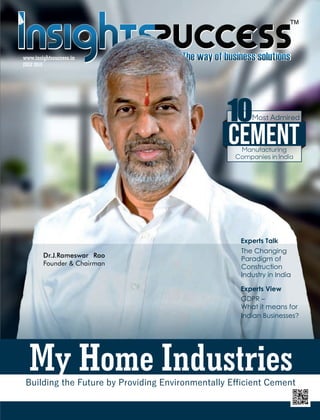

The 10 most admired cement manufacturing companies in india

- 1. JULY 2018 www.insightssuccess.in GDPR – What it means for Indian Businesses? My Home IndustriesBuilding the Future by Providing Environmentally Efficient Cement Dr.J.Rameswar Rao Founder & Chairman Cement 1010Most Admired Manufacturing Companies in India Experts View Experts Talk The Changing Paradigm of Construction Industry in India

- 4. Editorial he cement industry in the country has undergone a major Tchange as several companies in the sector are focusing on building global capacities, modernizing and augmenting efficiencies of plants and restructuring their businesses to keep pace with growing competition. Although infrastructure developments like the construction of roads, flyovers and highways and metro projects, will increase the demand for cement, it is the housing development sector that will take up the lion’s share when it comes to the consumption of cement. There is a total of 188 large cement plants which together contribute 97 percent of the total installed capacity in the country and another 365 small plants contribute to the rest. The housing sector is the key demand driver for the cement industry and accounts for about 67 percent of the total demand. The quantity of cement produced in India is to the tune of 350 million tonnes per year. It is expected to become 550 million tonnes by the financial year 2020. The demand for cement is steadily on the rise owing to rapid urbanization and construction activities. Playing a vital role in the socio-economic development of the nation cement is one of the vital components for infrastructural facilities and public welfare constructions. It has been a major contributor to the modernization of human civilization. The massive urban infrastructure that one sees today across the world would have been far from imagination without cement. Not only attracting global players, the Cement industry is also paving the way for new mergers and acquisitions (M&A). Industry giants namely Unthatch Cement, Birla Corporation Ltd and Delia Bharat have acquired Jaypee Cement, Odisha Cement and Reliance Cement, respectively. Further, M&As are expected to happen between steel and cement companies. Evolving significantly during the last two decades the cement industry is going through all the phases of a typical cyclical growth process. The industry went into a consolidation phase after a period of over- supply and a phase of massive capacity additions. Due to the sturdy economic growth and infrastructure development, the demand for cement has gone up. A further addition to capacity is coming up to cater to the increasing demand for cement. The per capita consumption of cement in India is 125 kg which is only about a third of the world average. It pointed out the growth potential for this industry. The demand for cement is mainly relied upon the level of development and the rate of growth of the economy. The outlook for 2018 is bright, as liquidity in the economy has moved towards normalization, with expectations for early revival and growth in overall consumption across several sectors including construction and building materials. Cement Industry: Paving Way for the New Mergers and Acquisitions Shweta Priyadarshini Shweta Priyadarshini

- 5. Editor-in-Chief Pooja M. Bansal Database Management Prashant Chevale Technology Consultant Swapnil Patil Circulation Manager Vivek Bangade Research Analyst David Business Development Executives Vaishnavi, Divya, Rutuja Contributors Sapana ShindeArt Editor Business Development Manager Akansha Garewal Visualiser Savita Pandav Marketing Manager Dhruv Apte Picture Editor Alex Noel Art & Design Director Amol Kamble Co-designer Karan Gaikwad Managing Editor Shweta Priyadarshani Senior Editor Shraddha Deshpande Bhavithiran Copyright © 2018 Insights Success, All rights reserved. The content and images used in this magazine should not be reproduced or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without prior permission from Insights Success. Reprint rights remain solely with Insights Success. Printed and Published by Insights Success Media and Technology Pvt. Ltd. Corporate Ofces: Insights Success Media Tech LLC 555 Metro Place North, Suite 100, Dublin, OH 43017, United States Phone - (614)-602-1754 Email: info@insightssuccess.com For Subscription: www.insightssuccess.com Insights Success Media and Technology Pvt. Ltd. th Off. No. 513 & 510, 5 Flr., Rainbow Plaza, Shivar Chowk, Pimple Saudagar, Pune, Maharashtra 411017 Phone - India: +91 7410079881/ 82/ 83/ 84/ 85 Email: info@insightssuccess.in For Subscription: www.insightssuccess.in sales@insightssuccess.com July 2018 Follow us on : www.facebook.com/insightssuccess/ https://twitter.com/insightssuccess We are also available on : Cover Price : RS. 150/- Copy Editor Shruti Jambhale

- 6. MY HOME INDUSTRIES BUILDING THE FUTURE BY PROVIDING ENVIRONMENTALLY EFFICIENT CEMENT 08 Contents Cover STORYCover STORYCover STORY Effective Strategies to Develop Healthy Customer Relationships The Changing Paradigm of Construction Industry in India GDPR – What it means for Indian Businesses? Experts View 443422 Experts Talk CRM Strategies

- 7. ArticleArticleArticle New Horizon Shree Cement: Creating Superior Impact by Ensuring Timely & Seamless Delivery 16 Embracing Technology to Innovate Smart Cement for the Future Technological Innovation The Growth of Cement Industry in India Industry Insights 28 An Advanced Revolution in Indian Cement Industry Duraton Cement: Exploring Premium Services beyond Customer Expectations Emami Cement: Ultra-Modern Cement Plant Satisfying the Evolving Needs of Consumers KJS Cement: Improving Quality of Life by Ensuring Safe Infrastructure Vijay Cements: 40 20 26 32 38

- 8. ement is the most important and profitable product in building the material sector. It is predicted that the Cconsumption of cement is going to touch 600 million tonnes by the year 2020, in India. The current and future trends in cement industry exploring enumerate the key business strategies. The Indian cement industry is a market of opportunities with an 8% GDP growth rate, waiting to be tapped. Thus, the increasing growth rate of Indian cement companies are building industry that are adapting new business strategies to complement the higher demand and competition. In the Insights Success Magazine, we have introduced “The 10 Most Admired Cement Manufacturing Companies in India”, who assist businesses to choose their right cement manufacturing companies for the construction. Assessing the versatile scenario perceptions, our magazine has brought into light the companies who have flaunted some excellent Trusted Risk and Compliance Solutions. This examined list will lessen the search for the organizations to have perfect risk and compliance solution providers. In this issue, we have specially featured My Home Industries Private Ltd, as the cover story. It provides all kinds of cement that are environmentally efficient and creates an environment of empowerment. Apart from this, we have chosen Duraton Cement (Asian Fine Cements Pvt. Ltd) It is India’s Most Advanced Cement manufacturing company, is a flagship brand of Asian Fine Cements Pvt. Ltd. who is a leader in supply chain & contract manufacturing services for a variety of industries provides quality services to customers on site. Emami Cement Ltd., which provides the on-site testing of concrete, to ensure the best possible construction practices to consumers. K. J. S. Cement Ltd., which has worked on product up-gradation and developed PRR Technology. Vijay Cements, the company is building a safe infrastructure that is improving the quality of life. Nuvoco Vistas Corp Ltd. is balancing innovative infrastructural solutions with the community. Penna Cement Industries Ltd. is one of the largest privately held cement companies in India, and grown organically by developing in-house expertise and capabilities, across the entire value chain in the cement industry. Star Cement, The largest cement manufacturer in north east India that ensures easy availability of high-grade limestone. Wonder Cement Ltd. is a cutting-edge cement manufacturing company with an ambition to establish itself as a leading player in the industry. We have also introduced Shree Cement Ltd. as a special profile, which focuses on providing customer-centric cements products and services by ensuring timely and seamless delivery of the product. We have encompassed Expert’s View on ‘GDPR - What it means for Indian Businesses’, by Seema Jhingan, the a senior Partner and Co-founder of LexCounsel, Law Offices; and Expert’s Talk on ‘The Changing Paradigm of Construction Industry in India’, by G. Vamsi Krishna, the Joint Managing Director, at Visaka Industries. Also, we have included “Embracing Technology to Innovate Smart Cement for the Future”, and “The Growth of Cement Industry in India” scripted by our in-house editors in the delightful pages of this magazine. So, flip the pages of our magazine and treat yourself with the innovations in the Risk and Compliance Industry! The Incredible Indian Cement Industry: Adapting New Business Strategies

