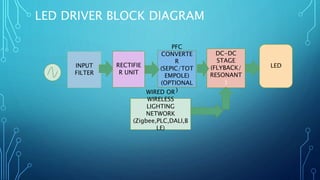

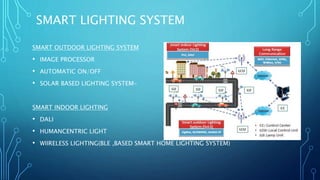

The document discusses power electronics in smart LED lighting, highlighting advantages like energy efficiency and long lifespan. It outlines recent trends in LED drivers, including the use of fly-back converters and programmable drivers in IoT-enabled systems. Future developments in lighting technologies such as LiFi and AI applications are also mentioned.