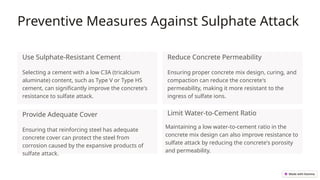

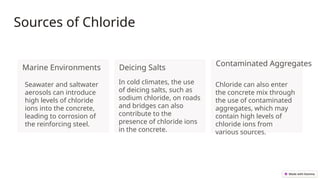

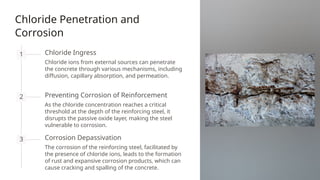

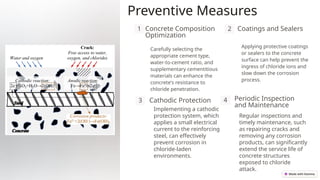

The document discusses two primary types of concrete deterioration: sulphate attack and chloride attack. Sulphate attack involves the reaction of soluble sulfate ions with cement hydration products, leading to expansive compounds that damage concrete, while chloride attack is primarily caused by corrosion from chloride ions in marine environments or deicing salts. Preventive measures for both types of attacks include using resistant materials, optimizing concrete composition, and maintaining regular inspections.