- 10. MY HOME INDUSTRIESMY HOME INDUSTRIES Building The Future By Providing Environmentally Efcient Cement India is one of the world’s most vibrant markets for building and infrastructure at the moment. Huge sums are being poured into a comprehensive range of construction projects, from major infrastructure upgrades, sweeping residential housing programs and wholesale city building. As per global economists and development initiations India is among the top five largest economies in the world. One which forms the foundation of any building, whether it is an architectural wonder or a residential place, is cement. Among the sectors that have played a crucial rule in rejuvenating the economy is the cement industry which has vital relevance for housing and infrastructure like road highways and industrial civil work. My Home Industries Private Ltd (MHIPL) is one of the largest cement producers in South India registering fast growth during last 20 years, rising from 0.2 million tons PA to 10 million tons PA. The company has ambitious plans further to expand its capacity in the near future. A joint venture with CRH plc, Ireland, My Home Industries Private Limited has built a formidable reputation by winning prestigious national awards for quality, reliability, and energy efficiency. The quality parameters followed by My Home Industries Private Limited have led the company being awarded with ISO 9001- Cover Story

- 12. 2015, ISO 14001-2015, OHSAS 18001-2007 certifications, India’s Most Promising Brand for the Year 2015, Best Cement Company of the year 2017, Golden Peacock Award for Sustainability 2016, Greenco Cementech 2017 and many more. My Home Industries Pvt. Ltd is part of a leading 4000cr business conglomerate- My Home Group headquartered at Hyderabad. Their flagship product the world-class Maha Cement, is a renowned name in the industry. To suit various construction needs of different geographies, Maha Cement offers variety of products suiting all types of requirement. My Home Industries produces OPC 43 & 53 grades and premium blended cement products PPC, PSC & CC. All the products surpass the standards set by the Bureau of Indian Standards (BIS). Maha Cement has achieved phenomenal success in the states of Andhra Pradesh, Telangana, Tamil Nadu, Karnataka, Kerala and Odisha and also has presence in the states of Maharashtra, Bihar, Chhattisgarh and West Bengal. The company has also forayed into international markets by supplying cement and clinker to Sri Lanka and Bangladesh. The Visionary Dr.J.Rameswar Rao, Founder-Chairman of My Home Group of Companies is a well-known industrialist, humanitarian, and philanthropist. After completion of a 4-year homeopathy course in 1978, he decided to set up

- 13. his own private practice at Hyderabad. Dr. Rao in pursuit of his passion later ventured into real estate by starting My Home Constructions in the year 1981, and by his vision started My Home Industries (Maha Cement) in the year 1998, and further My Home Power (presently Abja Power) in 2000. Today the Group is valued over INR 4,000 crores. The core of his business philosophy, “A firm’s accounted profit does not reflect its true business performance,” may sound baffling to many but then Dr. Rao, blessed with the midas touch, is no ordinary entrepreneur. After firmly establishing himself first as a realtor and then as a developer who set up My Home Constructions Private Limited in 1981. My Home constructions to date have built projects of 10.5 million sq.ft. area, 14.5 million sq.ft. under construction and tens of millions sq. ft. under planning stage. Being a medical doctor himself, Dr.Rao is not oblivious to the health needs of the poor and the marginalized, especially in rural areas inspired and guided by the towering spiritual personality of Sri Tridandi Chinna Jeeyar Swamiji, Dr.Rao helped setup a homeopathic college in Shamshabad, near Hyderabad with a turnout of 100 students per year. Alongside the college an 80 bed hospital was setup to cater to the needs of the poo in the neighboring village, the hospital is equipped with state–of–the–art facilities and dispenses holistic medicine staffed by eminent surgeons and physicians. The foregoing is a brief narrative about My Home Industries and the all-round achievement of its presiding genius Dr. J. Rameswar Rao who has approved in addition several other institutions to create the void in the cultural and spiritual space of Hyderabad. His personality is unique and his mission boundless. An Environmentally Efficient Cement Waste Management - MHIPL as part of the waste management drive for resource conservation, environmentally efficient and sustainable development has initiated use of alternate fuel in its cement klins. MHIPL has installed and commissioned alternate fuel handling and firing system in April’12 with a capital expenditure of about Rs.12 crores and started utilizing liquid organic hazardous waste generated from pharmaceutical industries as alternate fuel in cement klins.

- 14. The consistency in quality is a big question since the receipts are from different pharmaceutical companies with a wide range of solvents and products. Hence continuous monitoring (pre testing of liquid wastes) and data collection is of utmost importance for effective usage of these wastes without compromise on safety, environment operations, and quality of clinker. MHIPL’s alternate fuel consumption (TSR) has increased from 0.9% to 2.5% over years with a target to reach 3% for FY 18-19. MHIPL initiatives for waste management ensure environmental benefits include conservation of fossil fuel, waste to energy, reduction of carbon footprints, HW waste disposal in environmental sound manager etc. Superior Manufacturing Process Maha Cement gives the modern builder the desired strength and superior quality. Today Maha Cement has four ISO 9001:2015 certified factories with one of the most efficient production parameters in Asia located at Mellacheruvu in Telangana, Yanakandala & Mulkalapalli in Andhra Pradesh and Tuticorin in Tamil Nadu. Efficient Logistic Network Maha Cement through its Group Company arranges to transport cement and reaches their customers through an efficient and dedicated fleet of more than 1200+ trucks & bulkers that guarantee quick, efficient and prompt delivery of Maha Cement to its 5000+ dealer base. Captive Power Plants At present, My Home Industries has two coal-based CPPs with a total capacity of 75 MW at its Mellacheruvu Cement Plant and one solar power plant with a capacity of 1.2MW at SJCPL. Of this, the first CPP of 15 MW was installed in March, 2006; and the second CPP with a capacity of 60 MW in March 2012. After meeting entire power requirements of the plants, the surplus power of about 25 MW is sold through Indian Energy Exchange Limited. Mellacheruvu Plant also has a 12.5MW Waste heat recovery based power plant which was set up at a cost approx. Rs. 100 crore. It also helps the company to reduce 57,638 tonnes of CO per annum.2 My Home Social Initiatives “Children are the innovators of tomorrow,” says Dr. Rao.

- 15. child is “Build to Succeed”. The dream did not stop here. In fact the school has been an inspiration to envisage a chain of international institutes which are in the pipeline, bringing home the intent of creating an ideal environment for India’s next generation who will shine as global citizens. Future Roadmap At MHIPL, the vision is to continue to develop solutions that “Make Living Better”, be it through Construction of “World Class” Living and Working Spaces or illuminating households through the generation of power or manufacturing products like quality cement to build dream homes or enriching lives through imparting quality education. MHIPL’s foray into education is empowered by a vision of providing children a platform on which they can build their future. My Home Educational Society was incorporated to make this vision a working reality. Along with Dr. Rao’s commitment to delivering value at every step, the company has achieved a string of milestones. The year 1991 saw the birth of Little Scholar School in Hyderabad. The school in an articulation of the Group’s business purpose “Make Living Better”. It offers an ideal balance of quality education at an affordable price thus bringing education within the reach of many. Meru International School is the latest venture of the Group. It has been built on the legacy of quality, integrity, and trust with every project undertaken. It was founded on the belief that every

- 16. Read it FirstRead it First Subscribe today Global Subscription Address : Country :City : State : Zip : Date : CORPORATE OFFICE Name : Telephone : Email : Insights Success Media and Technology Pvt. Ltd. Off No. 513 & 510, 5th Flr, Rainbow Plaza, Shivar Chowk, Pimple Saudagar, Pune, Maharashtra 411017. Phone - India: 020- 7410079881/ 82/ 83/ 84/ 85 USA: 302-319-9947 Email: info@insightssuccess.in 1 Year.......... Rs. 2500(12 Issues) .... 6 Months ..... (06 Issues) .... Rs. 1300 3 Months .... (03 Issues) .... Rs. 700 1 Month ...... (01 Issue) ..... Rs. 250 Yes I would like to subscribe to Insights Success Magazine. Cheque should be drawn in favour of : INSIGHTS SUCCESS MEDIA AND TECH PVT. LTD.

