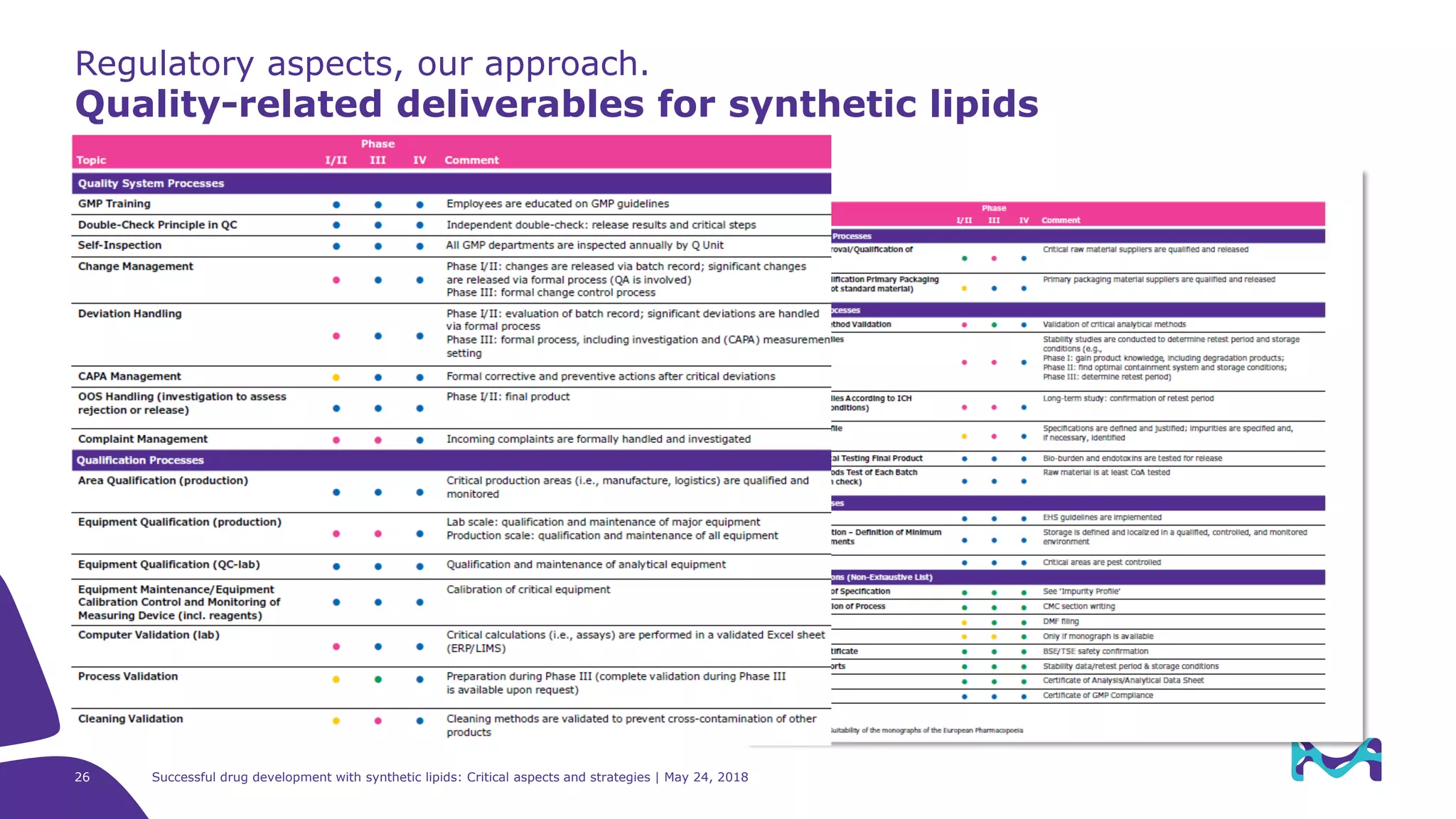

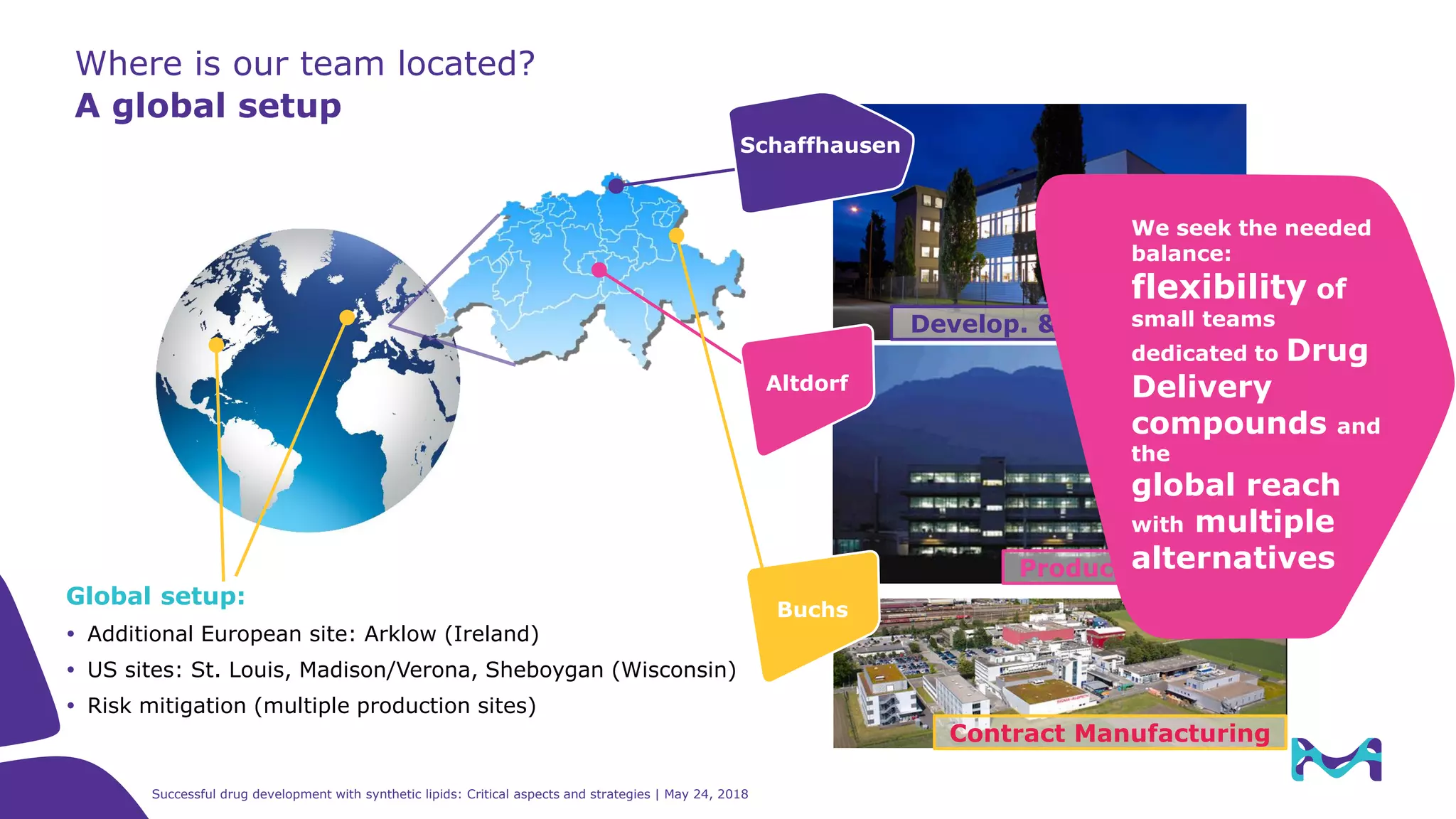

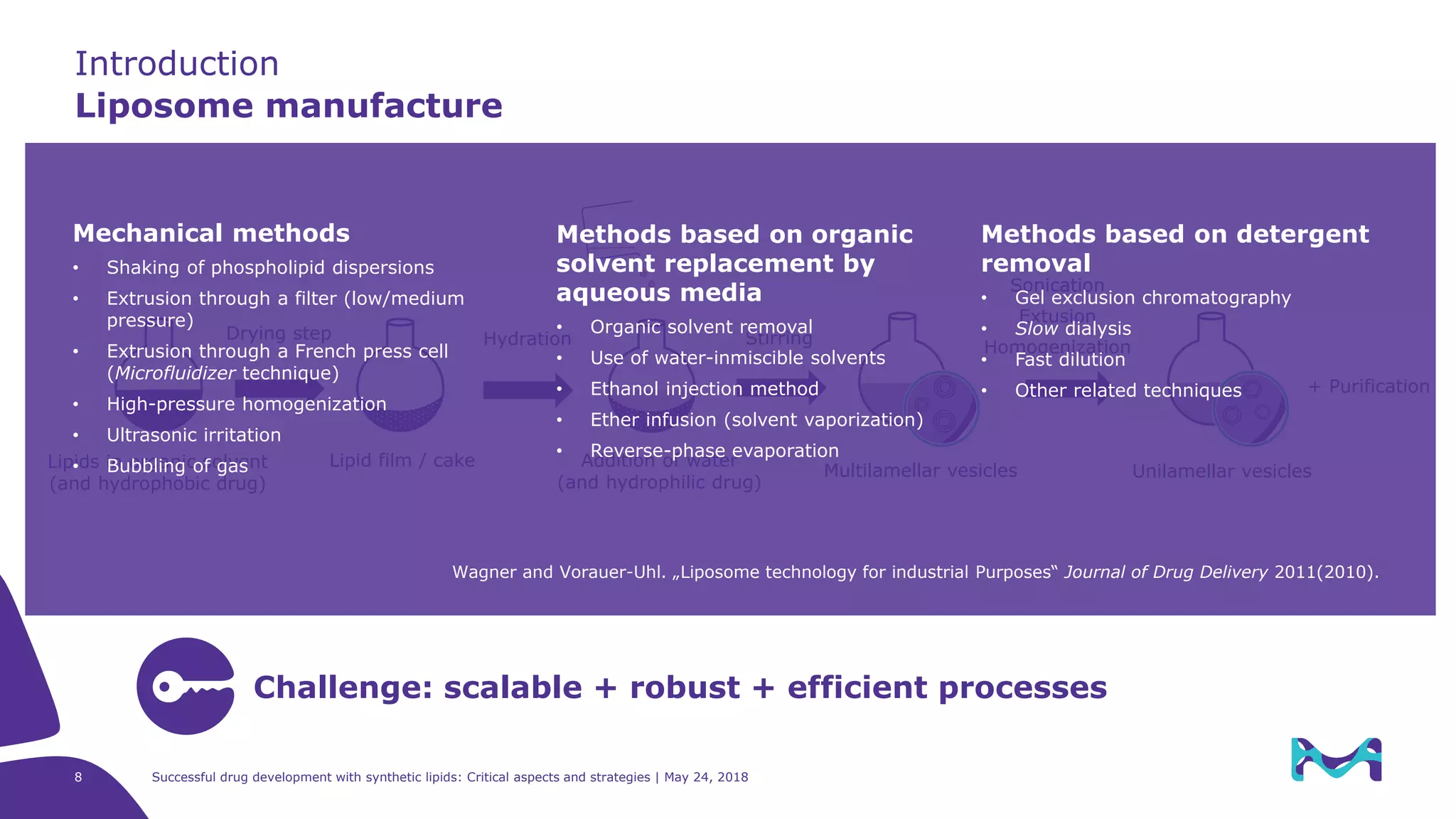

