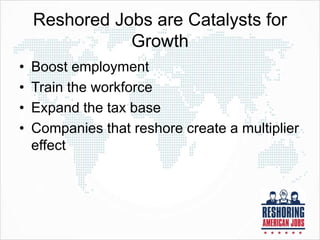

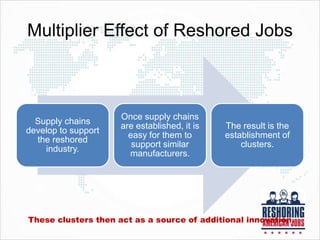

The document outlines strategies for economic developers to support the reshoring of jobs to the United States, emphasizing the growth and innovation potential that reshored jobs bring to local communities. It discusses the reasons behind reshoring, including cost changes and supply chain reliability, while also highlighting the importance of preparing the workforce for technological advancement in manufacturing, particularly in the context of Industry 4.0. Additionally, it suggests strategies for community appeal, necessary infrastructure improvements, and workforce development to attract reshoring companies.

![Why Companies Reshore

“In 2005, our labor costs in

China were only around 10

percent and by 2012 [labor

costs] was 37 percent.”

Marvin Cunningham, Long-

Stanton Manufacturing

Decline in

cost savings](https://image.slidesharecdn.com/toolkit-for-slideshare-170629162440/85/Supporting-Reshoring-in-Communities-Tools-and-Strategies-for-Economic-Developers-5-320.jpg)