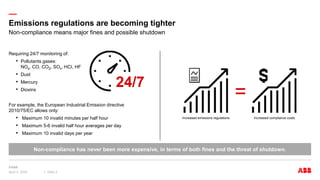

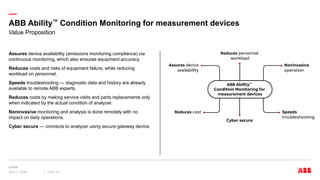

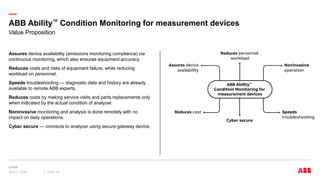

1) Emissions regulations are becoming stricter, requiring 24/7 monitoring and allowing minimal invalid readings, meaning increased compliance costs and risk of fines or shutdowns for non-compliance.

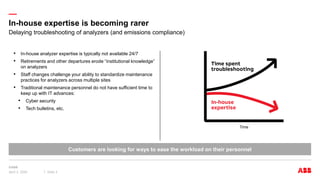

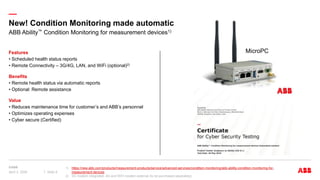

2) In-house expertise on analyzers is declining due to retirements and staff changes, and traditional maintenance personnel lack time to keep up with advances, so customers seek ways to ease workload.

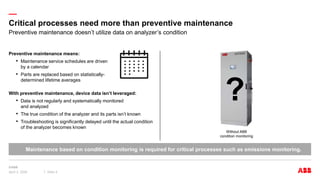

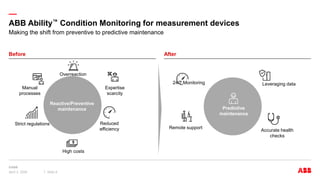

3) Preventive maintenance alone is not sufficient for critical emissions monitoring processes - condition monitoring is needed to optimize costs and labor by enabling predictive maintenance based on the actual device condition.