- 17. Management BriefCompany Name Satish Sharma CEO Vivek Chawla WTD & CEO Emami Cement provides the on-site testing of concrete, to ensure the best possible construction practices to consumers. K. J. S. Cement Ltd kjscement.com Medha Ahluwalia, Executive Director Pawan Kumaar Ahluwalia, Vice Chairman & Group MD My Home Industries Private Limited myhomeindustries.com Dr.J.Rameswar Rao Founder-Chairman My Home Industries Private Ltd provides all kinds of cement that are environmentally efficient and creates an environment of empowerment. Penna Cement Industries Ltd pennacement.com P Prathap Reddy Chairman & Managing Director Penna Cement is one of the largest privately held cement companies in India, and grown organically by developing in- house expertise and capabilities, across the entire value chain in the cement industry. Shree Cement Ltd shreecement.in The company focuses on providing customer-centric cement products and services by ensuring timely and seamless delivery of the product. Star Cement starcement.co.in Shri Sajjan Bhajanka Chairman The largest cement manufacturer in north east India. The plant is spread across 200 hectares of land in the idyllic town of Lumshnong, a strategic location at Meghalaya that ensures easy availability of high-grade limestone. Vijay Cements vijaycements.com - Wonder Cement Ltd wondercement.com Ashok Patni Chairman Wonder Cement is a cutting-edge cement manufacturing company with an ambition to establish itself as a leading player in the industry. KJS Cement has worked on product up-gradation and developed PRR Technology, which ensures effective particle size distribution in cement and optimum hydration of reactive fly- ash in applications; as a result KJS Cement makes Natural Dense Concrete. The company is building a safe infrastructure that is improving the quality of life. Nuvoco Vistas Corp Ltd nuvoco.in Maneesh Agrawal CFO It balance innovative infrasturctural solutions with the community. Hari Mohan Bangur Managing Director Emami Cement Ltd emamicement.com Duraton Cement (Asian Fine Cements Pvt. Ltd) asiancements.com India’s Most Advanced Cement manufacturing company, is a flagship brand of Duraton Cement (Asian Fine Cements Pvt. Ltd) who is a leader in supply chain & contract manufacturing services for a variety of industries provides quality services to customers on site.

- 18. Creating Superior Impact by Ensuring Timely & Seamless Delivery Shree Cement: Hari Mohan Bangur Managing Director Shree believe that integration of responsible environmental practices into business operations can add value both in terms of the environmental capital and its financial profitability ‘ ‘ July 2018|16

- 19. Established in 1979, Shree Cement is among the top three cement manufacturing companies in India in terms of production capacity. Shree is also among the top 100 listed companies in terms of market capitalization. It has earned the recognition of being one of the most efficient and sustainable organizations. It pursues multi-brand portfolio strategy, which consists of Shree Jung Rodhak Cement, Bangur Cement, and Rockstrong Cement. With annual cement manufacturing capacity of 37.90 million tons per annum these brands are enjoying the largest market share in North India market. Also, with total power capacity of 646 MW including 126 MW of Waste Heat Recovery (which is highest in global cement industry excluding China), Shree is active in power generation business. Shree cement has recently acquired Union Cement Company, UAE. This marks SCL’s first step outside India, towards becoming a global entity. UCC is one of the leading cement manufacturers in the UAE, with cement manufacturing capacity of 4.00 MTPA. With this acquisition, the total cement capacity of Shree has increased from 37.9 MTPA to 41.9 MTPA. SCL’s Influential Leader The Managing Director, H. M. Bangur, is a Chemical Engineer from IIT, Mumbai. He brings to the Board technical insights, which is driving force of the technical excellence achieved by the Company. He is responsible for overall management of the Company and provides strategic direction for business strategies, growth and expansion of business along-with taking all other policy decisions having significant business and financial implications. Shri Bangur was the president of Cement Manufacturers’ Association (CMA) from 2007 to 2009. He is Ex- executive member of FICCI. He is President of Rajasthan Foundation, Kolkata Chapter and is serving as a Chairman of “The Bengal” (an NGO market share. Further to ensure timely and seamless delivery of the products, its marketing and logistic teams work on minimizing the lead time of product movement from factories to the market. Waving the flag of Outstanding Achievements SCL has received various national and international awards throughout its remarkable thirty nine years of journey. The international awards are particularly received in the field of environment & sustainability from Green organization, London, World economic forum etc. While, national awards in the field of environment, sustainability, energy, social upliftment, HR excellence, quality excellence from Indian Chamber of Commerce, BEE, NCCBM, Govt. of Rajasthan, Society of Human Resource Management, FICCI etc. The UK based benchmarking firm, Whitehopleman, has also recognized the SCL as the World's first 5-Star rated cement company. Further, it has also been awarded ‘India Green Business Leader Award’ by Emergent Venture. Journey towards Success Shree’s family culture is the most important contributing factor towards the growth of the company. Globally, organizations are facing challenges in translating their strengths in terms of ‘Man, Material, and Machine’. Cement players are ramping-up their cement capacities by the way of green- field and brown-field expansions. However, government’s focus on rural housing and infrastructure development is likely to boost the cement demand. It has been extending its cement capacity regularly over the years. actively engaged with Kolkata Police) also. Coming to the awards & achievements, Bangur has achieved various prestigious awards like “Ernst & Young Entrepreneur of the Year Award 2016”, “Forbes Leadership Award 2017”, etc. Providing Customer-Centric Products, Services and Building Vital Relationship Marketing strategy at Shree is based on a qualitative and quantitative customer segmentation and devising product offering strategy accordingly. Shree has been forerunner in formulating contrarian strategies and keep on adjusting to diverse consumer requirements. Company has adopted multiple brands strategy catering to specific segments of customers in contrast to prevailing practice of single brand which assumed customer behaviour as homogeneous. Such a purposeful approach gives Shree the much required efficiencies, better execution capabilities and more accountability. Shree’s relentless focus on providing customer-centric products and services has made it market leader in north Indian states. Building win-win relationship is vital at Shree. This can be illustrated with our unique `Hub and Spoke’ model in the Indian Cement Industry which started a trend of sorts. The Company has set up its Grinding Units nearer to the key cement consuming markets with an aim to serve the customers better and faster. This resulted in a win-win situation for both the customers as well the company. The customers benefited by a faster turnaround time, minimal inventory and smaller order size. The company benefitted by faster acceptance of its products and ability to tap larger ‘ New Horizon Shree Cement is the first Indian cement company to release Corporate Sustainability Report in the year 2004-05 July 2018| 17

