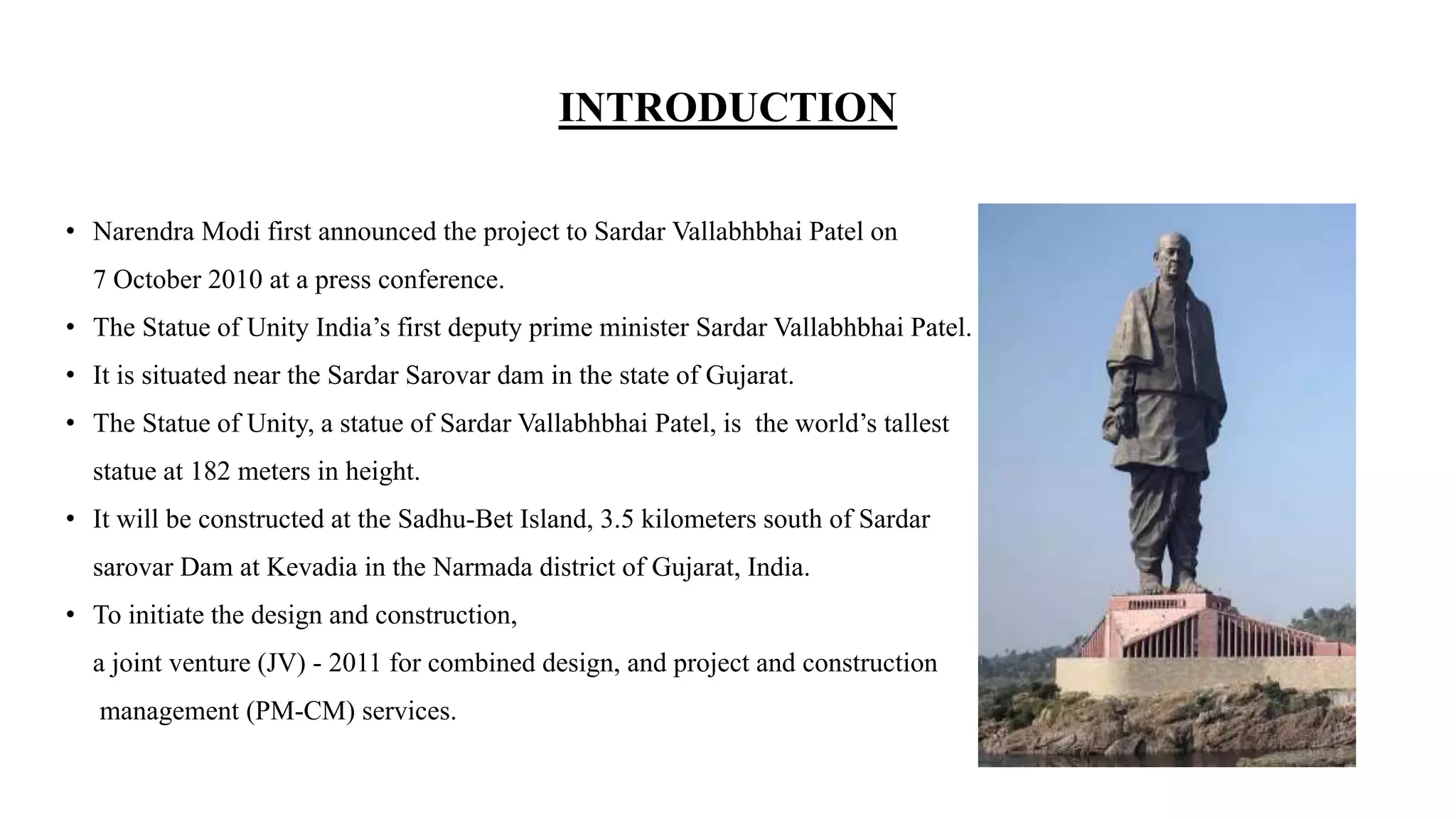

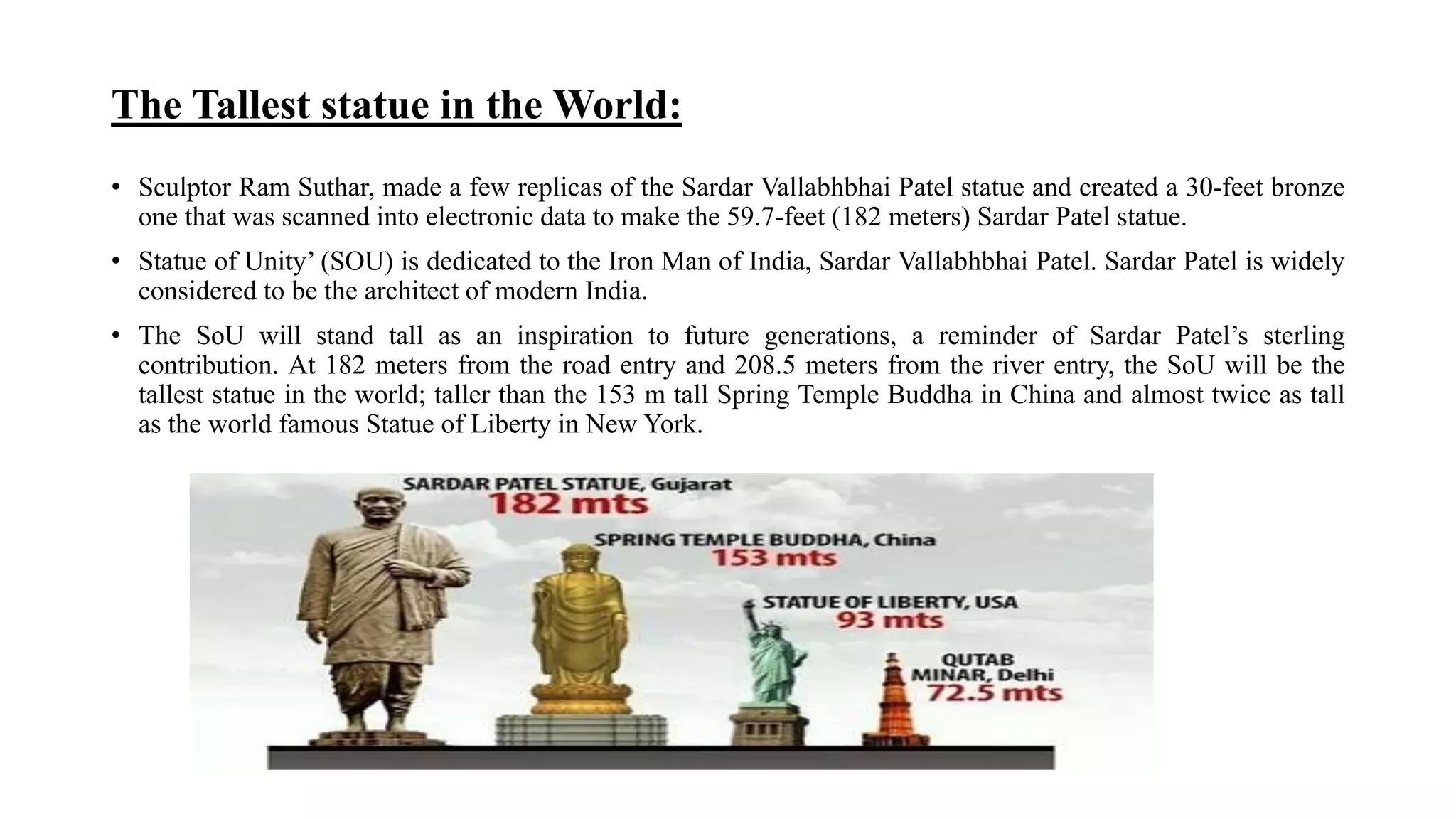

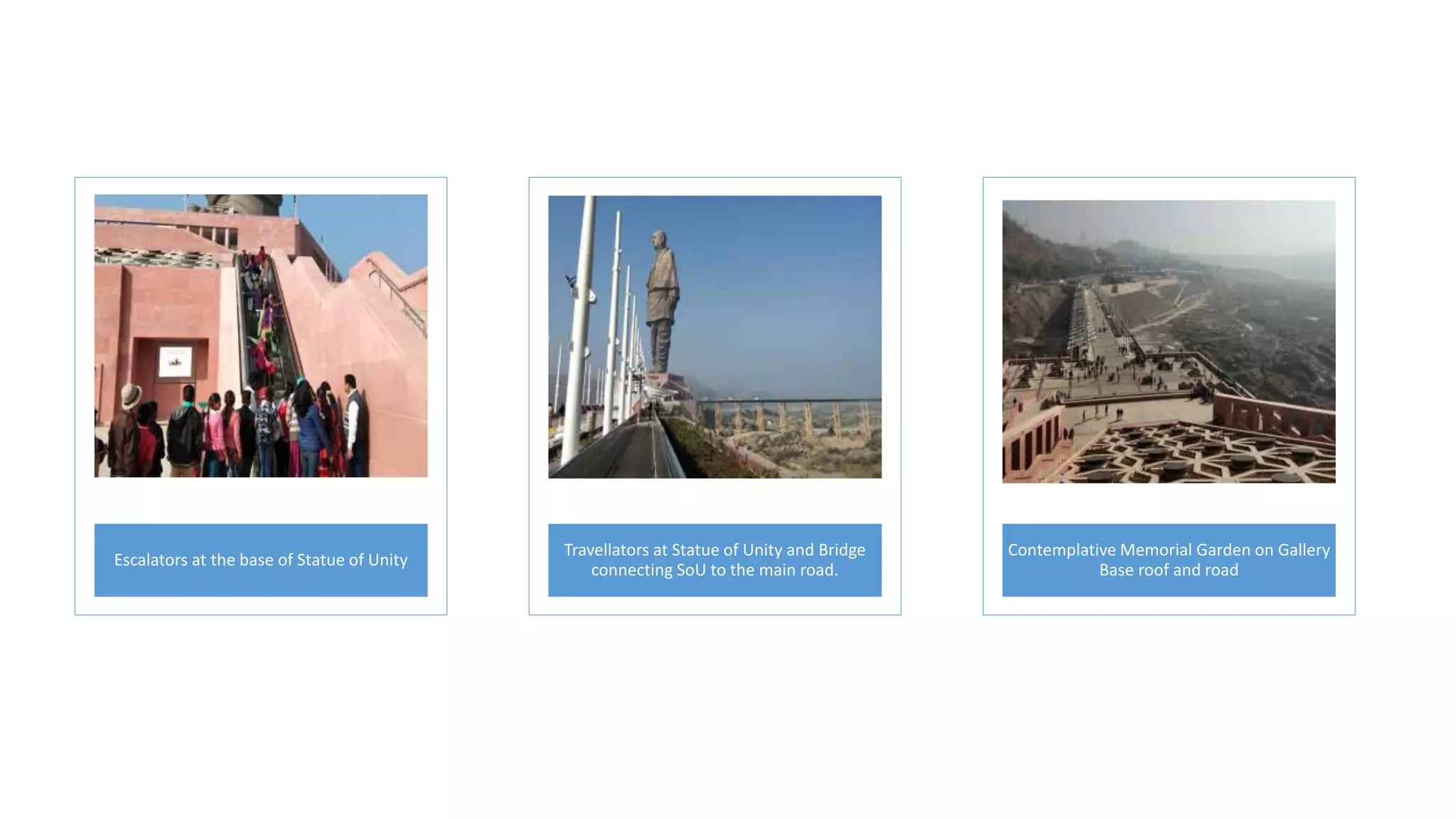

The document provides details about the Statue of Unity, the world's tallest statue located in Gujarat, India. It discusses the following key points:

1) The 182-meter tall statue was constructed between 2015-2018 to honor Sardar Vallabhbhai Patel, costing over $400 million.

