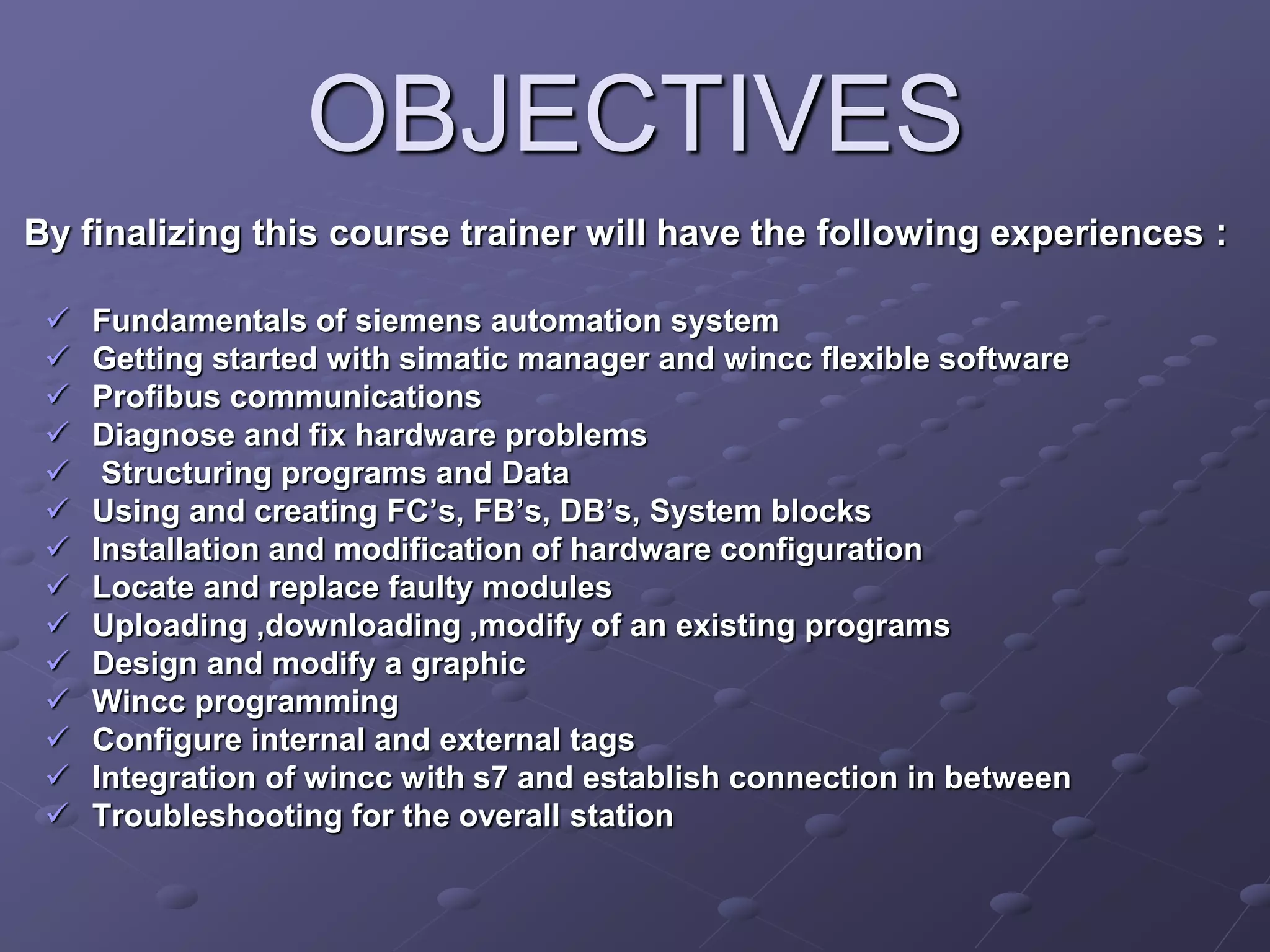

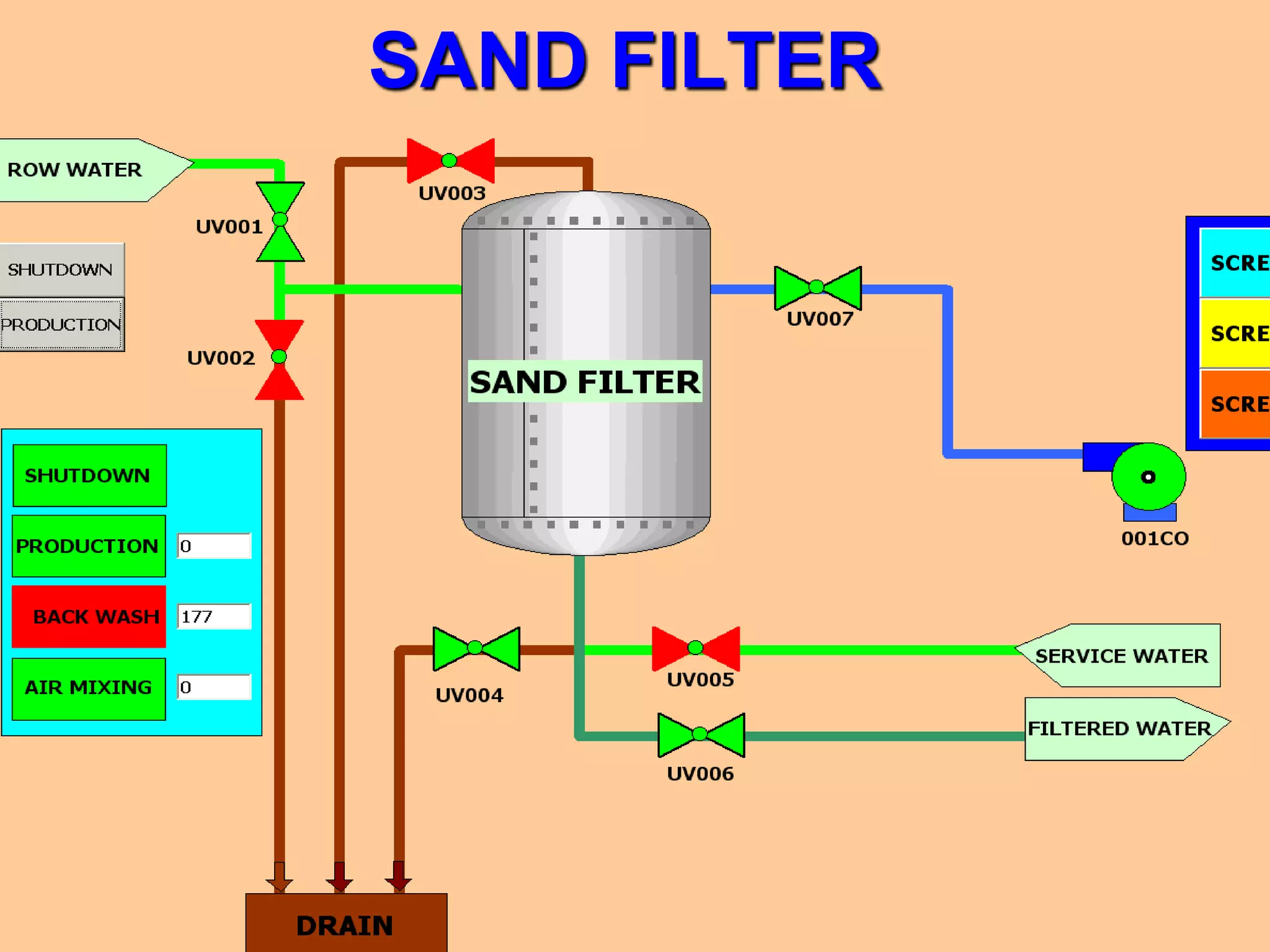

This document provides information about an upcoming training course on Siemens automation systems. The course will cover fundamentals of Siemens S7 PLCs and WinCC SCADA software, including programming in LAD, FBD and STL; hardware configuration; communication via Profibus; creating and modifying function blocks, data blocks and system blocks; graphic design in WinCC; and troubleshooting automation systems. Hands-on exercises will include projects for controlling motors, HCL dilution, a sand filter, and water treatment systems. The goal is for trainees to gain experience installing, maintaining and programming Siemens automation systems.