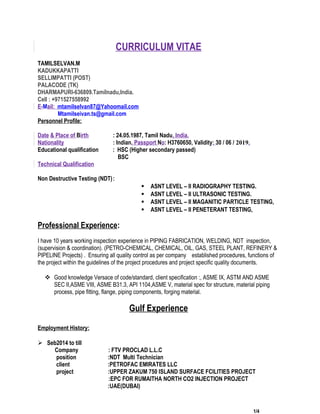

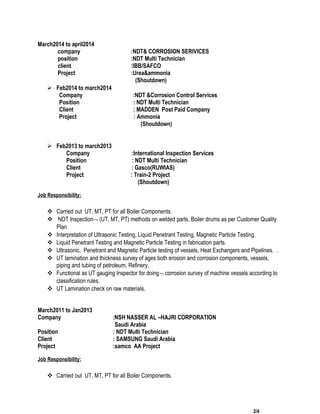

This document is a curriculum vitae for Tamilselvan M that provides personal and professional details. It includes his contact information, educational background of an HSC and BSC, and NDT technical qualifications of Level II in Radiography, Ultrasonic, Magnetic Particle, and Penetrant Testing. It details over 10 years of experience in inspection roles for various petrochemical, chemical, oil, gas, and steel projects in India and the Gulf. His responsibilities included performing various NDT techniques like UT, MT, and PT on welds, vessels, and pipelines per customer quality plans and standards.