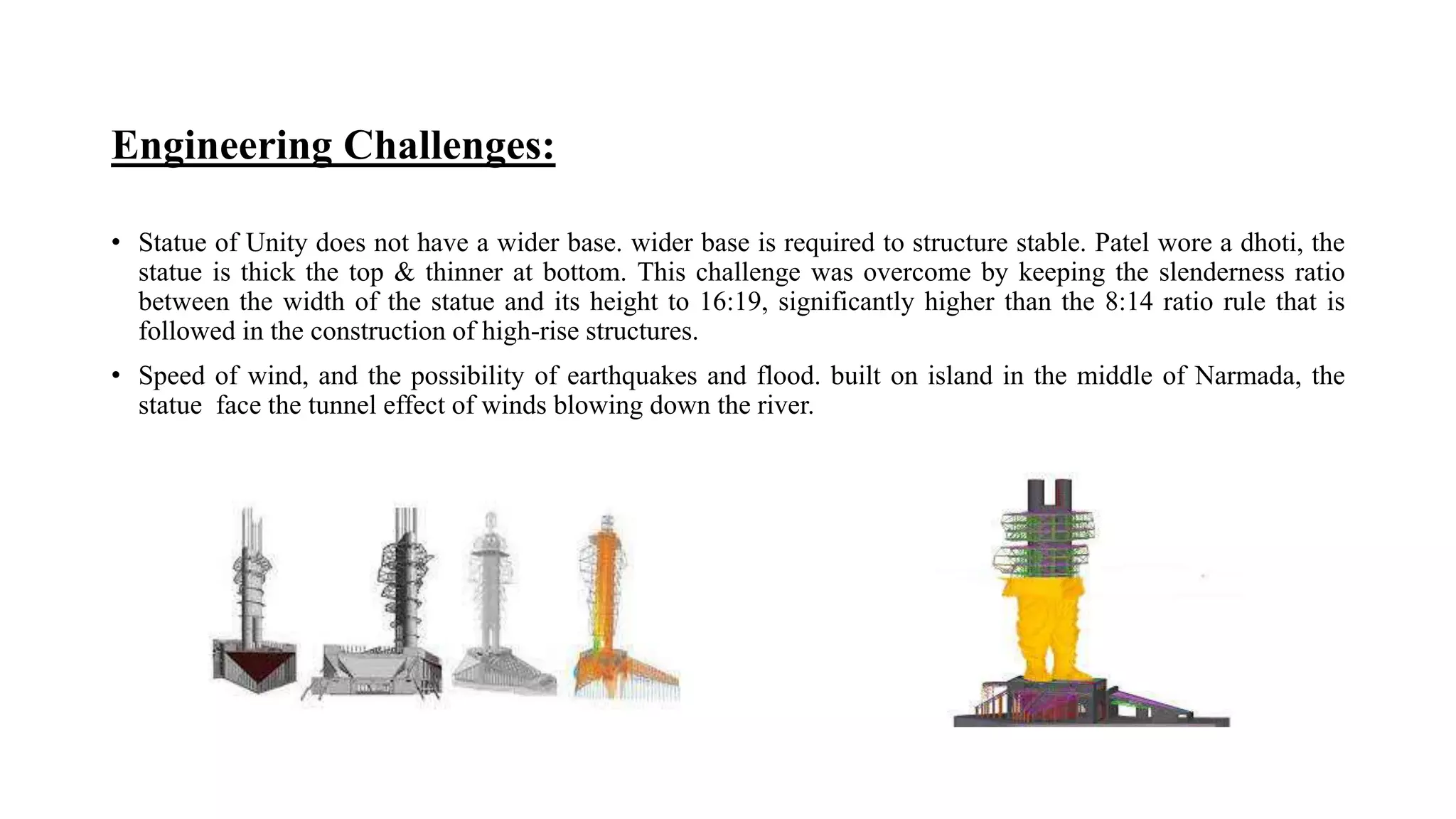

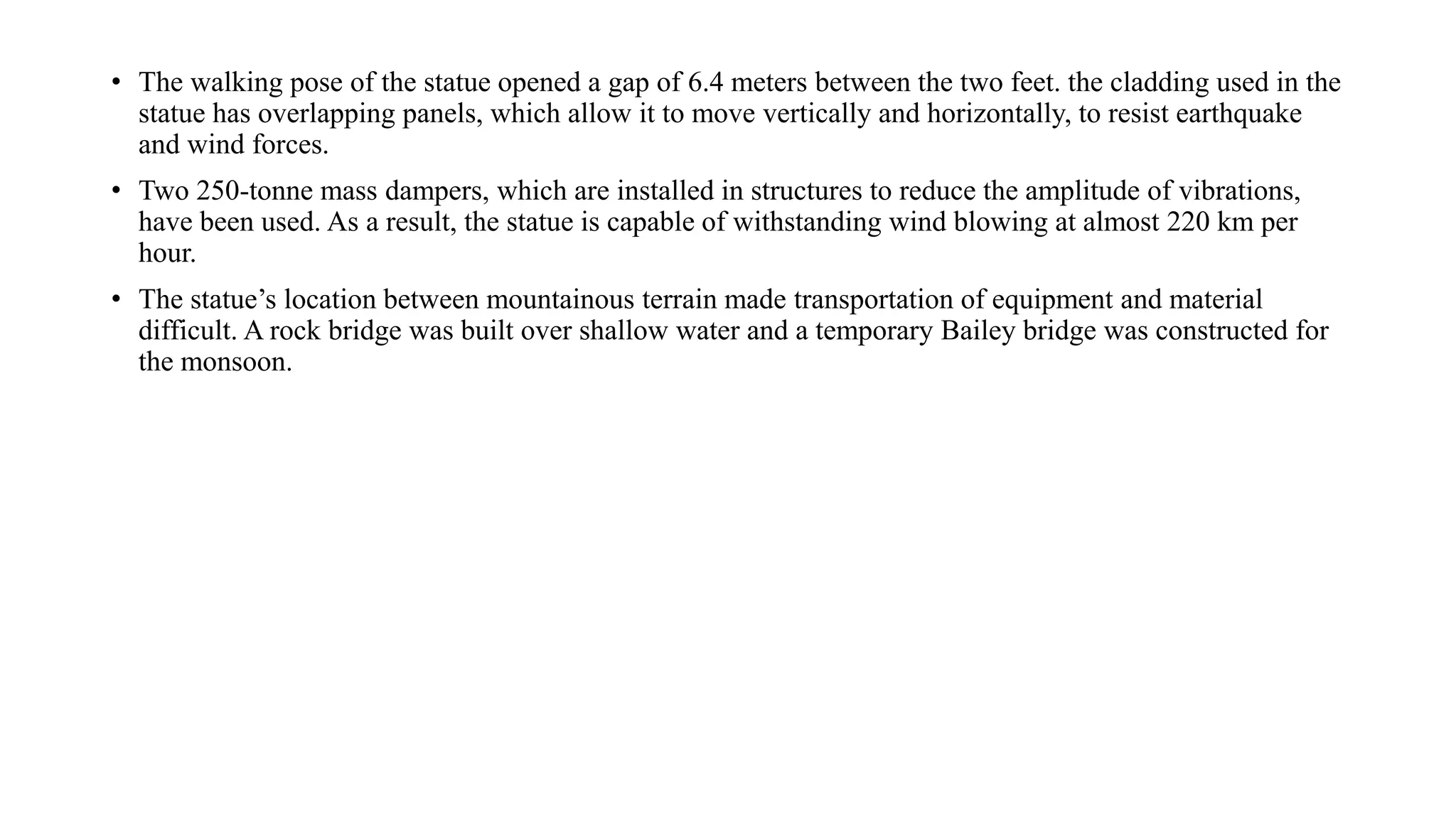

2) Unique engineering challenges included its slender shape with a narrow base, high winds, and seismic activity. The design incorporated dampers and overlapping cladding.

