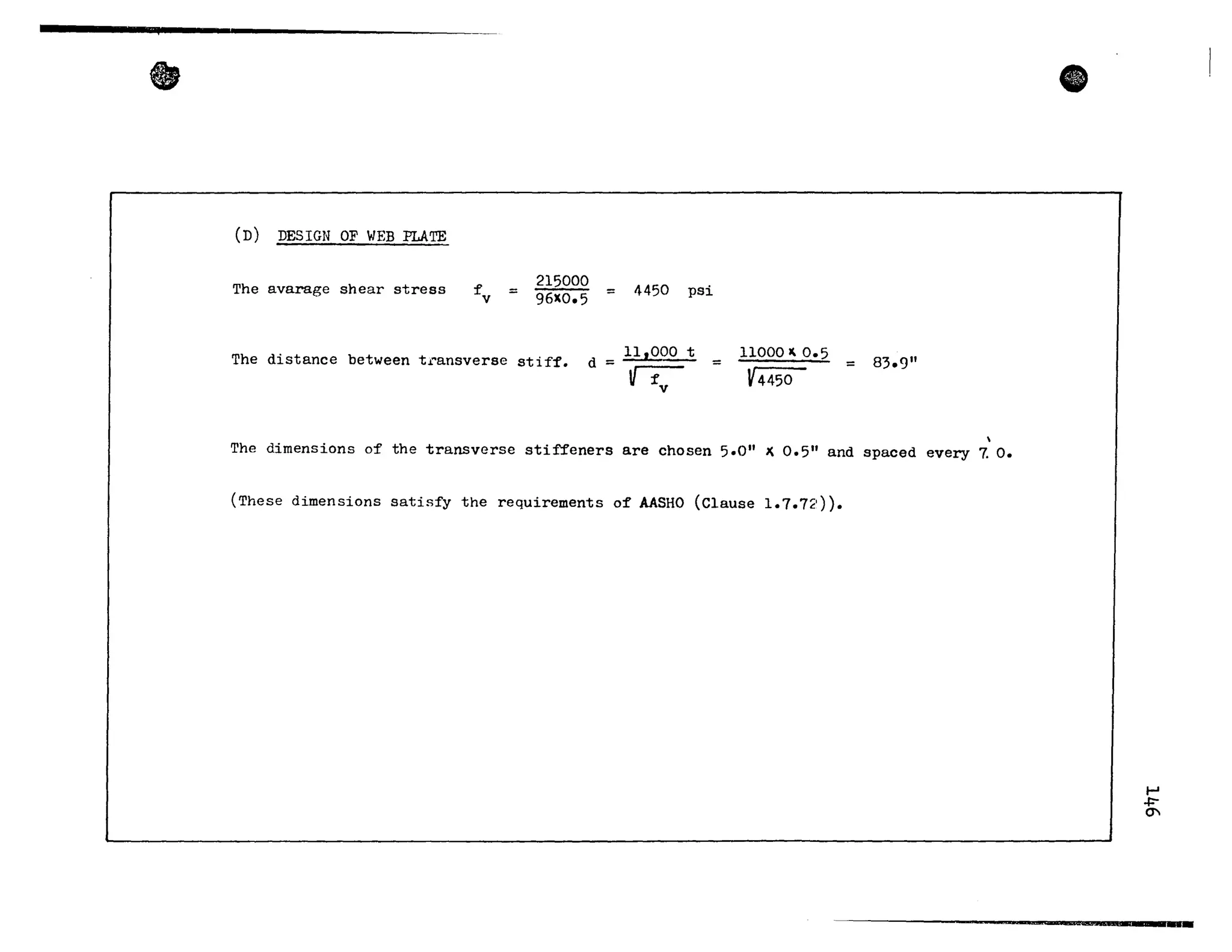

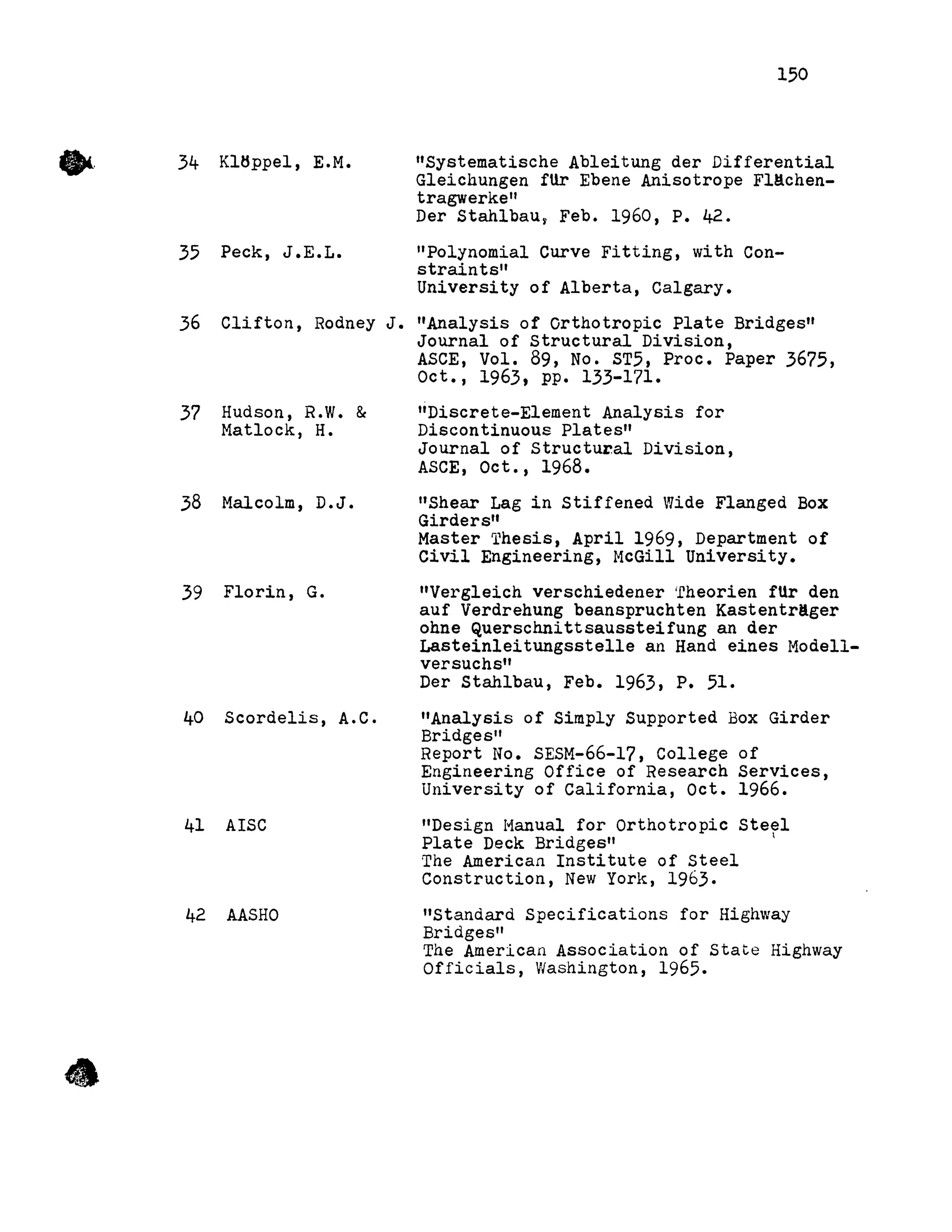

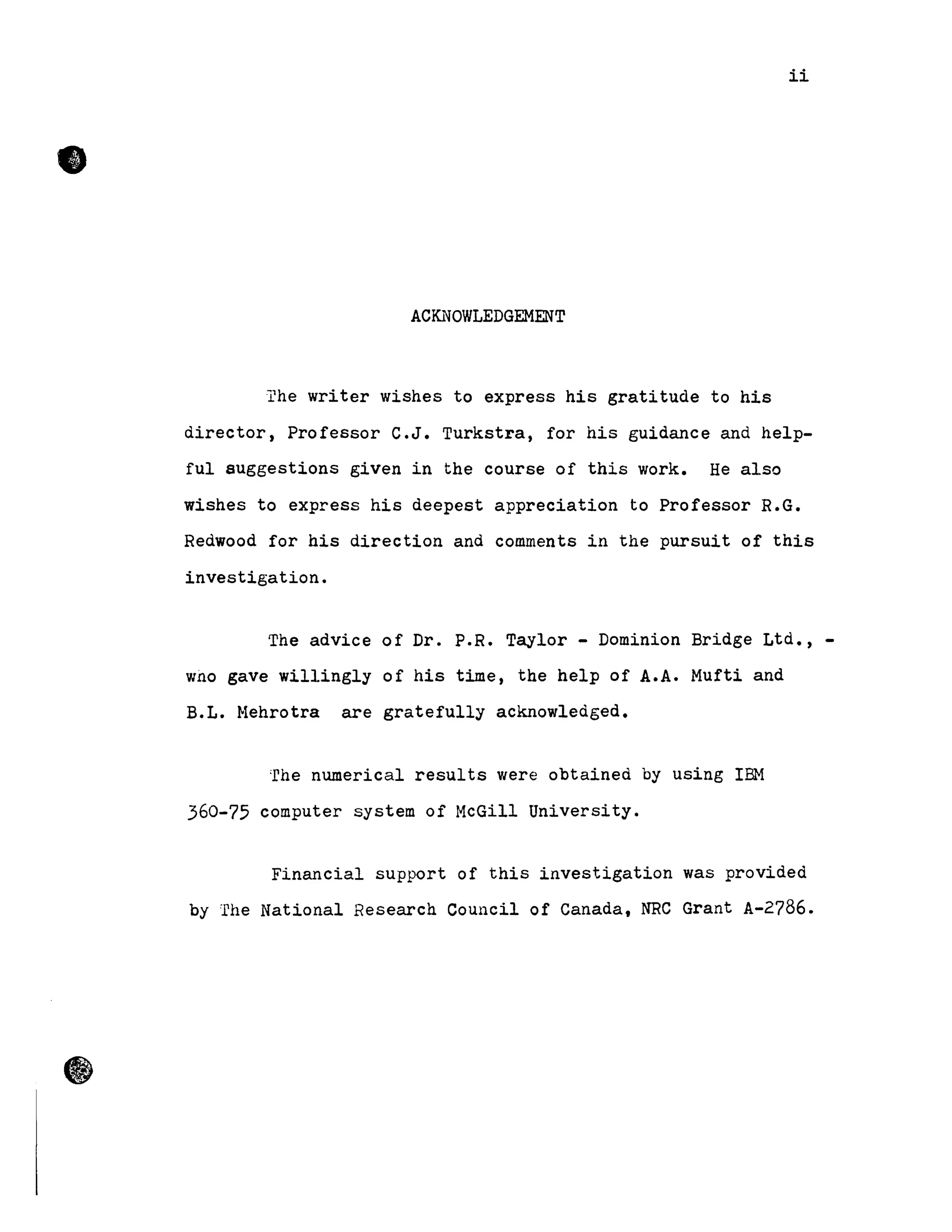

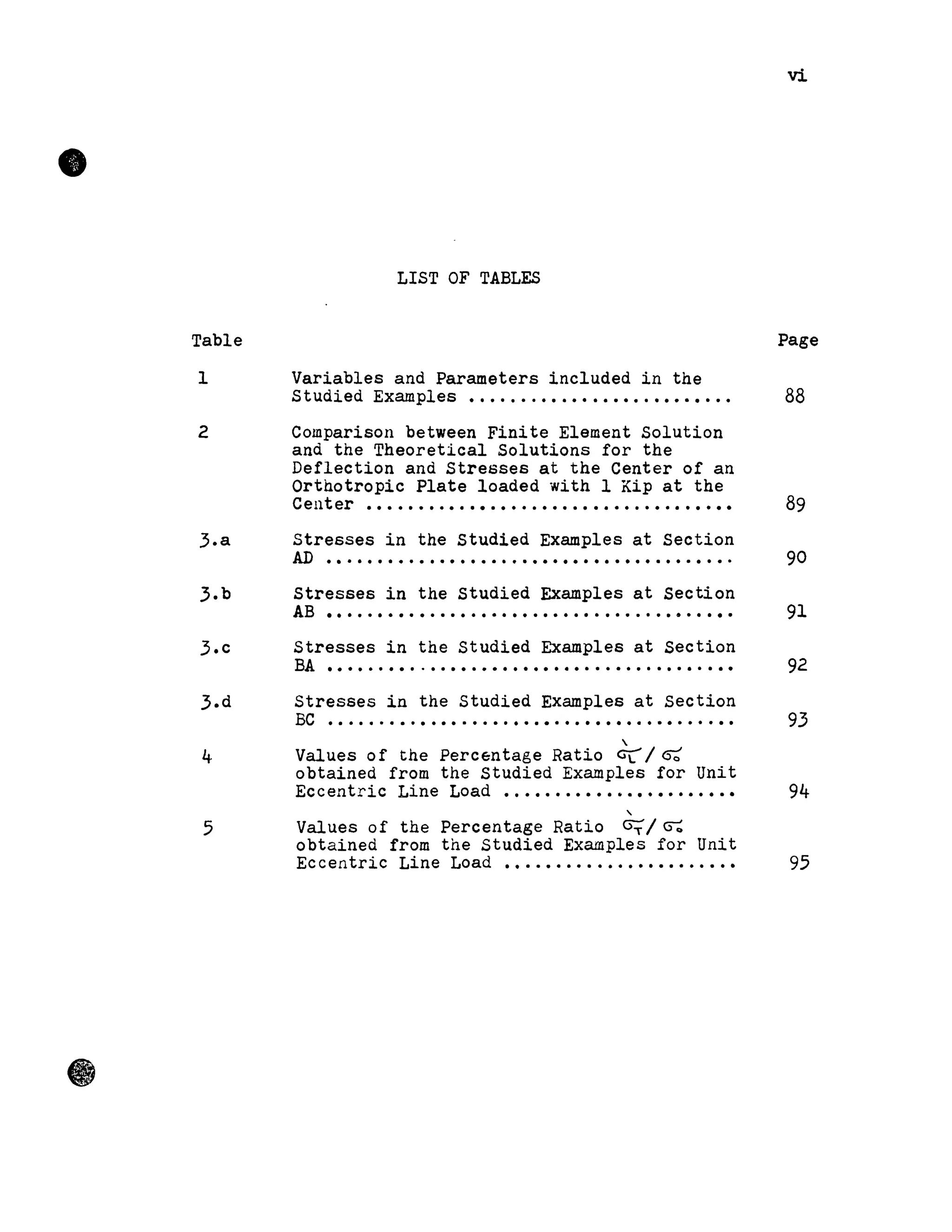

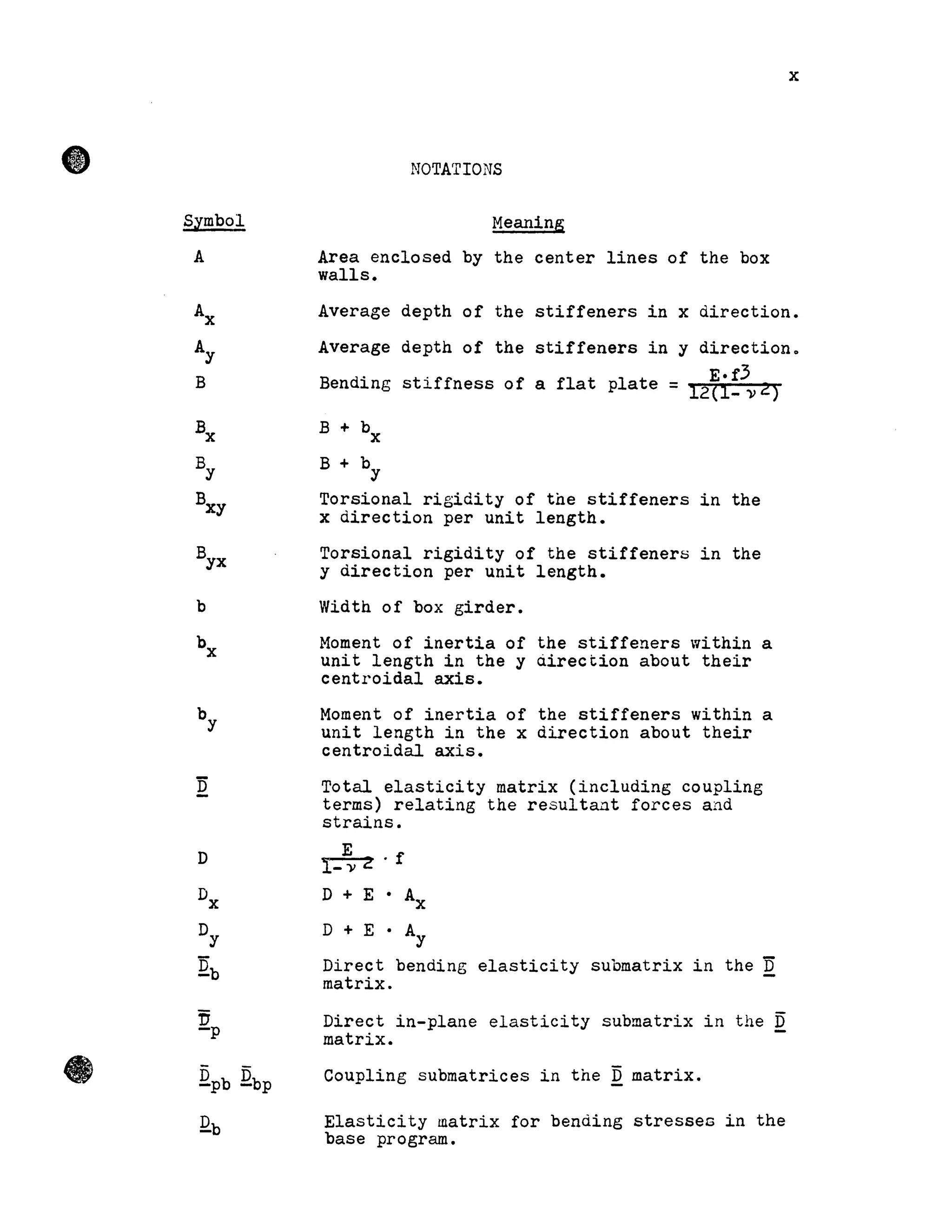

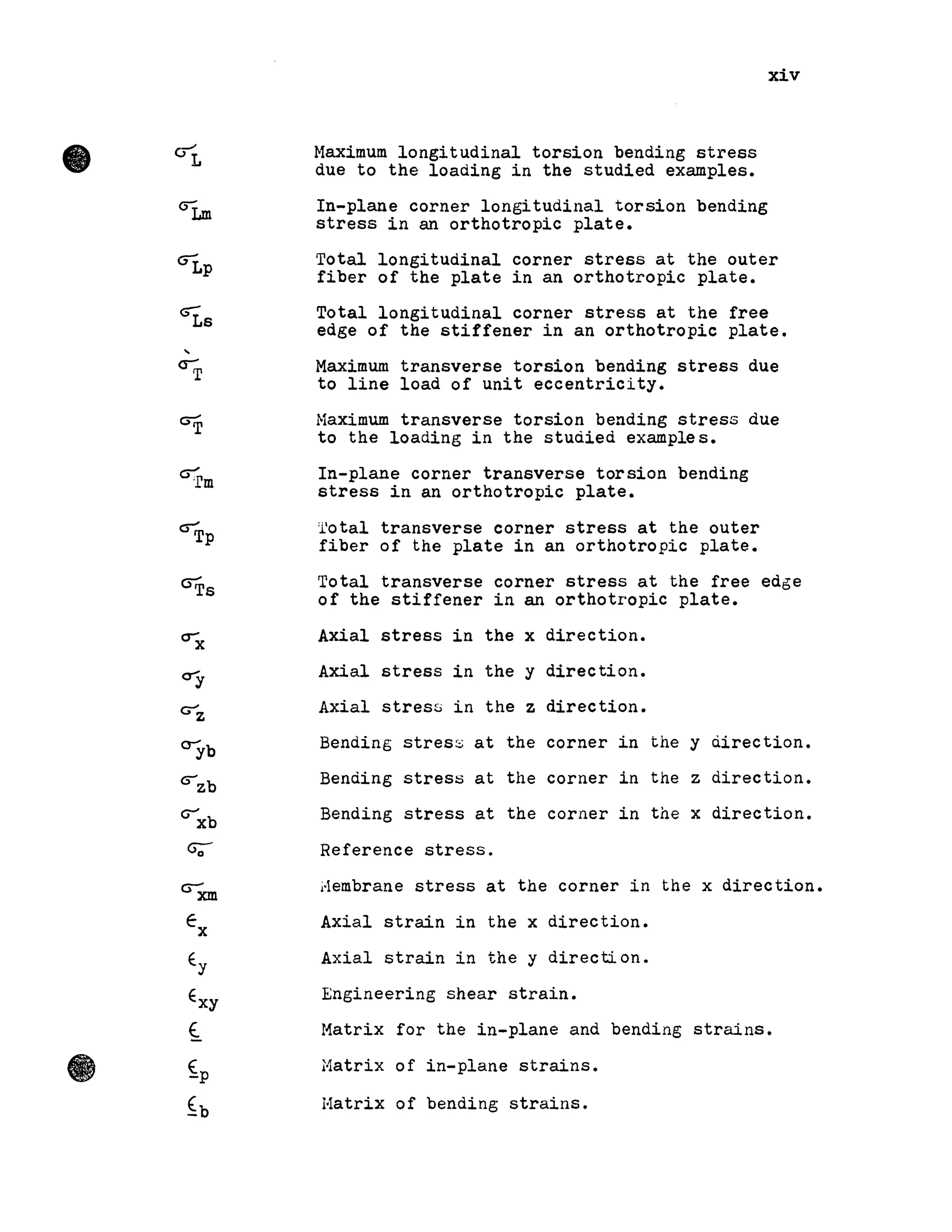

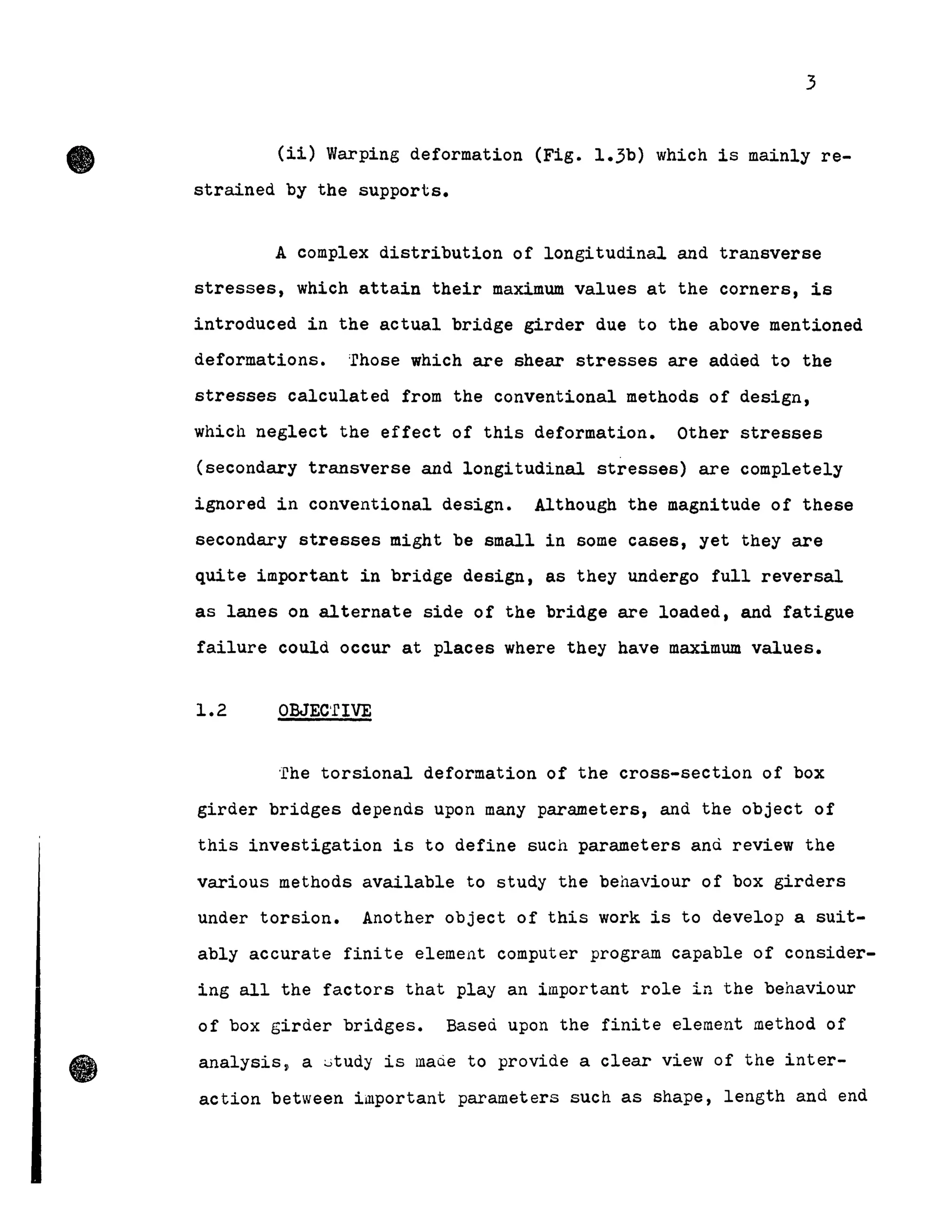

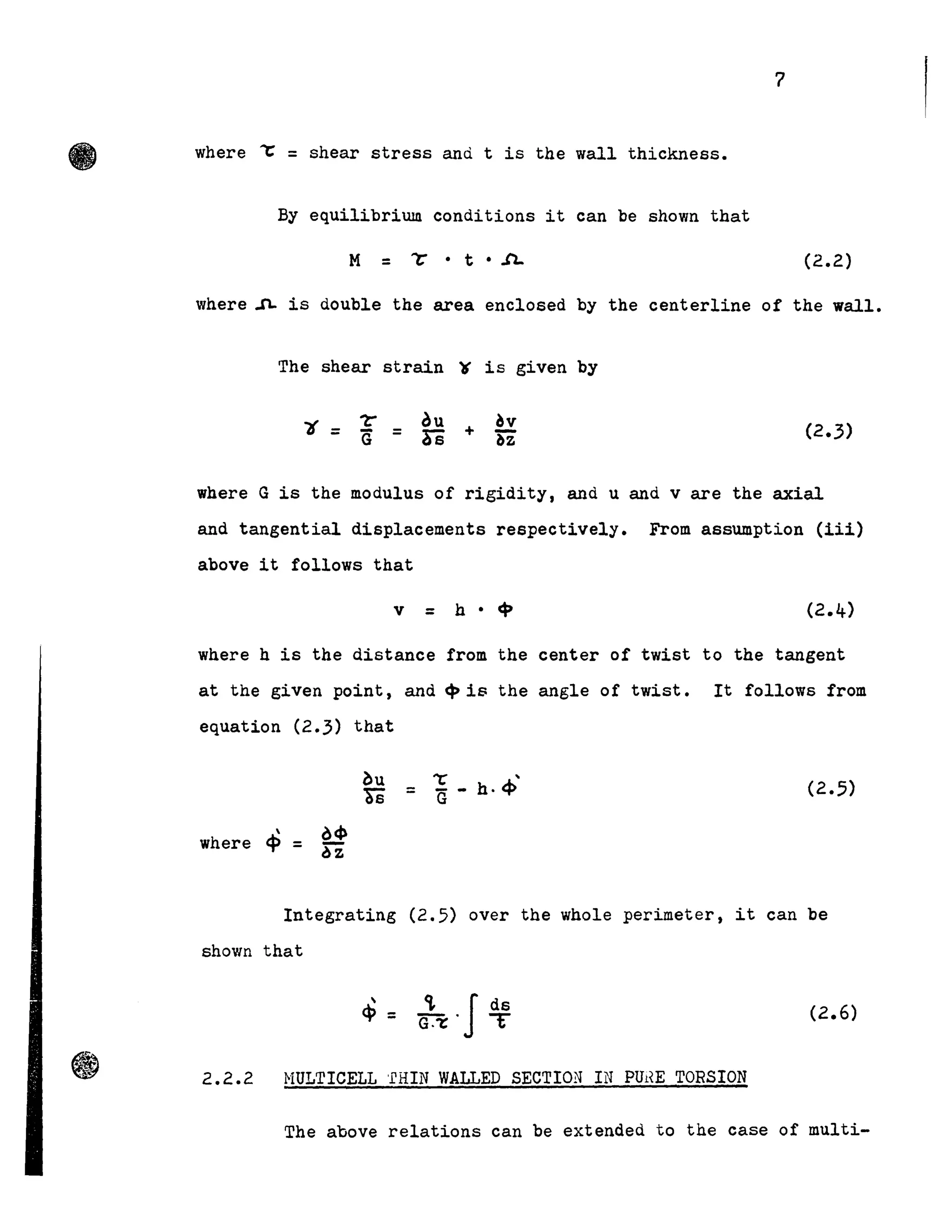

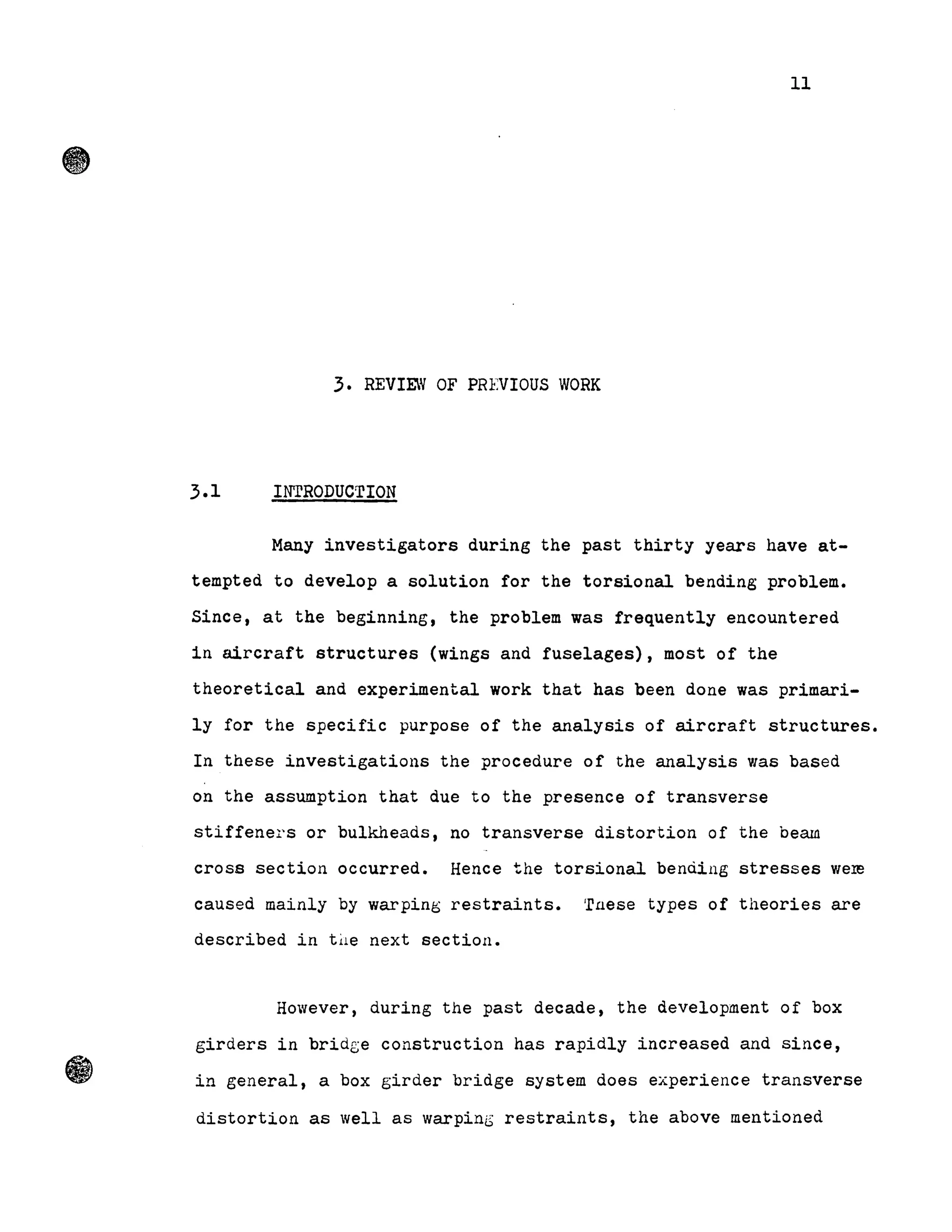

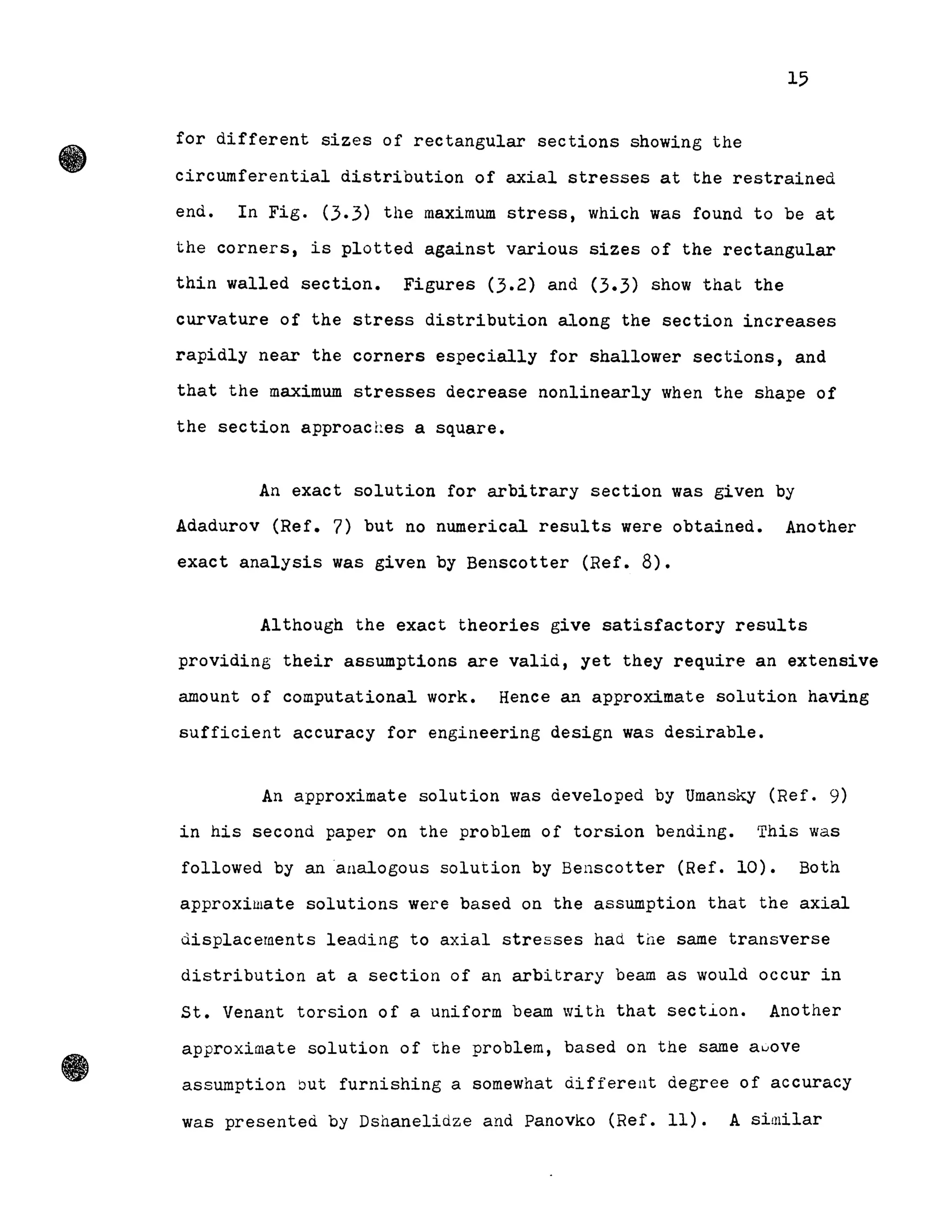

