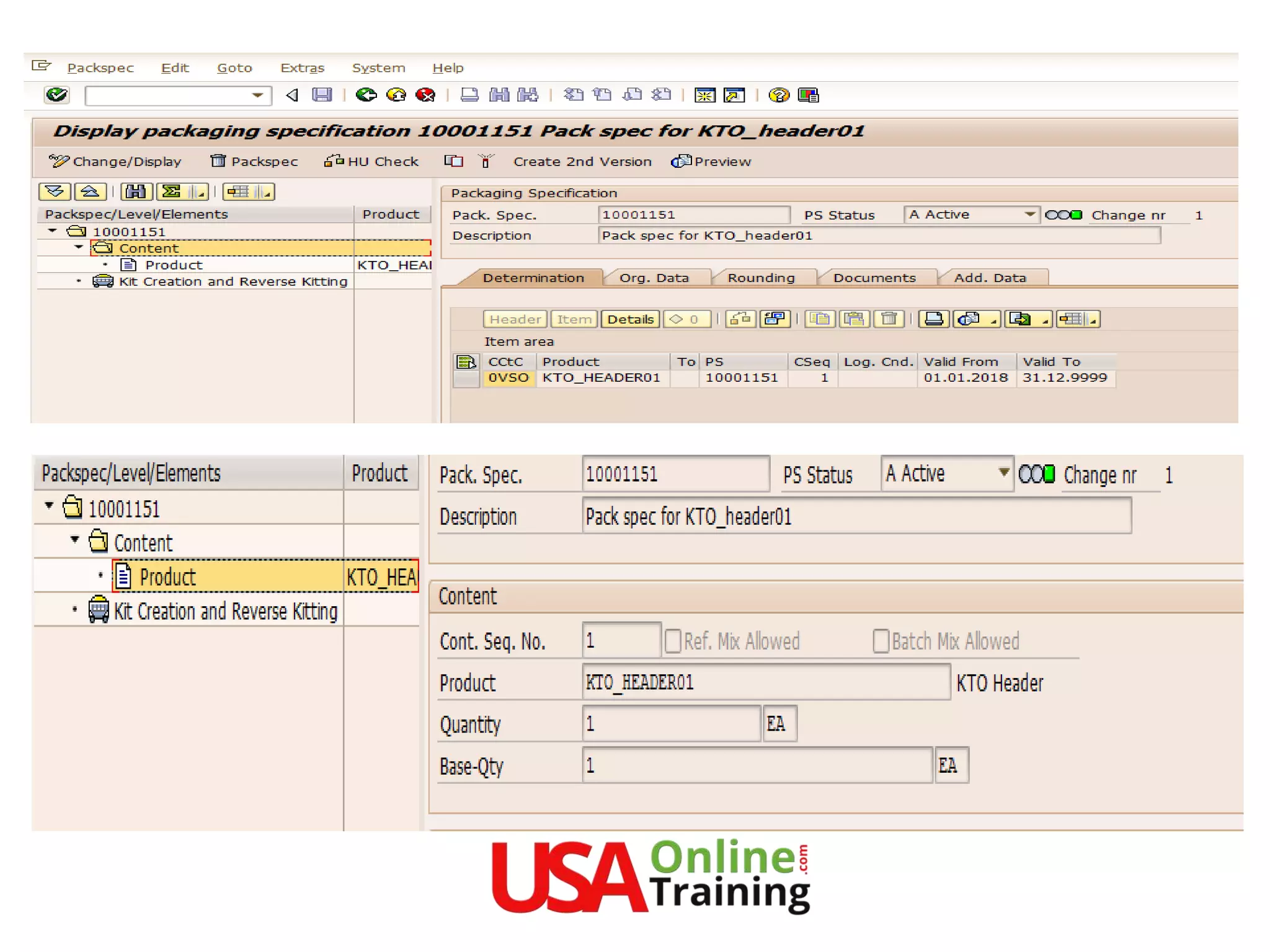

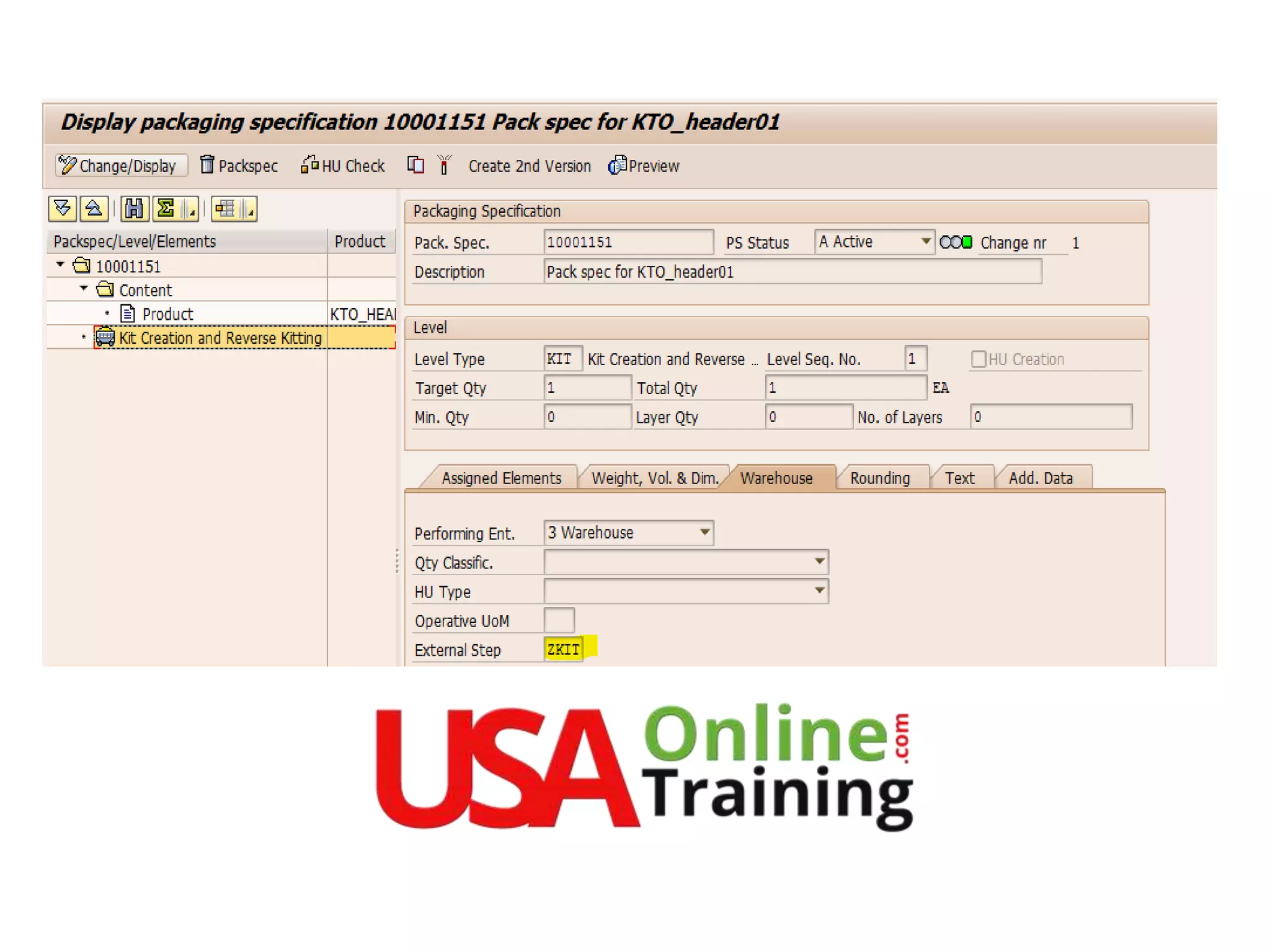

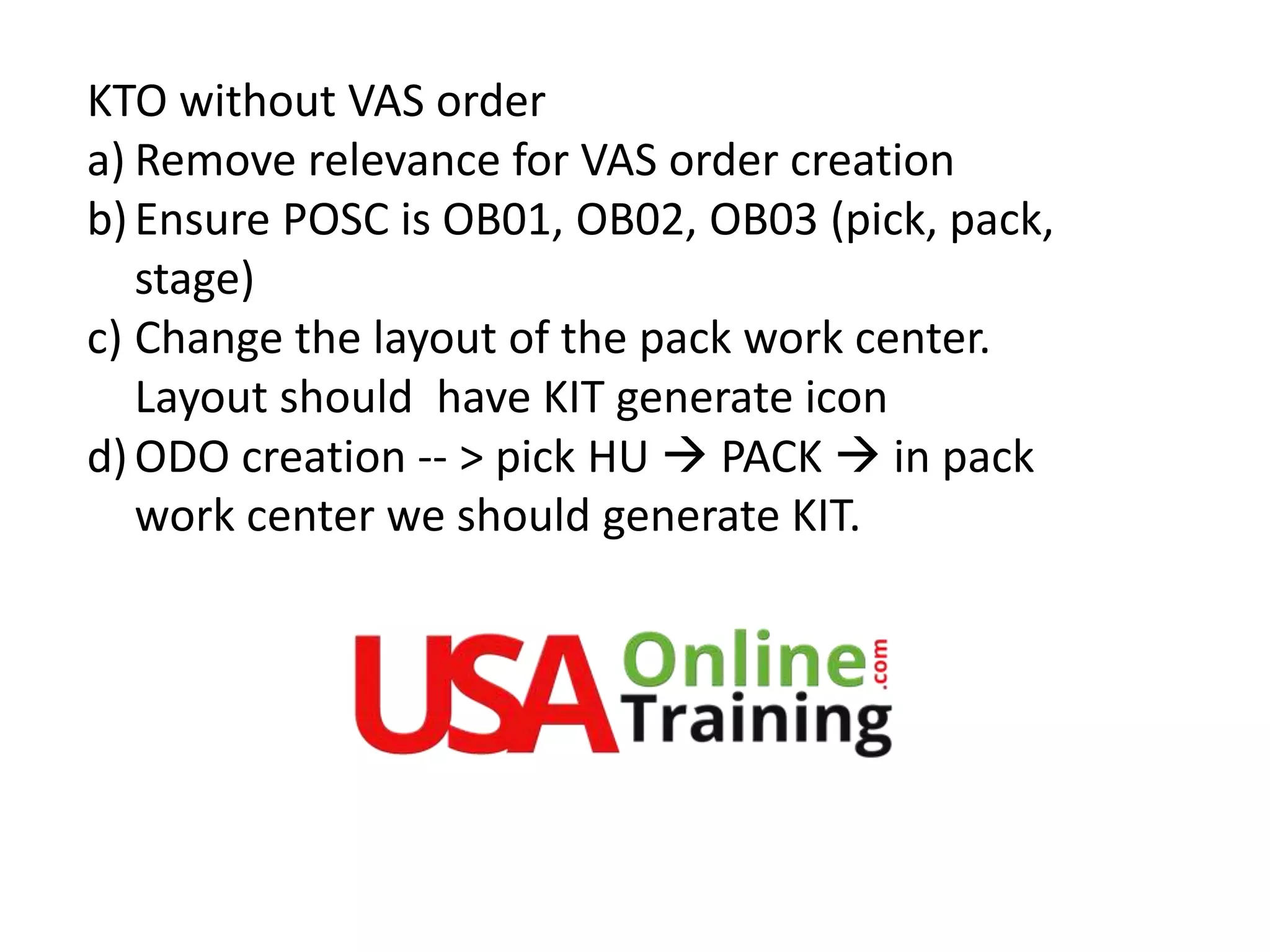

The document explains the process and functionalities of kitting in SAP Extended Warehouse Management (EWM), detailing how kits are created, managed, and delivered. It outlines three main methods: kit to order, kit to stock, and reverse kitting, while emphasizing that kits are treated as composed of components rather than saved as master data. Additionally, it discusses system integration requirements, order processing, and the settings needed for efficient kitting operations in EWM.