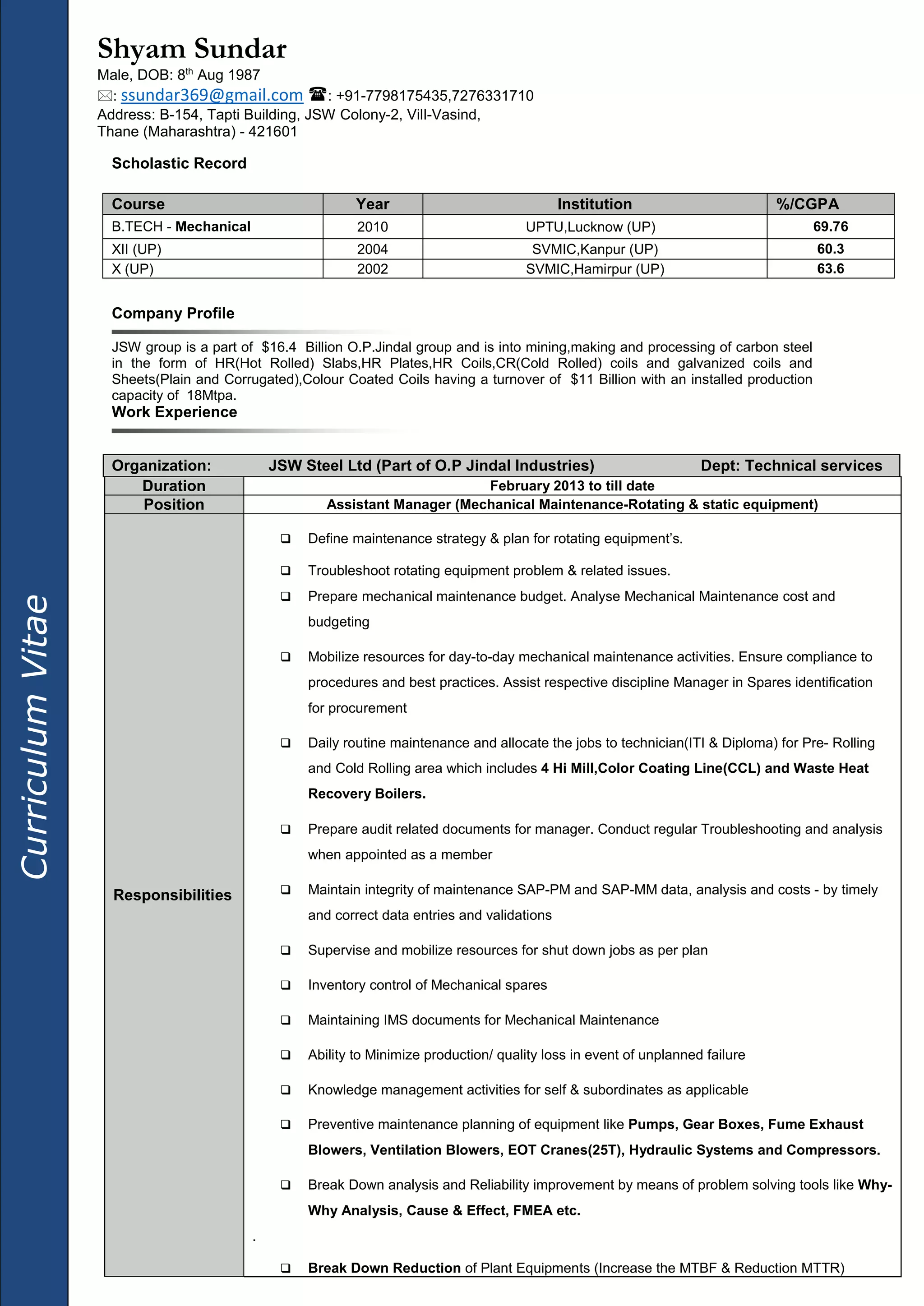

JSW group is a $16.4 billion steel manufacturing company with an annual turnover of $11 billion and production capacity of 18 million tons per annum. The applicant has over 9 years of experience in mechanical maintenance roles at JSW Steel and Bhushan Steel, including defining maintenance strategies, troubleshooting equipment issues, budgeting, and ensuring compliance with ISO and other standards. Currently serving as Assistant Manager of Mechanical Maintenance at JSW Steel, responsibilities include preventative maintenance planning and allocation, breakdown analysis and reliability improvement, and shutdown coordination.