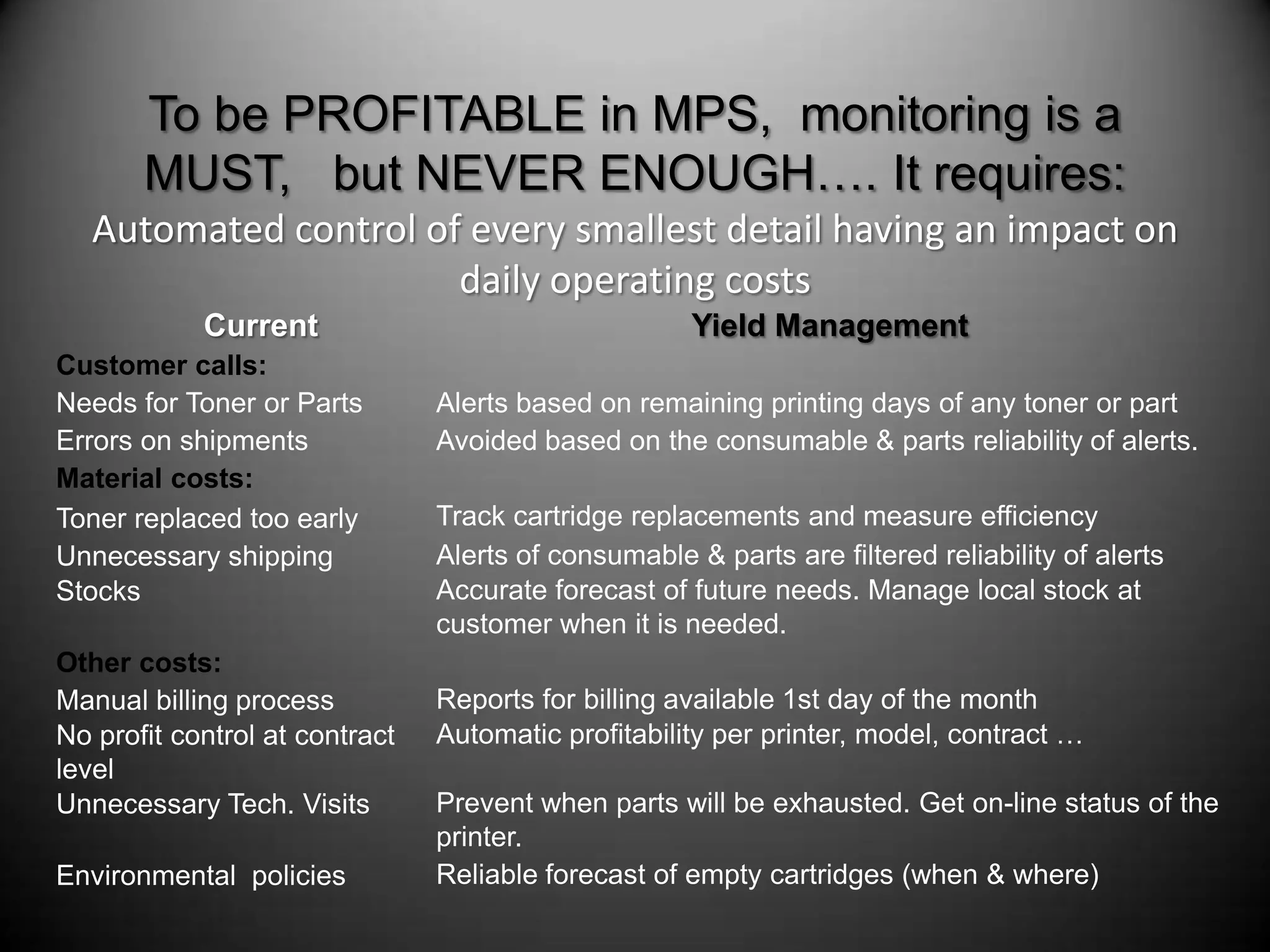

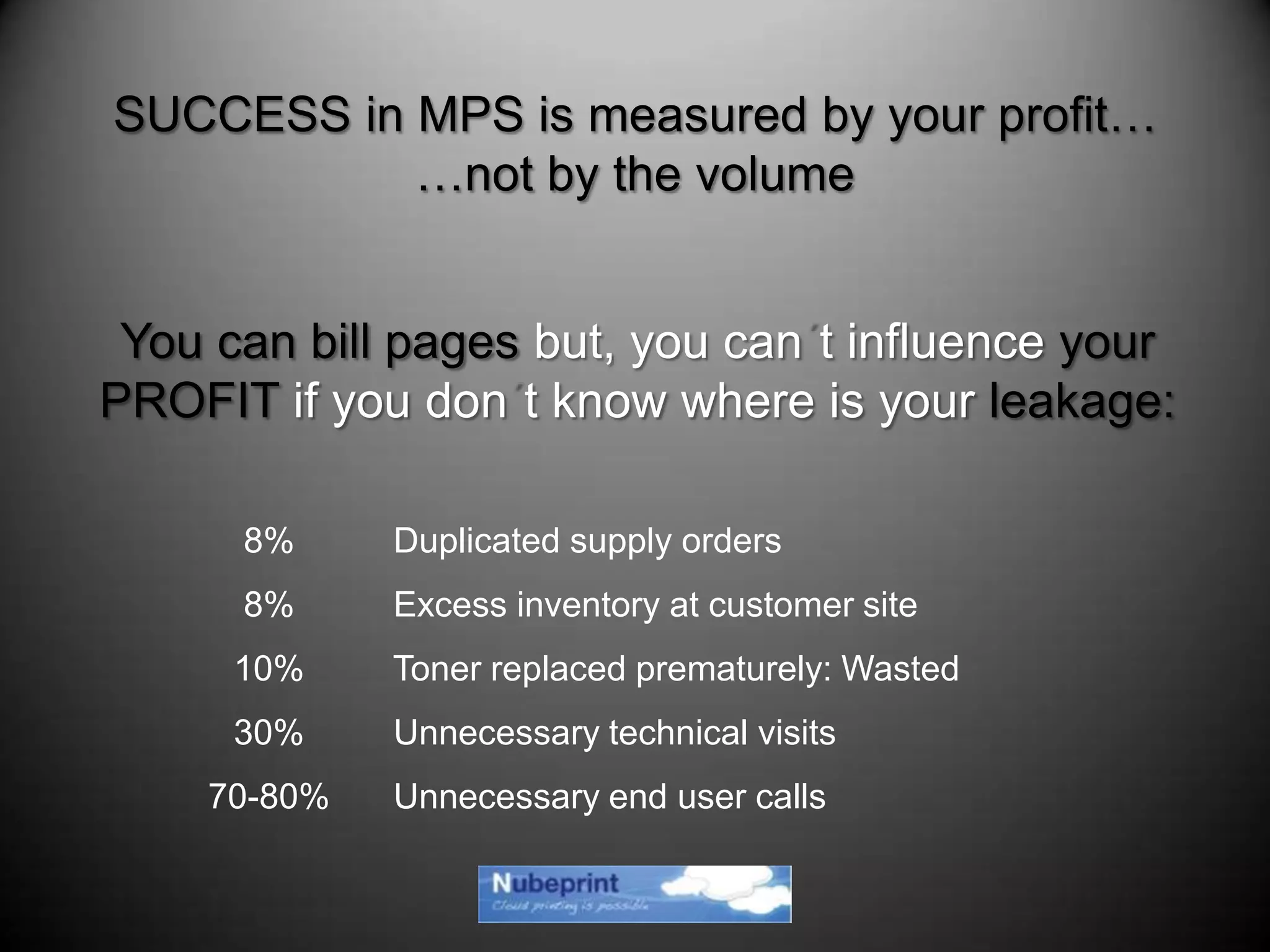

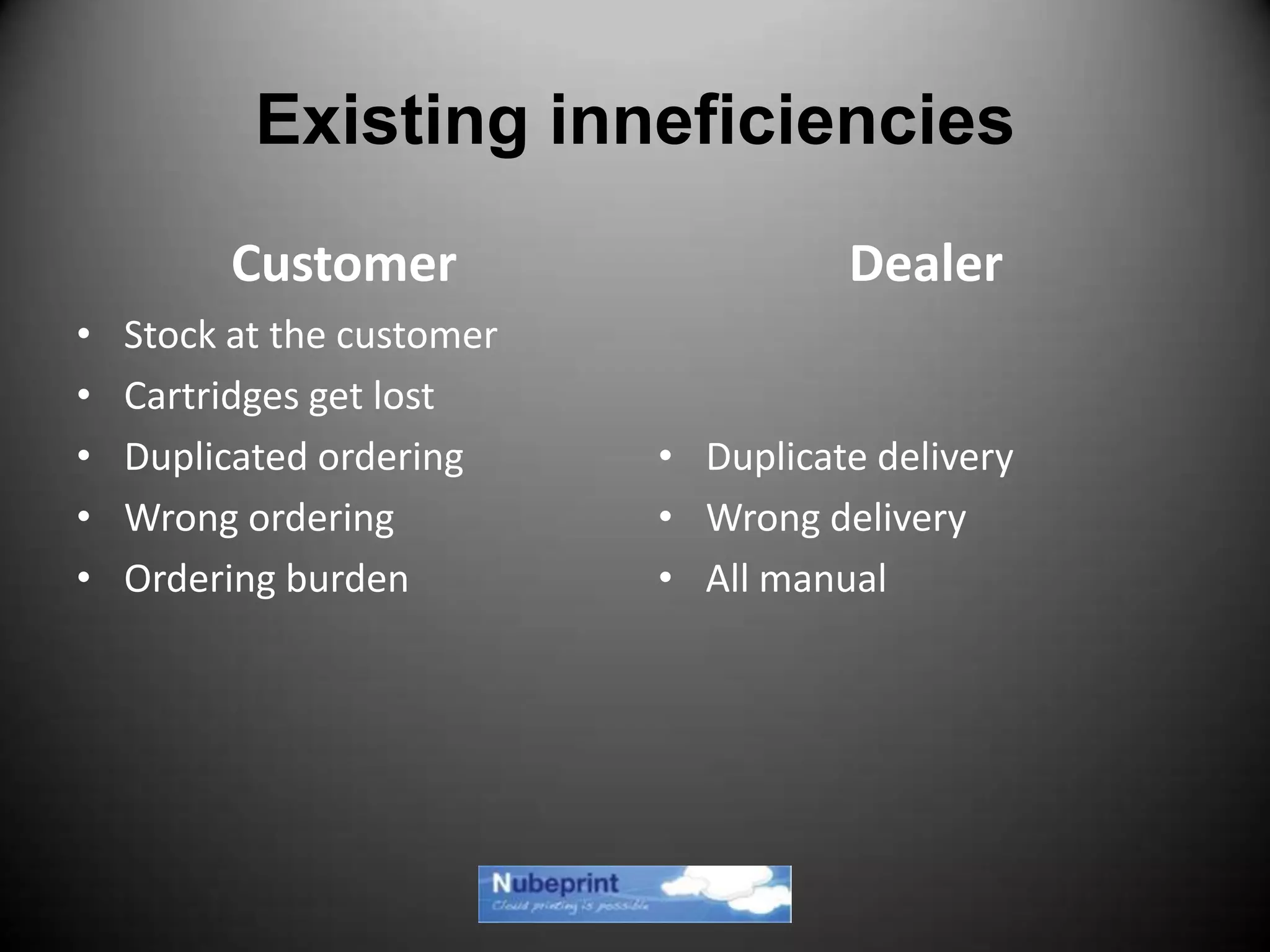

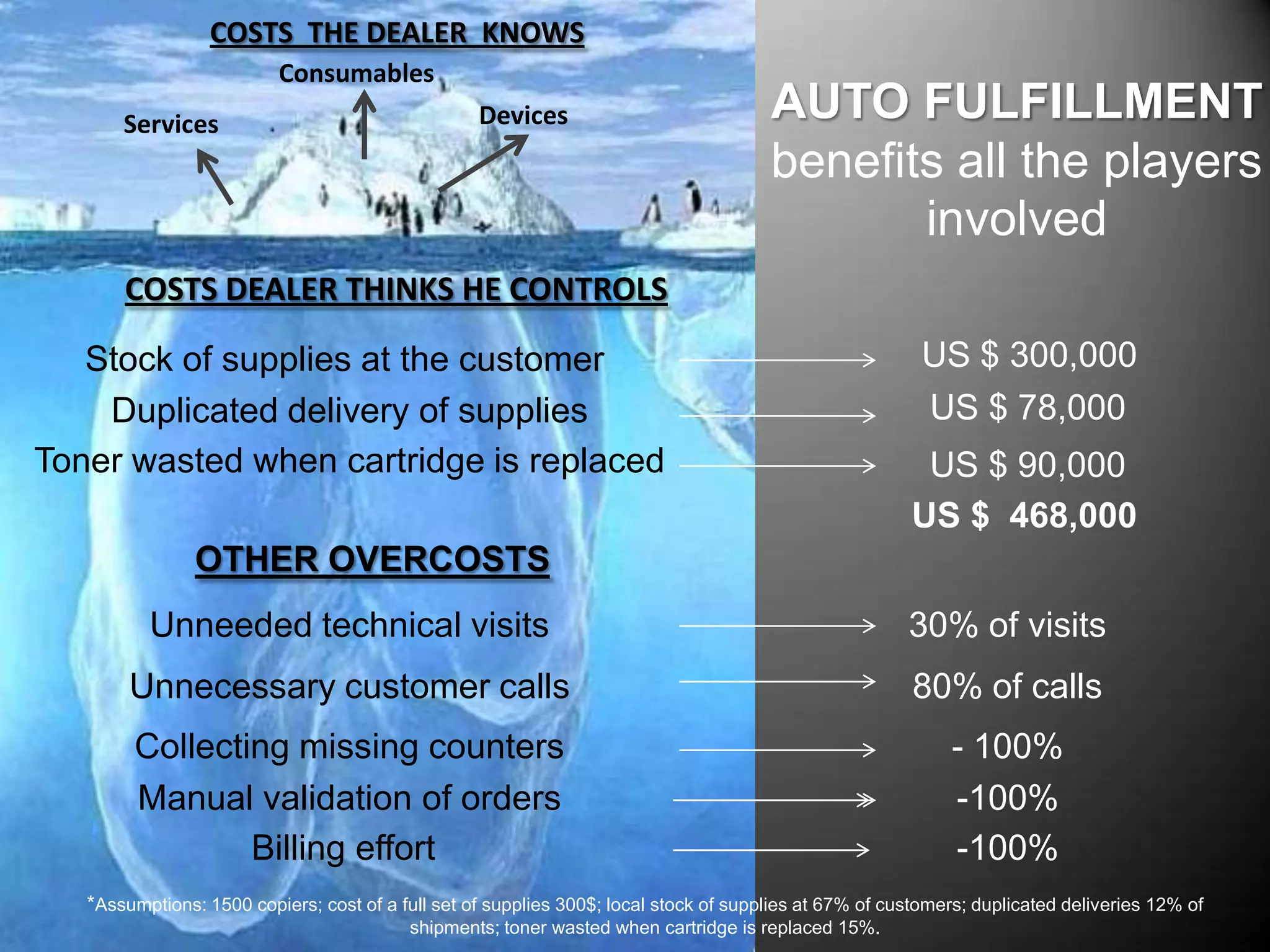

Nubeprint is a technology company focused on cloud and SaaS solutions with offices in Europe and the US. It has several technology pillars including being the 1st to patent DCA in 2000. The document discusses Nubeprint's solutions for managing printers and MPS contracts, including auto-fulfillment which can eliminate inefficiencies for both customers and dealers. Auto-fulfillment allows tracking of supply usage and automated ordering to reduce costs from things like premature cartridge replacements and excess inventory.

