This document provides guidance on the selection and use of subsea leak detection systems. It summarizes current industry experience with subsea leak detection technologies and methods. The document covers relevant regulations, field experience to date, available technologies and their characteristics. It also provides guidance on designing, installing, operating, calibrating and improving subsea leak detection systems to reliably detect hydrocarbon discharges to the environment.

![DET NORSKE VERITAS

Recommended Practice DNV-RP-F302, April 2010

Page 23

advanced stage in the development of activities and their meth-

ods of operation which indicate the practical suitability of par-

ticular techniques for providing in principle the basis for

emission limit values designed to prevent and, where that is not

practicable, generally to reduce emissions and the impact on

the environment as a whole:

- "techniques" shall include both the technology used and the

way in which the installation is designed, built, maintained,

operated and decommissioned,

- "available" techniques shall mean those developed on a scale

which allows implementation in the relevant industrial sector,

under economically and technically viable conditions, taking

into consideration the costs and advantages, whether or not

the techniques are used or produced inside the Member State

in question, as long as they are reasonably accessible to the

operator,

- "best" shall mean most effective in achieving a high general

level of protection of the environment as a whole.”

The BAT principle is also referenced in PSA Norway’s Frame-

work regulation /21/, section 9, paragraph 2:

“In effectuating risk reduction the party responsible shall

choose the technical, operational or organisational solutions

which according to an individual as well as an overall evalua-

tion of the potential harm and present and future use offer the

best results, provided the associated costs are not significantly

disproportionate to the risk reduction achieved.”

From the guideline to section 9:

“The second paragraph expresses the principle of best availa-

ble technology (the BAT principle). This entails that the party

responsible for the petroleum activities must base its planning

and operation on the technology and methods that, based on

an overall assessment, produce the best and most effective

results.”

More information can be found at

http://eippcb.jrc.es/

http://ec.europa.eu/environment/air/pollutants/stationary/

ippc/index.htm

B.3 THE UNITED KINGDOM

The Health and Safety Executive (HSE) in the United King-

dom have the Pipelines Safety Regulations [PSR] (SI 1996/

825) /27/ as the key regulations concerning pipeline safety and

integrity. There are at present no specific regulations concern-

ing subsea production systems. The regulations came into

force in 1996, replacing earlier prescriptive legislation on the

management of pipeline safety with a more integrated, goal-

setting, risk based approach encompassing both onshore and

offshore pipelines. PSR does not cover the environmental

aspects of accidents arising from pipelines but compliance

with the regulations will help to ensure that a pipeline is

designed, constructed and operated safely, provide a means of

securing pipeline integrity and thereby will contribute by

reducing risks to the environment.

More specifically in relation to pipeline leak detection sys-

tems which are covered (but not explicitly) by Reg. 6 of PSR -

Safety systems. The regulation states:

“The operator shall ensure that no fluid is conveyed in a pipe-

line unless it has been provided with such safety systems as are

necessary for securing that, so far as is reasonably practica-

ble, persons are protected from risk to their health & safety.”

However, the associated PSR guidance L82 booklet (ISBN 0

7176 1182 5) states:

“36 Safety systems also include leak detection systems where

they are provided to secure the safe operation of the pipeline.

The method chosen for leak detection should be appropriate

for the fluid conveyed and operating conditions.”

HSE Information relating to Pipeline safety and integrity can

be found on the HSE web http://www.hse.gov.uk

B.4 THE UNITED STATES

Pipeline and Hazardous Materials Safety Administration, DOT

Part 195 - Transportation Of Hazardous Liquids By Pipeline

/26/

§ 195.134 CPM leak detection.

“This section applies to each hazardous liquid pipeline trans-

porting liquid in single phase (without gas in the liquid). On

such systems, each new computational pipeline monitoring

(CPM) leak detection system and each replaced component of

an existing CPM system must comply with section 4.2 of API

1130 in its design and with any other design criteria addressed

in API 1130 for components of the CPM leak detection sys-

tem.”

§ 195.452 Pipeline integrity management in high consequence

areas.

“Leak detection. An operator must have a means to detect

leaks on its pipeline system. An operator must evaluate the

capability of its leak detection means and modify, as neces-

sary, to protect the high consequence area. An operator’s eval-

uation must, at least, consider, the following factors — length

and size of the pipeline, type of product carried, the pipeline’s

proximity to the high consequence area, the swiftness of leak

detection, location of nearest response personnel, leak history,

and risk assessment results.”

Alaska Department Of Environmental Conservation. 18 AAC

75

“Oil and Other Hazardous Substances Pollution Control”,

Revised as of October 9, 2008 /25/:

18 AAC 75.055 Leak detection, monitoring, and operating

requirements for crude oil transmission pipelines.

“(a) A crude oil transmission pipeline must be equipped with a

leak detection system capable of promptly detecting a leak,

including

(1) if technically feasible, the continuous capability to detect a

daily discharge

equal to not more than one percent of daily throughput;

(2) flow verification through an accounting method, at least

once every 24 hours;

and Register 188, January 2009 ENVIRONMENTAL CON-

SERVATION 12

(3) for a remote pipeline not otherwise directly accessible,

weekly aerial surveillance, unless precluded by safety or

weather conditions.

