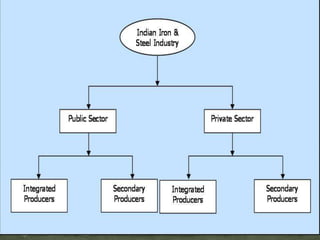

The steel industry produces steel which is an alloy of iron and carbon. World steel production has greatly increased over the past decades. China is currently the largest steel producer. Steel has a variety of important uses including in construction, automobiles, appliances, and infrastructure. The Indian steel industry has also grown significantly. It faces challenges regarding safety, profitability, competition, and will need to focus on R&D and infrastructure to support future growth.