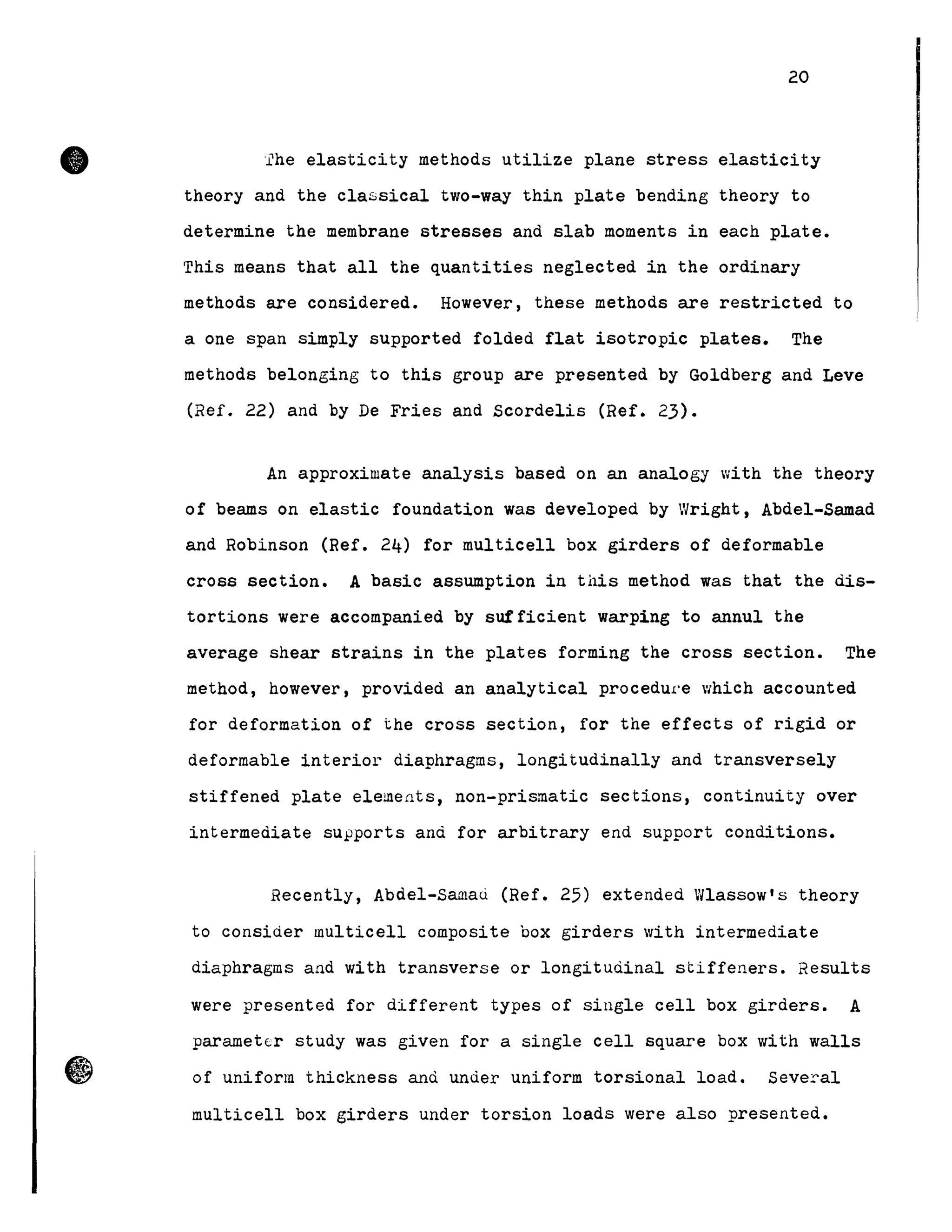

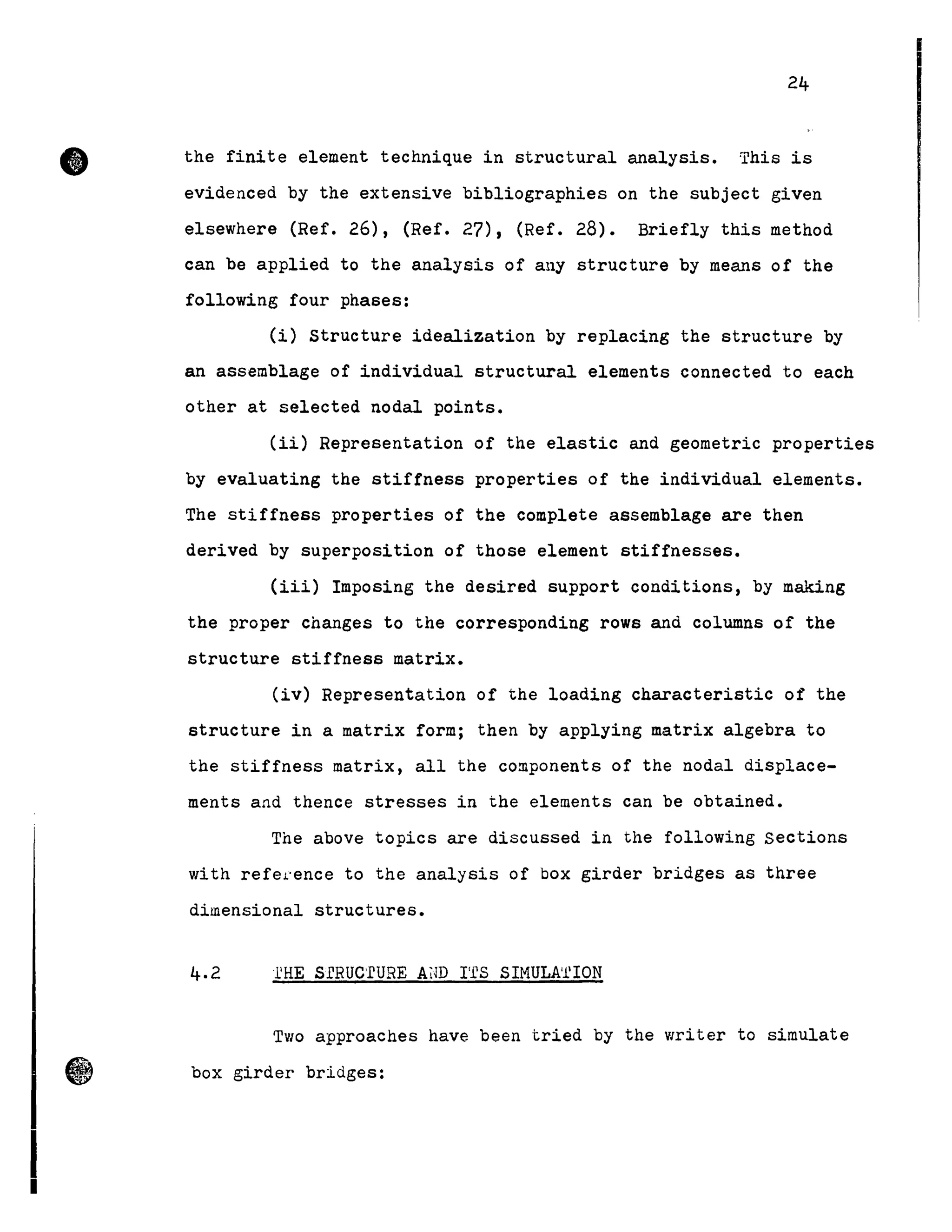

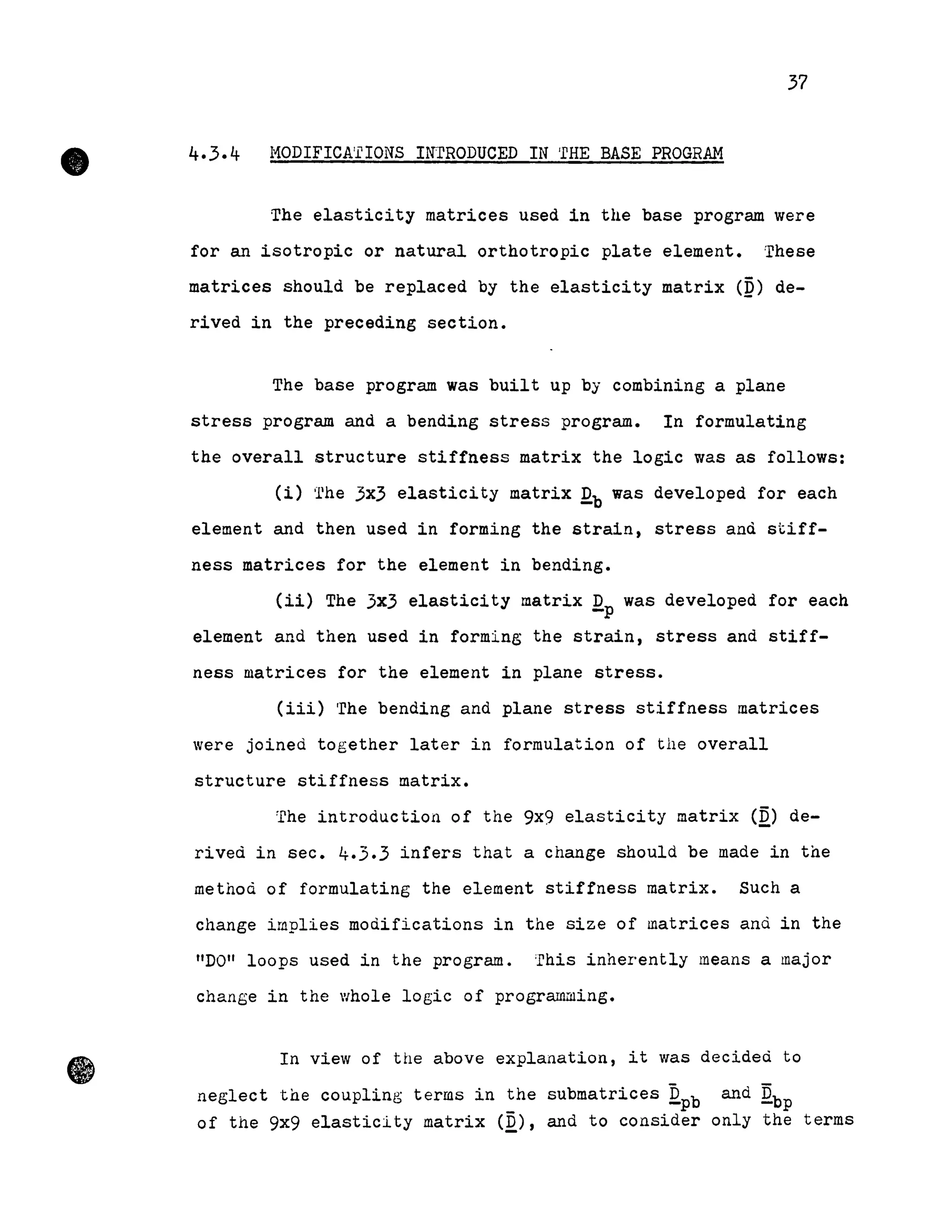

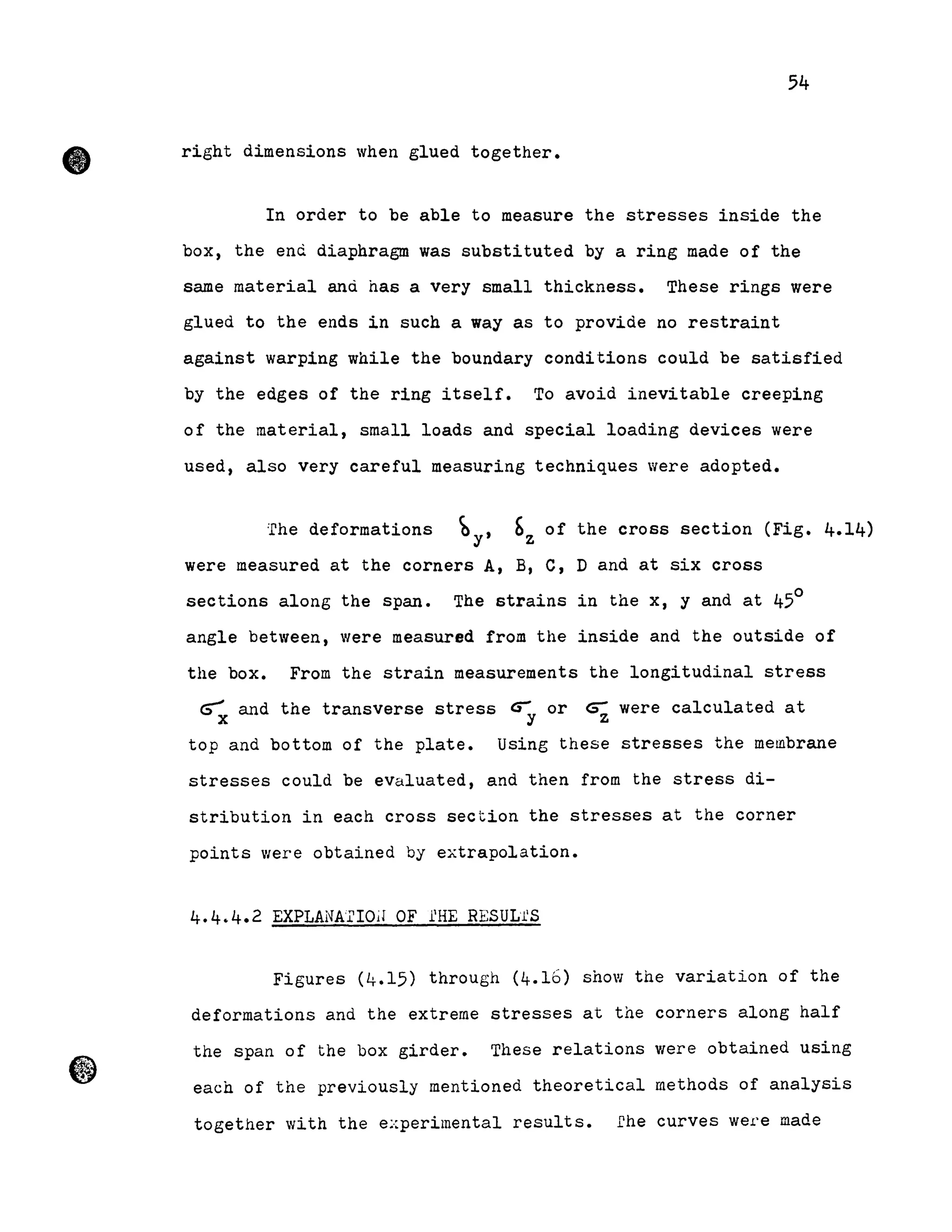

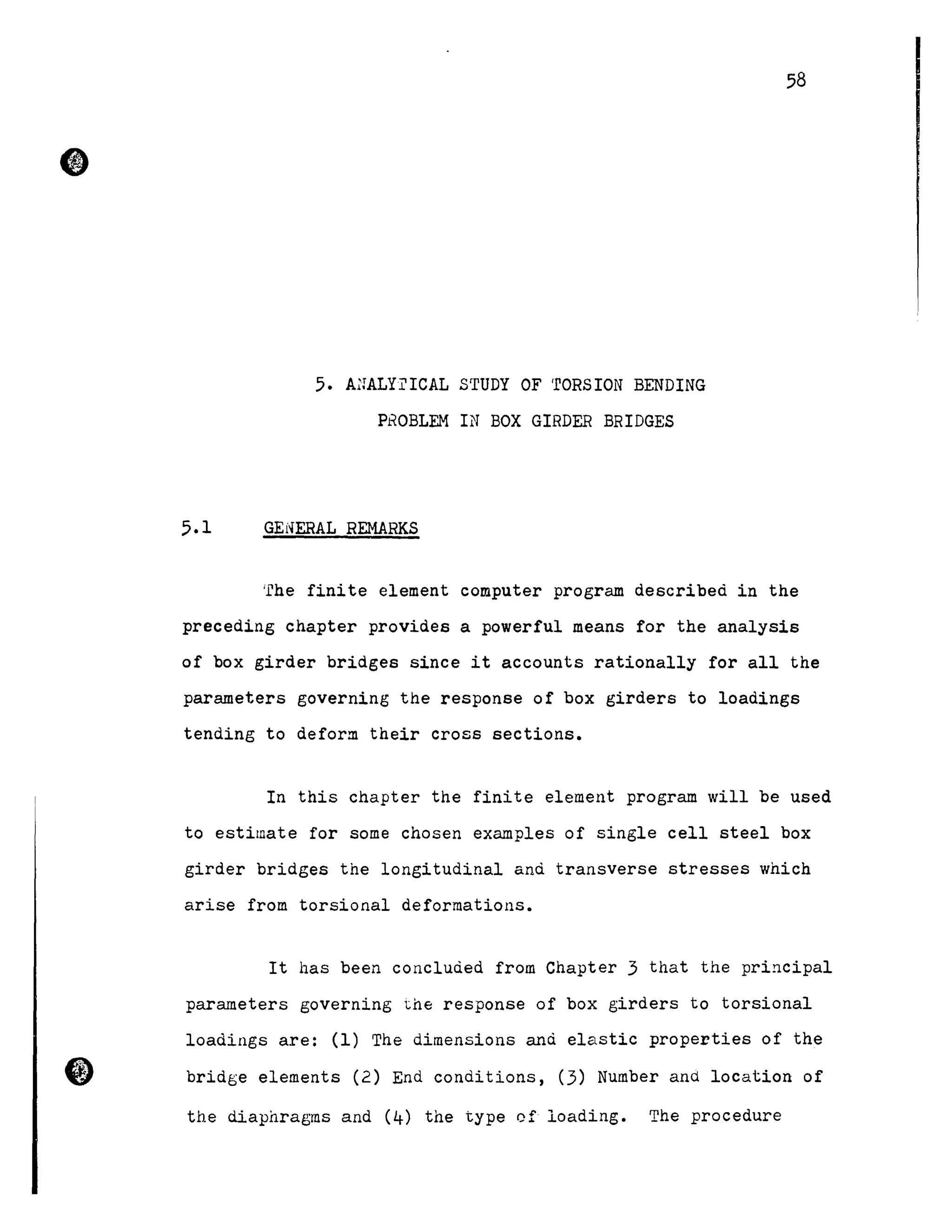

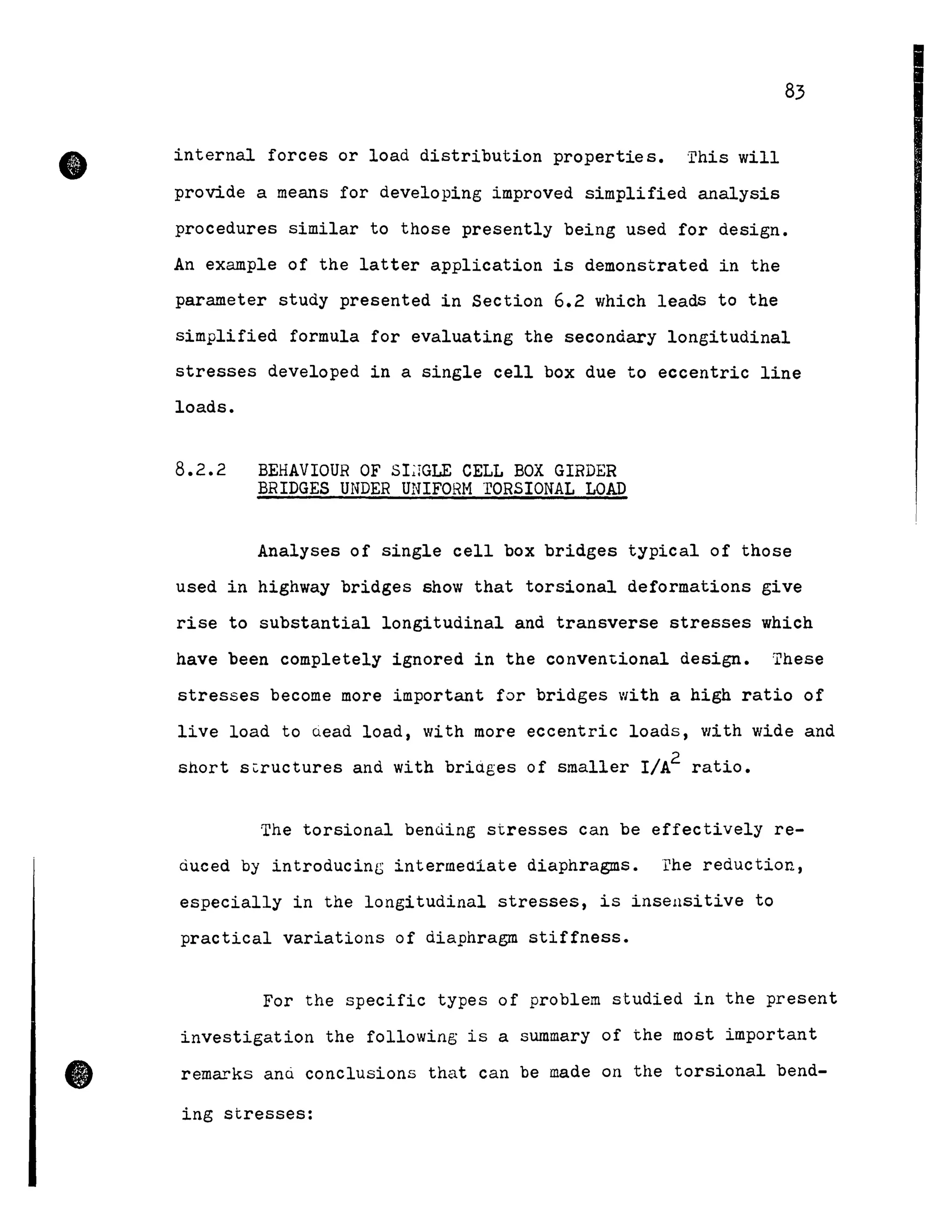

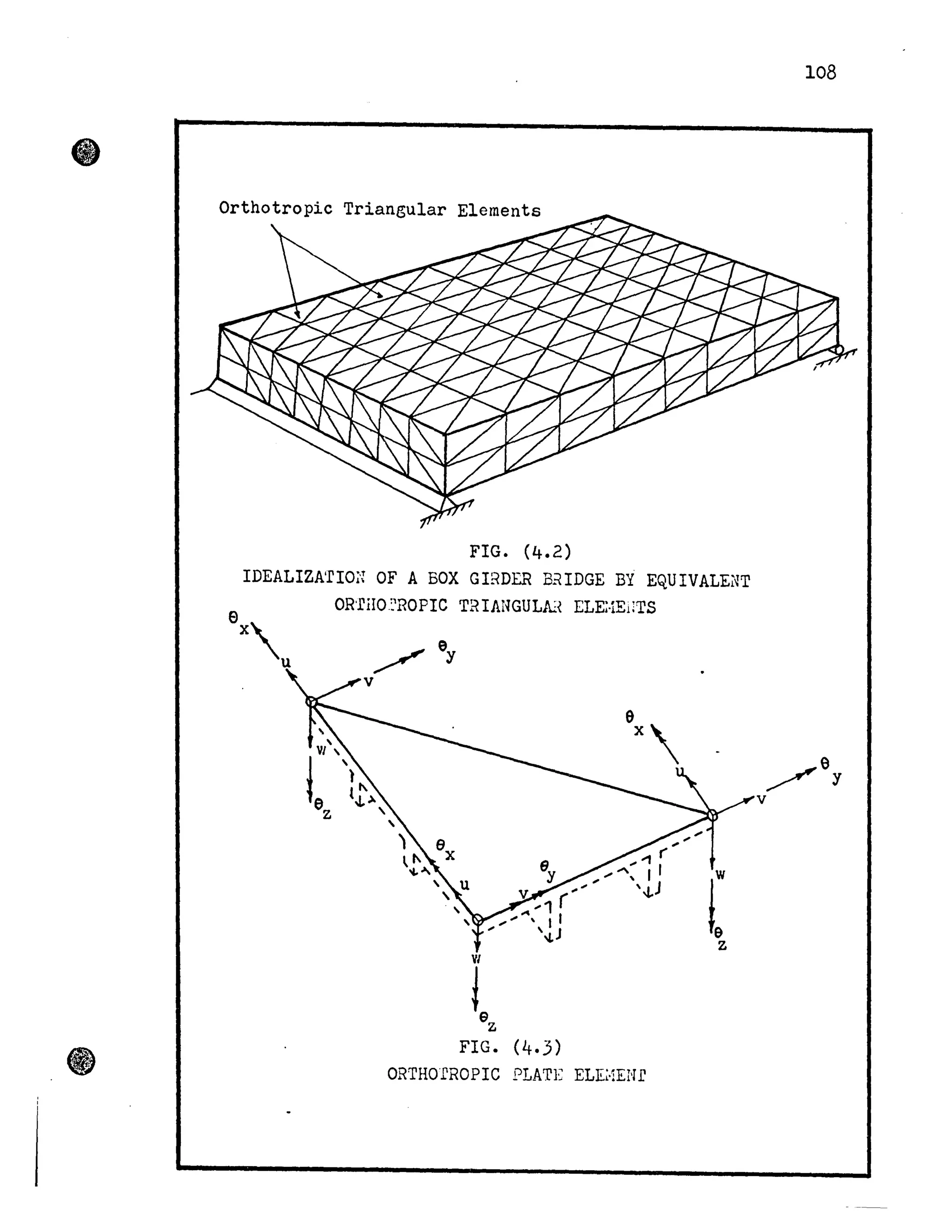

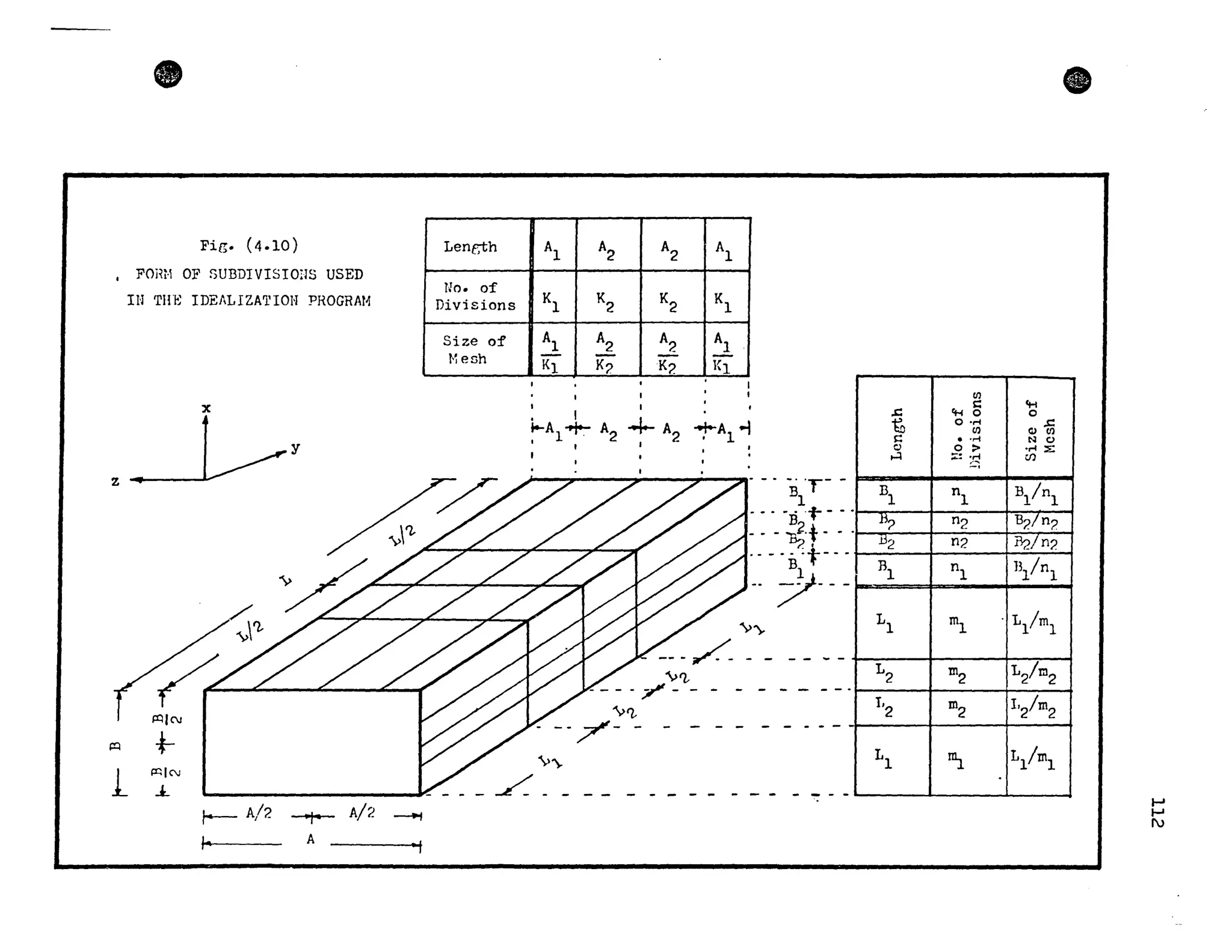

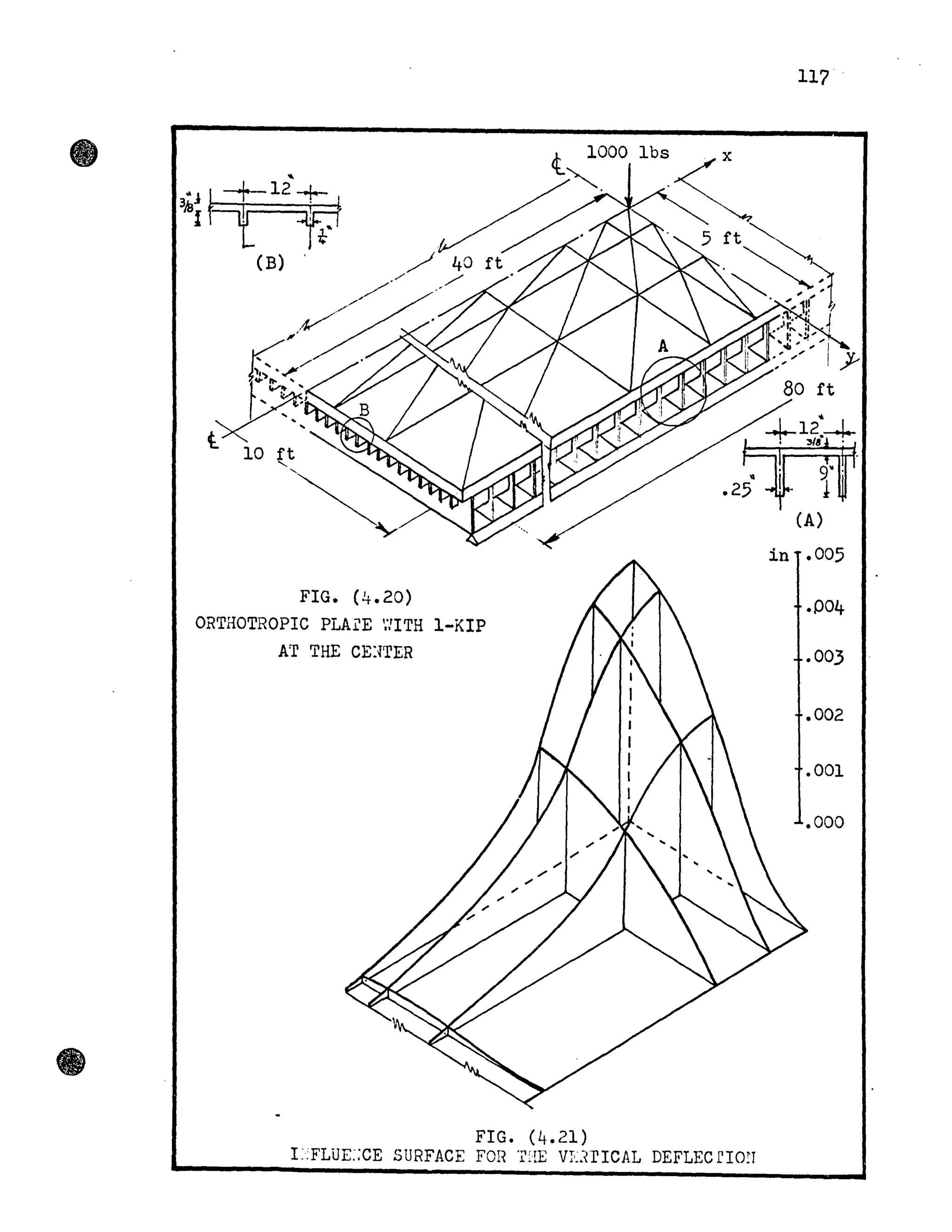

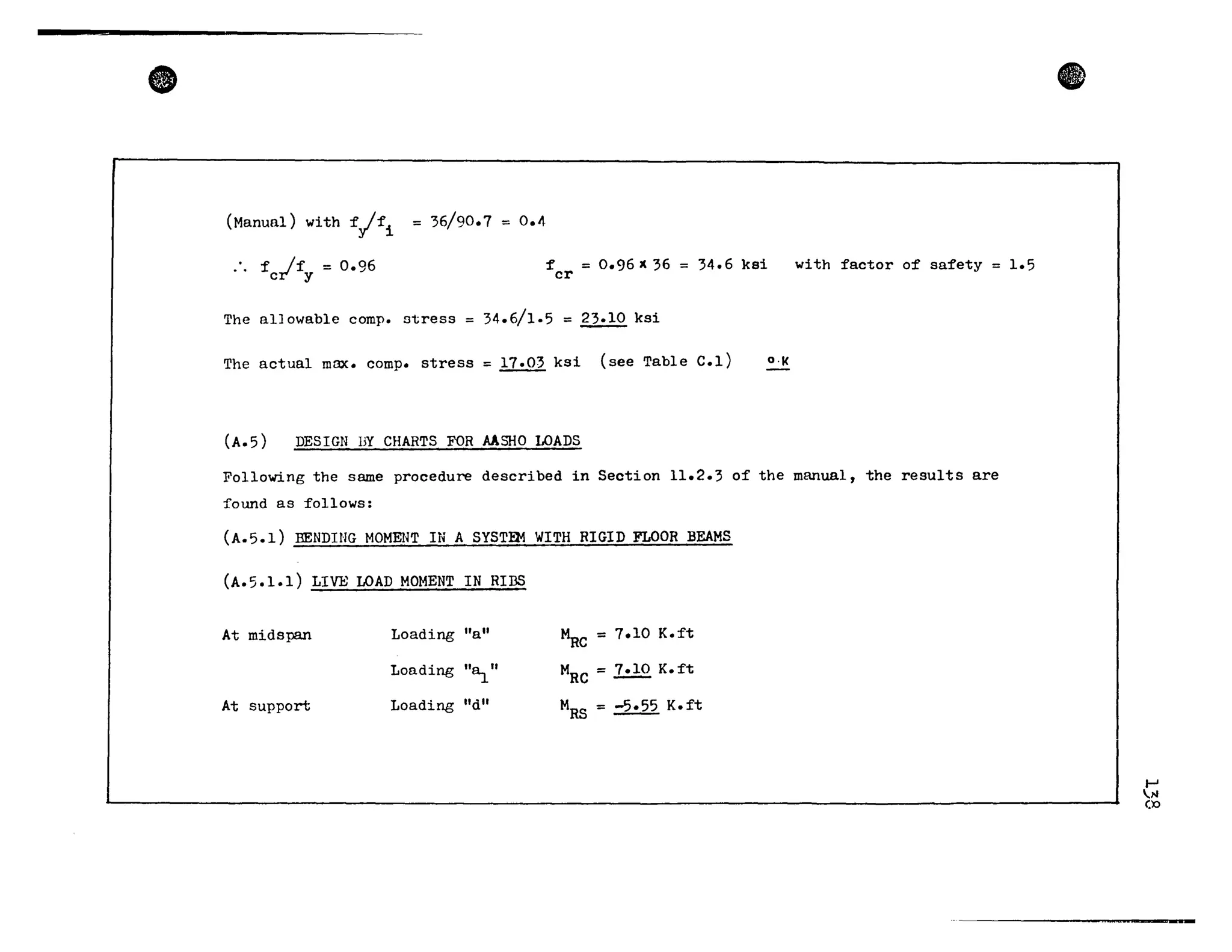

![c 0.8

Oz

byo

C:) Finite Element

- Theory 0 f Bjtlrk und

_._ Theory of '::lasl;:i W

----Mode1 Experimen

115

0.4~------+-------~~~~4-------~------~

0.0

_

~________~________~________~______________________ x/L

0.6

0.2

0.0

0.1 0.2 0.3 0.5

FIG. (4.16)

VARIATIO;'I OF DISrORTIO?lAL DEFOrt:·IATID:l ( bz) ALONG

t THE SPA]

-

0 Finite Element

t- - l ..--------- Hoae ExperimenL.

-- 0

--... - 0... ...,,

., ., (!)

