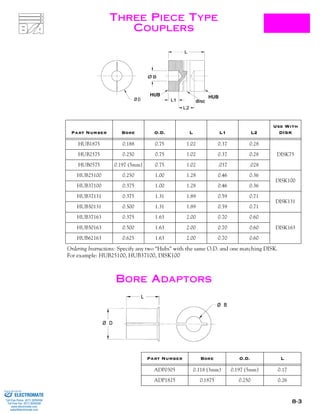

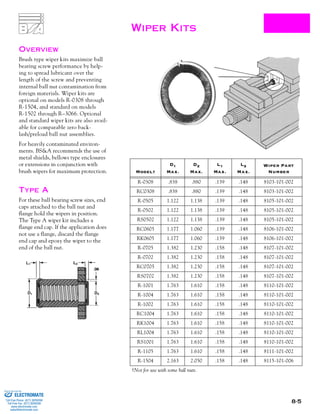

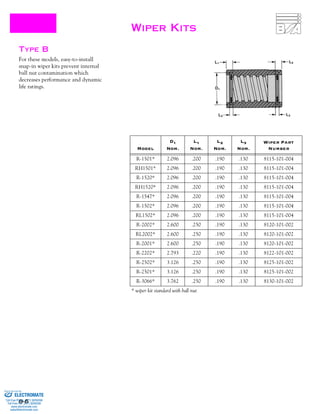

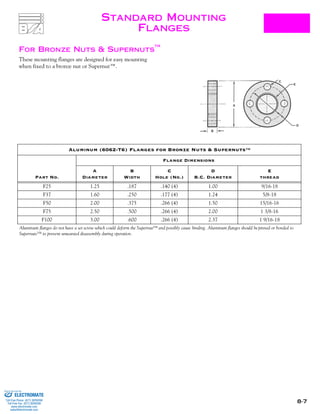

The document describes various accessories for ball screw assemblies, including flexible couplings, three-piece couplers, grease options, wiper kits, and standard mounting flanges. It provides details on part numbers, specifications, and applications for each type of accessory. Flexible couplings come in various sizes and materials to allow for misalignment. Grease options include specialized gels for different temperature ranges and environments. Wiper kits help spread lubricant and prevent contamination. Mounting flanges are designed for easy installation on bronze nuts and supenuts.