- 20. Shree has developed strong Research and Development capability at Beawar and Ras. These R&D centres are recognized by Department of Science and Industrial Research (DSIR), Government of India. SCL R&D Centers have expertise in multiple aspects of cement manufacturing which combines chemistry, geology, environment, mechanical, instrumentation, energy management and building material mechanics. Shree continuously focuses on improving resource efficiency in clinker and cement production by optimizing energy usage, utilizing waste in production processes and targeting higher alternative fuel & material usage. In the process, we also endeavor to minimize its impacts on climate, water and air. Shree believe that integration of responsible environmental practices into business operations can add value both in terms of the environmental capital and its financial profitability. At Shree, the team of experts have identified several alternate raw materials such as fly ash, bed ash, synthetic gypsum and lead zinc slag, among others, to replace conventional raw materials. Their efforts resulted in replacement of 23.5 % of conventional materials with alternate materials. Shree is Co-processing hazardous and non- hazardous waste where a significant amount of energy is being recovered. Shree has also installed Air Cooled Condensers in place of Water Cooled Condensors in all its Power Plants, which involved substantial capital investment and also reduced the water consumption up to 90%. Shree strive towards minimising the energy consumption and also focus on better energy efficiency. The company is proud to have over achieved its targets for PAT cycle I and received 1,58,257 ESCerts for their Beawar and Ras sites combined. Managing Director, H. M. Bangur expressed that “SCL believes that just because we can pay; we must not exploit natural resources”. Further, he added –“One of the challenges that we are facing currently is that how we can use alternate energy in an economical way for cement production? We want to change our energy mixture”. The use of renewable energy will not only save direct GHG emissions but also facilitate for a permanent solution to depleting natural resources. Digitalized System Providing Game- Changing Experiences SCL believes in Total Prosperity Management. The company has a digitalized system for whole internal and external process to bring transparency, save time and reduce carbon footprint. The entire cradle to gate and gate to source operations such as transportation of cement and other raw material, selling of scraps undergoes computerized e-bidding. This pays to the clients by allowing- saving of time and money, hassle-free paper processing, fair and competitive environment, environment- friendly process. Customers, these days, expect to be more delighted with an experience rather than the product or service attributes and features, as they get more and more ‘on-time, on-demand’ services and products in this busy world. Thus, the markets today are trying to find a solution to satisfy ever-changing customer preferences. As a business, instead of chasing all, the company focuses more efficiently by concentrating on few top growth opportunities available at a given time. A strong focus on specific customer segments and offering products accordingly has ensured better execution and more accountability, which apparently created a better and bigger impact on the organization. Marching towards Improving Quality Life Educating and spreading awareness of the correct methodology of using cement not only benefit the customers in terms of improving the quality and life of the construction; but also helps the company to gain their valuable trust. With this objective, the company has set-up specialized teams of technical experts who visit construction sites to train masons and owners about the right way of using cement. At Shree, it sees CSR not a something externally imposed but it is internally driven Samaj Seva. The company is what it is because of its integrated model of sustainability, which allows us to undertake the initiatives towards green world and care for community as integral part of its operations. It is very natural that the company want its stakeholders to grow and prosper along with them. Futuristic Business Approach From the business point of view, the Shree Cement is looking to create a market share across the country, as it is already has a substantial presence in North India. As only if it is able to create a country-wide presence, it will be able to capitalize on the benefits of the growing economy of India. SCL ventured into the wind energy and undertook a project of 21 MW Wind Power Plant at district Koppal of Karnataka. The wind power generated would be utilised captively by the company’s cement plant being set up in Karnataka. We create prosperity & happiness for all stakeholders through innovation & sustainable practices ‘ ‘ July 2018|18

- 22. Creative Visionary Leader Mr. Satish Sharma is the CEO of Duraton Cement, Asian Fine Cements Pvt Ltd. He had been a part of senior management team in the top cement companies of India. He has been an iconic leader with proven record of operational leadership, strategy development, customer building, and team building prowess, relationship management skills, and sales generation. He has been acknowledged for his stints in establishing one of the top cement brands in North East market, making it one of the highest selling brands in that region . He is leading the plant operations and sales of Duraton Cement in North India. His solid experience comes with a strong belief and is pivotal in leapfrogging DURATON Brand to next level of the business growth. Under his executive leadership, the company is embarking upon a very exciting new phase of journey of growth and development. With an unerring thirty plus years of commitment, a deep passion & an extensive understanding of the industry, it is ensured that all group Duraton Cement is the flagship brand of - Asian Fine Cements Pvt. Ltd, a brand icon in the industry with a rich experience of more than 15 years. With 7 manufacturing units, 9 production lines, 10 MNC business partners and a strong work-force of over 1800 employees, the group has evolved as a customer- centric organization and has set a benchmark for its competitors in the industry. Asian Fine Cements Pvt. Ltd. has been an invigorating frontrunner in delivering supply chain and contract manufacturing services for FMCG, building materials, lifestyle, and healthcare industries. The manufacturing unit at Rajpura, Punjab is a prime example of how innovative technologies can be embraced by the construction industry in the today’s modern era. The company has deployed the most advanced European cement processing technology and is undoubtedly the pioneering stature behind the introduction of such advanced technologies in the country. With an annual capacity of 1.5million ton, the ultra-modern unit is totally mechanized. The company uses robotic technology to ensure optimum quality without any human interference resulting in zero human error. An Advanced Revolution in Indian Cement Industry Satish Sharma CEO July 2018|20

- 23. stakeholders are in sync with group objectives and strategies. Cutting-Edge Features of Duraton Cement The key attribute which distinguishes Duraton Cement from the other players is the fact that it has redefined the cement industry with its innovative, updated and most advanced technologies. This is itself the biggest differentiator as the company focuses to deliver ‘intelligent’ solutions to its esteemed clients. It has installed a fully automatic robotic lab from ‘FL Smidth’, Germany, which is able to automate all the critical activities and erase the manual intervention ensuring superior quality cement. The company has designed a comprehensive ‘outside-in’ approach which is an innovative and customer-driven policy. This has enabled the company to create value and design the products, services, and business models as per the needs and requirements of its customer. Using a two-stage superfine grinding process, the company achieves higher cohesiveness with greater durability. This further assists in strengthening the basic mixture while lowering the usage of water during the manufacturing process. Duraton cement is the only company in India to introduce an innovative ‘vacuum-tight waterproof’ packaging methodology which ensures zero-loss or damage while transportation alongside increasing the shelf life. In order to deliver a world-class customer service, the company has also designed a ‘Duraton Cement Care Van’. This van is manned by a well-trained & qualified Civil engineer & offer services to its clients, directly at the construction site. Backed by a dedicated helpline number, customers also have an option to call and ask questions and get proper technical advice along with guidance from the experts. All these distinctive innovative features and measures implemented by Duraton have assisted the company to stand ahead in the market and maintain its supremacy in the industry. Delivering the Best Quality Services In today’s crowded market, competing with numerous cement brands; is the biggest challenge. Amidst this competitive market the company sees an opportunity to make a mark as a customer-centric company. The company is gaining momentum in sales with wide acceptance of the brand in multiple states. The main motto is to deliver quality services to end consumers and by understanding the needs of every cement buyer, the company is delivering nothing less than the best. It genuinely indicates that the company is on the right track, when the influencers of the industry - architects, contractors & masons share the feedback; as world class quality cement. Such incidents define the brand right from the beginning. Technologically Advanced Initiatives The company is working on the project of educating IHB (Individual House Builder), through a series of awareness camps and training modules on good construction practices. Through these the brand educates them on significance of quality & the technological advancements, which have been incorporated in the plant to ensure consistent quality & strength in every bag of Duraton cement they use. Future Footsteps As the inception of Duraton Cement itself was on the grounds of being technologically ‘The Most Advanced Cement of India’, the company has ensured to keep the plant fully automatic & follow the best practices. It constantly thrives to bring innovation with the help of technology & bring quality product in the market. The company is evolving at every stage & developing the best quality product. Also, upgrading & improving the technology to support the same. The Company is positively looking ahead to create a position for itself and have committed to become one among the top players in its market. “ “Going above & beyond in the cement industry, we create a ‘build intelligent’ experience for our consumers with technologically advanced quality products & unmatched services. July 2018| 21