.... "'0'".,

... .,. -t:;)-

--0.1 0.2 0.3

FIG. (4.17)

VARIATIOlT OF L03GITUDnrAL BE:mnm STHESS ~b

ALOnG t rrHE SPAN

0

XIL

0.5](https://image.slidesharecdn.com/torsionalbehaviourofsinglecellboxgirderbridges-140613171733-phpapp01/75/Torsional-behaviour-of-single-cell-box-girder-bridges-132-2048.jpg)

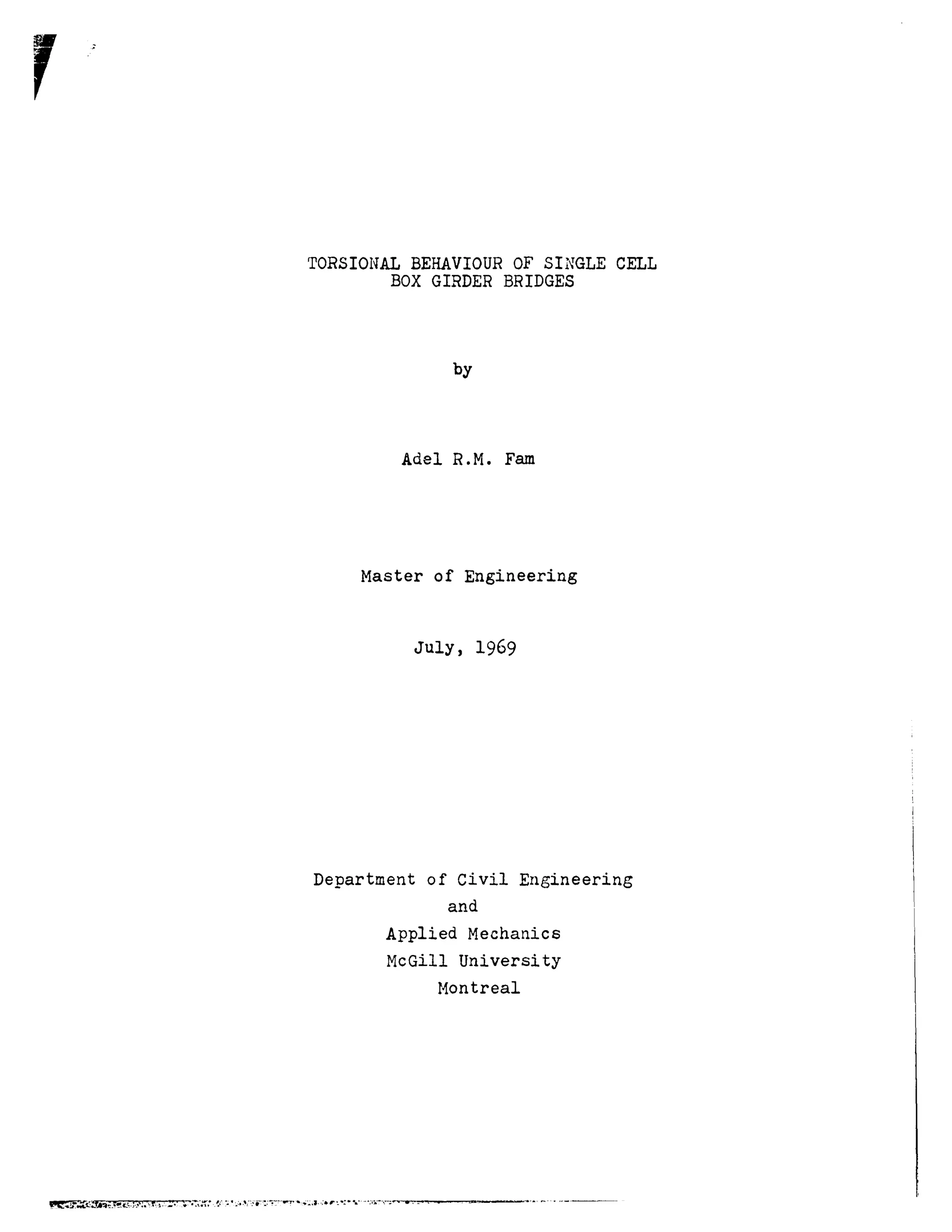

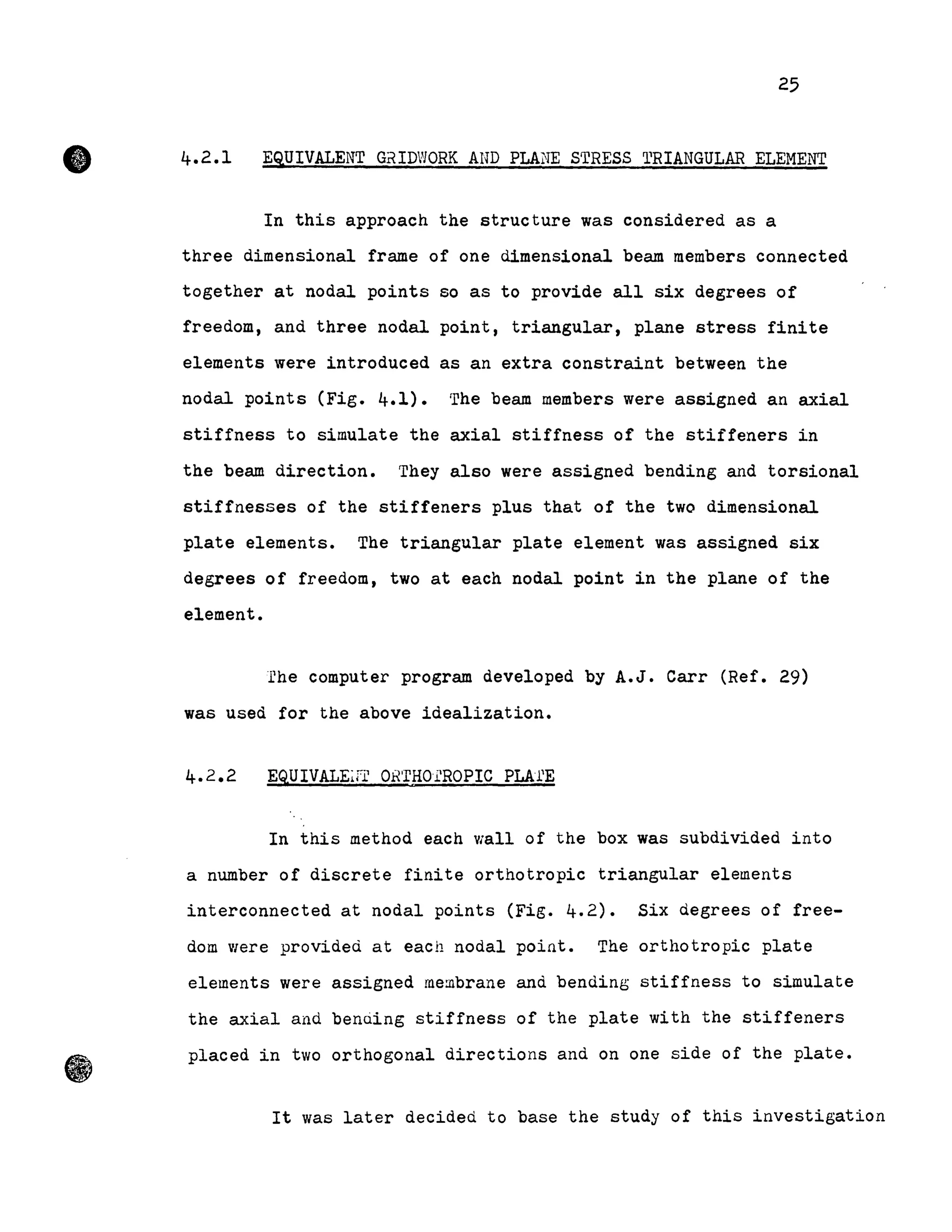

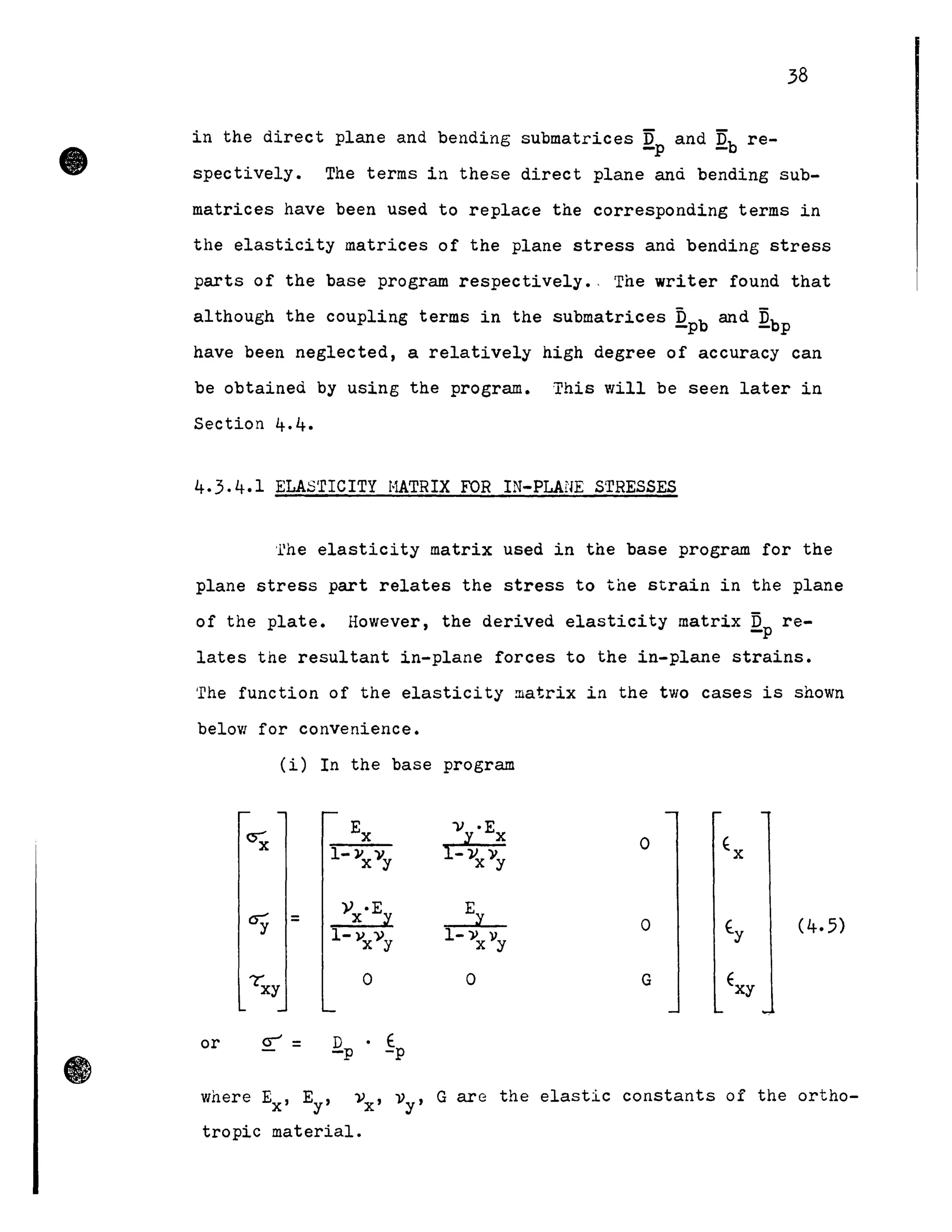

![•

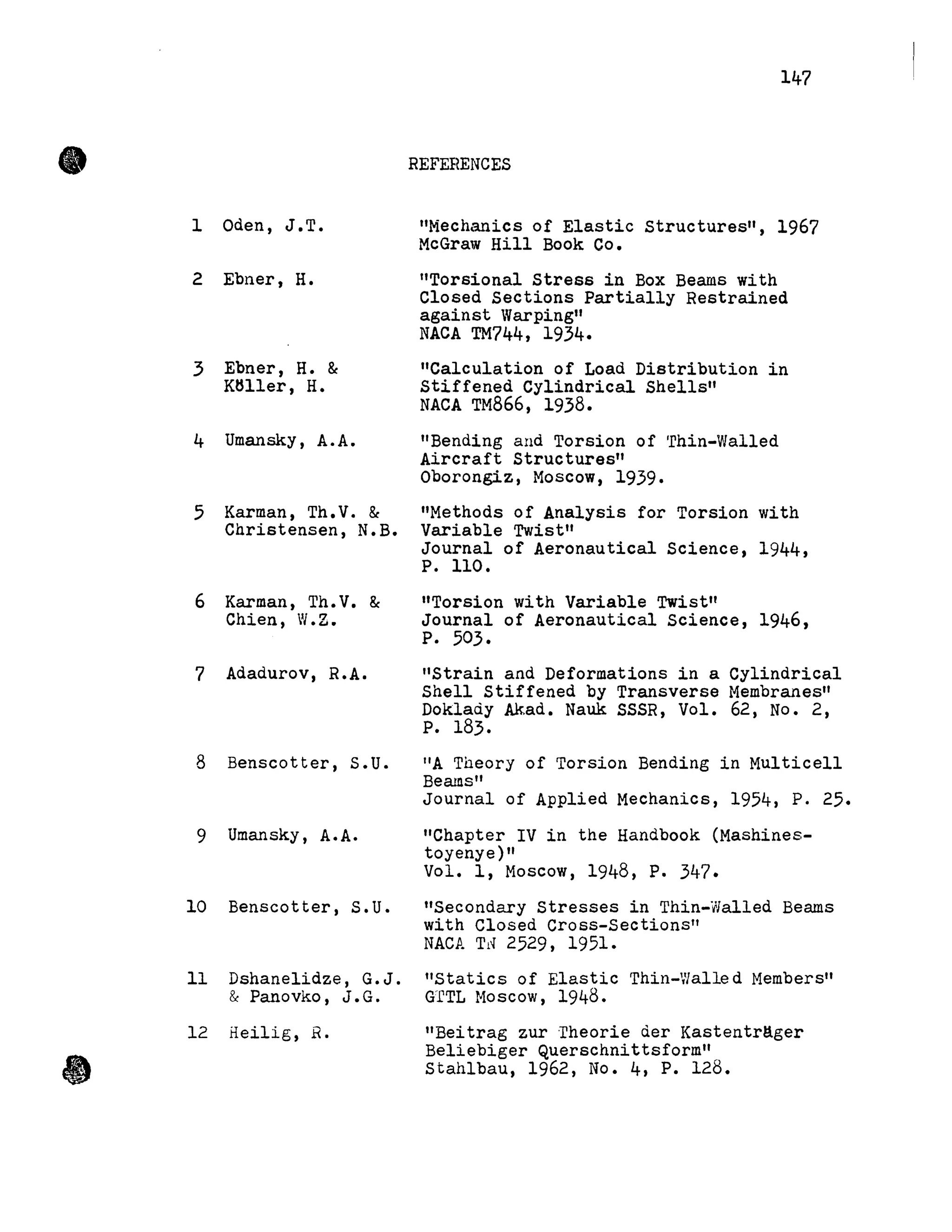

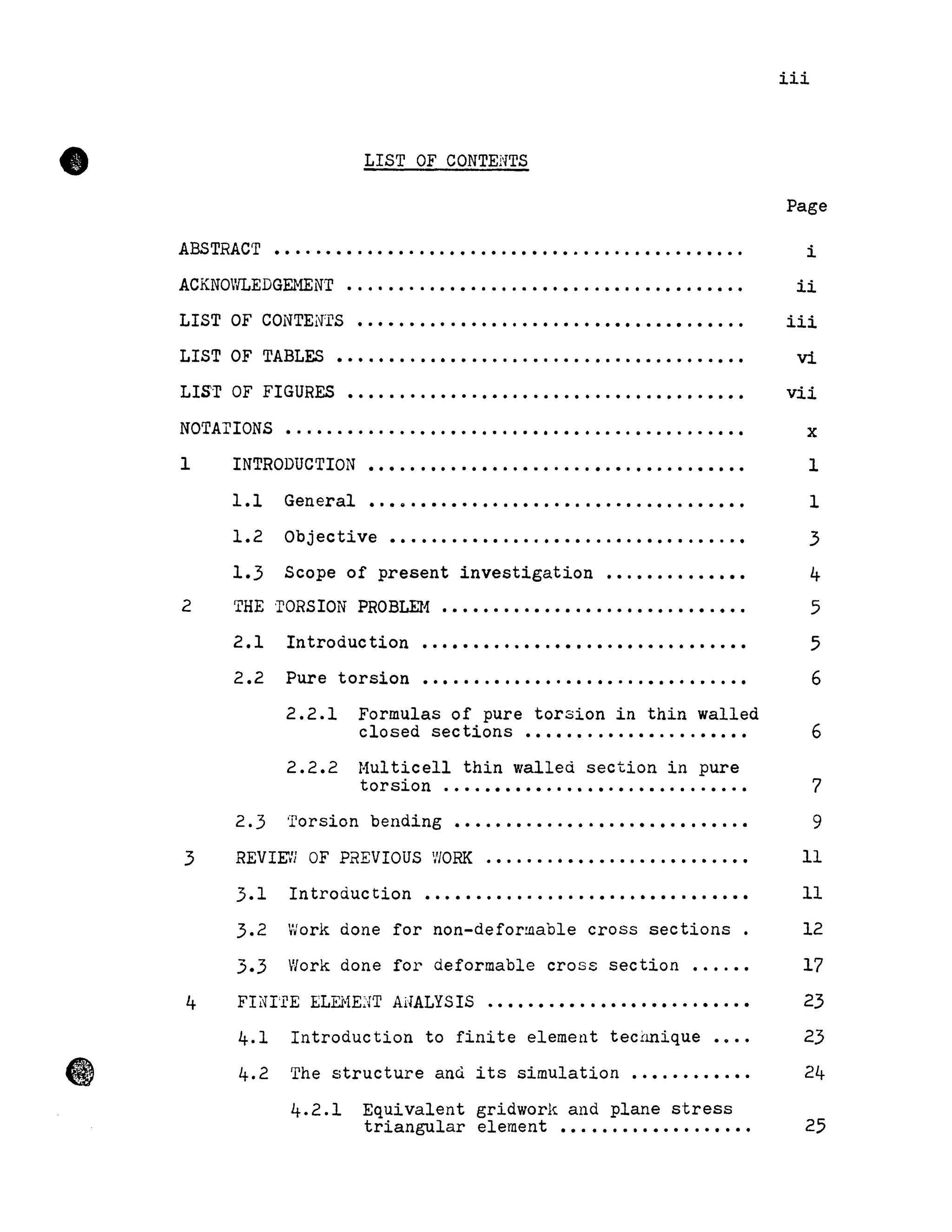