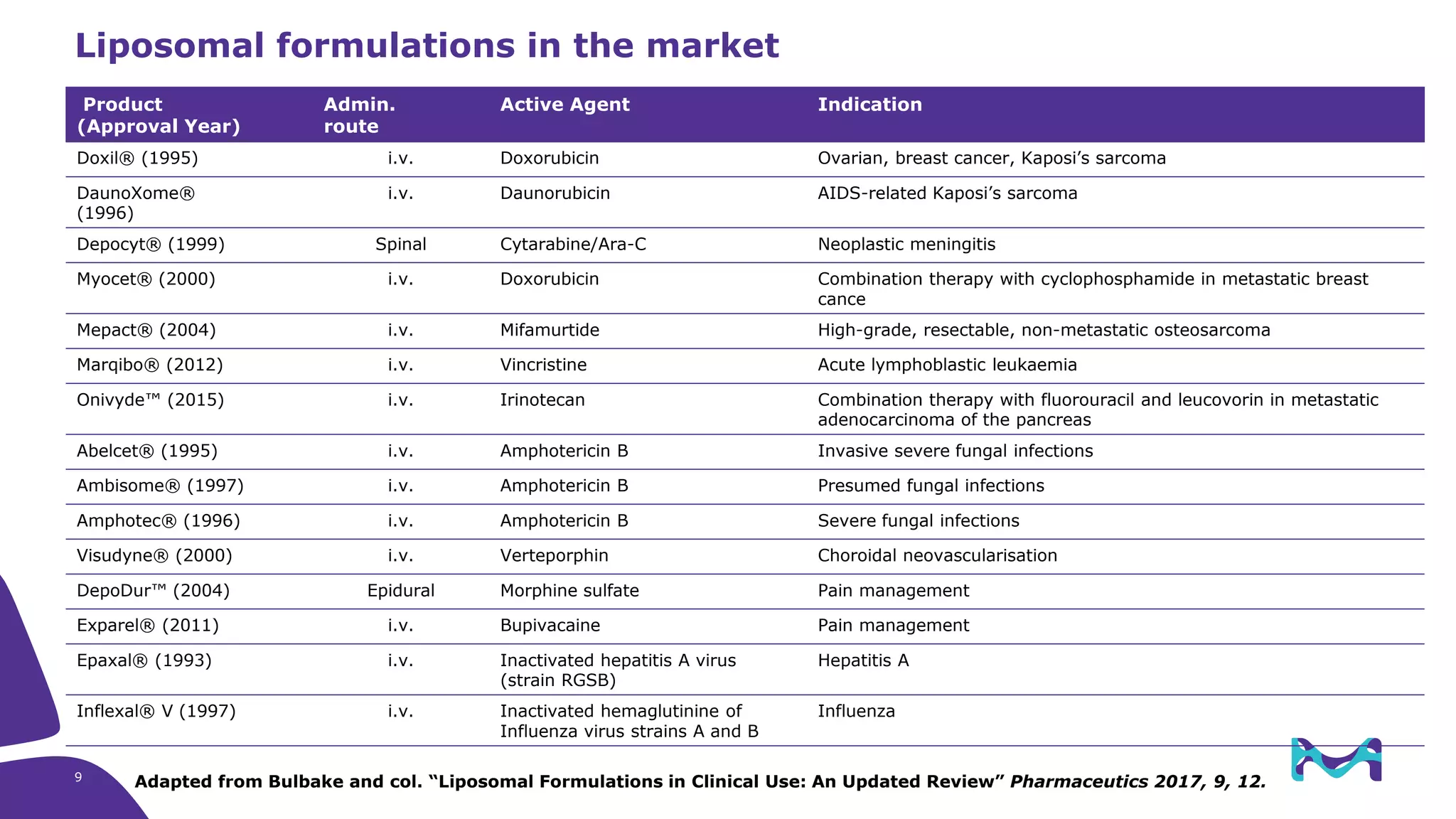

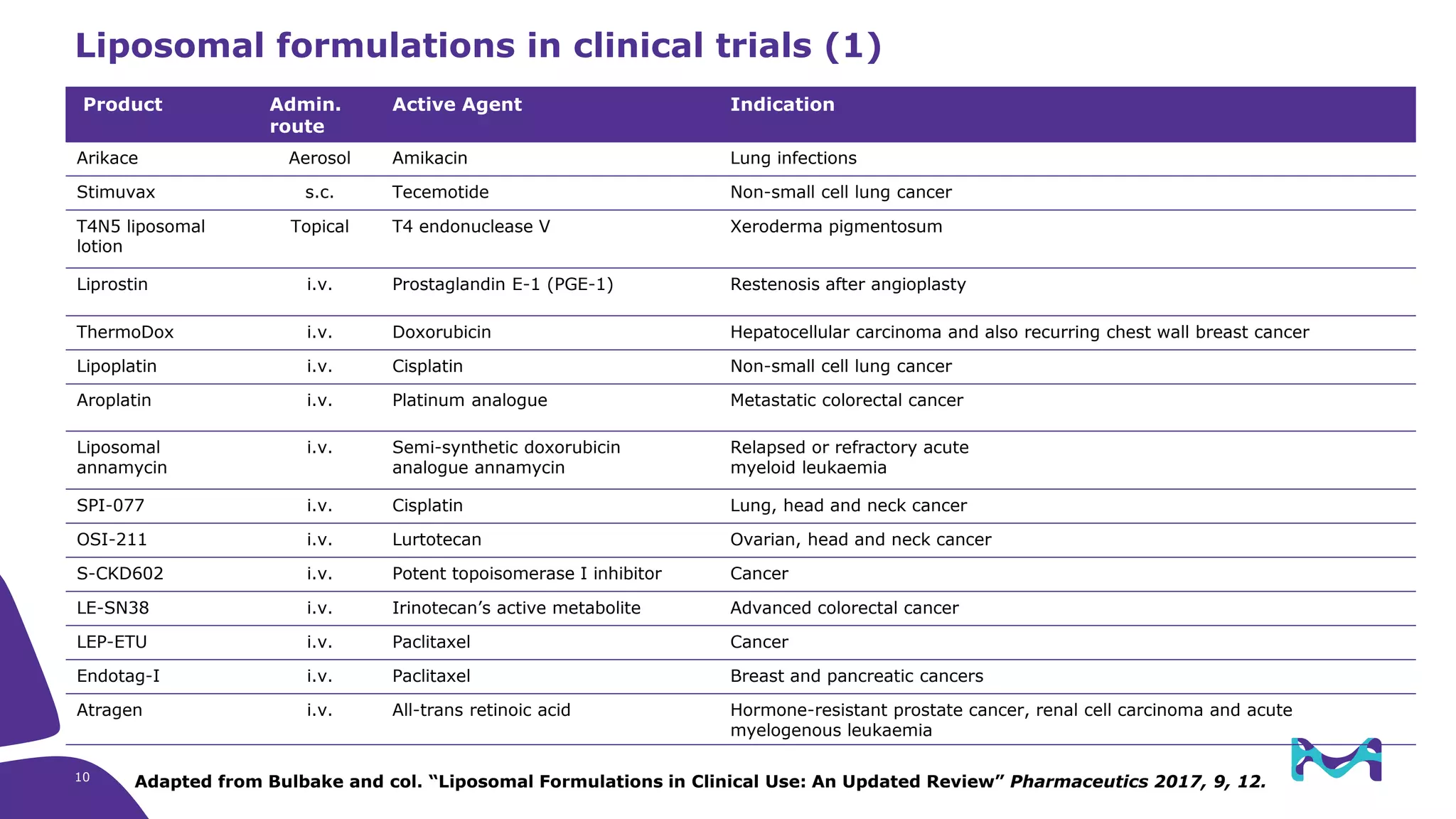

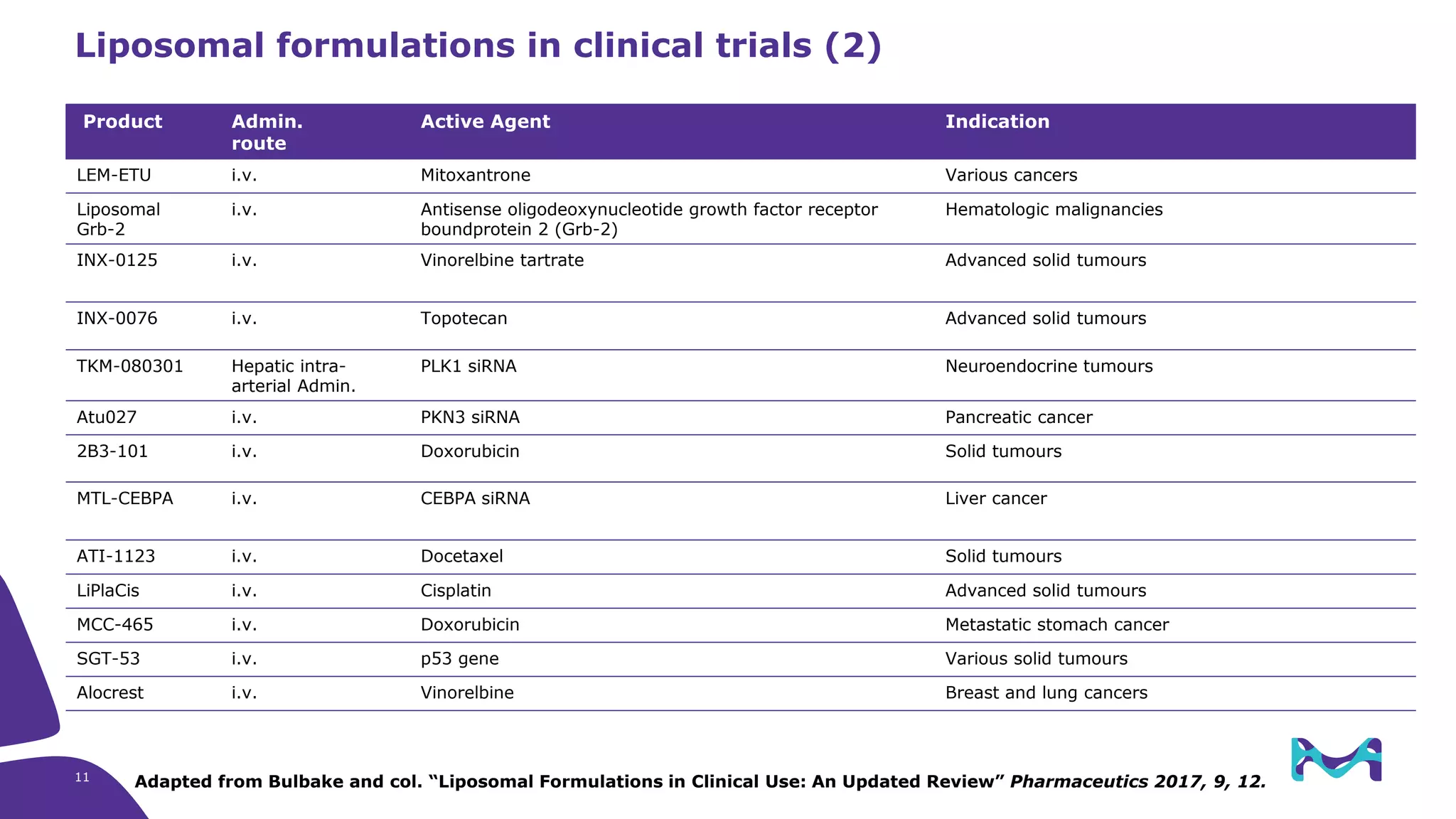

