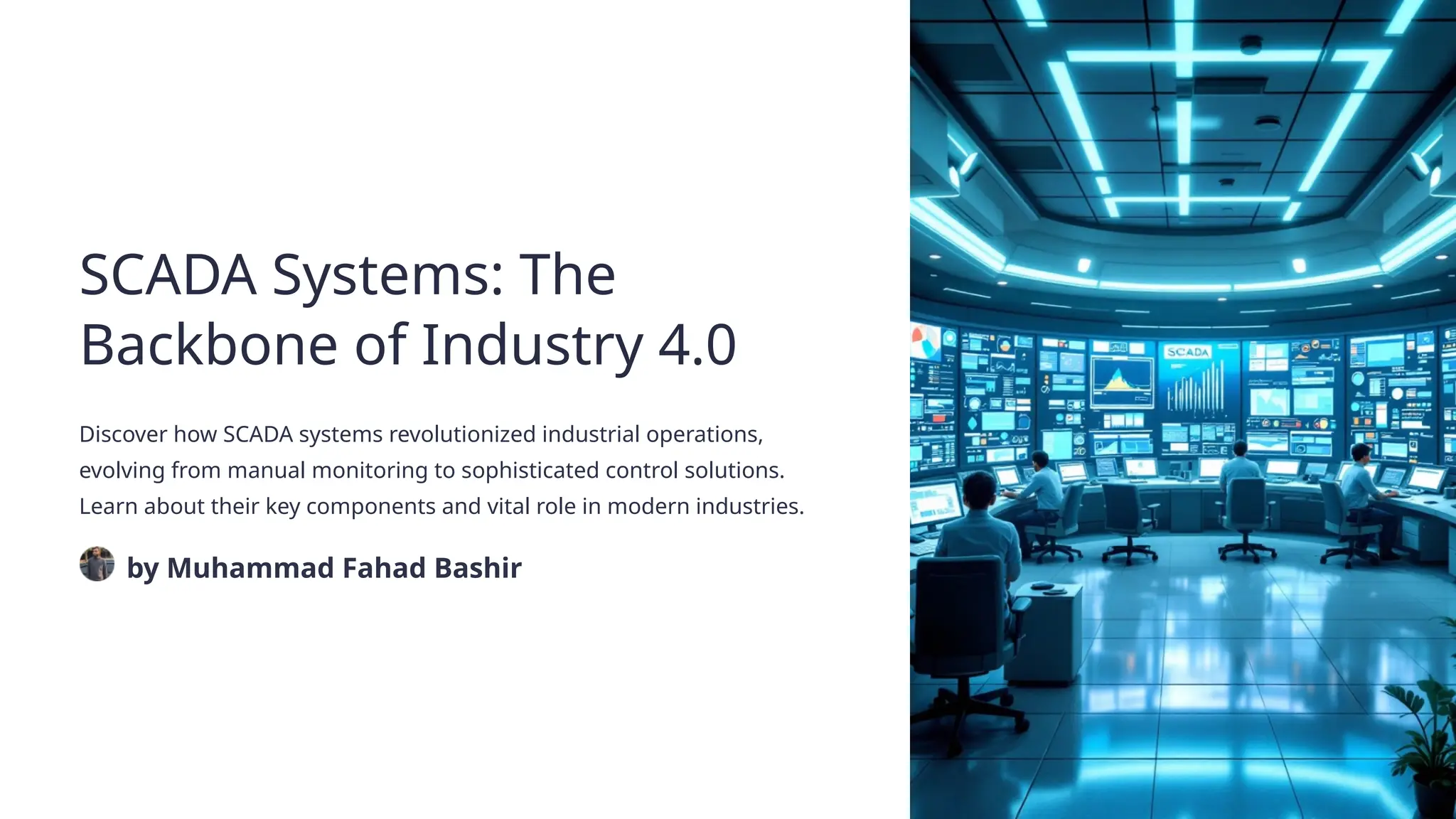

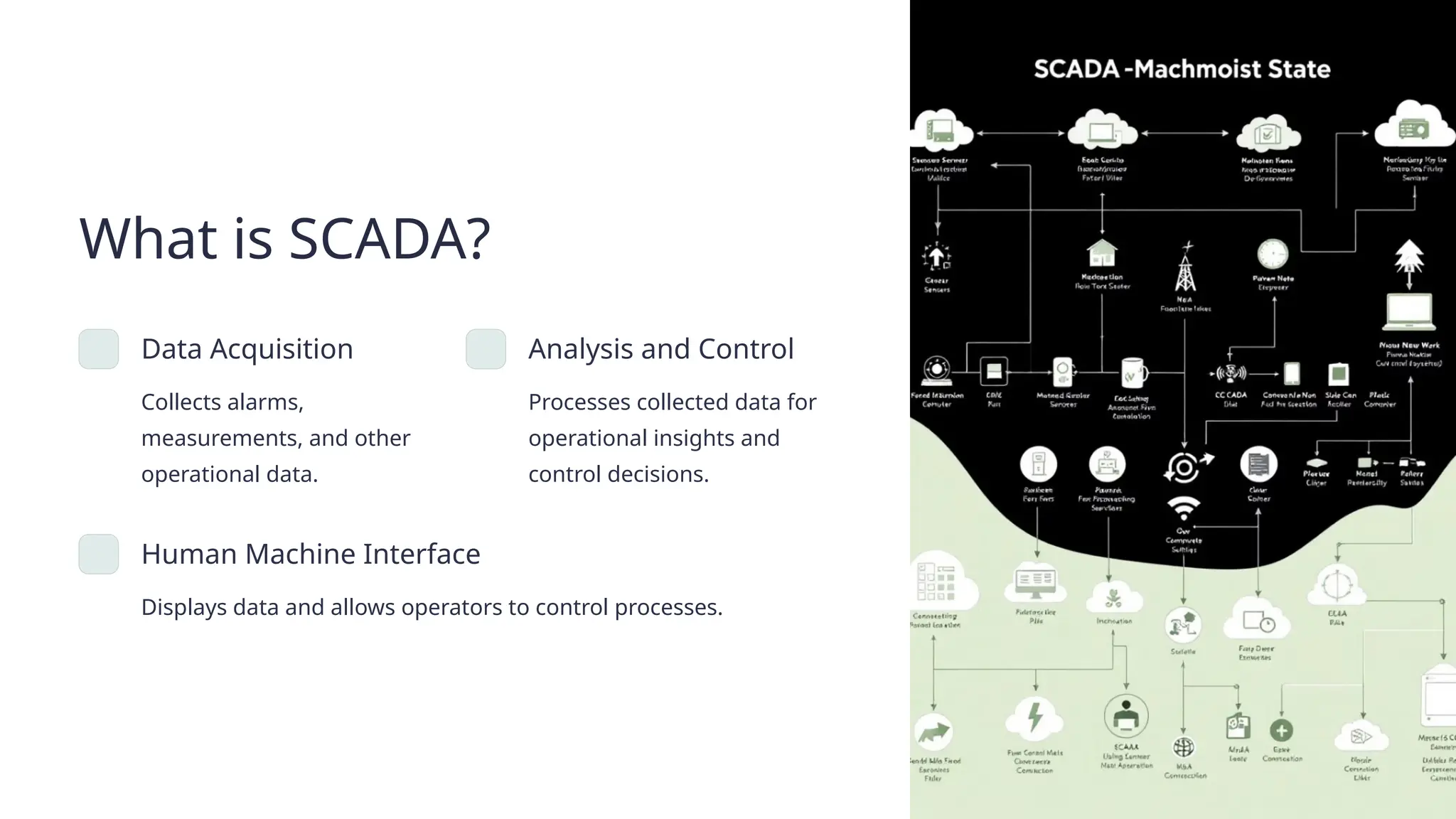

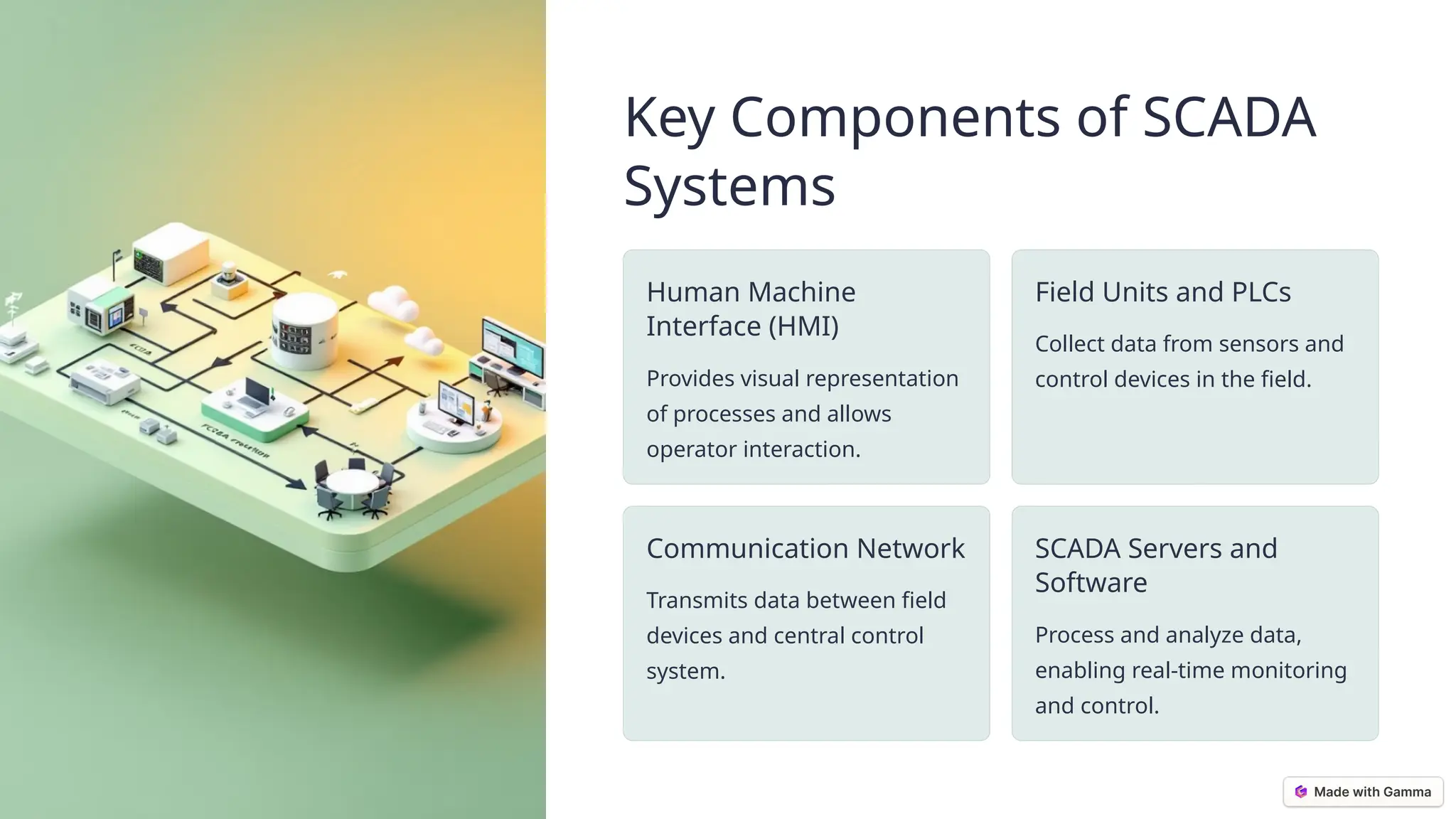

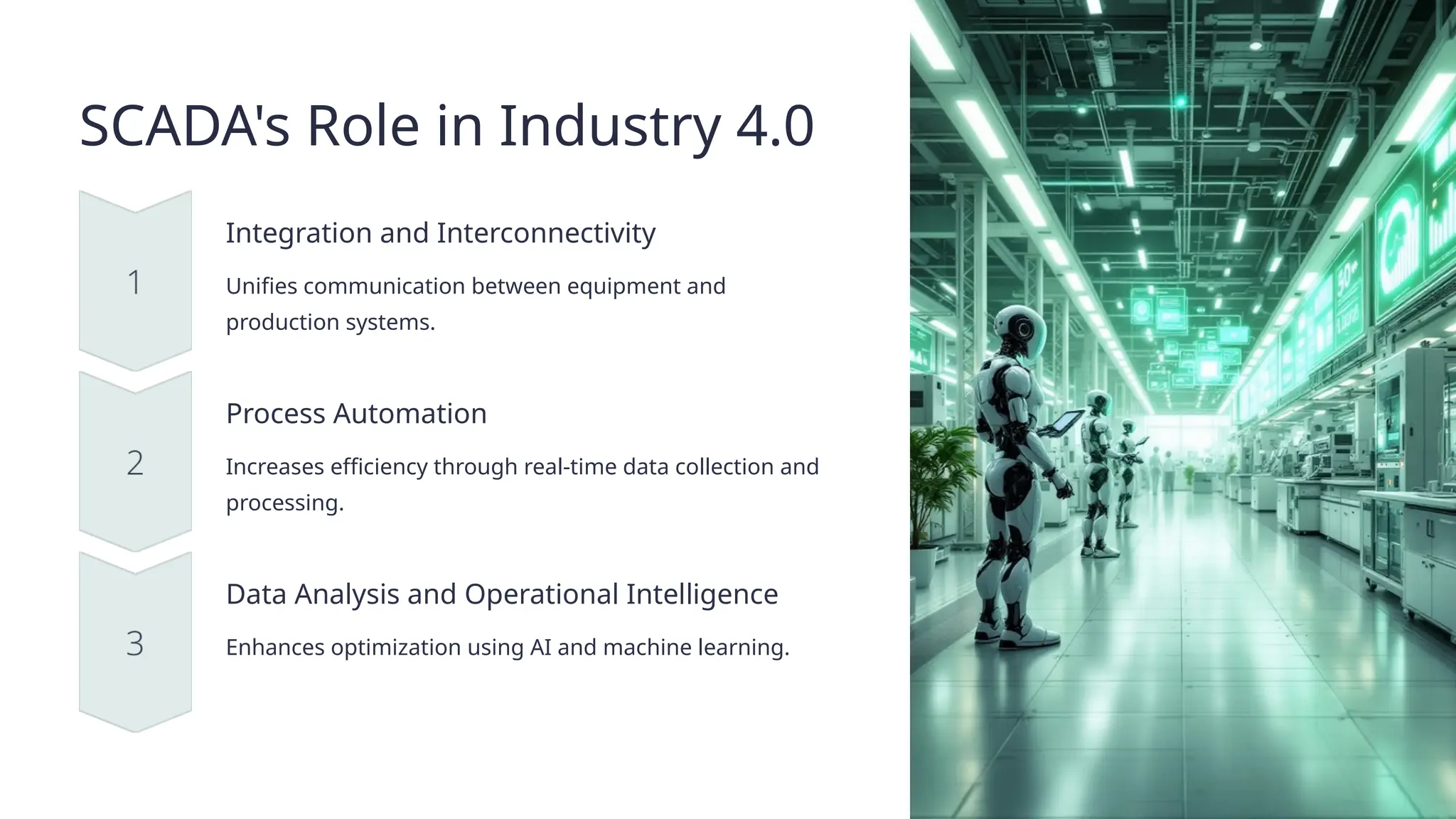

SCADA systems have evolved from manual monitoring to advanced control solutions, playing a vital role in modern industries such as manufacturing, water distribution, and energy. Key components include human-machine interfaces, field units, and communication networks, contributing to enhanced process automation and data analysis. The future of SCADA involves operational intelligence, advanced analytics, and improved security measures to foster smarter industrial management.