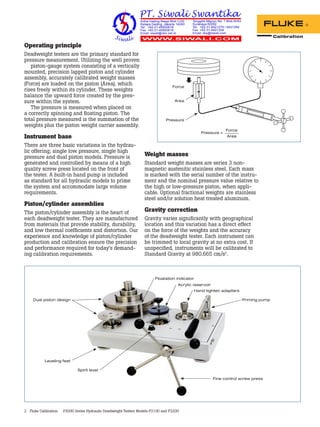

The document details the specifications and features of the Fluke Calibration P3000 series hydraulic deadweight testers, specifically models P3100 and P3200, which offer pressure ranges up to 20,000 psi and accuracy levels better than 0.015%. These testers incorporate advanced design elements such as a dual piston system, built-in hand pump, and an acrylic reservoir for easy operation and accuracy. Each unit comes with a calibration report, various adaptors, and options for improved accuracy and finer weight increments.