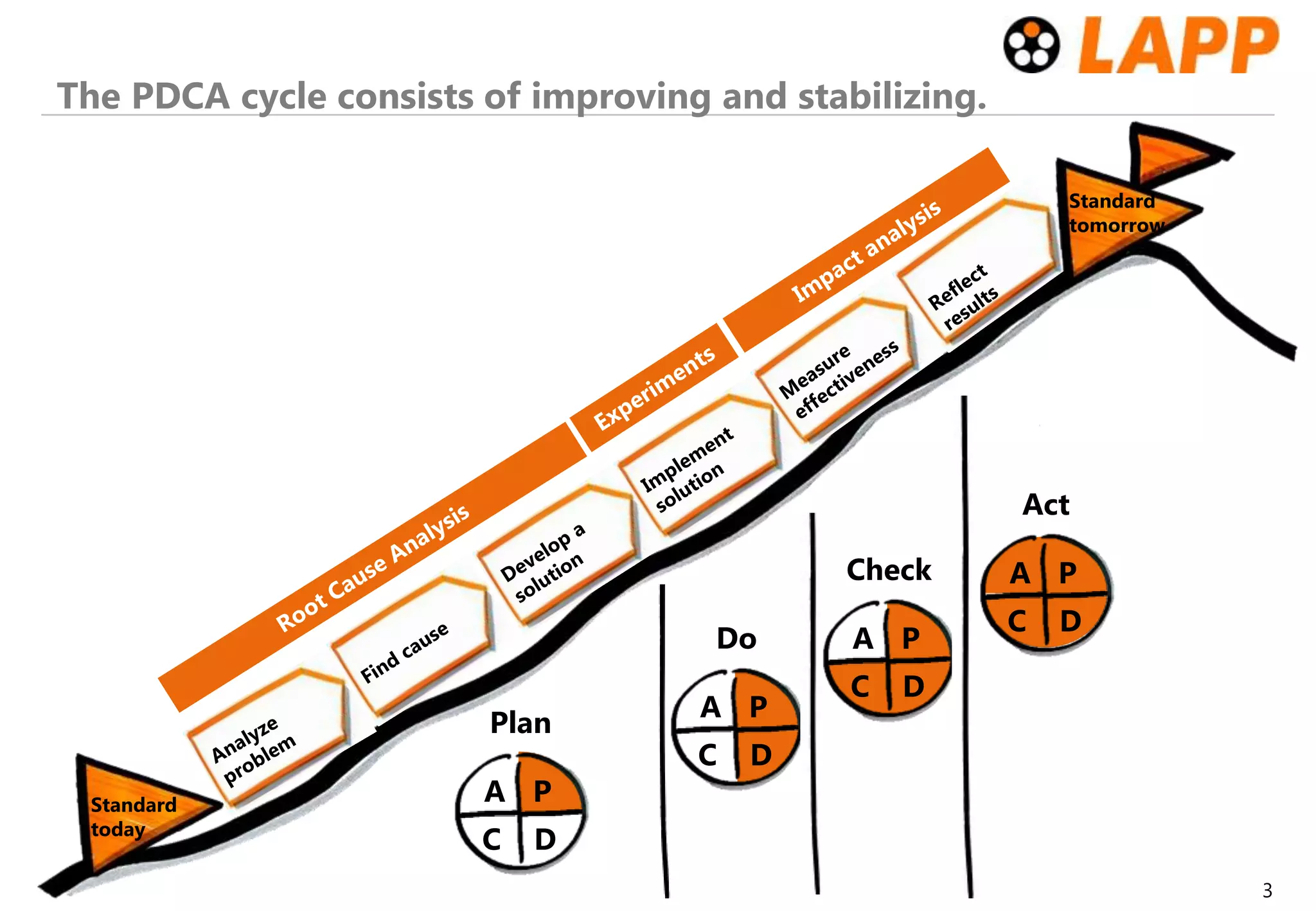

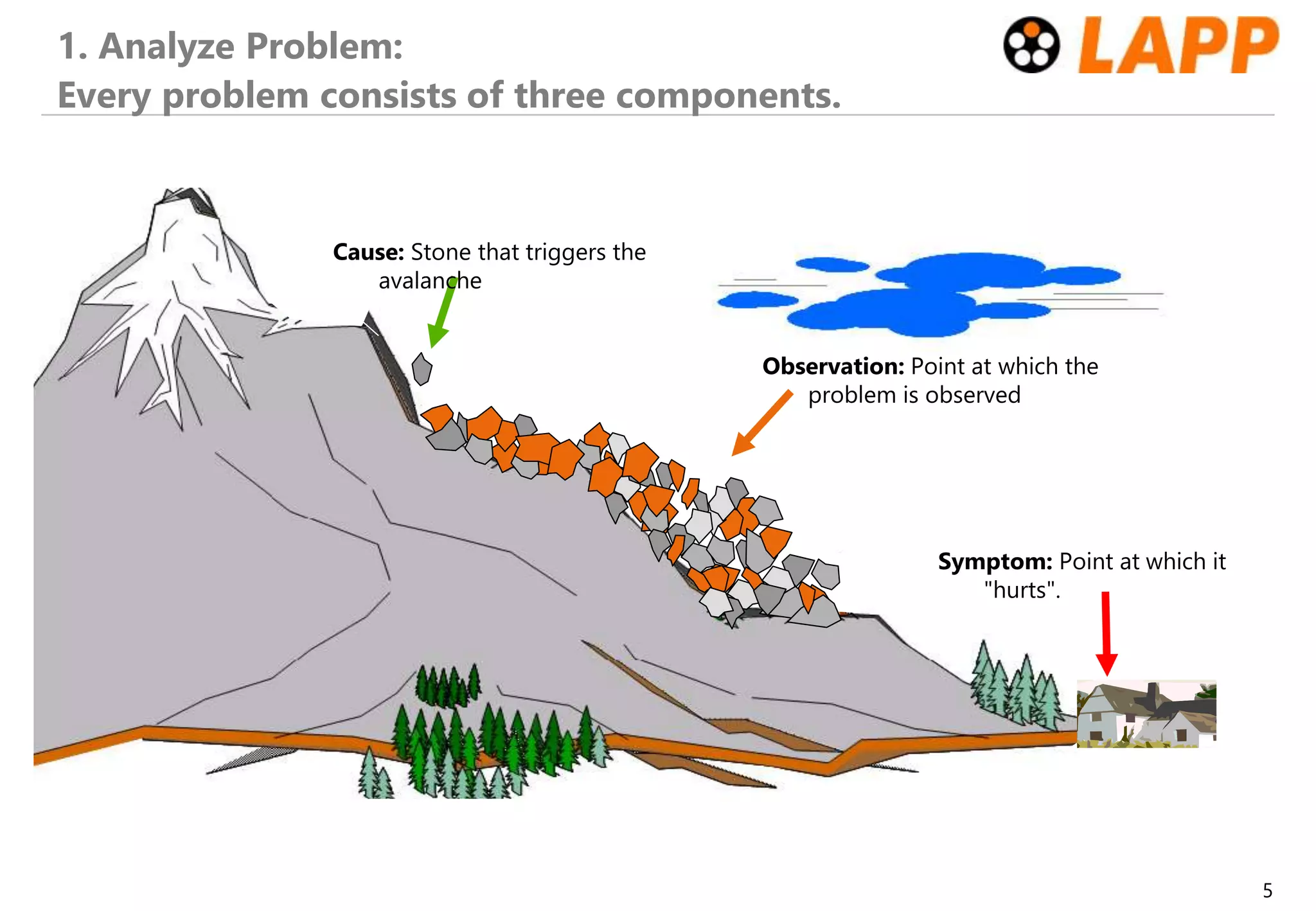

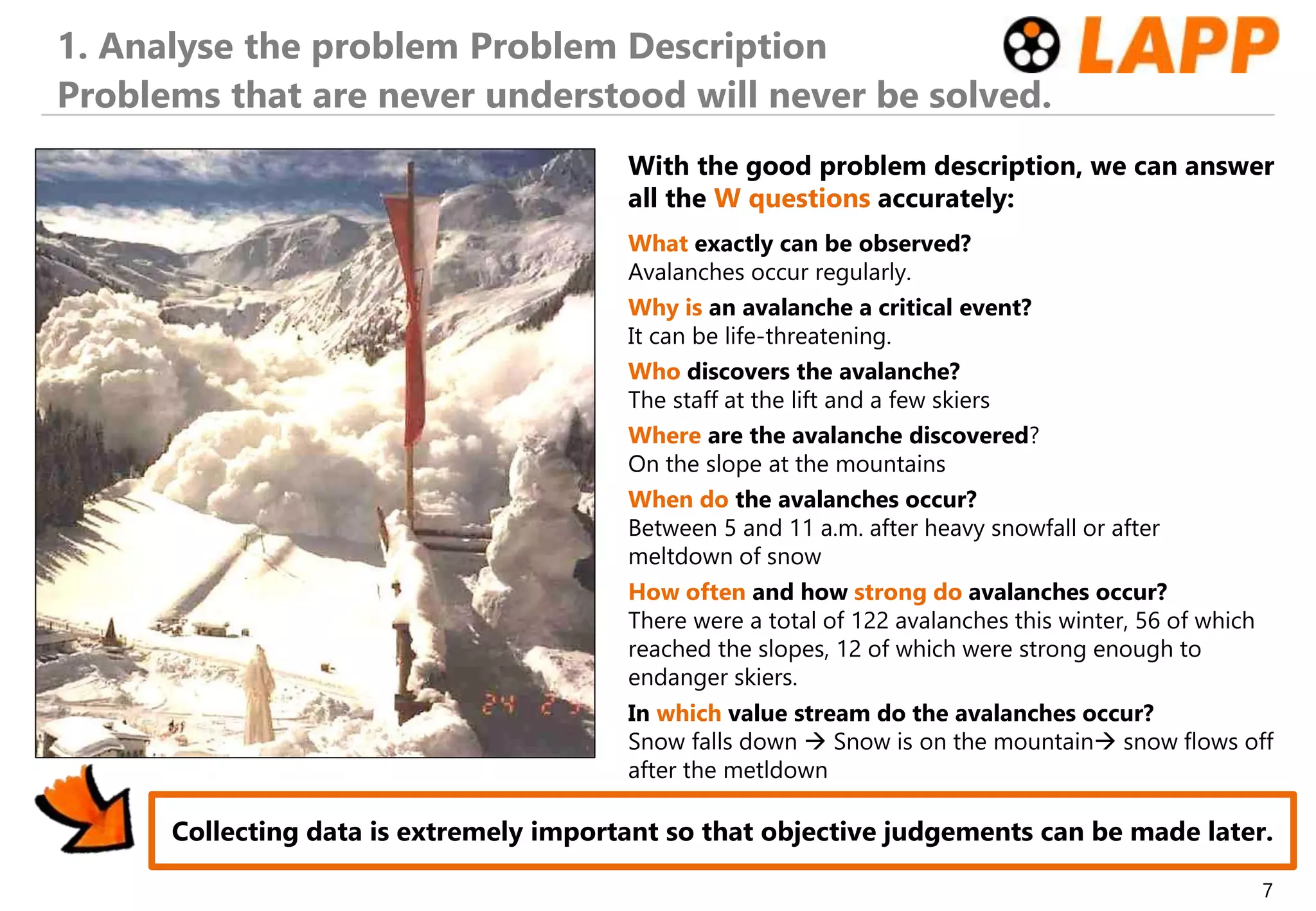

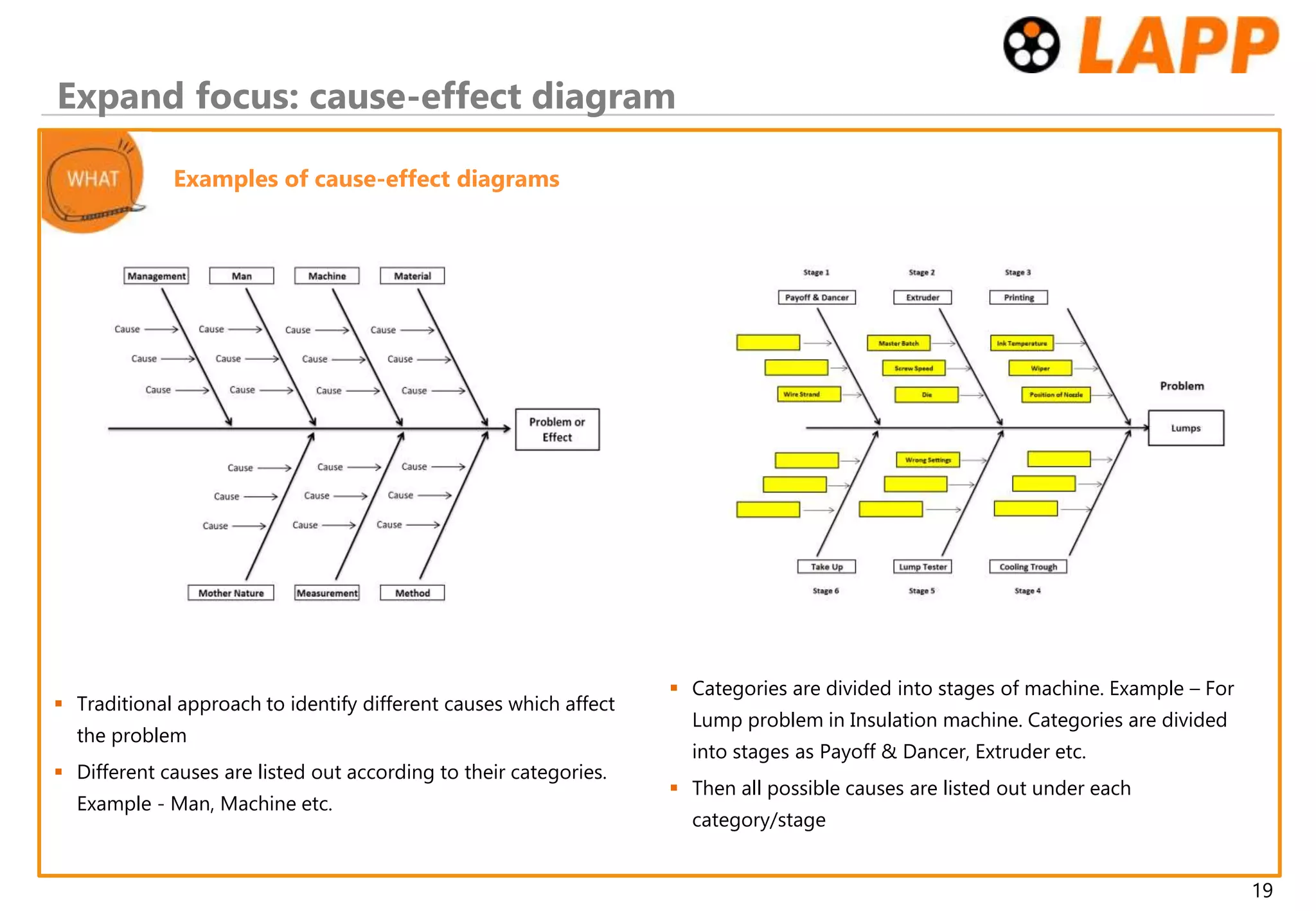

Structured problem solving follows a scientific approach to identify the root causes of problems in a repeatable way. The PDCA (Plan-Do-Check-Act) cycle is used to continuously improve and stabilize processes. When analyzing a problem, it is important to clearly describe what is observed, including the five W questions. To find the root cause, the focus starts by expanding to consider all possible causes, then narrows down using tools like cause-effect diagrams or the 5 why method. Developing solutions includes considering both short-term measures to reduce symptoms and long-term solutions to address the root cause. Alternatives should be evaluated against objective criteria.