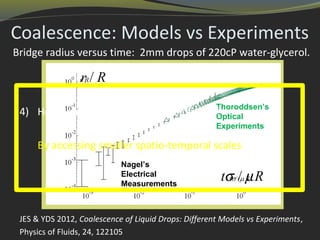

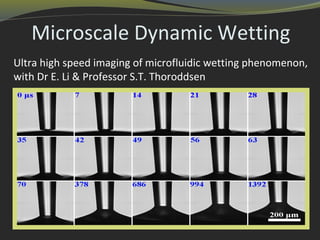

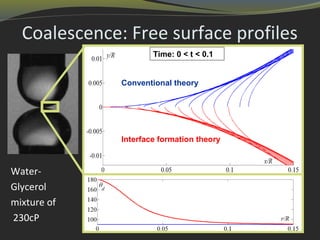

1) Computational techniques are essential for accurately simulating high-speed coating flows that conventional asymptotic models cannot capture. Accessing smaller spatio-temporal scales through computation and experiment is needed to identify the true physics.

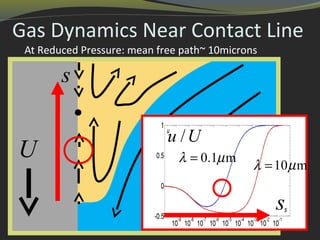

2) Gas dynamics, particularly the mean free path of gas molecules, play a key role in phenomena like air entrainment in coating flows. At reduced pressures, the longer mean free path can delay air entrainment.

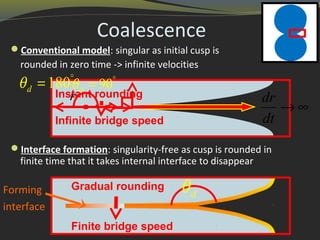

3) There is still debate around wetting because different models can describe experiments reasonably well using different parameter values. Fully resolving interfaces and accessing microscales may be needed to definitively identify the governing physics.

![2u 1

u 0, u u up

t

ν

ρ

∂

∇× = + ×∇ = − ∇ + ∇

∂

s s

1 1 1 2 2 2

1 3 2

v e v e 0

cos

s s

d

ρ ρ

σ θ σ σ

× + × =

= −

s

1

*

1

*

1

s 1 1

1

s 1 11

1 1

1 1|| ||

v 0

n [( u) ( u) ] n n

n [( u) ( u) ] (I nn) 0

(u v ) n

( v )

(1 4 ) 4 (v u )

s s

e

s ss

s e

s

f

f

t

p

t

µ σ

µ σ

ρ ρ

ρ

τ

ρ ρρ

ρ

τ

αβ σ β

∂

+ ×∇ =

∂

− + × ∇ + ∇ × = ∇×

× ∇ + ∇ × − + ∇ =

−

− × =

−∂

+ ∇ = −

∂

+ ∇ = −

In the bulk (Navier Stokes):

At contact lines:

On free surfaces:

Interface Formation Model

θd

e2

e1

n

n

f (r, t )=0

Interface Formation Modelling

( )*

2 || ||

s 2 2

2

s 2 22

2 2

2|| || || 2

2

1,2 1,2 1,2

1n [ u ( u) ] (I nn) u U

2

(u v ) n

( v )

1v (u U )

2

( )

s s

e

s ss

s e

s

s s

t

a b

µ σ β

ρ ρ

ρ

τ

ρ ρρ

ρ

τ

α σ

σ ρ ρ

×∇ + ∇ × − + ∇ = −

−

− × =

−∂

+ ∇ × = −

∂

= + = ∇

= −

Liquid-solid interface](https://image.slidesharecdn.com/sprittlespresentation-131004084147-phpapp02/85/Sprittles-presentation-23-320.jpg)