- 24. About the Author G. Vamsi Krishna Joint Managing Director G. Vamsi Krishna – Joint Managing Director, at Visaka Industries. Vamsi revitalised the idea, ‘Build the future’, and created a brand called Vnext that deems to be futuristic. Vnext by Visaka is a pioneer in construction space offering unique, transformational products in the ‘Green Building and the Sustainability’ space. Also, the first integrated solar roof called ATUM is being developed by Mr. Vamsi. ATUM is also energy generating eco- friendly product. July 2018|22

- 25. CHANGING PARADIGM CONSTRUCTION Industry in Indiandia in Construction Space through the Years IOver the last 60-70 years, there hasn't been any crucial development with regards to the methods deployed for construction or the building materials used in the existing market. There have been several technological advancements in this space across the world, especially in the developing countries like China, Singapore Indonesia etc. Although when compared to these booming markets India as a country is still lagging in the construction race, but the future looks promising. We have developed new technologies which are adding renewable building materials and efficient construction processes. We are launching eco- friendly products which will be having a positive impact on the society at large by saving trees and our planet as we know today. The objective behind such conscious developments is the basic understanding of the fact that development which is not sustainable is like taking a medicine which suppresses the symptoms for once but does not heal. Challenges and Obstacles for Green Construction Companies The entire concept of green development is known all over yet not banked upon. As one of the most evolved if not intelligent species on this planet, the Human Race has to take up the responsibility of useful and renewable concepts to create a greener and a positive impact on our planet. In India, it takes time for a new concept to swoop in and get adopted at a large scale. Lack of quick acceptance is the key issue we face in our country, be it in any field. We are seeing a growth of about 20% year on year, but the challenge always lies in convincing the end consumers about the advantages of going green, adding up to the gigantic task of how effectively can we spread the message and more importantly change the mind-set. The Future The Indian construction industry is making big moves on the affordable housing and general infrastructure development. Government focus in this area can be clearly seen in policies like 100% Foreign Direct Investment (FDI) permitted through the automatic route for townships, cities, dedicated Fund for Affordable Housing under National Housing Bank, Identification of 99 Smart Cities, having an outlay of USD 31.38 billion fuelled with increasing investment in retail projects in Tier 1 & 2 cities reaching up to USD 6.19 billion from 2006-17. The latest breakthrough is the development of the integrated solar roof called ATUM. The Indian roofing industry hasn't changed over the last 60-70 years! There have been several attempts at providing a suitable roof for the Indian market but nothing yet fits the bill like that of an energy-generating, eco-friendly roof. ATUM is here to do that - with great thermal efficiency, a lifespan of 50 years, and the ability to generate electricity for you. Vnext by Visaka having developed multiple options for various segments, strongly feel a huge scope and are all geared up to offer strong, useful and impactful products that will propel and drive the construction industry. OF THE Experts Talk July 2018| 23

- 28. Thus, in Risda, it is having a state-of-the-art integrated plant, were the robotic lab consistently maintaining the clinker quality. However, this plant is proactively reducing its carbon footprint, were it has installed a waste heat recovery system to utilize the hot gases of the kiln for power generation. Additionally, the company proudly stands with its policy, mentioning that they are living with the communities around its manufacturing facilities, by conducting CSR activities as a commitment towards sustainable development, and by involving the villagers in various self- development programs. Profound Leaders of Emami Cement Mr. R S Agarwal and Mr. R S Goenka are the founders of the Emami group and they are considered as unparalleled achievers of the modern business. Mr. Manish Goenka and Mr. Aditya Vardhan Agarwal are Directors of Emami Cement Ltd., and spearheaded the Group’s foray in setting up the cement operations. Vivek Chawla is the Whole Time Director & CEO of Emami Cement Limited. Who brings with him a high degree of entrepreneurial zeal combined with humility. He is a very committed to his cause of building a strong cement brand and is leveraging all his thirty-five years of experience to culminate to that effect. As a dedicated person in gaining global and varied exposure, his efforts have been strongly applauded by several industry leaders and analysts. Vivek has led many organizations such as ACC Limited, India is the second largest cement producer country in the world. With the adoption of massive modernization and assimilation of state-of-the-art technology, modern Indian cement plants are energy-efficient and environment- friendly. In terms of kiln size, technology, energy consumption or environment-friendliness, Indian cement plants match up to the international standards and quality. Today’s cement industry is set for healthy growth, due to the increasing growth in the sectors such as housing, commercial and industrial construction. One such admired cement manufacturing company, Emami Cement Limited is from a diversified business conglomerate “Emami Group” with interests in FMCG, edible oil, paper, real-estate & health care with diverse products. Emami Group’s portfolio includes trusted power brands like Zandu, BoroPlus, Navratna, Fair & Handsome and Kesh King. Emami cement is the latest venture with the brand name of “Emami Double Bull Cement” and has a brand assurance to provide strength beyond expectation. Emami Cement: A unique Organization Emami has achieved an admirable market share of over five percent, within a short span of time, and created strong channels. The company includes many trusted power brands, which have gained repeated orders after initial trials, such as Individual Home Builders, Head Masons and Contractors. Emami has become a player to reckon for leading amongst channel partners. Emami cement is pioneer in utilizing the latest technology. Emami Cement: Exploring Premium Services beyond Customer Expectations Vivek Chawla WTD & CEO July 2018|26

- 29. Dangote Cement PLC, and Hindalco Industries at top levels in the past. However, as he has more interest in cement industry, he took up the challenge to bring all his cement experience to play and to build a leading cement business from scratch. He is adept at large scale transformation management and is passionate in the relentless pursuit of excellence. He considers people engagement as a cornerstone of his leadership style. Emami’s Best Quality Products & Services Emami Double Bull cement has become an encouraging part of the cement industry, by providing “best in class” quality of cement in all its variants – OPC 43, OPC 53, PPC, PSC. Also, Emami cement is a front runner in product and packaging innovation, where the premium PSC has been launched under the brand name SUBH and premium PPC has been launched in pilot markets with a formal launch in the pipeline. Besides, the technical expert team of Emami cements provides value added on-site services to the consumers through their mobile Tech Express. However, its unique feature is the on-site testing of concrete, to ensure the best possible construction practices. Further, Vivek mentioned that—“A fast expanding network of logistics partners and channel partners ensures the product is seamlessly available to all consumers” Transforming Challenges into Opportunities While sharing the challenges & opportunities, Vivek said –“One of the key tasks is to rapidly expand its capacity and network footprint, and increase its market share in both existing and new markets, for Emami Cement to moving ahead”. Further, he also added—“As the organization grows, it becomes imperative to ensure a smooth transition and maintain a strong focus on talent development and retention”. Key Elements that help them to Achieve their Objective Employees of Emami Cements organization are from different companies and backgrounds. However, in any organization, it is very important to have a clear objective, which unites the entire organization and an enabling architecture for ensuring execution rigor, and cross- functional coordination. With the same objectives, Emami group of company is having a companywide transformation program—SPRINT (Sales & profitability improvement & transformation), that works across all functions & locations. Vivek further mentioned few important points on which they have consciously worked such as— By targeting the ambitious goals of the organization with performance and success, this is becoming the baseline for future growth, and driving execution rigor across the organization through structured review rhythm. Also, by applying the data driven approach for business decision making to leverage the advanced analytics. Company is constantly challenging the status quo with innovations – e.g. robotic lab, branding. Appreciated Ongoing Projects Vivek Chawla explained regarding ongoing project that—“Currently, the company is working on an end to end large scale transformation program, for sales and profitability improvement. This encompasses a cycle of continuous improvement driven by process excellence in terms of structured problem solving, driving execution rigor through impact center, and inculcating ownership across all levels in the organization” Envisioning the Future Emami group of company is aiming to be a long term player in the industry, with the future expansion plans beyond Eastern Indian markets, by providing a robust and aggressive marketing strategy for becoming a “Brand of Choice” for its consumers. Thus, Emami Cement Company is working on a range of new products that will soon hit the market. Furthermore, Vivek said –“The Company will continue its commitment to set quality benchmarks and redefine the criteria for ‘A category’ brands in cement. Also, it will continue to strengthen its channel strength, exceed customer expectation, and attract the best talent across industries”. Emami has a field team of technical experts, who go beyond mere sales and provide value added on-site services to the consumers “ “ July 2018| 27

