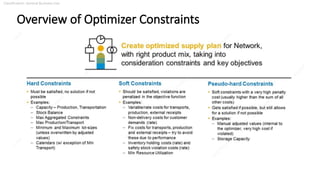

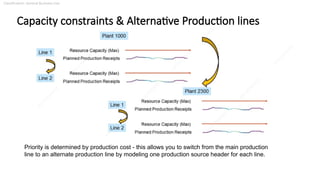

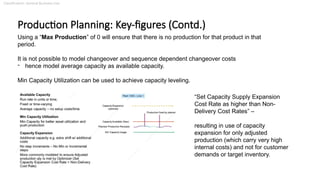

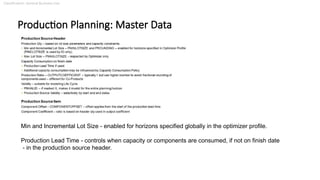

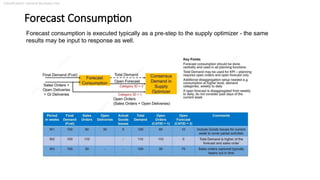

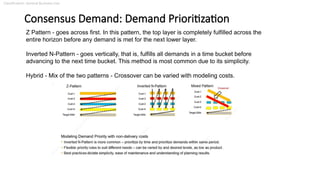

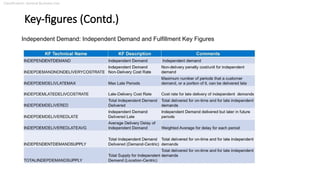

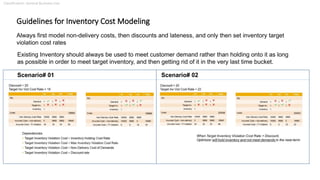

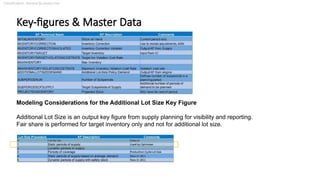

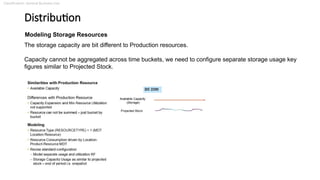

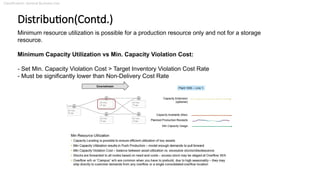

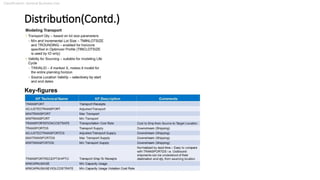

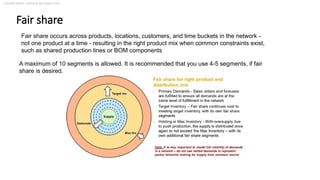

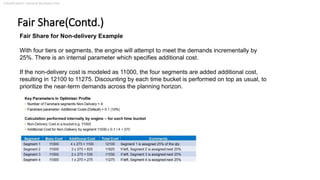

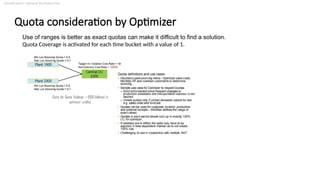

The document provides comprehensive guidelines for optimizing production planning, inventory management, and demand fulfillment within a business context. It outlines the classifications and key figures related to open-ended planning constraints, cost modeling, and demand prioritization patterns, emphasising best practices such as starting costs at reasonable levels and ensuring existing inventory meets customer demands first. Additionally, it discusses the importance of proper resource utilization and effective fair share strategies across products and time buckets within distribution networks.