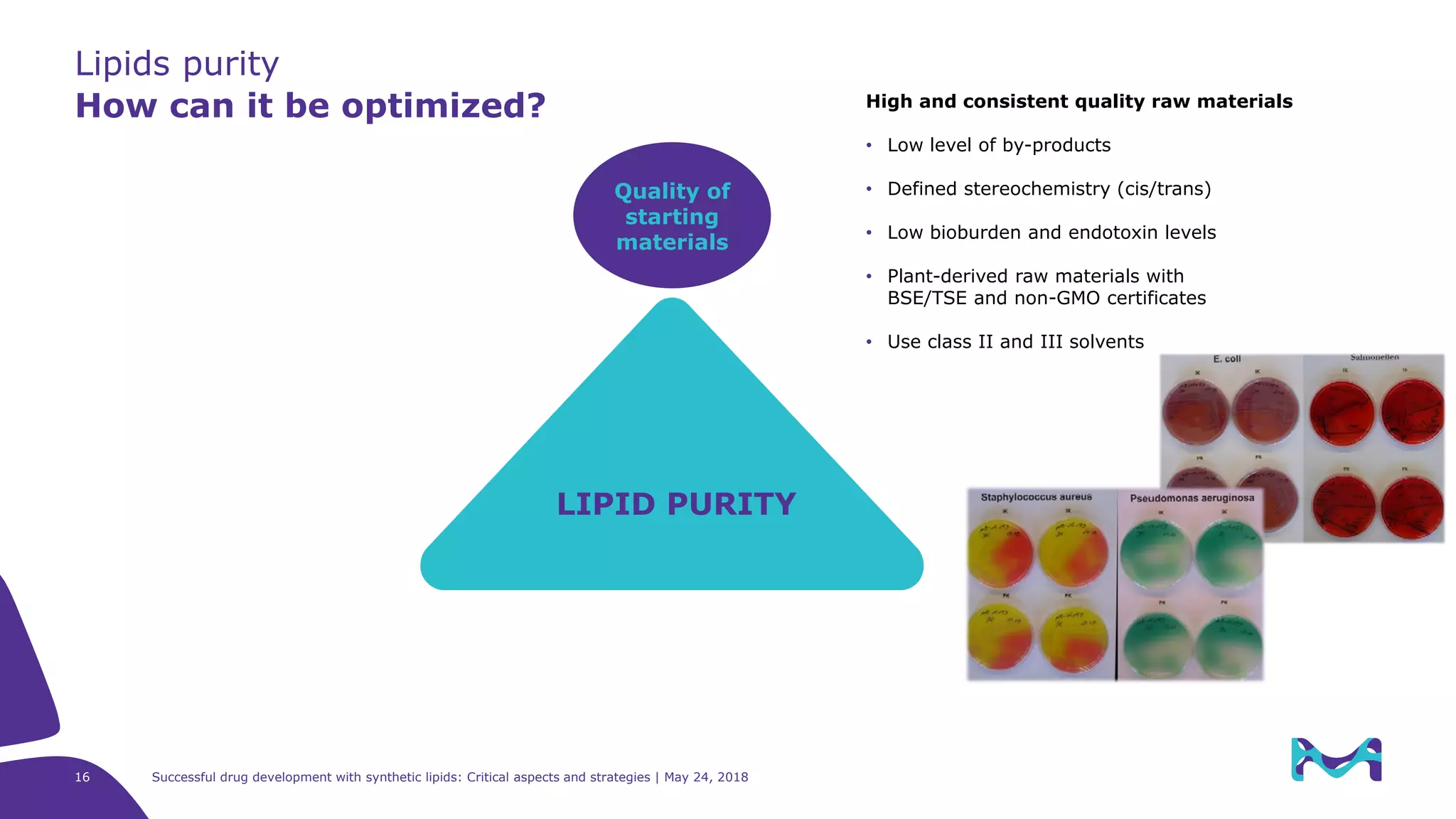

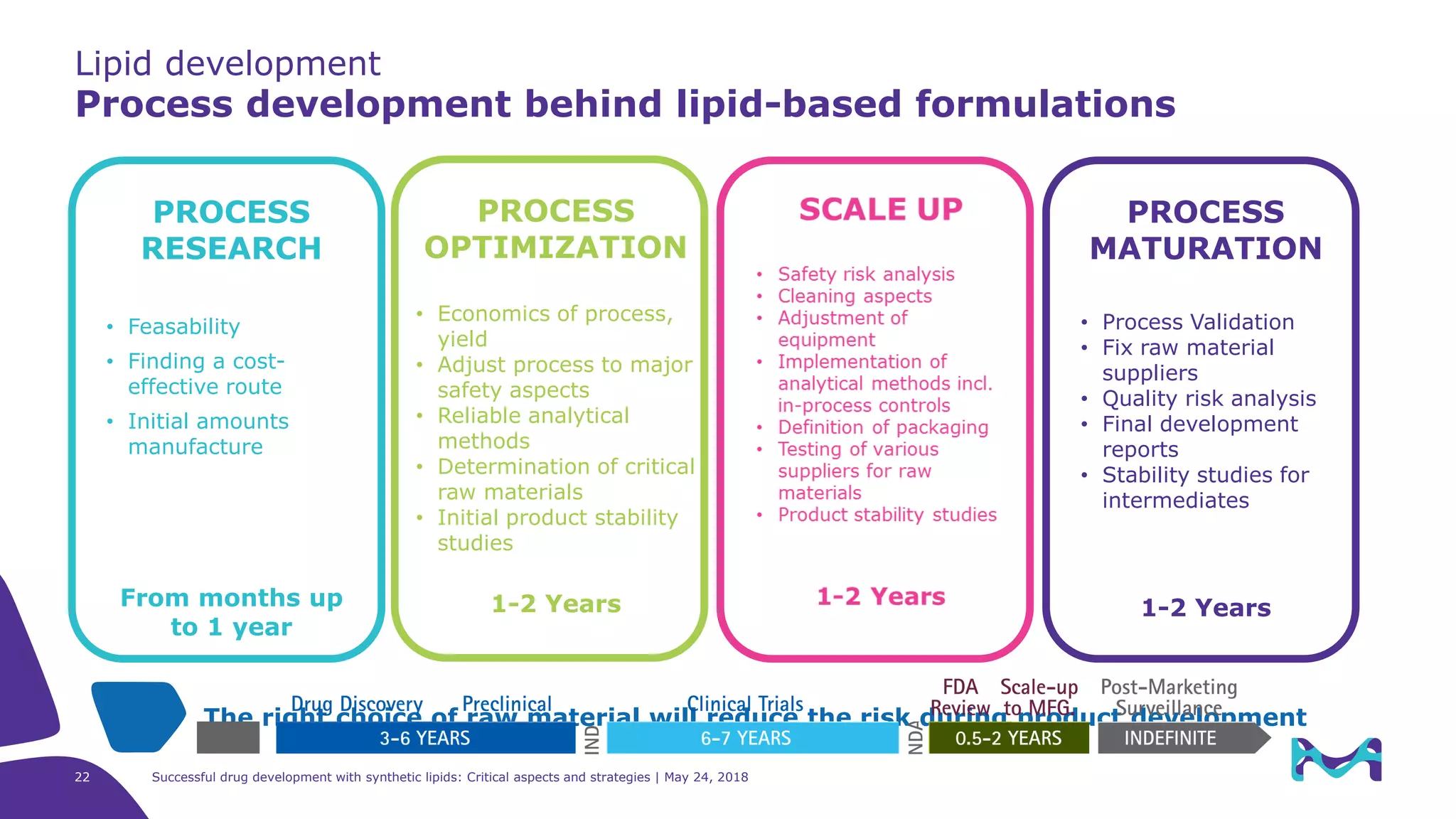

The document discusses critical aspects and strategies for successful drug development using synthetic lipids within Merck KGaA's life sciences operations. It covers the role of lipids in liposomal formulations, emphasizes the importance of lipid purity and consistent quality, and mentions regulatory considerations for developing lipid-based drug products. Additionally, it highlights challenges, process development, and enhanced surfacing techniques for improved drug delivery systems.

![Successful drug development with synthetic lipids: Critical aspects and strategies | May 24, 201824