- 31. India is the second largest producer of cement around the world says an independent research. The cement industries of India became a significant part of its economy in 1982 and granted employment to more than a million people, directly or indirectly. No wonder, the Indian cement industry has attracted the huge investors, both from Indian as well as the foreign experts. India has a lot of potential for developing the infrastructure and construction sector and the cement sector is expected to largely benefit from it. Due to some of the recent major initiatives such as development of smart cities, it is expected to provide a major boost to the sector. Recently, several foreign players have invested in the country and expected to be the contributor of major developments in the country aided by suitable government foreign initiatives. The growth of this sector is predicated because of the ready availability of the raw materials for making cement such as limestone and coal (Furnace). Production Capacity Presently, the biggest demand drivers of cement are these housing and real estate sectors, accounting for about sixty- five per cent of the total consumption in India. Some of the other leading consumers of cement include public infrastructure at twenty per cent and industrial development at fifteen per cent. July 2018| 29

- 32. India’s overall cement production capacity was nearly four hundred and sixty million tonnes as of 2017-18. Its consumption is expected to grow by five per cent in the financial year of 2019 supported by pick-up in the housing segment and higher infrastructure spending. Currently, the industry is planning to produce three hundred megatons in order to meet its domestic demand and five megatons for exports requirement. The Indian cement industry is currently dominated by certain companies. The top twenty cement organizations account for almost seventy per cent of the total cement production of the country. With four hundred small plants accounting for the rest, a total of two hundred large cement plants account for a cumulative installed capacity of over four hundred million tonnes. Out of these two hundred large cement plants, seventy-seven are located in the states of Andhra Pradesh, Rajasthan and Tamil Nadu. Due to the increasing construction and infrastructural activities, the cement sector in India has been viewing many investments and developments in recent times. The government has been approving their investment schemes; in order to help the private sector companies thrive in the industry. The government of India has also announced the budget in setting up an affordable housing fund of Rs 25,000 crore in 2018-19 under the national housing bank which will be utilized for easing credit to homebuyers. This action is expected to boost the demand of cement from the housing segment. The sector will grow and take India’ economy forward along with it, with the help of the government in terms of friendlier laws, lower taxation, and increased infrastructure spending. Additionally, so far the cement industry is expected to reach 550-600 million tonnes per annum by the year 2025 due to the increasing demands of various sectors such as housing, commercial construction and industrial construction, Emissions and Substitution The limestone materials including clay is heated in a huge furnace with high temperatures in manufacturing Portland cement, so that they fuse without melting to give clinker. “This is the utmost CO2-intensive part of the whole process. As the carbon dioxide comes both from the burning of the fuel needed to create that temperature and due to the breakdown of limestone into calcium oxide and carbon dioxide. The later part accounts for 60% of the CO2 emissions in manufacture of cement,” says Prof. Scrivener, Editor-in chief of Cement and Concrete research. The ultimate thing to do would be to substitute CO2-intensive clinker with a different material. Nowadays, fly ash – a waste produced in the burning of coal is used for producing energy and is also used in the manufacture of blended cement in India. On the other hand, this is been used in limited proportions. Therefore, to effectively reduce emissions, more clinker has to be substituted with calcined clay and limestone. So, this reduces emissions by over 30% with respect to Portland cement. According to independent research, the professionals compared the strength of the various LC3 samples with Ordinary Portland Cement and Portland Pozzolanic Cement - a variation of OPC in which locally available fly ash was added. Finally it is found that the strength of the LC3 made with low quality clay is comparable to the OPC and the samples containing superior quality clay of LC3 is higher than the OPC. In the near future, India might become a leader in exporting clinker and gray cement to the Middle East, Africa, and other developing nations around the world. The cement plants that are located near the ports will have an upper hand during exporting and will logistically be well armed to face stiff competition from cement plants in the interior of the country. In addition to this, owing to the profit margins and steady demand, numbers of foreign players are expecting to enter the cement sector. Plus, the domestic cement companies might go for global listings either through the FCCB route or the GDR route. July 2018|30

- 34. The Philanthropic Duos behind the Company Mr. Pawan Kumaar Ahluwalia is the Vice Chairman Group Managing Director, while Ms. Medha Ahluwalia is the Executive Director of KJS Cement (I) Limited. These two people are the roots of KJS Cement. P K Ahluwalia is heading the cement business, while Medha Ahluwalia is taking the KJS cement to soaring heights, with her vision, foresightedness, and unique leadership style. KJS Cement (I) Limited is revolutionizing the pattern of cement manufacturing process by implementing latest PRR technology. This key technological element of KJS Cement, helps in dynamic dosing of fly-ash in cement manufacturing process. PRR technology ensures effective particle size distribution in cement and optimum hydration of reactive fly-ash in applications; as a result KJS Cement is making Dense Concrete. KJS Cement started its production in 2012 and is catering to the markets in the states of MP, UP Bihar. This organization is a part of KJS Group of Industries. It is one of the most ultra-modern cement plant in India with machinery technology imported from FL. Smidth Co, Denmark and Loesche Germany. The annual turnover of INR 5,000 cr, with over 5000 employees are working in the multi-location and multi- unit KJS group of industries. KJS group’s presence is in mining, iron steel, power, media, infrastructure development such as housing, hotels, commercial space development, logistics transportation and cement. The company has been Certified for its Integrated Management system (IMS) by British Standard Institute (BSI) comprising of certification for ISO 9001 (2008), ISO 14001 (2004), OHSAS 18001 (2007), ISO 50001 (2011). KJS Cement: Ultra-Modern Cement Plant Satisfying the Evolving Needs of ConsumersPawan Kumaar Ahluwalia Vice Chairman Group MD Medha Ahluwalia Executive Director July 2018|32

- 35. With more than four decades of experience, P K Ahluwalia is managing businesses in several sectors including cement, power, sponge iron, mining, steel and hospitality. He is the one who believes in wealth creation and then passing on the fruits to the society. He has been responsible for the upliftment of the town of Satna and also, has mentored many of the start-ups. Ahluwalia family’s second generation face is Medha, who graduated in Economics Political Science from Lady Shri Ram College, New Delhi followed by her post-graduation from London. Recently she led the relaunch of KJS Cement (with PRR Technology) and has established it as a much sought after brand in central India. She is also a keen philanthropist and has passion in forming self-help groups. KJS Offering Technologically Advanced Cement for Far Better Performance KJS Cement has been working relentlessly to understand the ever-evolving needs of the consumers, to upgrade their offerings and to serve in a better way. While explaining the services, Medha Ahluwalia stated—“Last year, we got a comprehensive Market Research conducted through AC Nielsen to understand the stated hidden needs of consumers and the competitors' ability to fulfill all those needs. We realized that all the cement players are satisfying BIS standards, but the consumer is looking for more.” The RD team of KJS Cement took this as a challenge and started working on product up-gradation and developed PRR Technology. The company also hired a leading agency to help company with the new brand identity and then to launch new improved KJS Cement with PRR Technology in the market. Medha Ahluwalia exclaimed—“I am very happy to share that the new product has been very much liked by consumers by all the stakeholders and it has given us a boost for further product enhancements.” Converting Woven Dreams into Reality KJS Cement has three ambitious plans, to sustain long term viability and to strengthen the financial condition enumerated as: At very first, the plan is de-bottlenecking of capacity utilization of clinker, to enable the enhancement of existing production. This will surge the existing capacity by 2020. Secondly, the company is planning to have its own railway siding at a total length of 6.15 KM from Maihar Railway station. This will help the company to reach in the furthest areas, which inturn increases the volume of the company. Lastly, as KJS PPR cement has gained acceptance in the markets, company is now poised to launch a premium brand with Moderate Sulphate Resisting Properties – KJS Concrete Master Cement specially designed for critical applications like Slab Casting, Foundation Columns. The cement has high initial final strength, optimum fineness and features like making impervious concrete even under moderate aggressive conditions of soil and underground water. Futuristic Expansion Mode Looking at the future, KJS Cement has decided to put up a grinding unit with annual capacity of two million tons in Uttar Pradesh near power plant. Also, the company is aiming to start the production from this grinding unit from 2020. This will help in creating more job opportunities and serving a wider base. We have been working relentlessly to understand the ever-evolving needs of the consumers, to upgrade the offerings and to serve in a better way “ “ July 2018| 33

