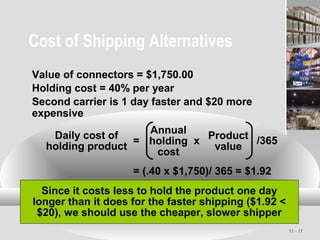

This document discusses key concepts in supply chain management including the importance of mutual goals, trust, and compatible cultures between organizations in the supply chain. It also discusses challenges like local optimization, incentives that prioritize short-term gains over efficiency, and the bullwhip effect. Opportunities in integrated supply chains are larger including accurate demand information, reduced lot sizes, and collaborative planning. E-procurement, vendor selection, logistics management, distribution systems, third-party logistics, and the tradeoffs of shipping costs and inventory holding costs are also summarized.