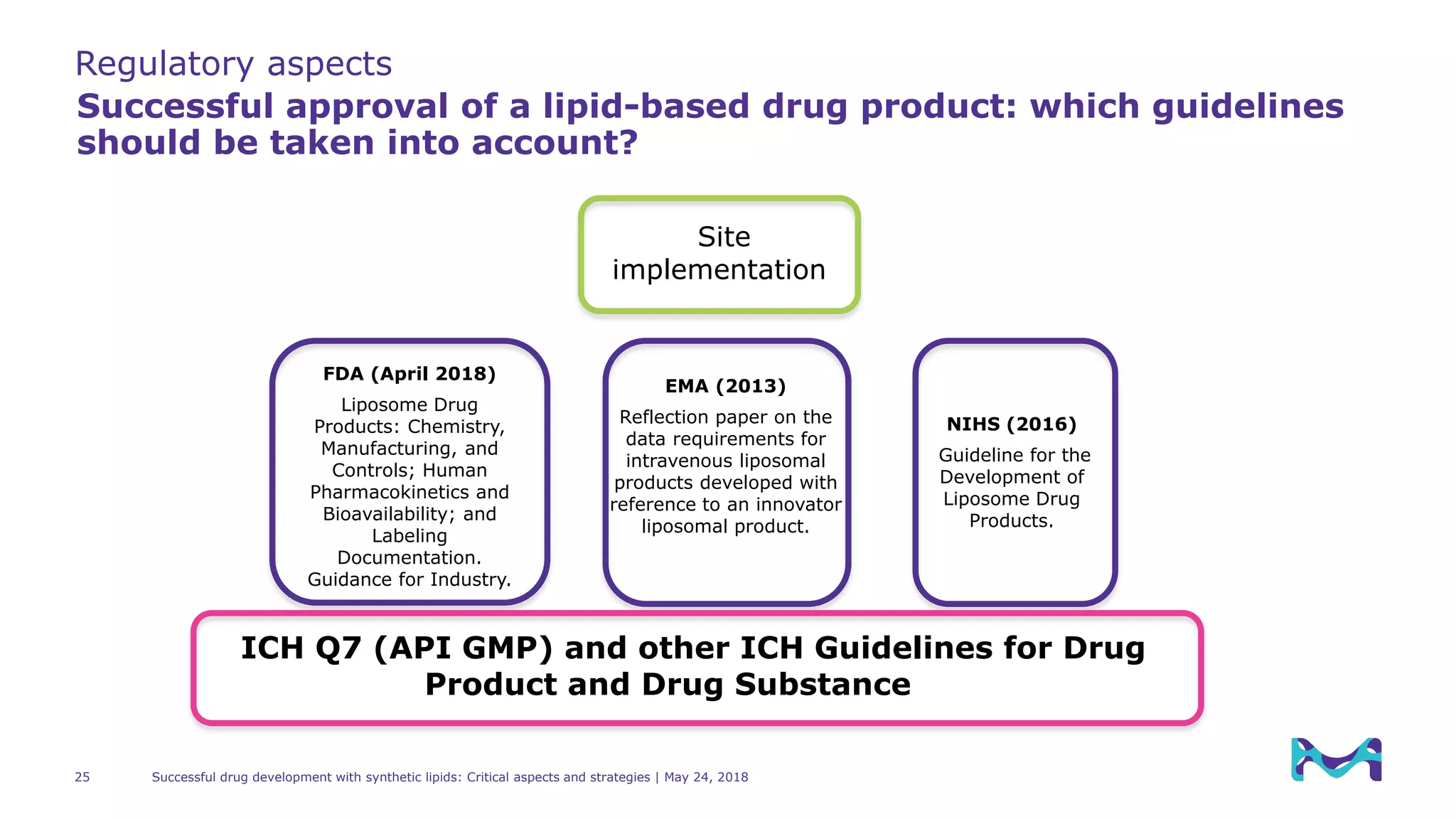

Regulatory aspects

Successful approval of a lipid-based drug product: which guidelines

should be taken into account?

“[…] The quality of lipid components, including

modified lipids (e.g., polyethylene glycol (PEG)

modified lipids), can affect the quality and

performance of the liposome drug product.

In cases of novel lipid components, the level of

detail provided in the submission should be

comparable to that for a drug substance.[…] see

ICH Q11 Development and Manufacture of Drug

Substances […]”

“[…] The quality and purity of the lipid

starting materials is essential for the later

quality of the drug product, therefore the

appropriate characterization and specification

of the lipid starting material is considered as

vital. […]

The level of information to be provided

with the relevant submission depends on

complexity of the excipients. […]”

“[…] Because the quality of liposome components

such as lipids can affect the quality of whole

liposome drug products, the quality of liposome

components should be appropriately controlled […]

In liposome drug products, lipid components […] and

molecules for liposome modification […] contribute to

an improvement in the in vivo stability,

pharmacokinetics, and intracellular behavior of the

active substance. Therefore, liposome components,

especially ligands (targeting moiety) and antibodies

that have a significant impact on the function of

the drug product, should be evaluated and

controlled to a greater extent than general

excipients to ensure their intended

properties.[…]”](https://image.slidesharecdn.com/successfuldrugdevelopmentwithsyntheticlipids-criticalaspectsandstrategies-180524160105/75/Successful-Drug-Development-with-Synthetic-Lipids-Critical-Aspects-and-Strategies-24-2048.jpg)