- 36. Effective Strategies to Rohan Agarwal Deputy Chairman July 2018|34

- 37. A young and visionary entrepreneur, Rohan Agarwal, Deputy Chairman, Geopreneur Group, at the age of 26, for his exceptional accomplishments in the construction eld, was awarded the 'Young Achiever's Award' by Mr. Pranay Vakil, Chairman of Praron Consultancy (India) Private Limited, at the National Awards for Real Estate and Infrastructure 2015 in Mumbai,. The event took place at Taj Lands End, Mumbai in the presence of several well-known dignitaries and individuals along with Chief Minister of Maharashtra, Devendra Fadnavis. This, however, wasn't the only award the group took home as it was certainly a double celebration for the construction rm, as the Geopreneur Group, India's rst boutique construction company bagged the 'Emerging Developer of the Year' Award. eopreneur Corp, India’s only boutique construction company has been established with the belief that G‘Quality sells itself and no hype is necessary’. The company was incepted in 2012 under my leadership and my father Ajay Agarwal, Chairman, Geopreneur Corp’s guidance with an aim to change the home buying experience for the Indian consumer. We are the flagbearers of the 45 years of legacy of Agarwal group, a total of 3 generations of strength and 4 generations of wisdom and as a company, aim at creating bespoke projects for real estate buyers. We have an outlook on providing the best home buying living experience to any client who envisions buying home in our projects by giving them various choices before purchasing it. As a brand, we believe that customer is the pillar of our success and customer relationship is one of the most important aspects of our business. As a group, we believe in creating real homes for real people. While designing any project, we first ask ourselves if we would like to stay in this home and what are the amenities we would need to live comfortably. Geopreneur Group’s only growth strategy I believe has been,” A satisfied customer”. Key Concerns that Impact a Real-Estate Brand On time delivery is one of the major concerns towards making a customer happy. Most people buy flats that are July 2018| 35 CRM Strategies

- 38. under construction and are single homeowners. They sell their existing home for an upgrade and shift on rent till the new home is ready. Which means, the customer is now bearing the rent of the temporary house, interest on loan and EMI and yet does not have his new home? This disrupts their financial planning and at the same time, makes them insecure as they have risked their financial safety on this decision. However, with regulations like RERA, this has reduced. Second most important aspect is, to deliver as promised to the customer at the time of selling the property. Miss-selling is the easiest way to make a customer unhappy and it also costs the credibility of the developer. Be it your ad campaigns or your sales team, as a company, make sure that they only promise what will be delivered to the customer. Many projects are currently promoting lower price of their properties to lure the customers. E.g. Own a home in Malad in 80 lacs. This claim looks very attractive on a billboard and triggers leads. However, when the customer gets into the details he realizes the property cost is at least 20% higher than what he perceived as the so-called MRP did not cover taxes and registrations costs. Listen to your market and understand their needs- Develop projects according to the current trends and customer sensibilities. If your project caters to the emotional benefits of the customer too, it will definitely lead to a happy customer. Innovate but don’t exaggerate- Our homes have unique features like Sound and Dust Proofing too that creates a sanitized living space in a city like Mumbai. These simple features create a wow factor for the customer. Innovation doesn’t have to be always disruptive. At times, even the simplest ideas work wonders. Price the product sensibly- We keep in mind that the price point is reasonable for a common man to afford. At the same time, we offer Designer lobby, Swimming Pool, rooftop garden with children’s play area, rainwater, harvesting and an automated car parking system too. This gives the customer value for money and the project stands out amongst its competitors in the vicinity, thus giving the developer an extra edge. Sell the USP and don’t make your weakness look like strength to make a sale- Many builders try to sell the weakness of the project as strength. Example, if a project is far from the city, mis-selling it as ‘an escape from noise’ and exaggerating the connectivity of the location is a definite no-no. Rather, promote it as a second home so that a first home buyer who is working doesn’t feel that he fell into a trap. The Property, Documents, and Approvals- Though with RERA it is not an issue anymore. Still, a builder should make sure that every step of the project is legally compliant so that the customer does not have issues after getting possession. It not only brings bad reputation but also disturbs the buyer’s life and financials as most homeowners are single property owners and invest their life savings in a home. Prioritize safety- Many builders pay a lot of attention to the aesthetics and experience of the property to convince the buyer to buy it. But safety too is important as due to it several accidents are constantly happening. Fire safety to making it senior citizen and child-friendly is important. Pay Attention to design and aesthetics along with amenities- It is essential that the customer feels special in their home and the living experience is pleasant and comfortable. In Mumbai, space is a luxury so designing smart interiors that consume less space but give comfort in the compact living area is important. As a brand we thus make sure that our projects are compact and cozy at the same time includes all the amenities like gardens, swimming pool, and security in a contemporary design that gives the customer an elite living experience thus strengthening our relationship with them. Quality- Many leading builders often use inferior quality products and thus the homeowner within 2 years of moving itself has to start investing in electricals and plumbing and leakage related issues. This may sound like a minor issue but if one has to live with them, the builder is constantly bad mouthed for ruining the customer’s living experience. Rather simply be more cautious with the material used and contractors assigned to make sure these bugs are eliminated from the property. July 2018|36

- 40. cement. Located in, Trichy, Tamilnadu, the company is in operation and leading a business with value-oriented and people-focused culture since its inception. The company is having outstanding products that protect human life and personal property. It improves the quality of life, generates economic prosperity and connects the society. The company is putting up all its efforts in excessive demand of increased consumption of cement. Each member of the company is proactively working towards achieving its goal. It has an established Mini Cement Plant in India is having the capacity of 250metric tons per day, with its well-known brand name ‘Vijay Gold Cement’. Initially, Vijay Cements was started as the cement grinding unit with the capacity of 100metric tons/day in 1992. Further, in 1995 it was upgraded to mini cement plant with In today’s infrastructure development of the country, the cement industry is playing a crucial role. The technological changes have been undertaken in every industry, including the cement industry. Every system and products are being upgrading continuously. Induction of advanced technology has immensely helped the industry to conserve energy and fuel to save materials substantially. In terms of technology, quality and productivity of today's advanced cement are undeniably at the top. One such progressive cement manufacturing company is Vijay Cements which is playing a vital role in building a safe infrastructure. Successive Journey of Vijay Cements One of the leading company, Vijay Cements is manufacturing environmentally and socially progressive Improving Quality of Life by Ensuring Safe Infrastructure Vijay Cements: July 2018|38

