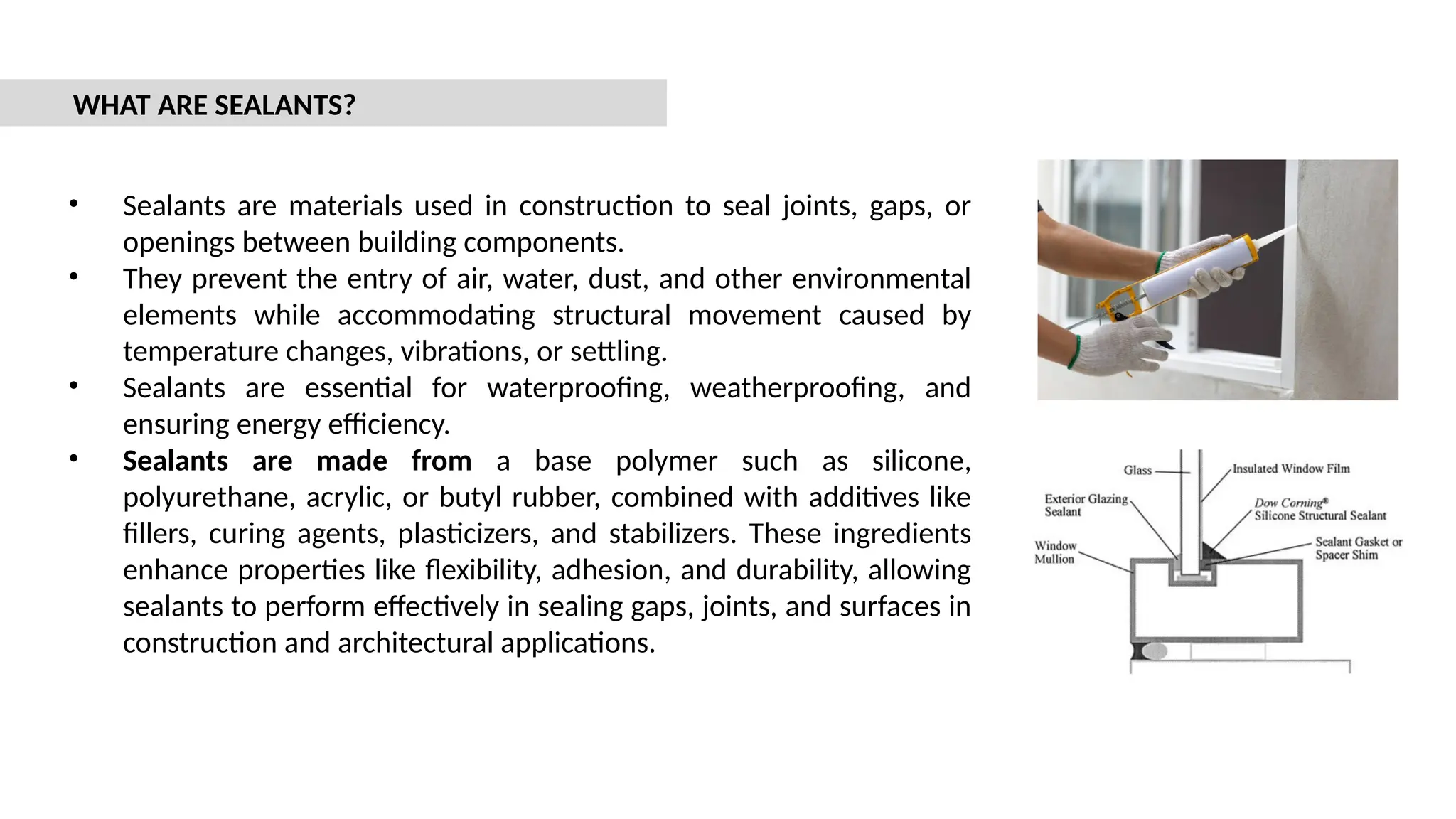

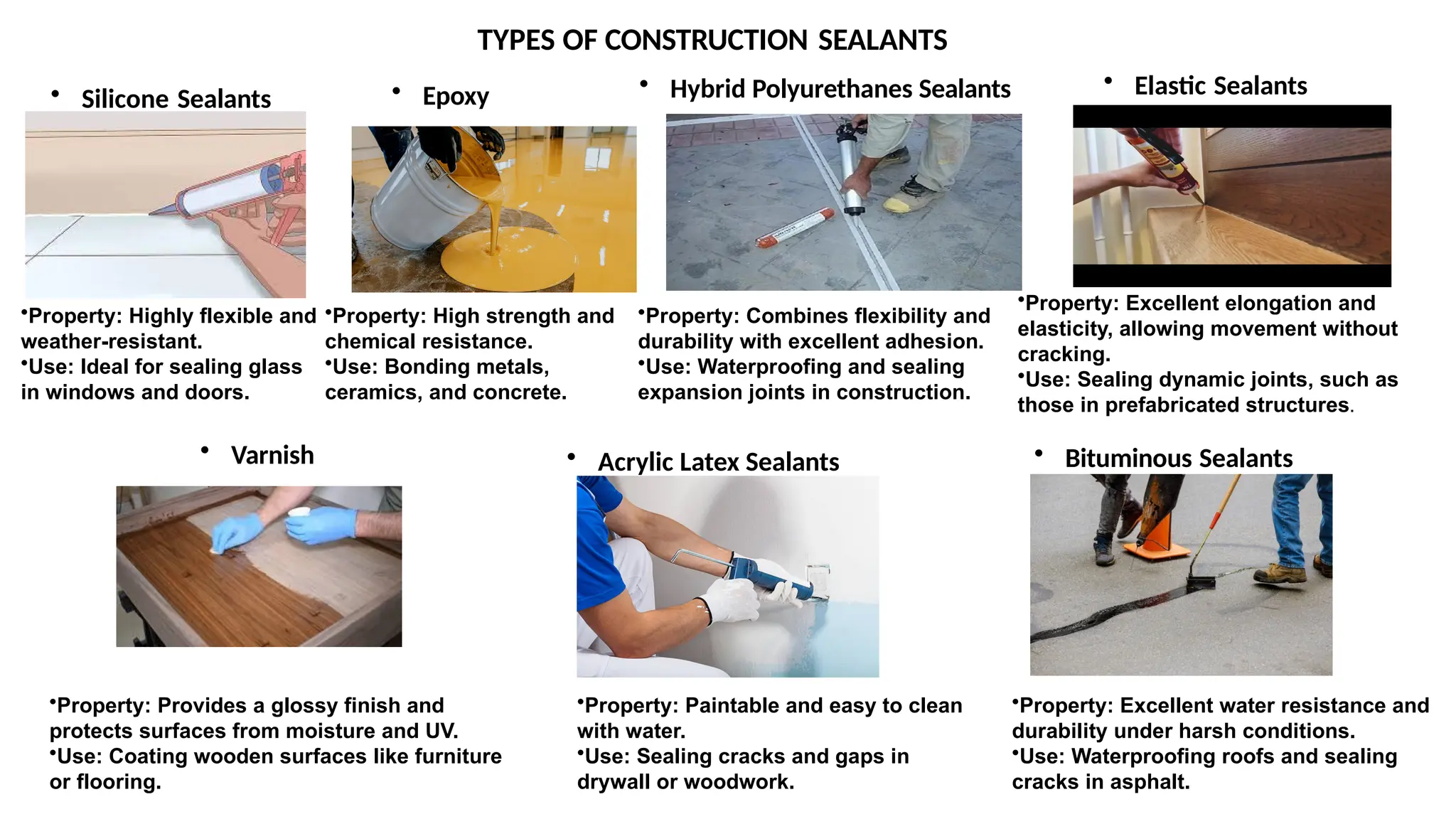

The document provides an extensive overview of mastic sealants, detailing their properties, types, and applications in construction. It highlights the essential characteristics of good sealants such as adhesion, elasticity, and durability, as well as the factors influencing their selection. The document also addresses the advantages and disadvantages of using sealants, along with best practices for their application to ensure effectiveness.