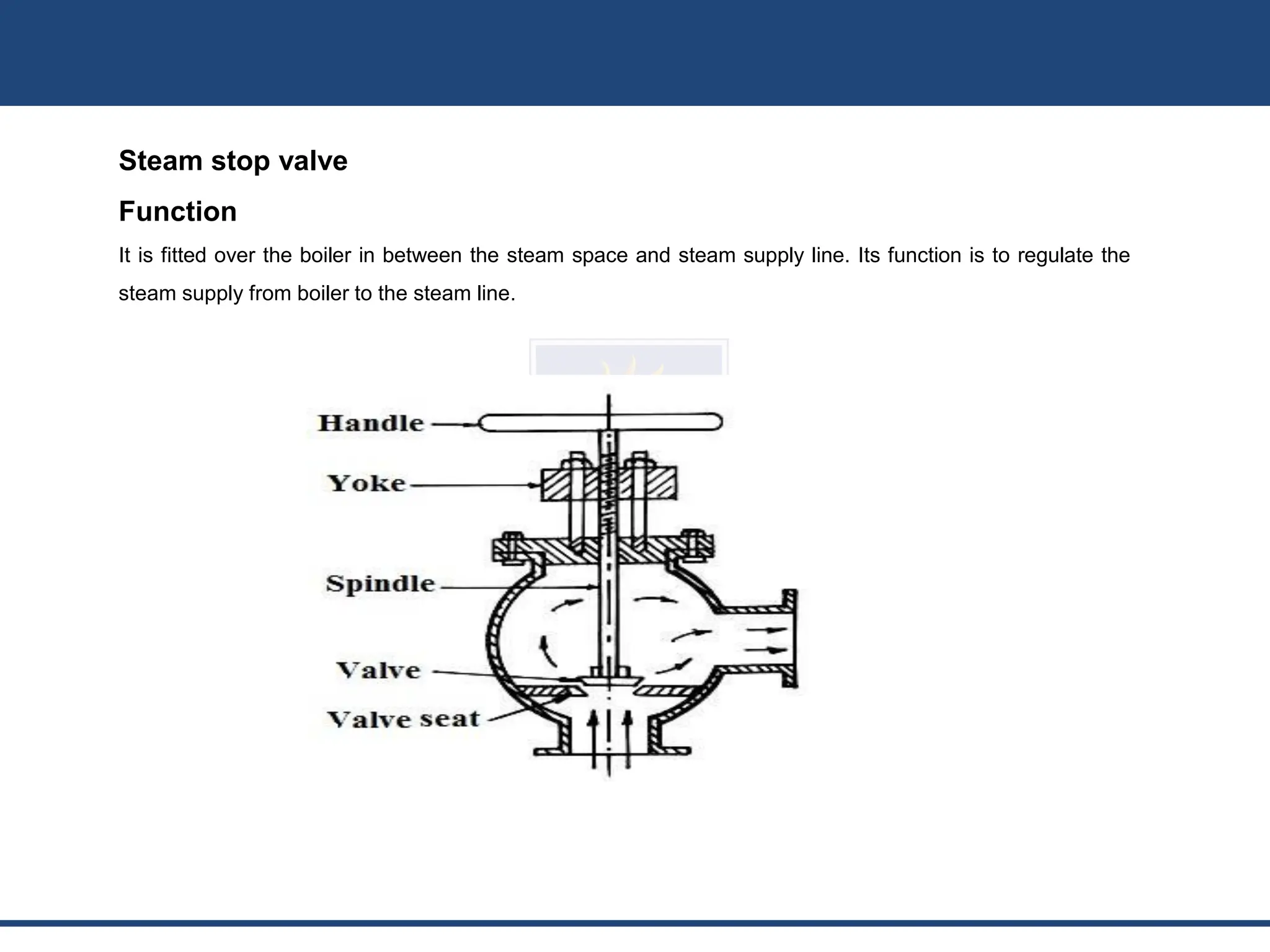

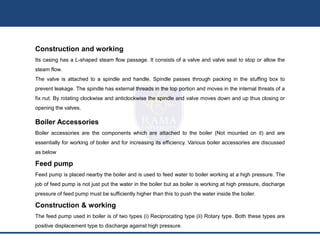

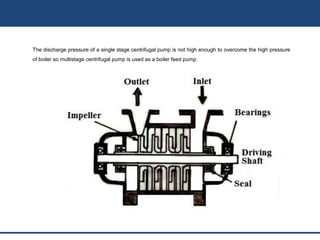

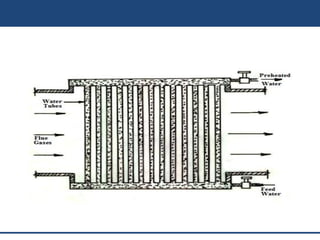

The document discusses the function and construction of a steam stop valve, which regulates steam supply between the boiler and steam line. It also covers boiler accessories, such as feed pumps and economizers, explaining their importance in increasing boiler efficiency and operational effectiveness. Feed pumps, categorized as reciprocating and rotary types, are critical for maintaining high discharge pressure, while economizers serve to recover heat from flue gases for preheating feed water.