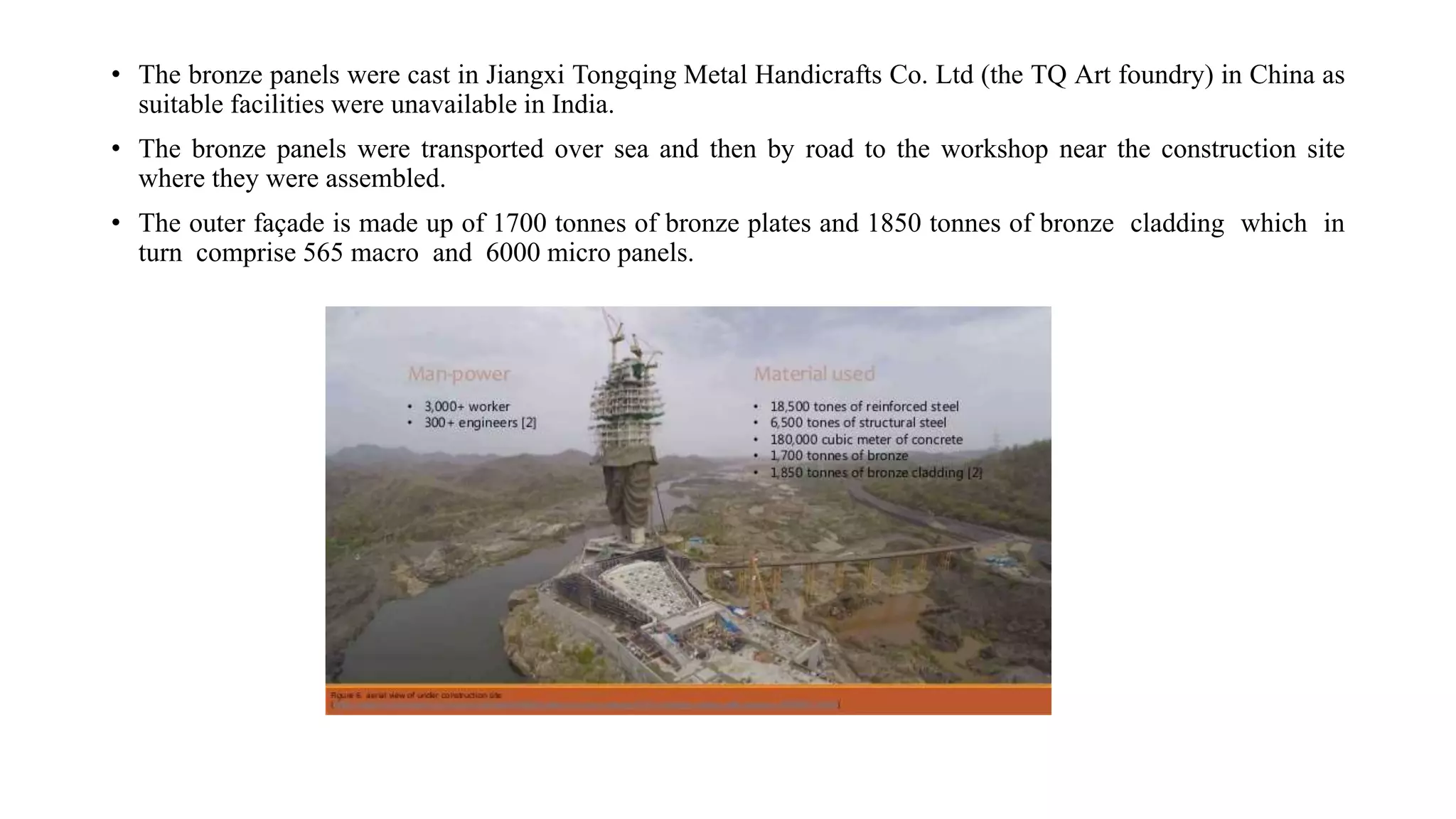

3) Over 6,500 tonnes of structural steel and concrete were used, with rebar collected from Indian farmers. The statue consists of two reinforced concrete cores within a cladded outer structure.