- 41. two kilnto produce clinker having capacity of 60metric tons/day/kiln. Further, from February 2014, after clubbing with VVM Group, the company is innovating more by giving extra attention to quality, environment, and safety. Apart from this; the firm has also placed its interest in various industries such as Textiles, Food and Agro, including Chemical and Pigments. The firm has always been investing in improving the safety aspect of the cement. Thus, in the year 2015, Vijay Cements succeeded with IMS Certification for the excellent improvement in cement quality, environment, and safety. Further, in the year 2016, the company’s innovation into the workplace and quality product process improvement led it to the successful implementation of5S Methodology and thus achieved 5S Certification. Also, it has been awarded by the renowned certifications called IS: 1489-Part:1-2015 Certification, as the company produces the best quality of Portland Pozzalana Cement. This makes the company one of the most comprehensive, holistic quality management endeavors, and considered as one of the trusted cement plants. Vijay Cements: Building reliability in Life The firm is committed to achieve growth through superior innovation, quality, customer satisfaction service. The firm is running its business in an ethical and professional manner. With the vision of building reliability in everyone’s lives and cities; Vijay cement is aiming to provide safe and reliable products and technology. To achieve this, every member of the company is working proactively towards a sustainable resource-recycling society, as they deeply understand the advance wide range of needs and requirements. Core Values of the Company The work of individuals is aligned with the common values, internal beliefs, and the best practices. Employees of Vijay Cements, share the four core values such as Safety First, People Development, Quality product, and Customer Satisfaction. This forms as the foundation for its people and to successfully build responsiveness in lives of customers and local communities. The company represents its core- commitment to become a truly valuable company by developing a variety of CSR activities that contribute to a better, safer and more progressive society. This is resulting in an improved quality of life for people of the present and future generations. Setting New Standards in Environmental Sustainability All the members of Vijay Cements are continuously endeavoring to build upon two central pillars. One is the steady commitment to the customers and employees, while other is ensuring a determined commitment, through their actions. The company is also a key investor in creating a better tomorrow, by engaging in the extensive CSR activities of education, health, and employment. It also believes that the long-term success depends on the existence of stable and economically feasible communities. The firm is committed to producing environment-friendly products in a very responsible manner. By encouraging the efficient use of resources, it is creating sustainable products. Providing Quality Assurance Vijay Cements is dedicated to provide the highest quality products in the industry. This quality is delivered due to its quality control laboratory. Despite of having huge competition in the market, the company is focusing on the delivering superior products to the markets. Today, it has it has become the most demanding company in terms of quality and performance of the cement. Heading Towards Revolutionary Future Vijay Cements believes that its success is primarily based upon the relationship with the community and helping environmental responsibility, encouraging technologies that do not harm the environment. The company is building responsiveness with its customers and local communities with an eco-friendly system. The company is planning to expand by creating value for all delighted customers, engaged employees, enlightened partners and sustainable development, along with creatively setting new values for the company. We make an impact by improving the quality of life ““ July 2018| 39

- 42. Embracing for the FUTURE Technology to Innovate SMART CEMENT July 2018|July 2018|40 Technological Innovation

- 43. July 2018| 41

- 44. The world is changing faster than ever thanks to the cutting-edge technology solutions. The technological revolutions are transforming the way humans live. With the successful adaption of the modern innovative technologies; various sectors are improving their overall productivity, including the cement manufacturing, health science, and many other sectors. The construction industry is the only global consumer of the resources and raw materials. The buildings are huge contributors to the release of carbon dioxide. Thus the value remains in improving the quality of construction and the quality of materials used. This is to contribute to a healthier environment, to increase the sustainability and reduce its cost. What can be done? Well, it is suggested that little or no ‘Ordinary Portland Cement’(OPC) should be used in the construction. But, today researchers are looking for radical alternatives to OPC, and as a result, all the companies are now focusing on ‘Eco-friendly Cement’. Cement and concrete have been used around since the times of the Roman Empire. That time, the lime-based cement was made from heating limestone gently, that are still available in the market. It has its own constraints. Today, we all are living in a world where one of the main concerns is the level of carbon dioxide in the atmosphere. Thus, the world needs a kind of cement that has the qualities like ability to harden quickly under water, strong, long-lasting, durable without the carbon emissions. Manufacturing of Newer and Sustainable Cements Sustainability has now become a requirement, rather than just a desirable characteristic. The researchers are concentrating to produce more sustainable cement, in the recent past, and continue to do so. This can be achieved through the reduction of clinker factor in cement, as well as by enhancing the utilization of low grade and waste materials in cement manufacturing and developing the composite cement, Portland-limestone cement as well as non-Portland cement such as geo-polymeric cement. Construction is one of the sectors which produce a huge amount of waste. Thus the efficient use and the recycling of raw materials, or even a small improvement in the sector, offers a huge potential benefit. For the eco-friendly purpose, the industries are increasingly using off-grid or distributed power sources, such as wind power, geothermal energy and solar panels on roofs. Along with the quality, the construction industry is also focusing on energy efficiency and eco-balance. Key Issues to be considered Some of the key issues which are to be taken into considerations are: Raw material conservation: The limestone is used because it is a nonrenewable mineral resource. Environmental considerations: Global emphasis on reducing the emission of greenhouse gases, use of alternate raw materials in clinker production, and producing cement with lower clinker factor. Standard Specifications: Formulation of standard specifications for newer and more sustainable cement. Cement properties and concrete performance: Rate of strength gain of cement at lower clinker contents/ newer cement and Durability of concrete structures. Benefits of Technological Change Today, cement is recognized as being ecologically safe, due to its outstanding properties. The number of available types will only continue to grow and further highly-effective processes will established the companies. Thus to proceed, the cement industries would implement automation. This advanced process of automation ensures that cement plants perform in a better way, which will be resulting in increased stability and higher profitability. However, the direct benefits of this technological change include increment in the production up to eight percent, decrement of fuel and energy consumption up to six percent. While, the indirect benefits are the low cost maintenance, long-term stability, the reduced equipment cost. The industries in the construction sector are facing numerous emerging challenges; the industries have successfully harnessed technological advances to improve and reshape their products and services. Today, the technology is offering the chance to reshape the cement industries, and also helping it to step up and to address some of these challenges to turn them into the opportunities. July 2018|42

- 46. GDPR What it means for Indian Businesses? With digital and cross border transactions growing at an exponential rate, protection of personal data has become a critical issue with multi-jurisdictional implications. The recent and most significant example of protection of personal data being that of the European Union's (“EU”) regulation on protection of natural persons with regard to processing of personal data and free movement of such data (“General Data Protection Regulation” or “GDPR”) that came into force from May 25, 2018 onwards. GDPR on account of its extra- territorial applicability has given rise to certain significant questions on its implications on non-EU organizations, which I have attempted to address below. Does GDPR apply to Indian Companies? One of the key underlying principles of GDPR is to ensure that when personal data of persons staying in EU is transferred to non-EU countries, the GDPR’s data protection safeguards goes with such data. To put it simply, GDPR has an extra-territorial application and even applies to processing by entities situated outside EU, of personal data of persons of EU in relation to offering of goods or services to such persons or monitoring their behaviour in so far as it takes place within EU. Consequently, Indian entities who are acting as either a ‘controller’ (i.e. the person who determines the purposes and means of the processing of data) or a ‘processor’ (i.e. the person who processes the personal data on behalf of the controller), of personal data of EU residents, become subject to GDPR. GDPR therefore is likely to have significant impact on the technology/data processing Indian companies operating in say the information technology, international e-commerce, outsourcing sectors. When is cross-border data transfer to non-EU countries (like India) permitted? Adequacy Decision: GDPR permits international data transfer to non-EU countries, subject to European Commission's (“EC”) decision that they ensure an adequate July 2018|44

- 47. Seema Jhingan Partner Co-founder Seema Jhingan, a senior Partner and Co-founder of LexCounsel, Law O ces, has over twenty three years of experience. She has extensively advised in areas including Mergers Acquisition, Education Laws, Defence Aviation, Venture Capital Private Equity, Franchising, Media Entertainment, Software/Information Technology, General Corporate and Commercial. About the Author Experts View July 2018| 45