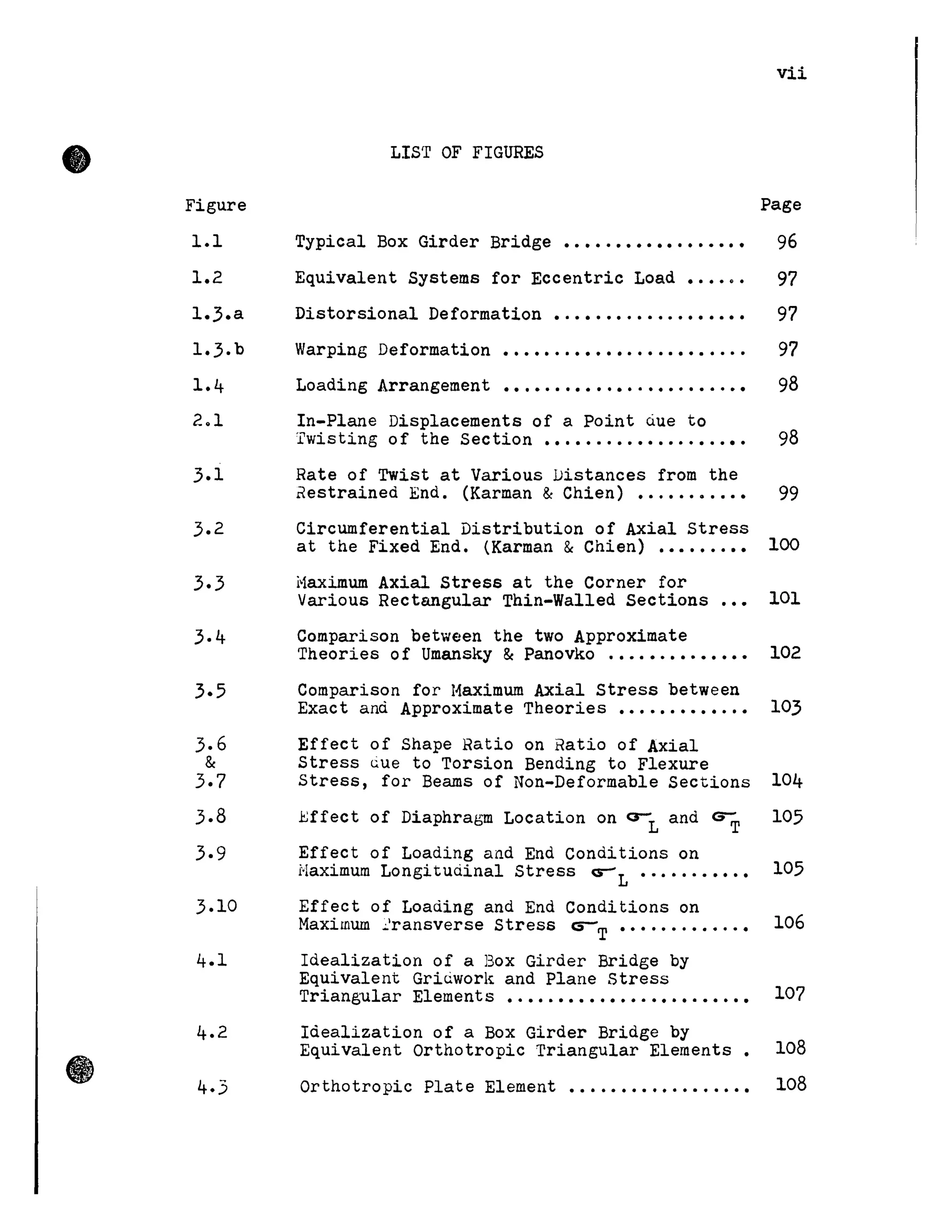

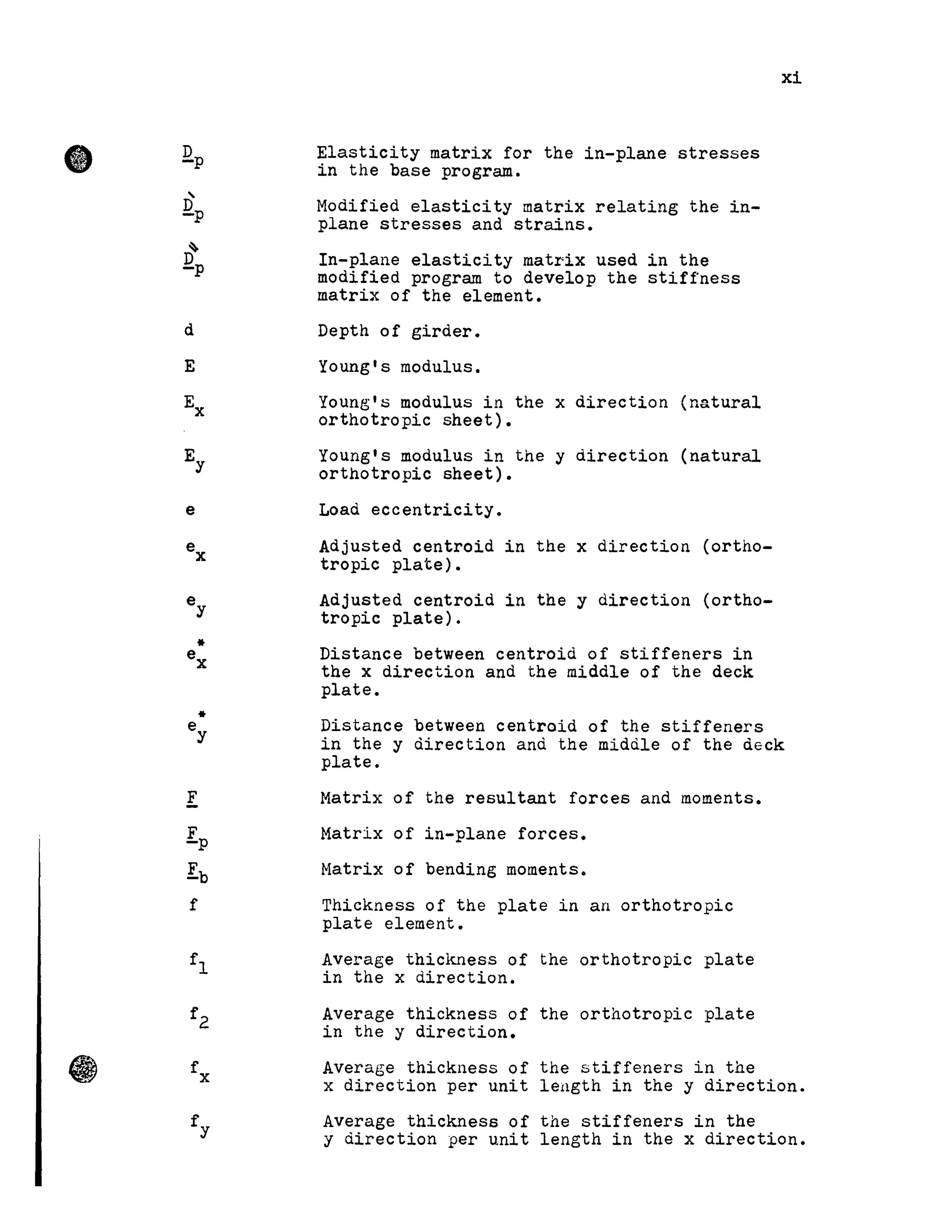

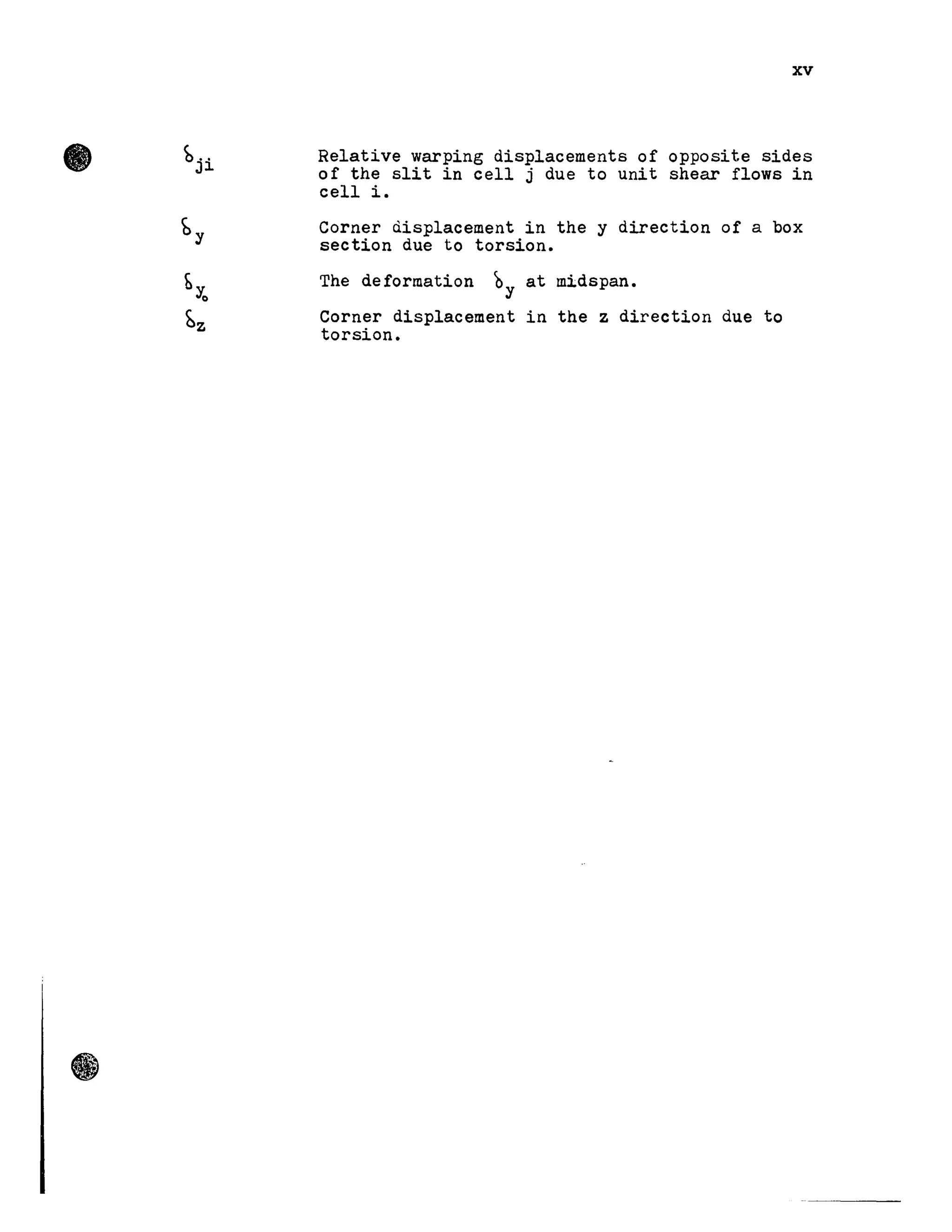

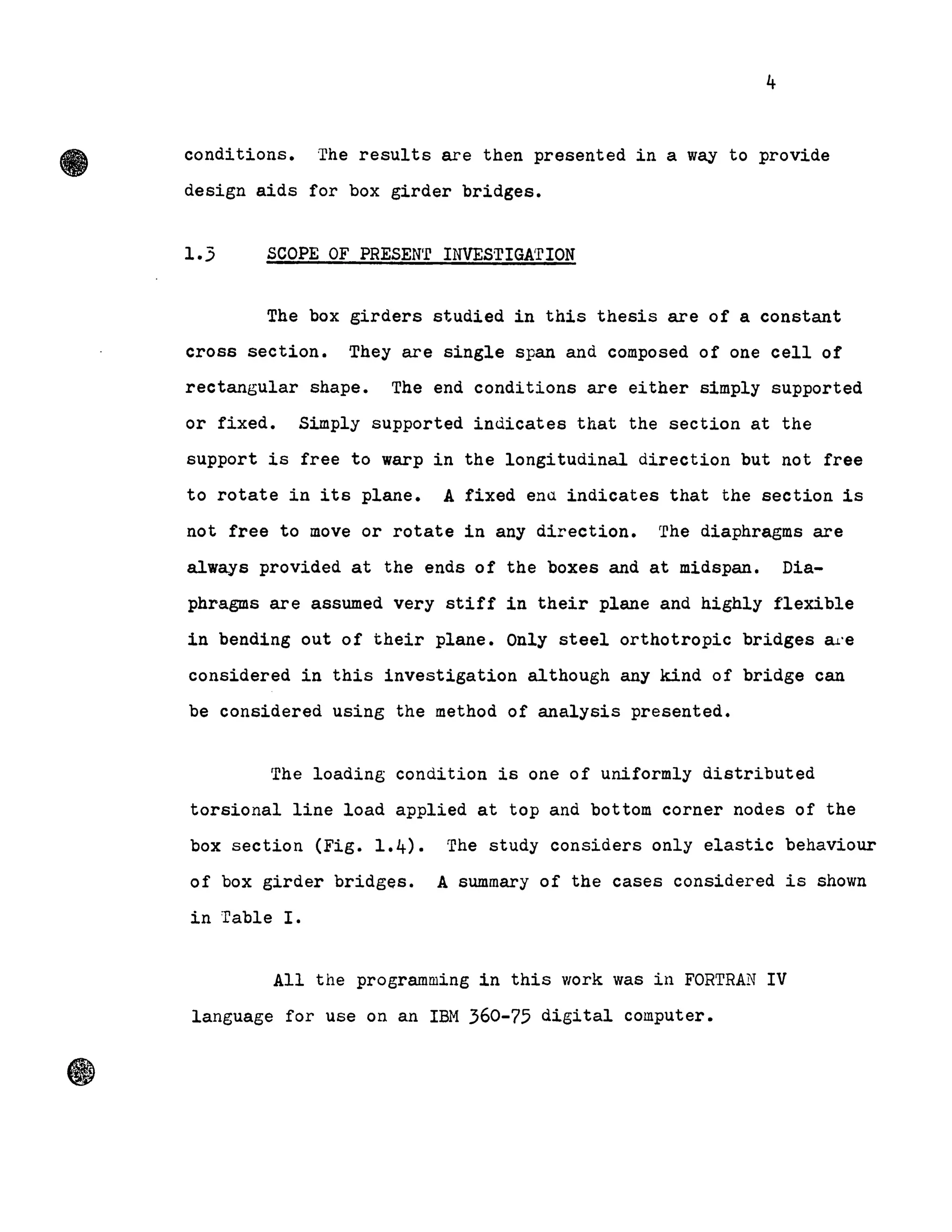

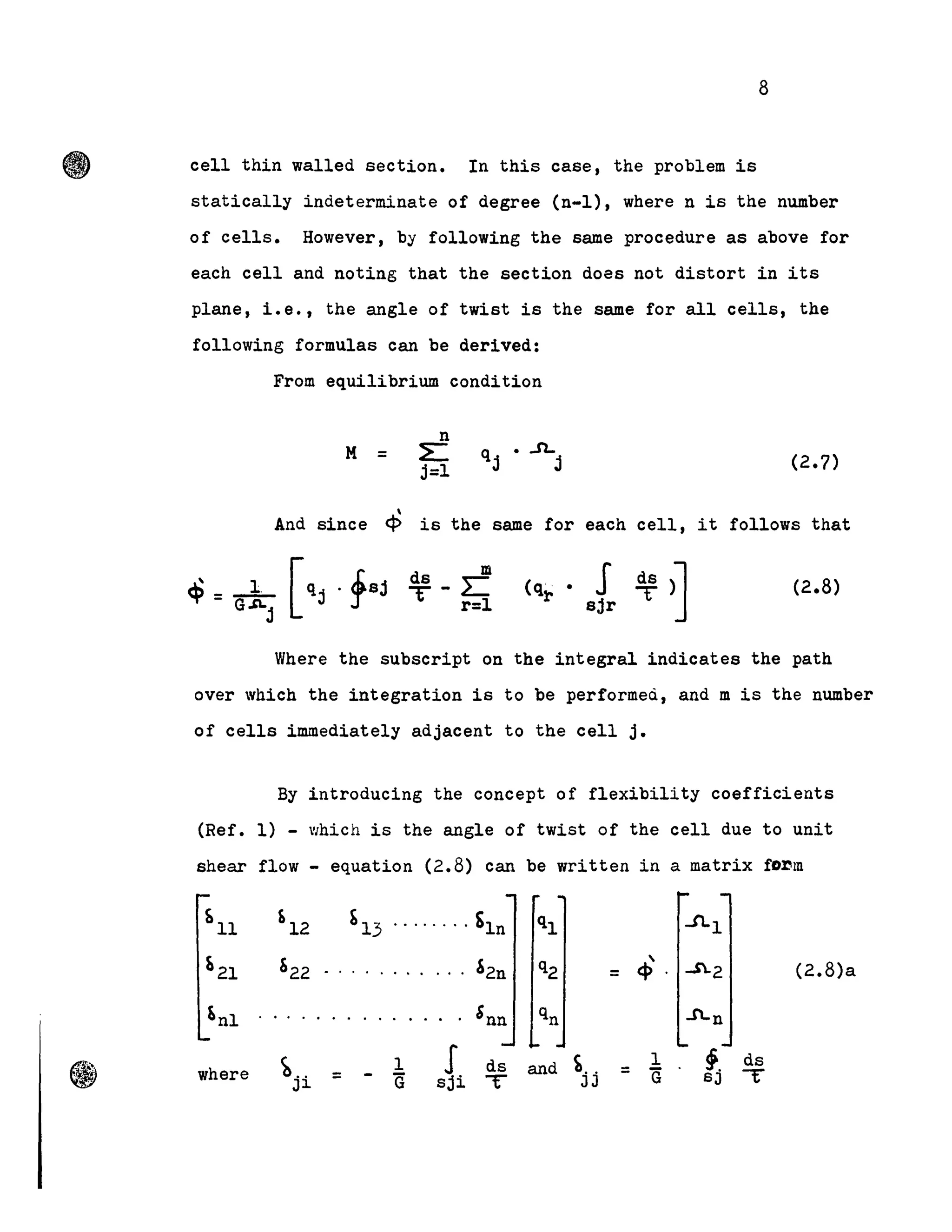

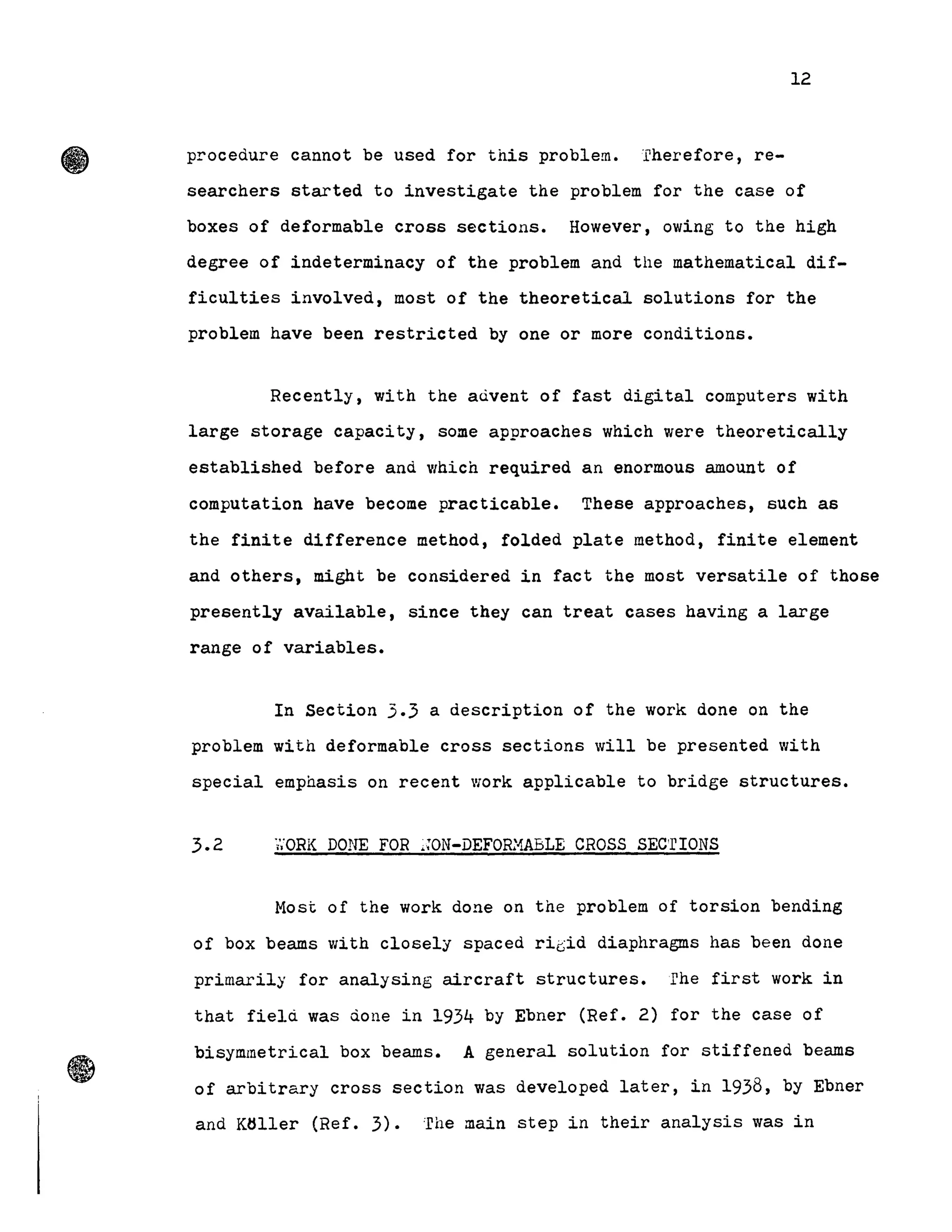

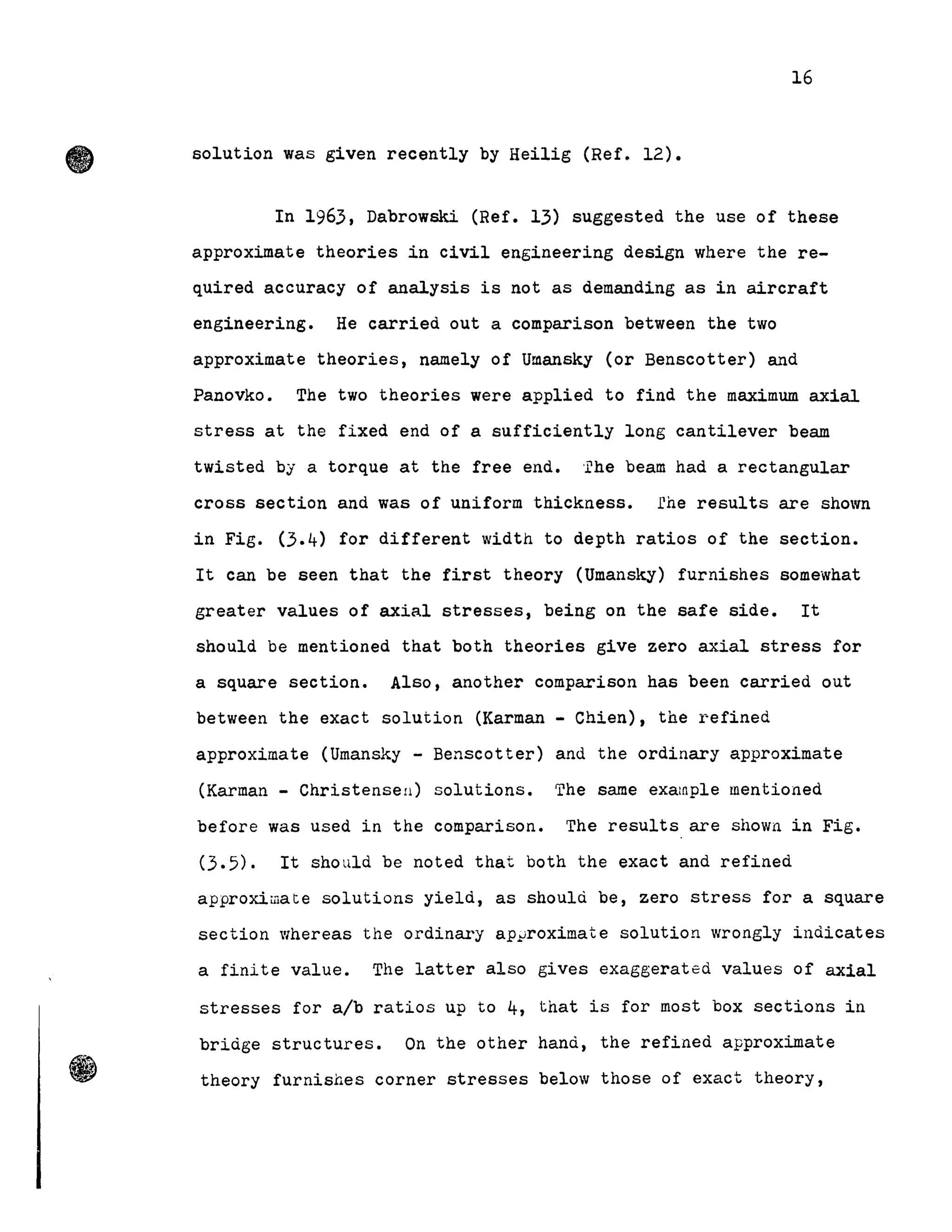

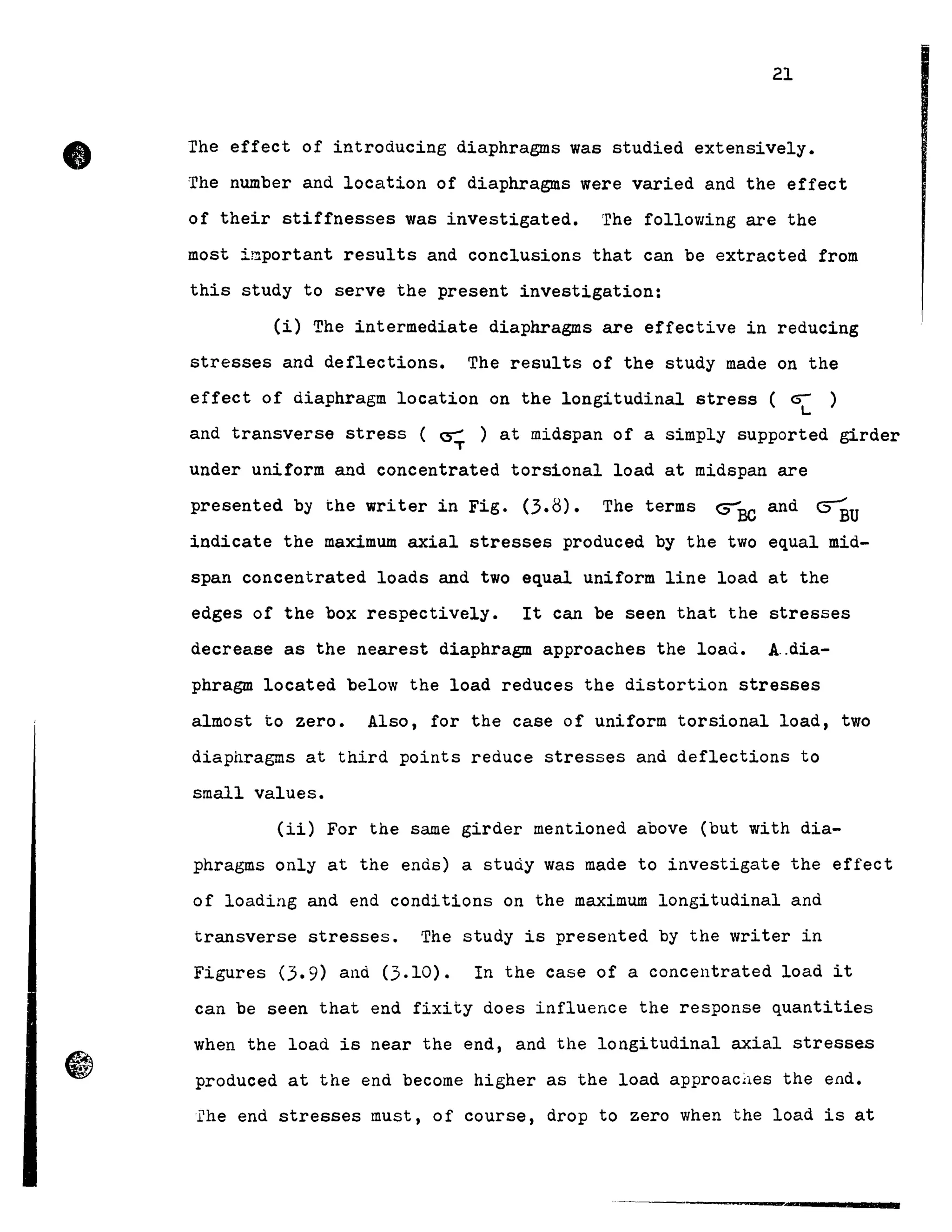

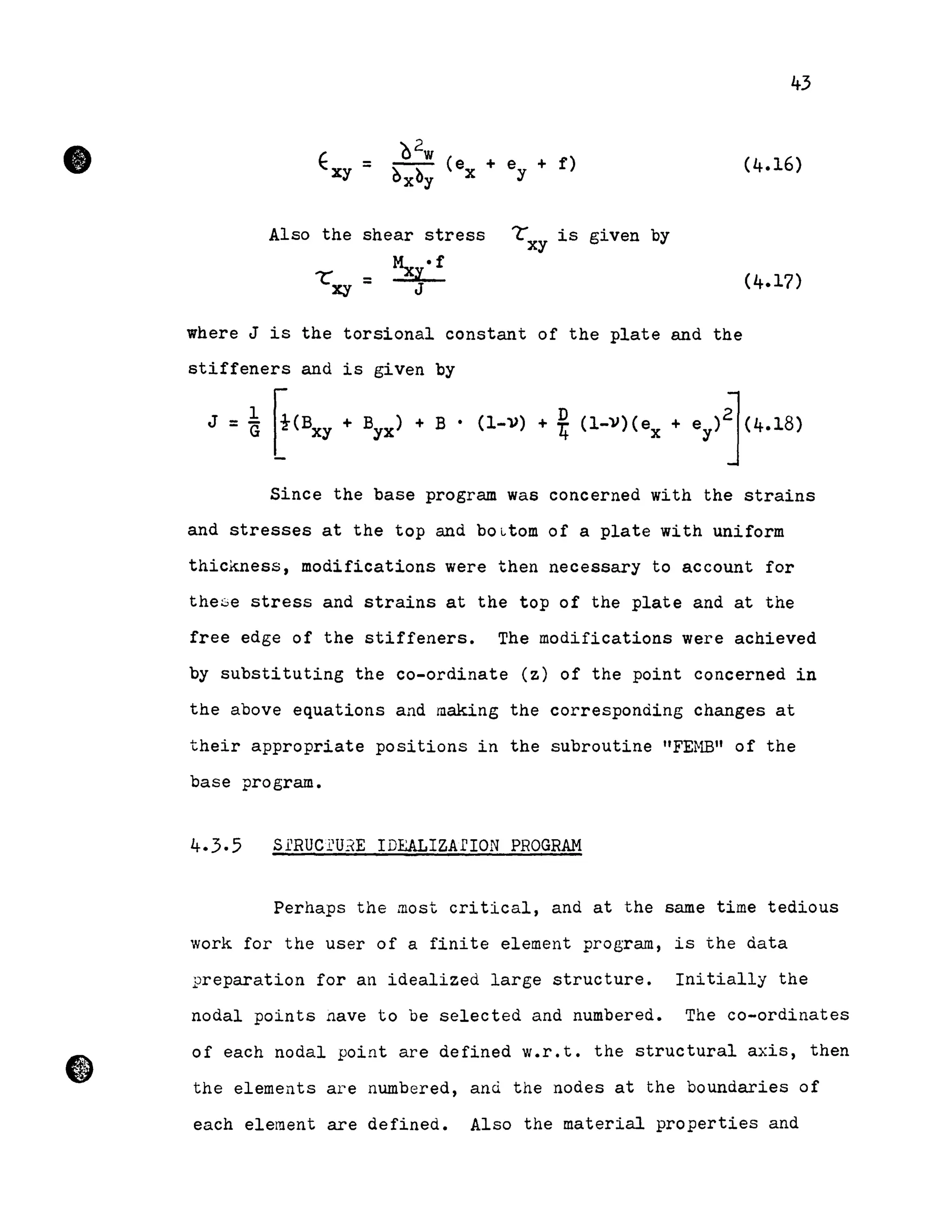

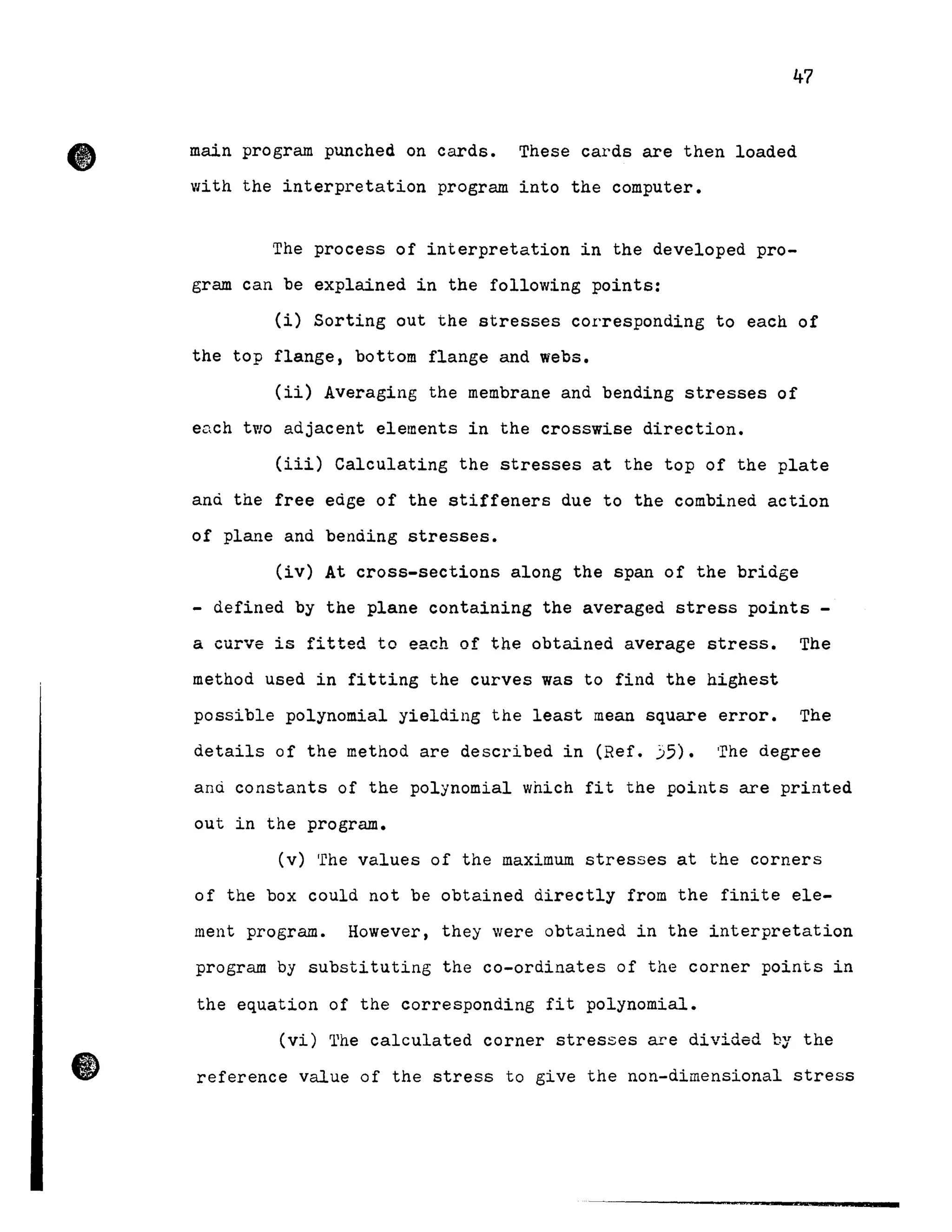

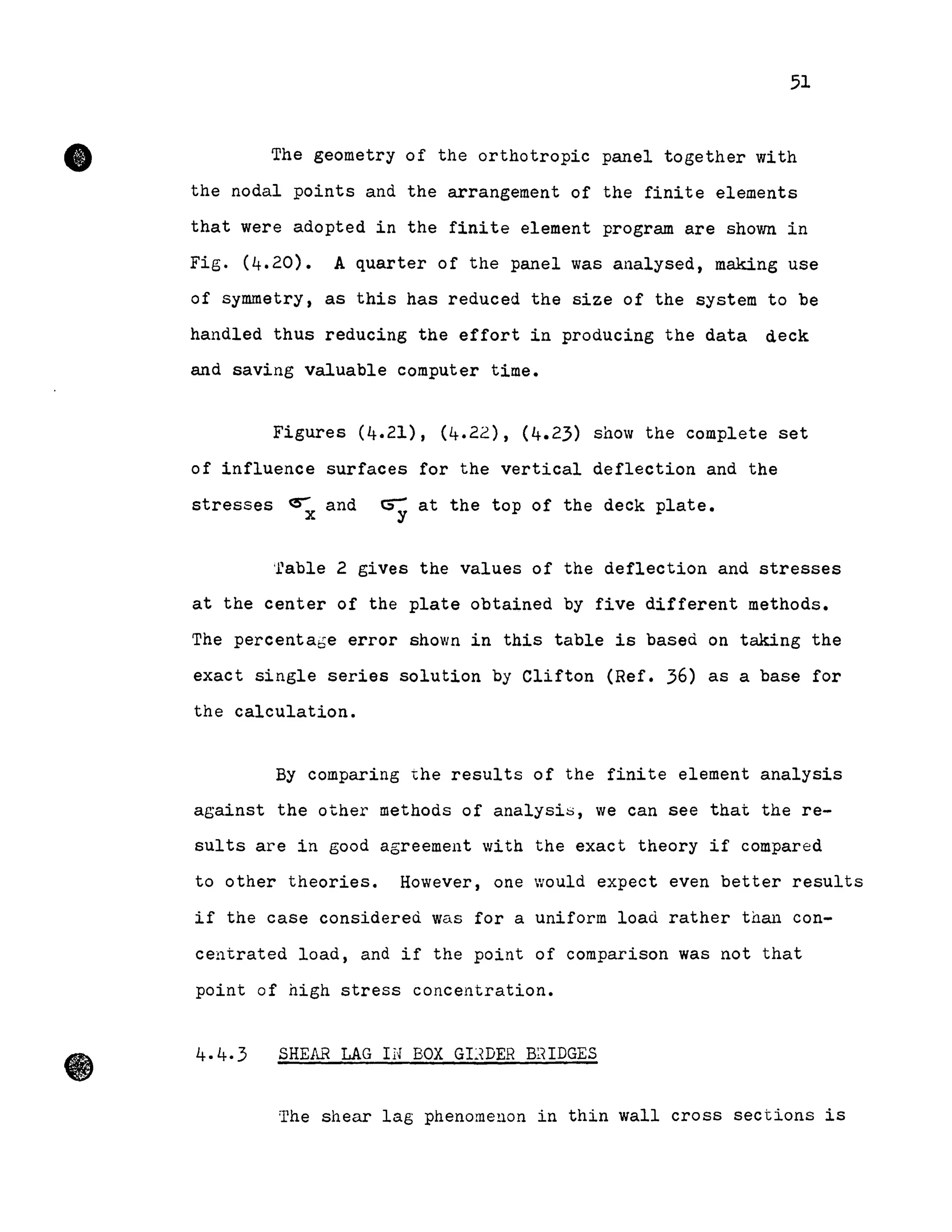

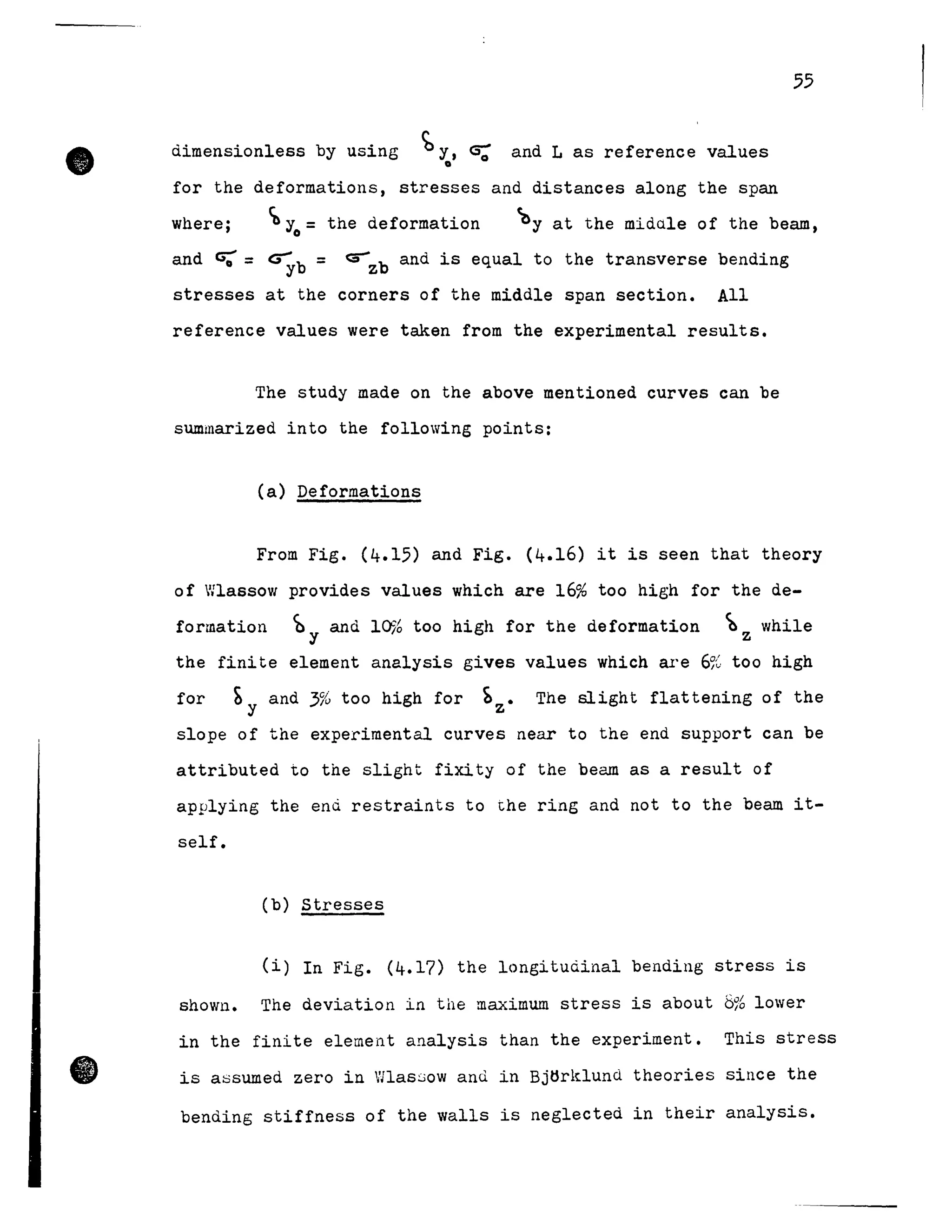

