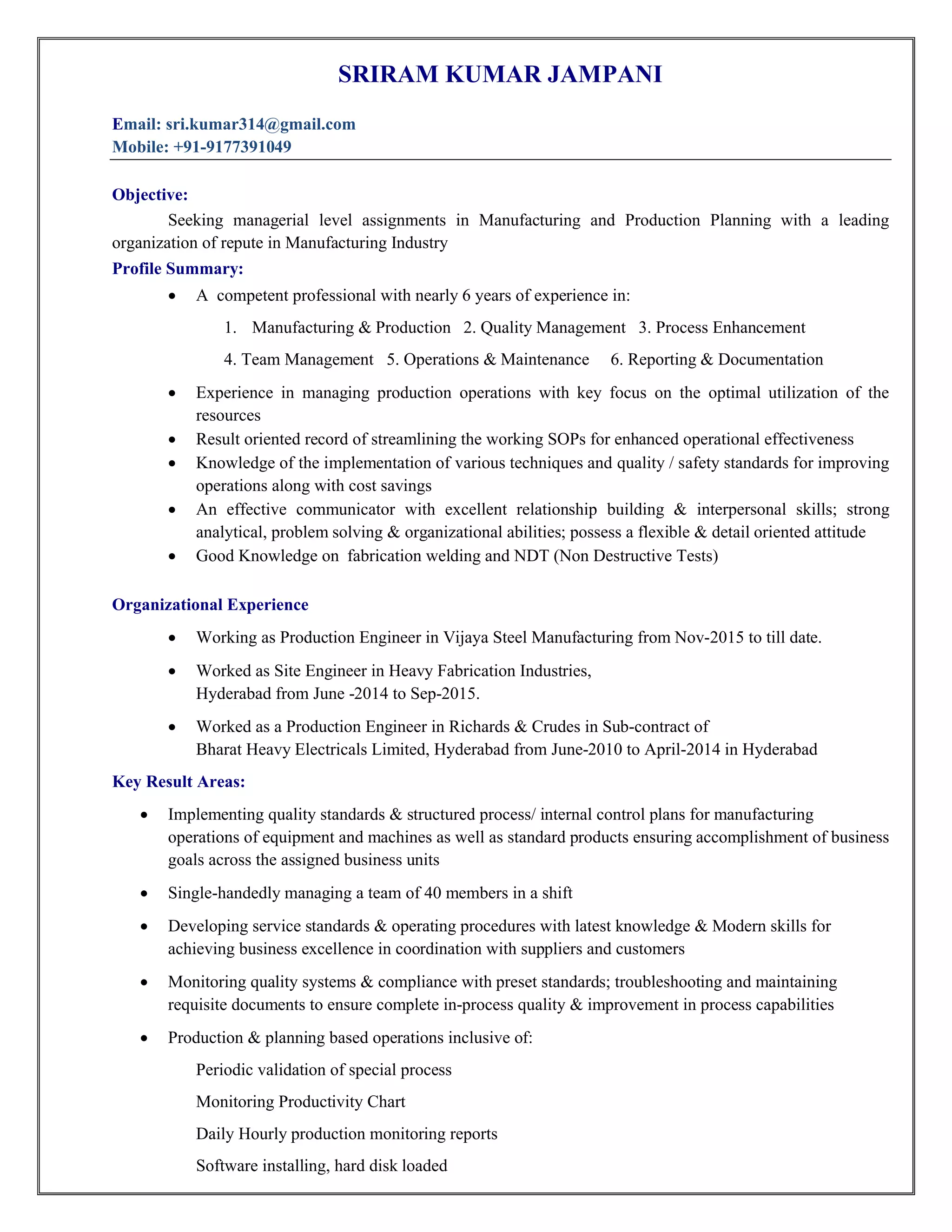

Sriram Kumar Jampani is seeking managerial level positions in manufacturing and production planning. He has 6 years of experience in manufacturing, quality management, process enhancement, team management, and operations. He is currently working as a Production Engineer at Vijaya Steel Manufacturing, with prior experience at Heavy Fabrication Industries and Richards & Crudes. He has experience managing a team of 40, implementing quality standards, and monitoring productivity. He holds a B.Tech in Mechanical Engineering and a diploma in Automobile Engineering.