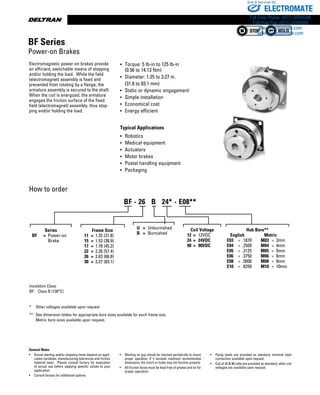

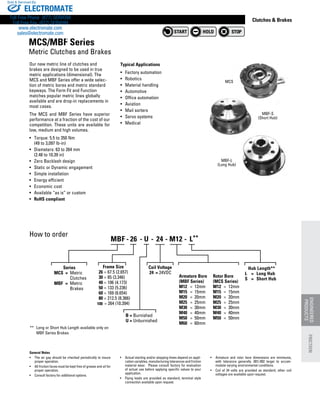

Thomson is a leading provider of linear motion technologies including clutches and brakes. The document discusses Thomson's broad portfolio of standard and custom mechanical motion solutions, and their ability to help customers identify optimal solutions balancing performance, life, and cost. It encourages contacting Thomson early in the design process to leverage their application experience and integrated control and motion technologies.