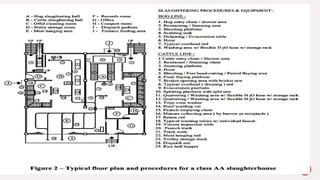

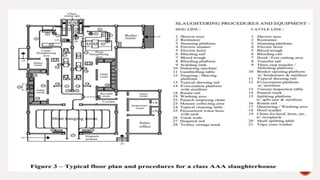

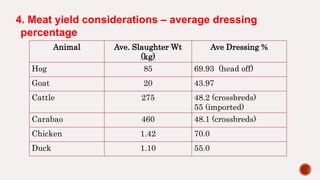

This document discusses slaughterhouses and factors to consider for slaughtering animals. It defines three classifications (A, AA, AAA) of slaughterhouses based on facilities and procedures. Classification AAA slaughterhouses have fully automated facilities and apply Hazard Analysis and Critical Control Point programs. Several requirements for slaughterhouse sites are outlined. The document also discusses types of slaughter systems, facility areas and equipment, extraction rates for different animal species, and factors to consider for animal handling and slaughtering such as cleanliness, hygiene practices, and meat inspection.