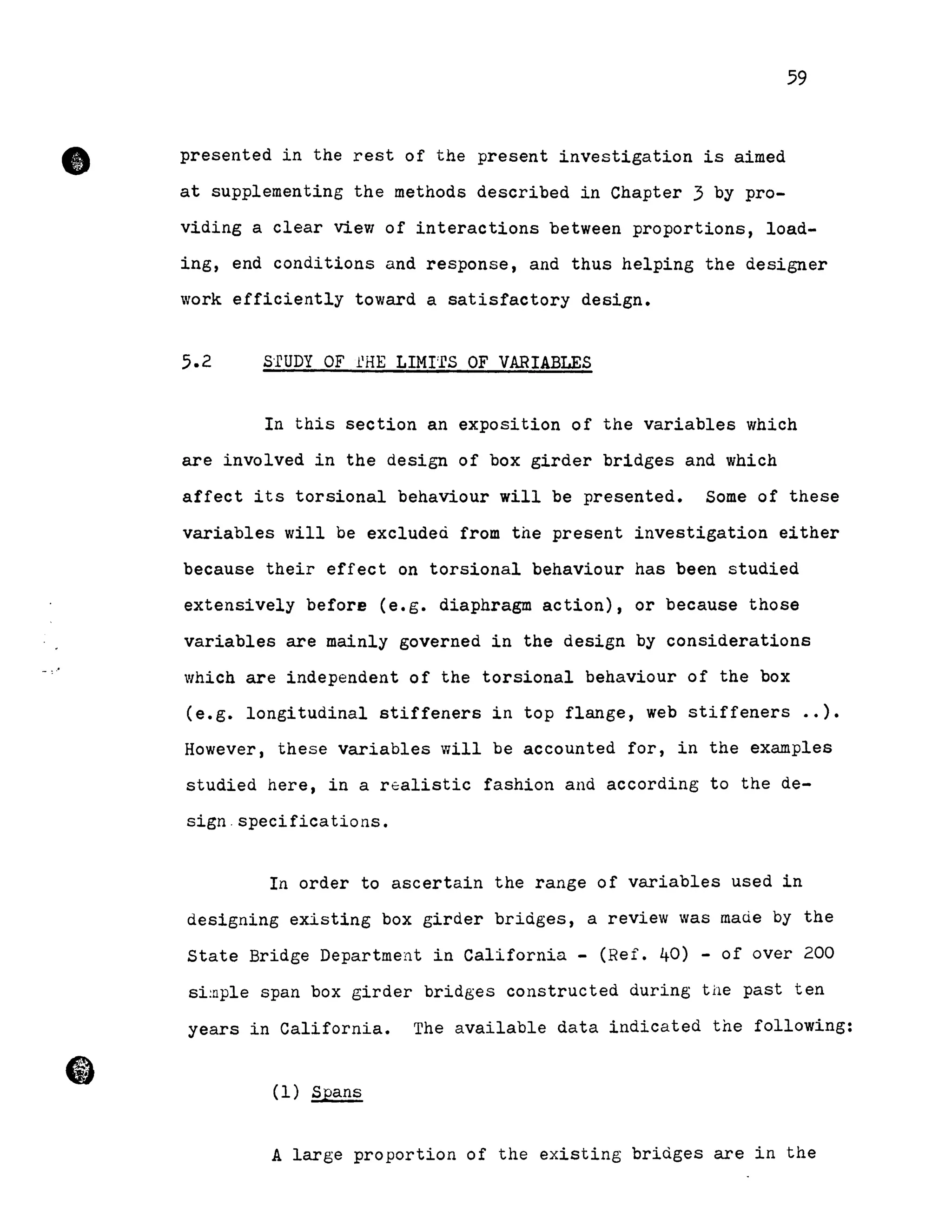

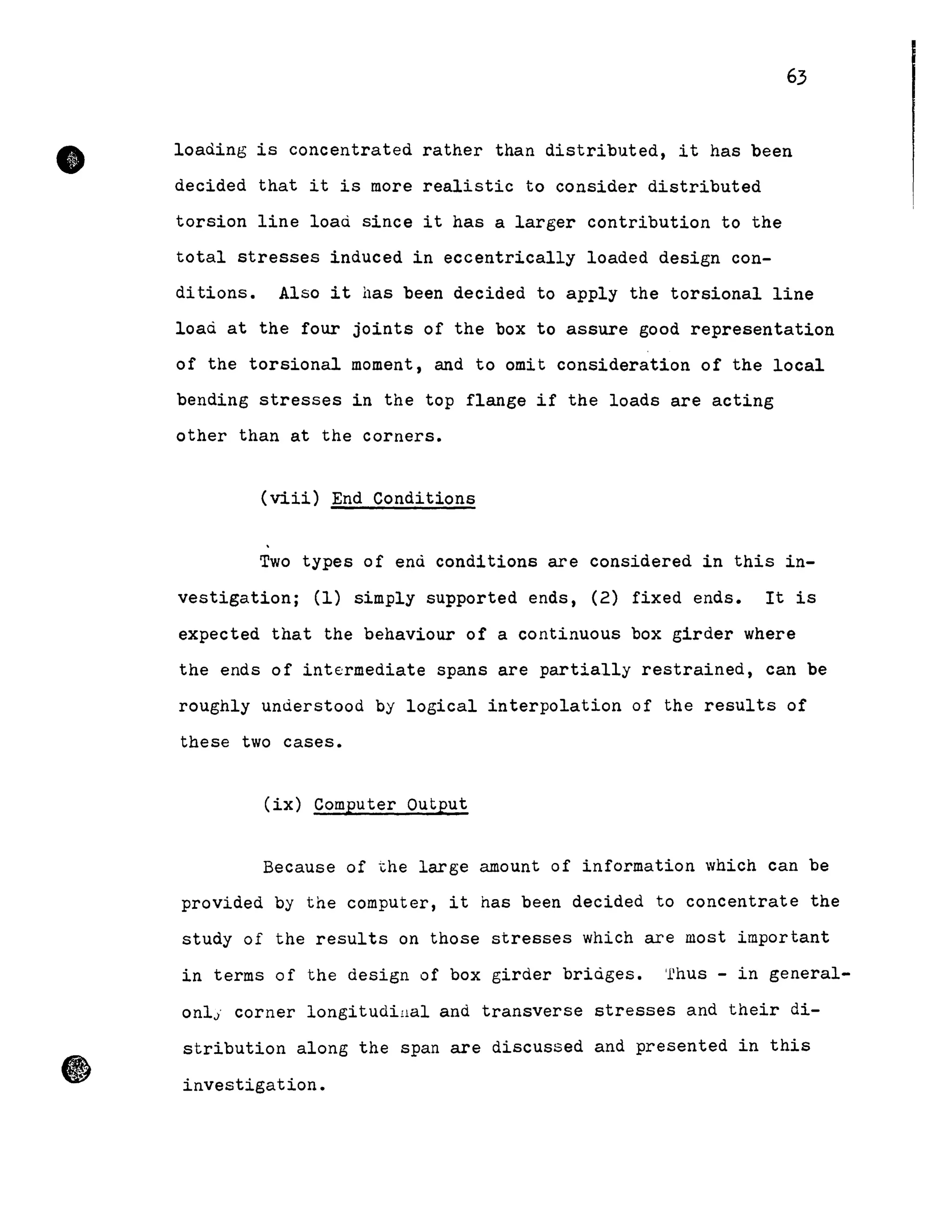

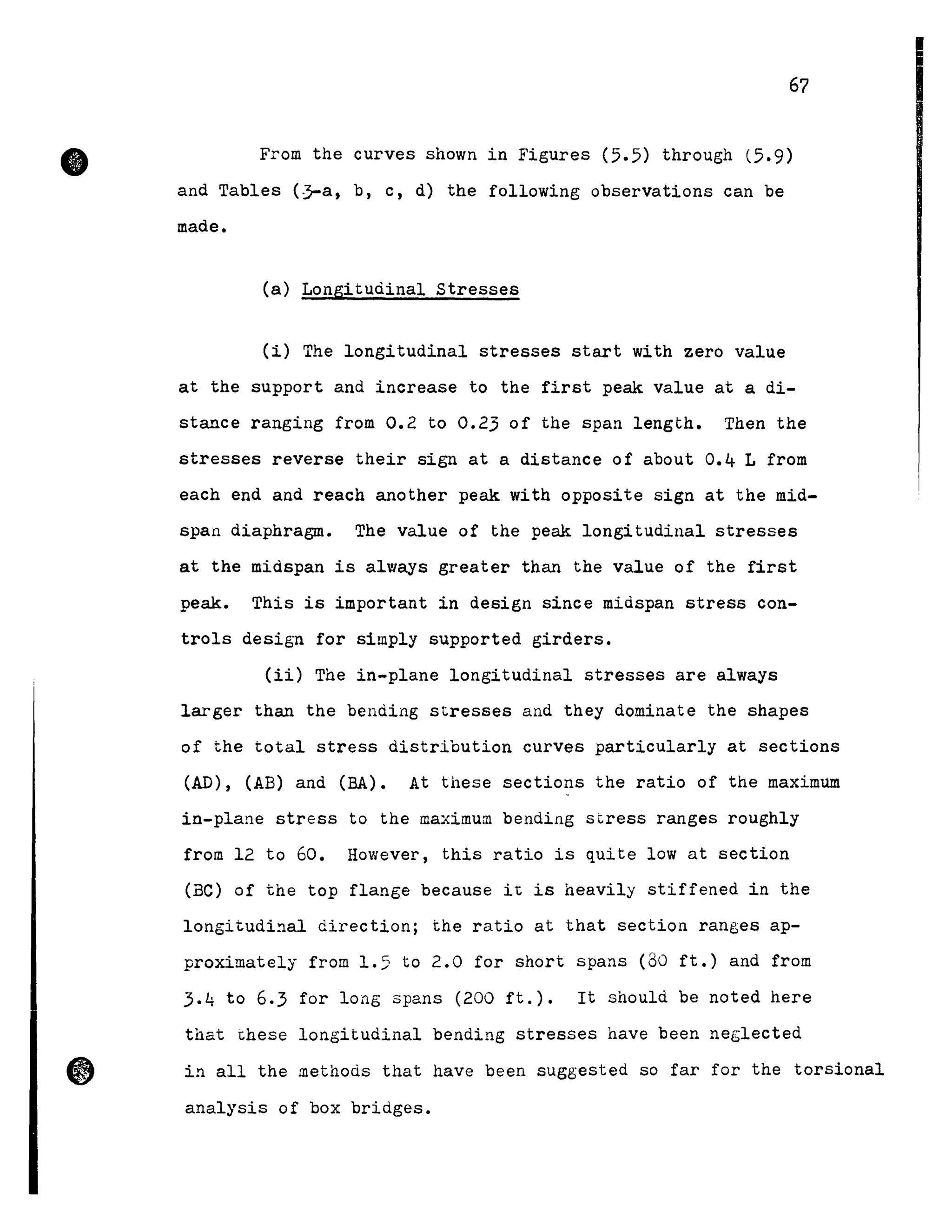

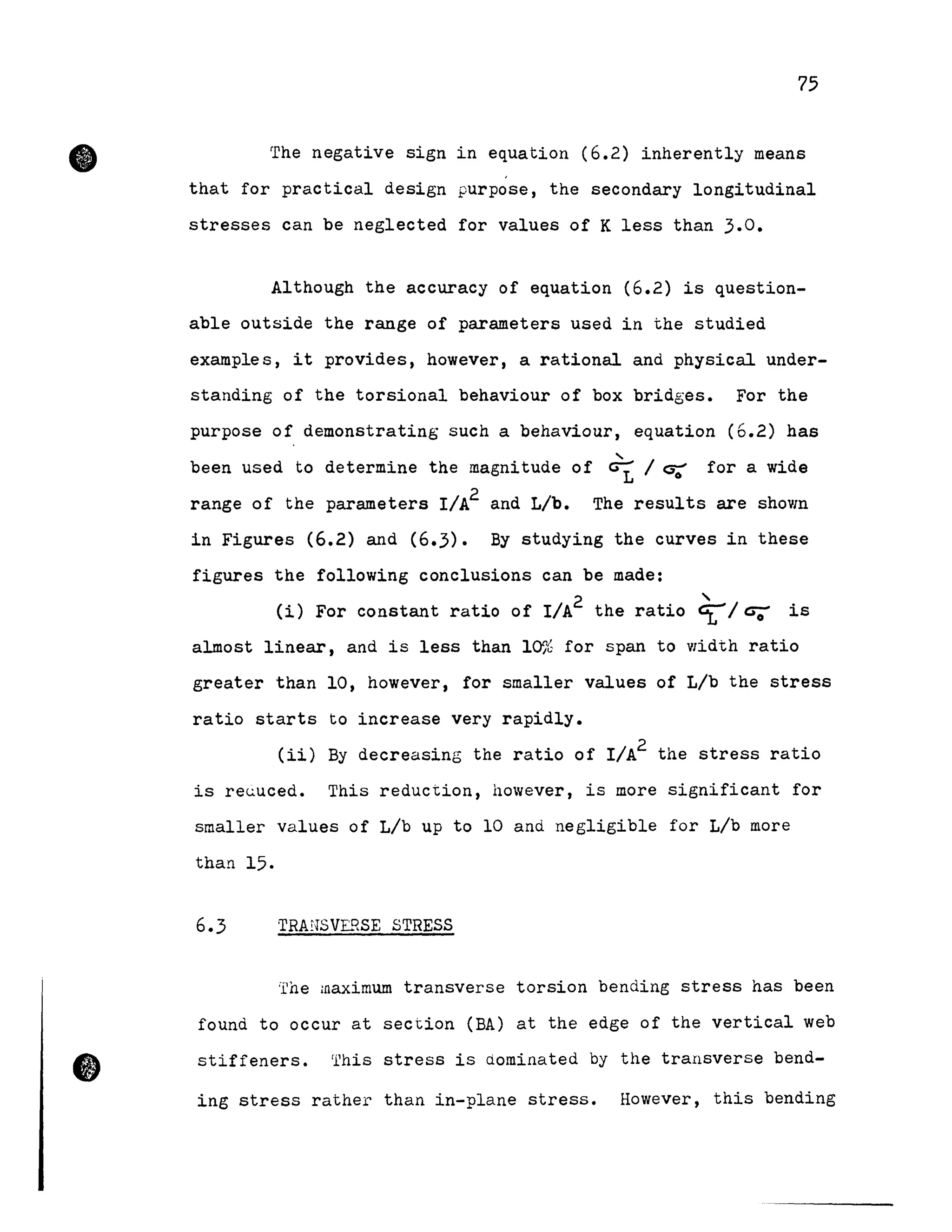

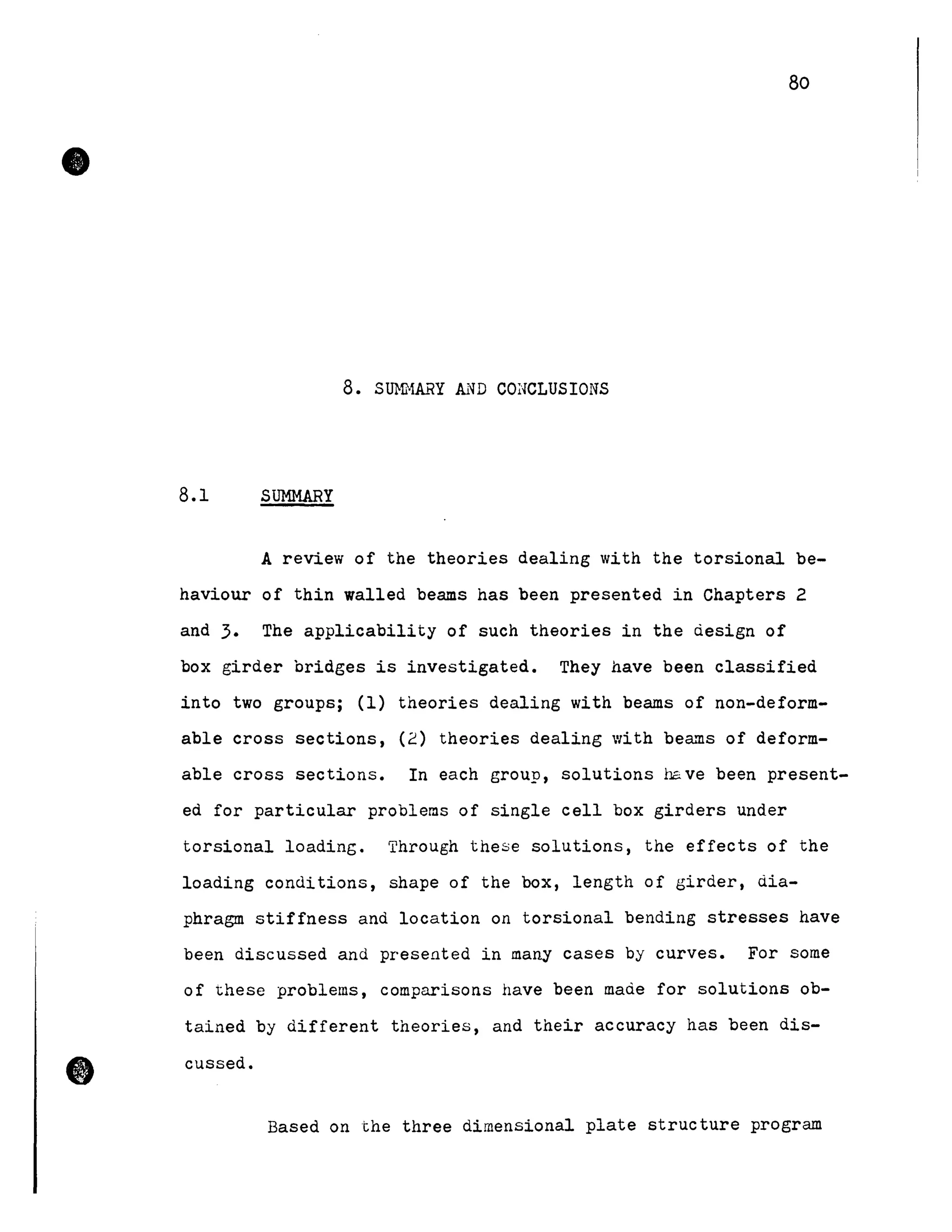

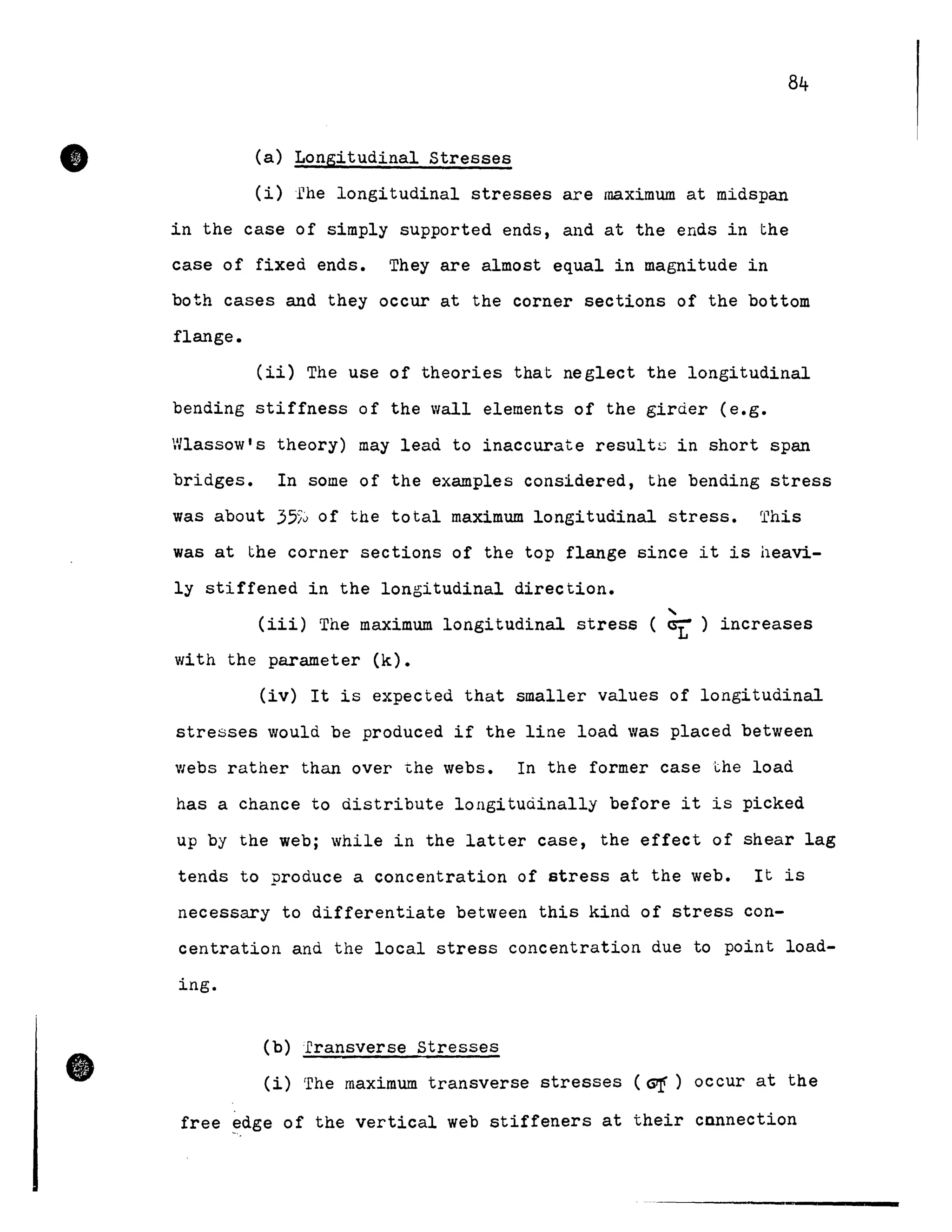

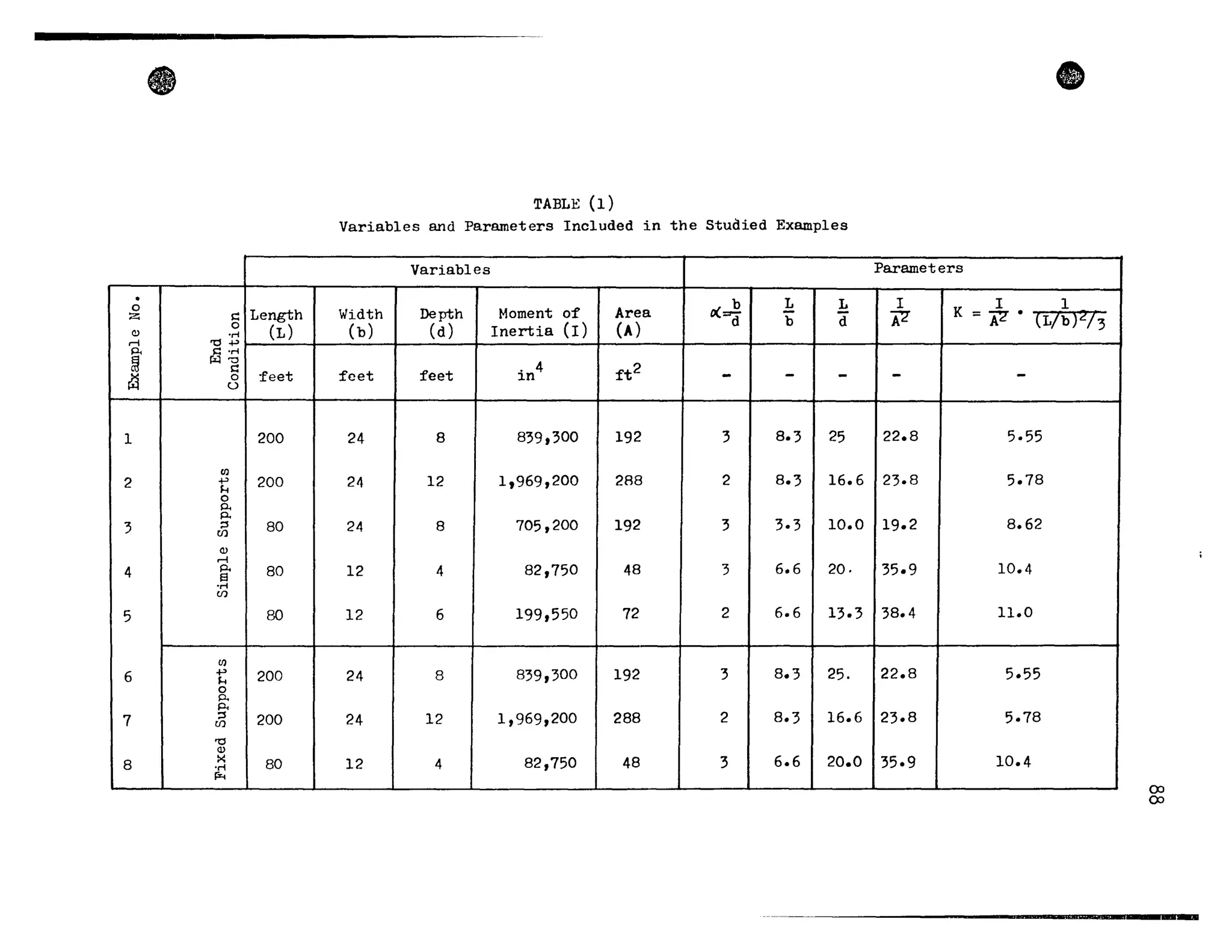

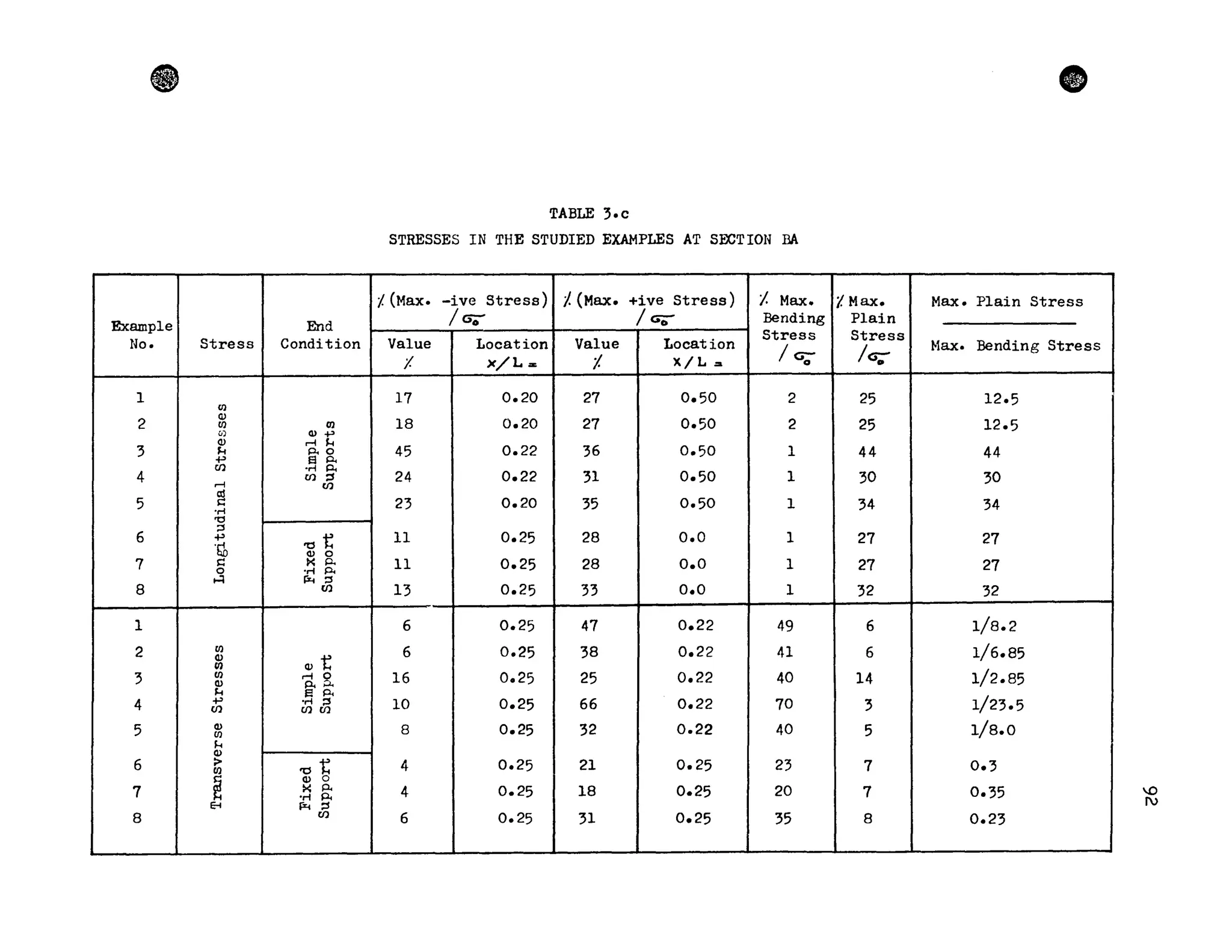

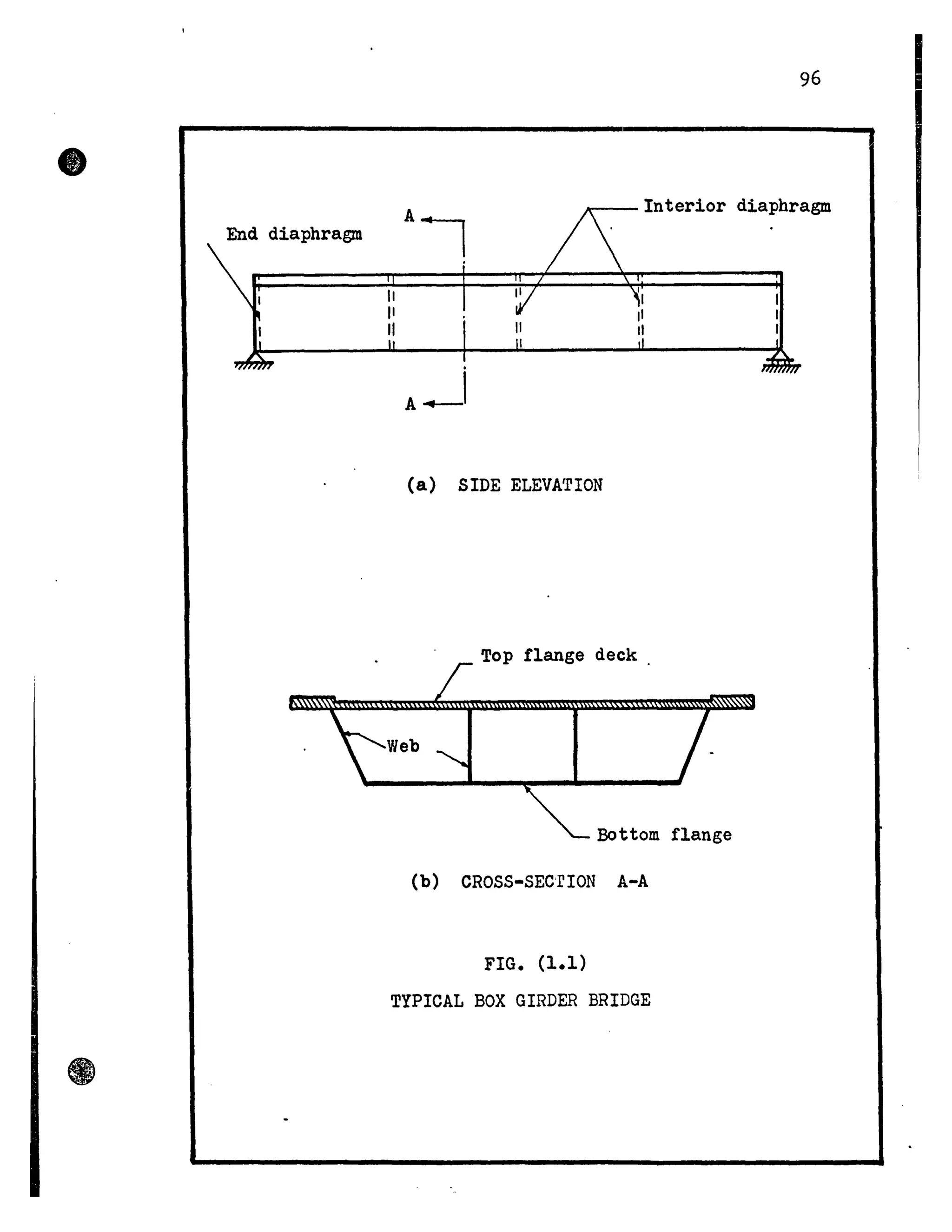

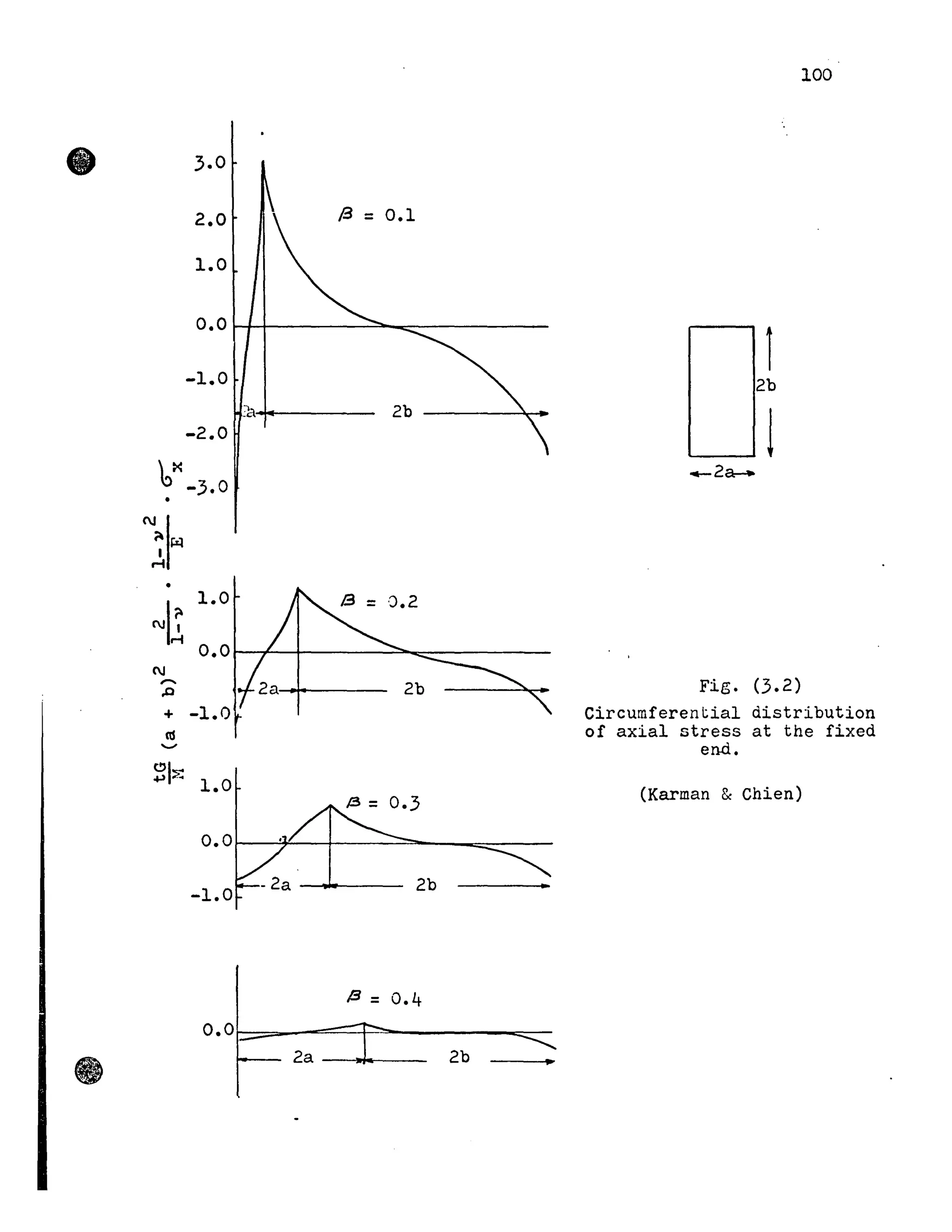

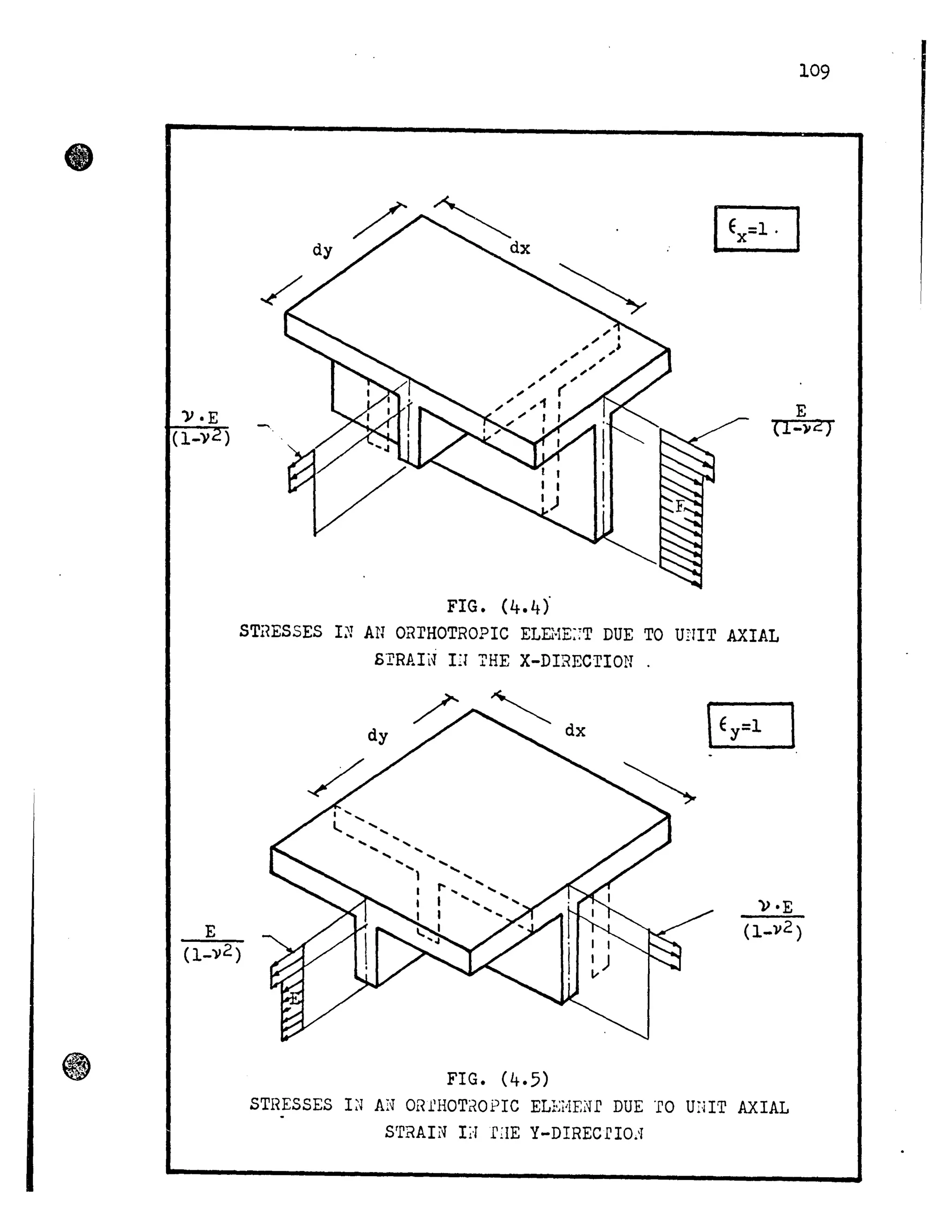

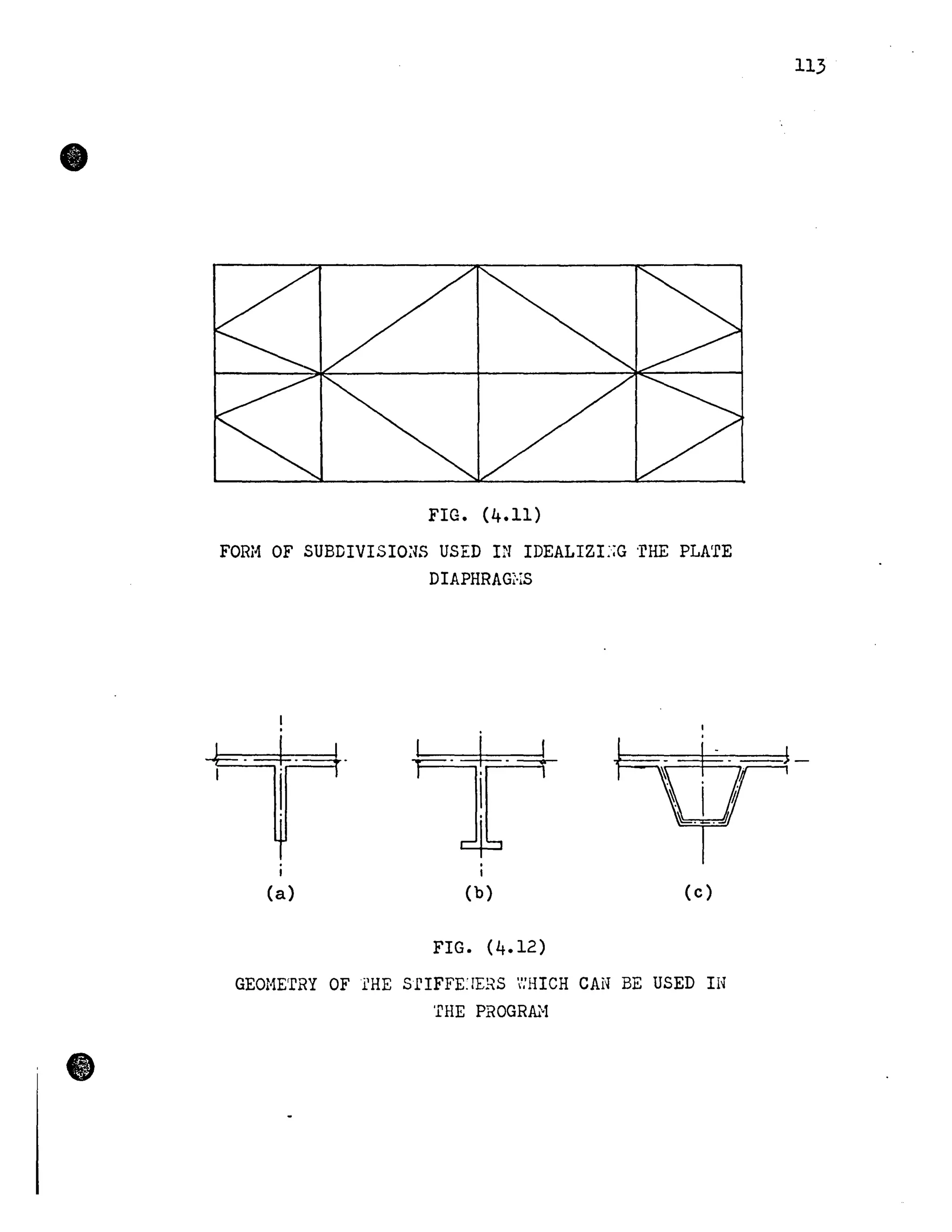

