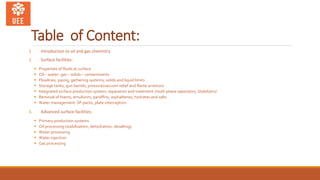

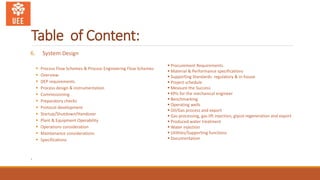

This document outlines the table of contents for a course on oil and gas chemistry and production. It covers topics such as surface facilities, offshore and onshore production systems, static and rotating equipment, cargo properties, and safety and risk management. Specific topics include multi-phase separation, water treatment, gas processing, pipeline infrastructure, storage tanks, pumps and compressors, properties of hydrocarbon cargos, fires and explosions, and risk assessment techniques. The course provides an overview of the key elements of oil and gas production facilities and operations.