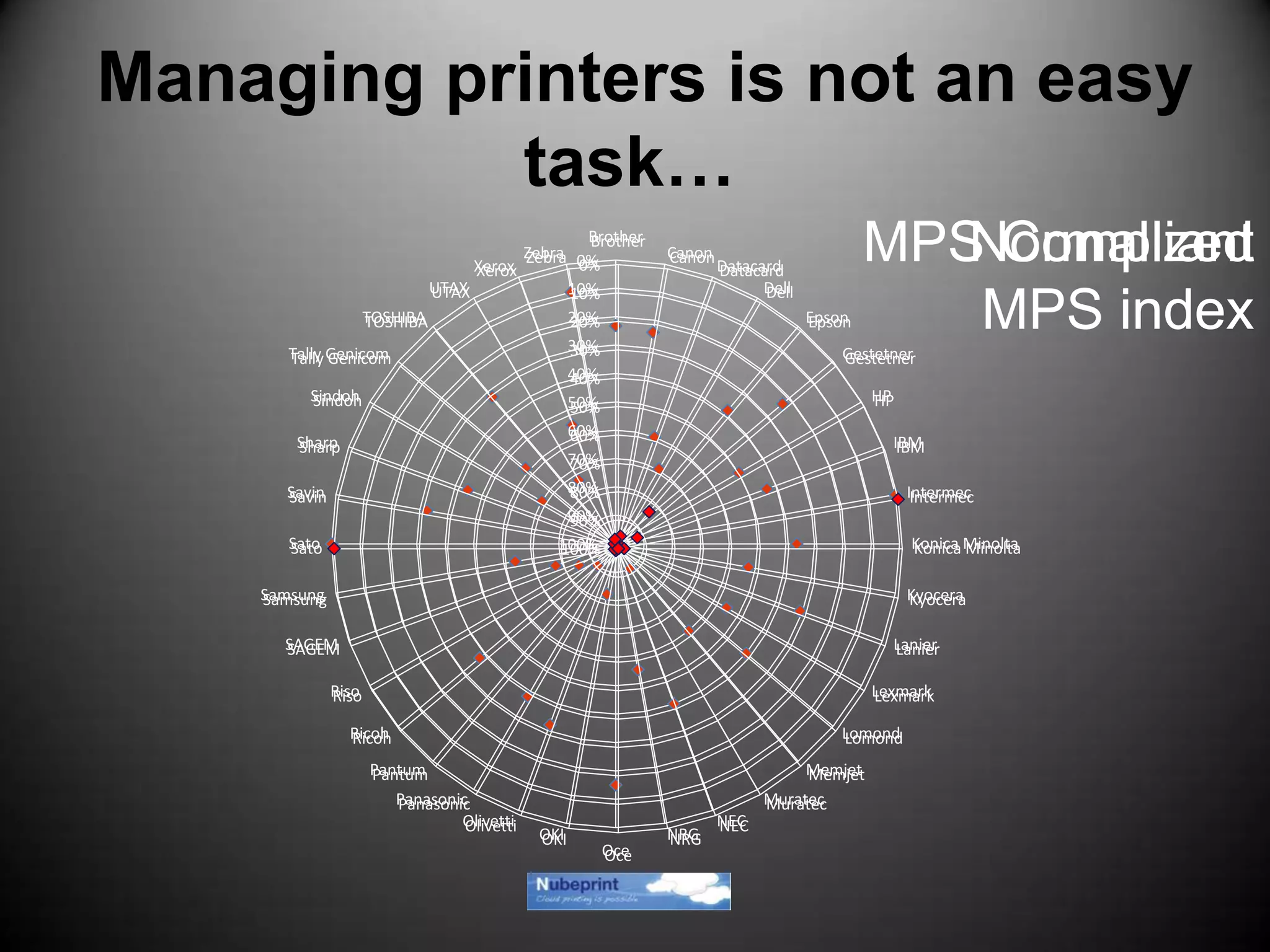

![Managing printers is not an easy

task…

FULL MPS

34%

[CATEGORY NAME]

[PERCENTAGE]

MEDIUM ISSUE

28%

MAJOR ISSUE

26%

Not Compliant

4%

MPS Compliance (% of models analyzed)

FULL MPS

MINOR ISSUE

MEDIUM ISSUE

MAJOR ISSUE

Not Compliant

Source: Nubeprint MPS Compliance Report Jan 2014](https://image.slidesharecdn.com/thechallengeinmps-140321024821-phpapp02/75/The-challenge-in-MPS-10-2048.jpg)