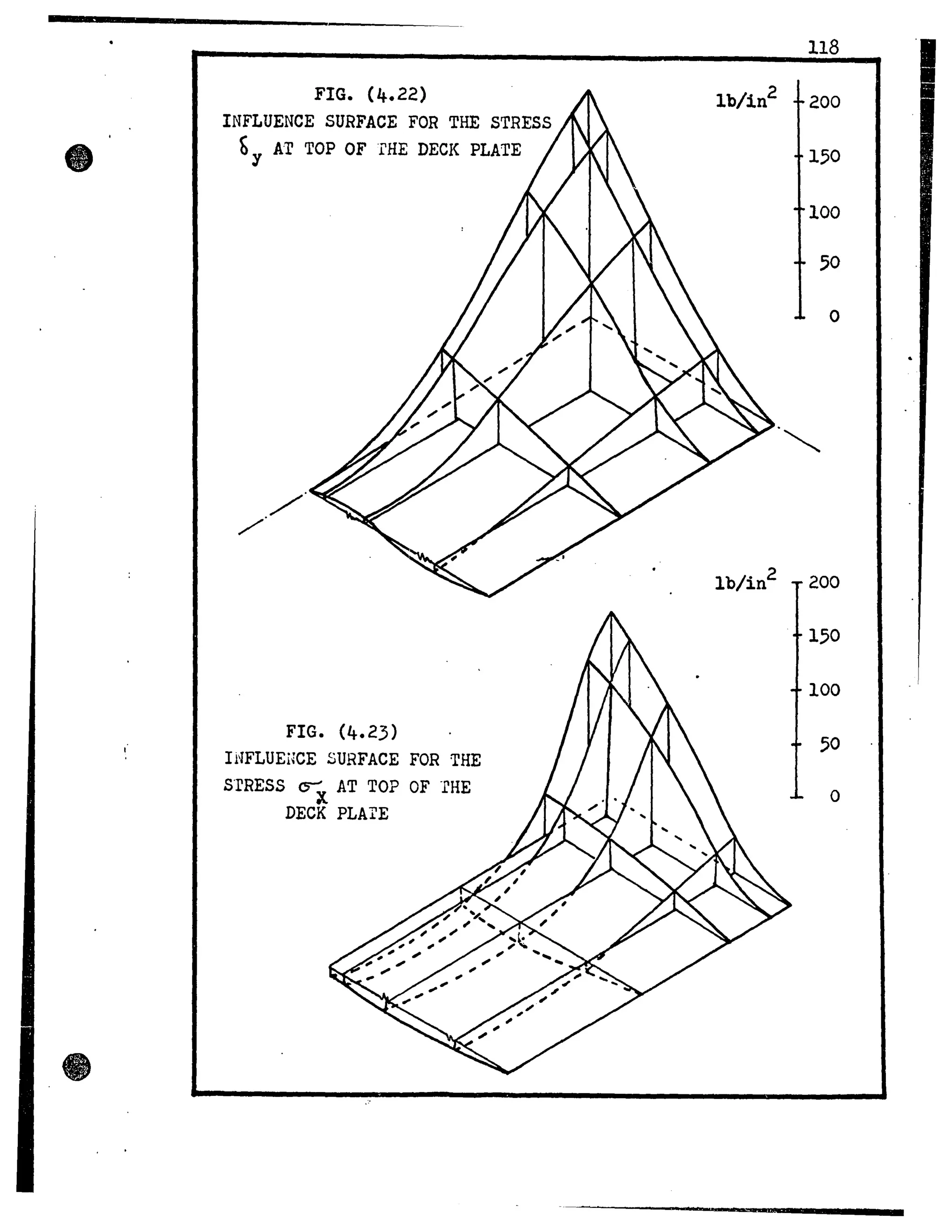

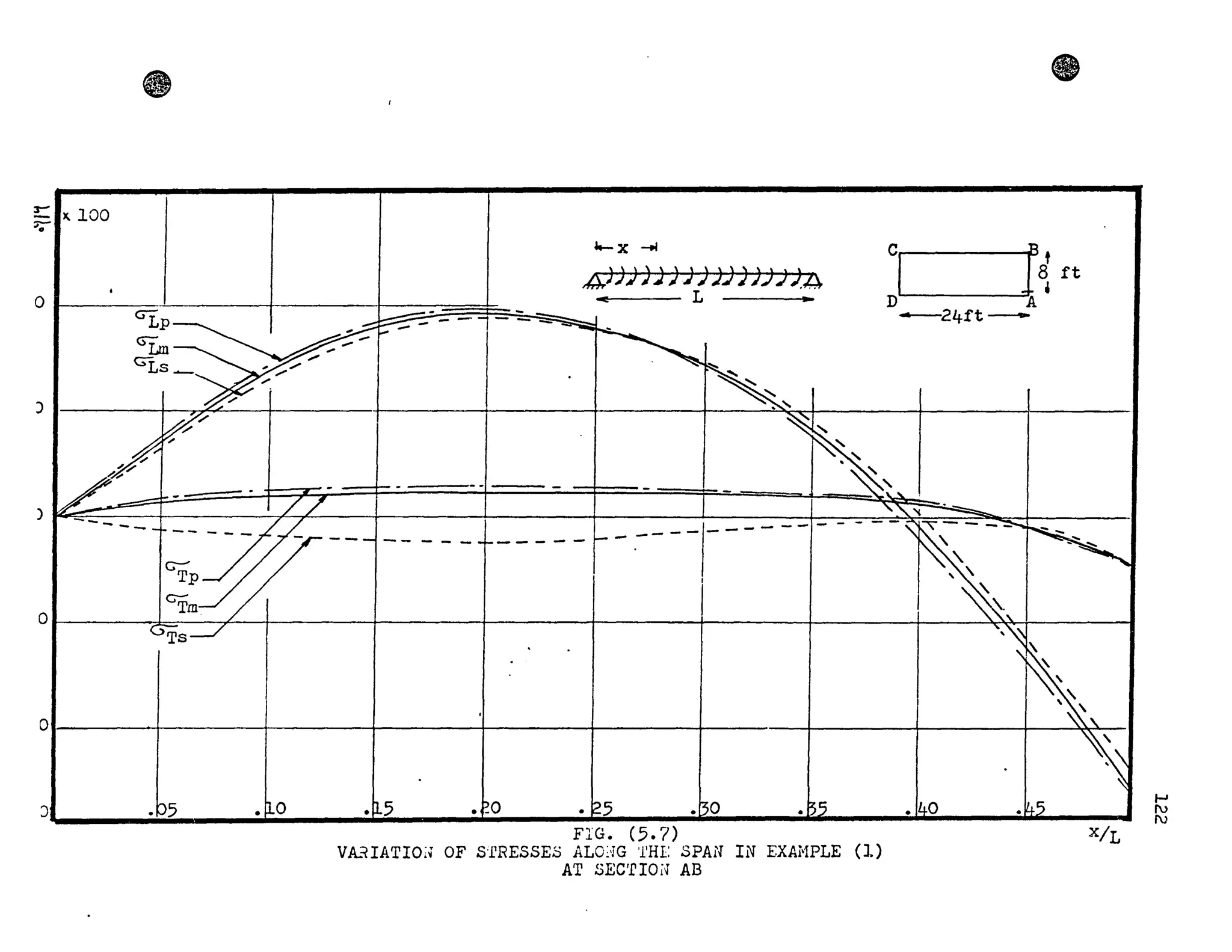

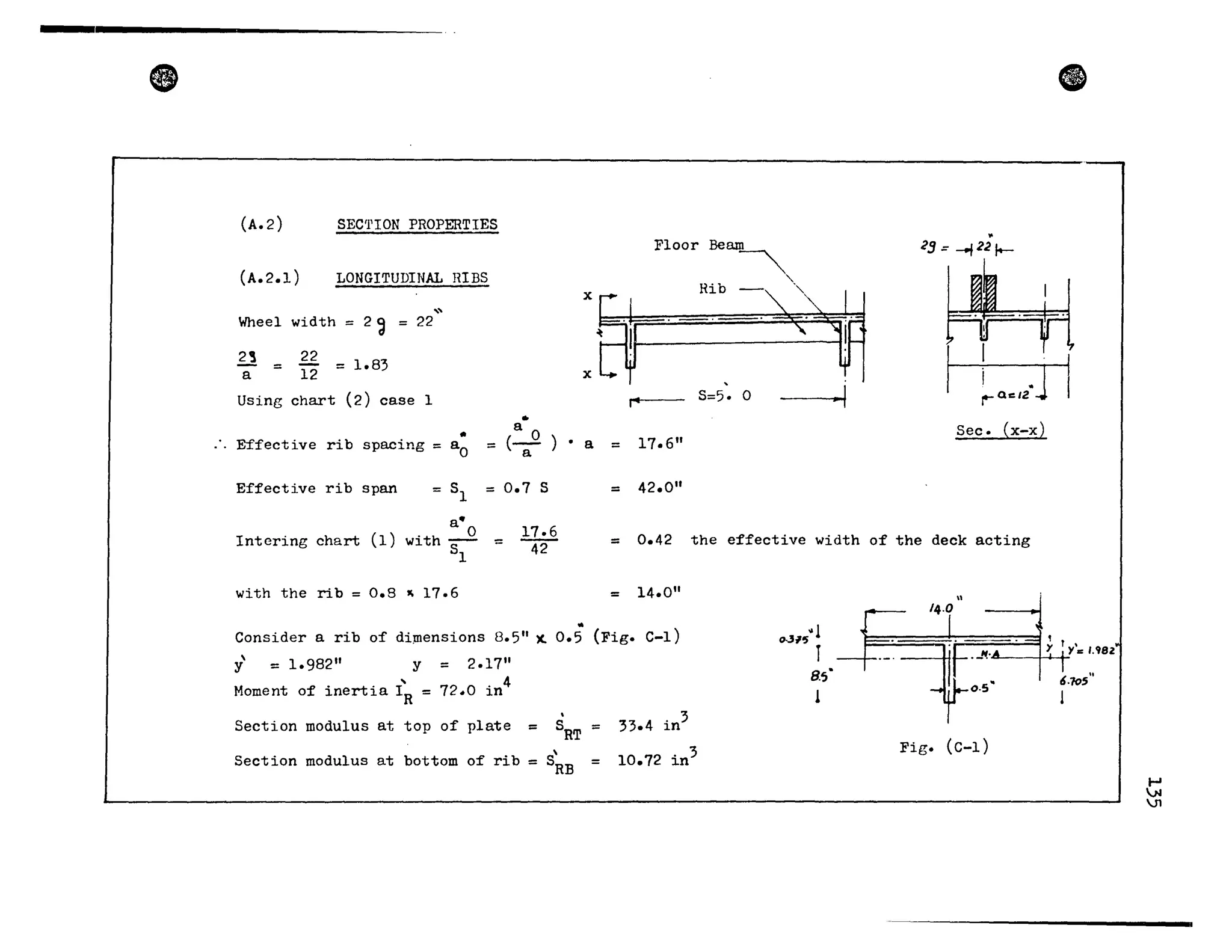

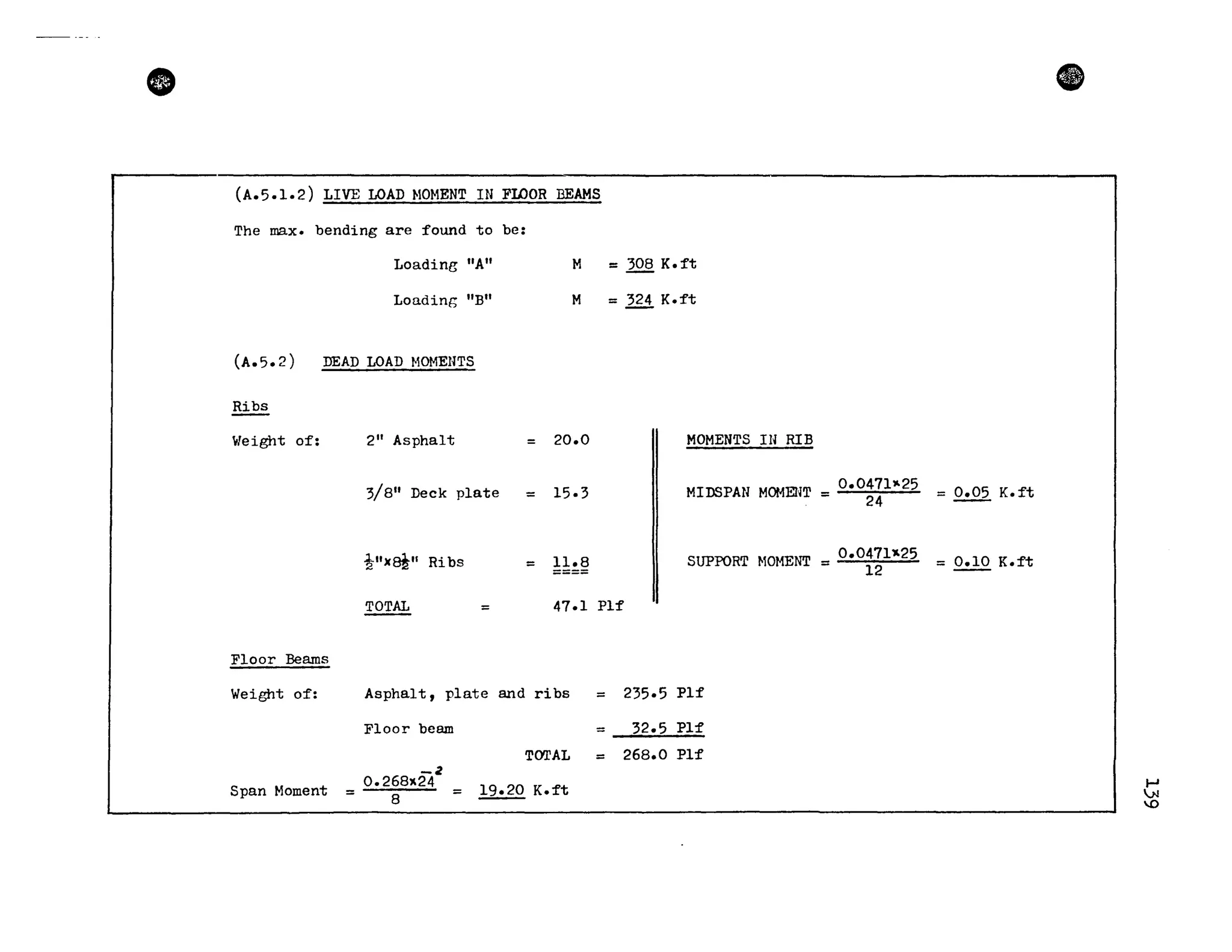

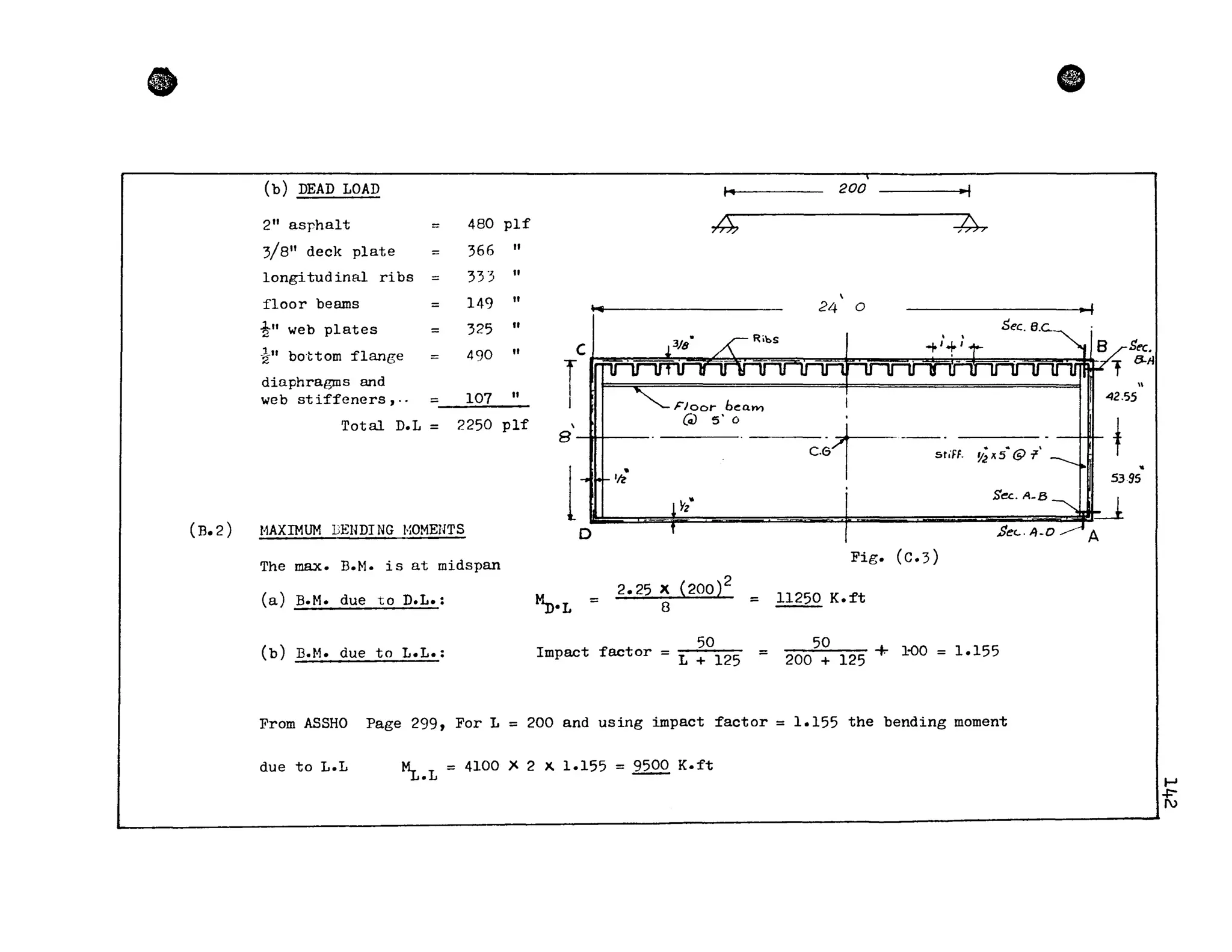

DESIGN BENDING M(l·1EUT M = MD•L + ~.L = 11250 + 9500 =20750 K.ft

(B.3) MAXIMUM· SHEARING FORCE:

The max. S.F. is at the supports

(a) Hax. S. ]t'. due ta D.L. sn.L 2.25~200 = 225 KIP

2 -

(b) Max. S.P. due ta L.L.

,

(See ASSHO page 299), for span = 200 and

impact factor = 1.155 SL.L = 90 J( 2 )( 1.155 = 205 KIP

Design shearing force for each web = 22S:205 = 215 KIP

(B.4) SECTION PROfi~RTIES

Area of the section = 446 in

2

Distance from top f1ange ta C.G. of section

Distance from bottom f1ange ta C.G. of section

Homcnt of inertia of the section

= 42.55 in )

= 53.95 in ~

= 839300 in

4

(See Fig. C.3)

e

1-'

~](https://image.slidesharecdn.com/torsionalbehaviourofsinglecellboxgirderbridges-140613171733-phpapp01/75/Torsional-behaviour-of-single-cell-box-girder-bridges-160-2048.jpg)