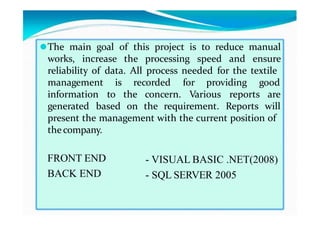

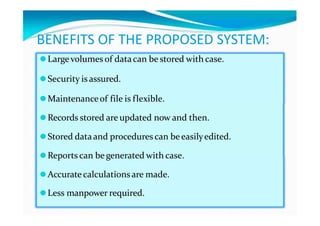

This document provides details about a textile management system project developed for AKC Garments using VB.NET and SQL Server. The project aims to automate the company's manual processes for order receiving, sampling, purchasing, production, transportation, shipment, and billing. By reducing manual work and increasing processing speed, the system seeks to provide reliable data and reports to management. Key modules in the system include order receiving, sampling, purchase, processing, production, transportation, shipment, and bills.