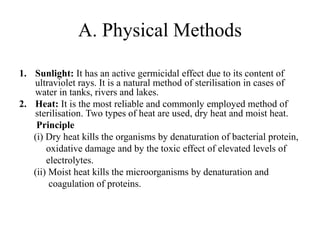

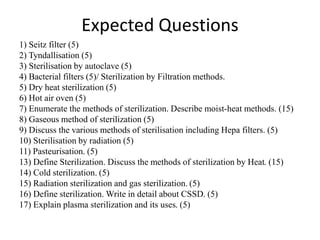

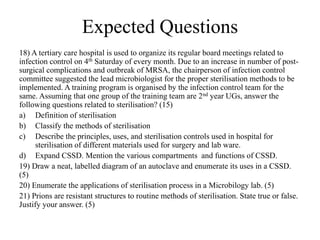

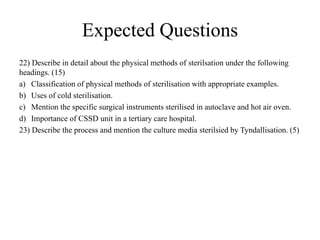

This document discusses various physical sterilization methods including heat, radiation, and filtration. It focuses on moist heat sterilization methods such as autoclaving, which uses steam under pressure at 121°C for 15 minutes to reliably kill microorganisms. Proper sterilization requires validation using biological indicators like Bacillus stearothermophilus spores to confirm sterilization conditions achieve a 6 log reduction in microorganisms. Physical sterilization methods are effective at eliminating pathogens but can damage heat or moisture sensitive materials so the appropriate method must be selected.