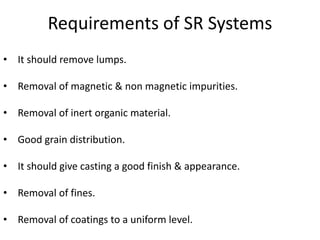

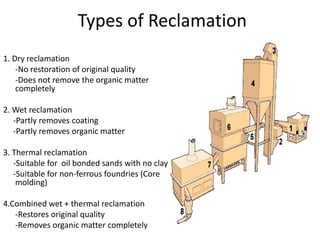

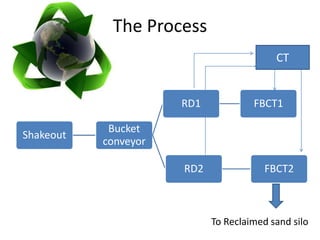

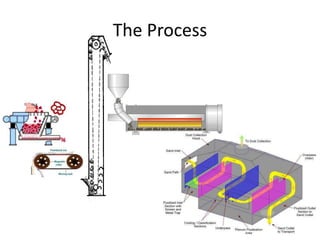

The document discusses foundry sand reclamation. It explains that reclamation offers economic and environmental benefits by reducing purchase and freight costs of new sand and complying with regulations. The key steps in reclamation are shakeout, crushing, cooling, scrubbing, classification, and storage. There are four main types of reclamation: dry, wet, thermal, and combined wet and thermal. The thermal process is suitable for oil-bonded sands without clay and for non-ferrous foundries. Reclamation systems must effectively remove impurities, coatings, and fines to produce sand with uniform properties for casting.