(b) The owner or operator of a crude oil transmission pipeline

shall ensure that the incoming flow of oil can be completely

stopped within one hour after detection of a discharge.

(c) If aboveground oil storage tanks are present at the crude

oil transmission pipeline facility, the owner or operator shall

meet the applicable requirements of 18 AAC 75.065, 18 AAC

75.066 and 18 AAC 75.075.

(d) For facility oil piping connected to or associated with the

main crude oil transmission

pipeline, the owner or operator shall meet the requirements of

18 AAC 75.080. (Eff. 5/14/92,

Register 122; am 12/30/2006, Register 180)

18 AAC 75.425. Oil discharge prevention and contingency

plan contents.

(a) An oil discharge prevention and contingency plan submit-

ted for approval under 18 AAC 75.400 - 18 AAC 75.495 must

be in a form that is usable as a working plan for oil discharge

prevention, control, containment, cleanup, and disposal. A](https://image.slidesharecdn.com/rp-f3022010-04-150513092724-lva1-app6891/75/Rp-f302-2010-04-23-2048.jpg)

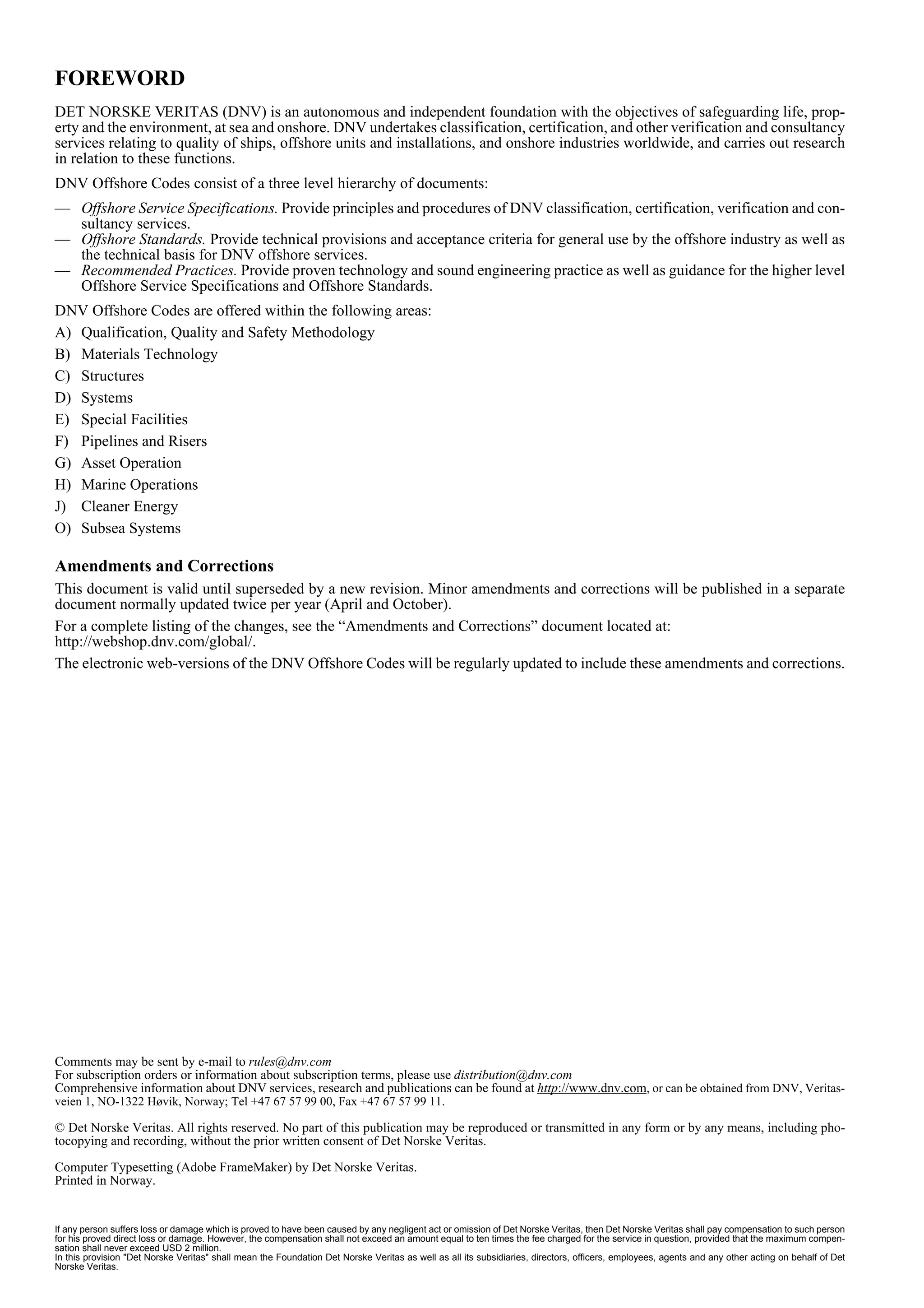

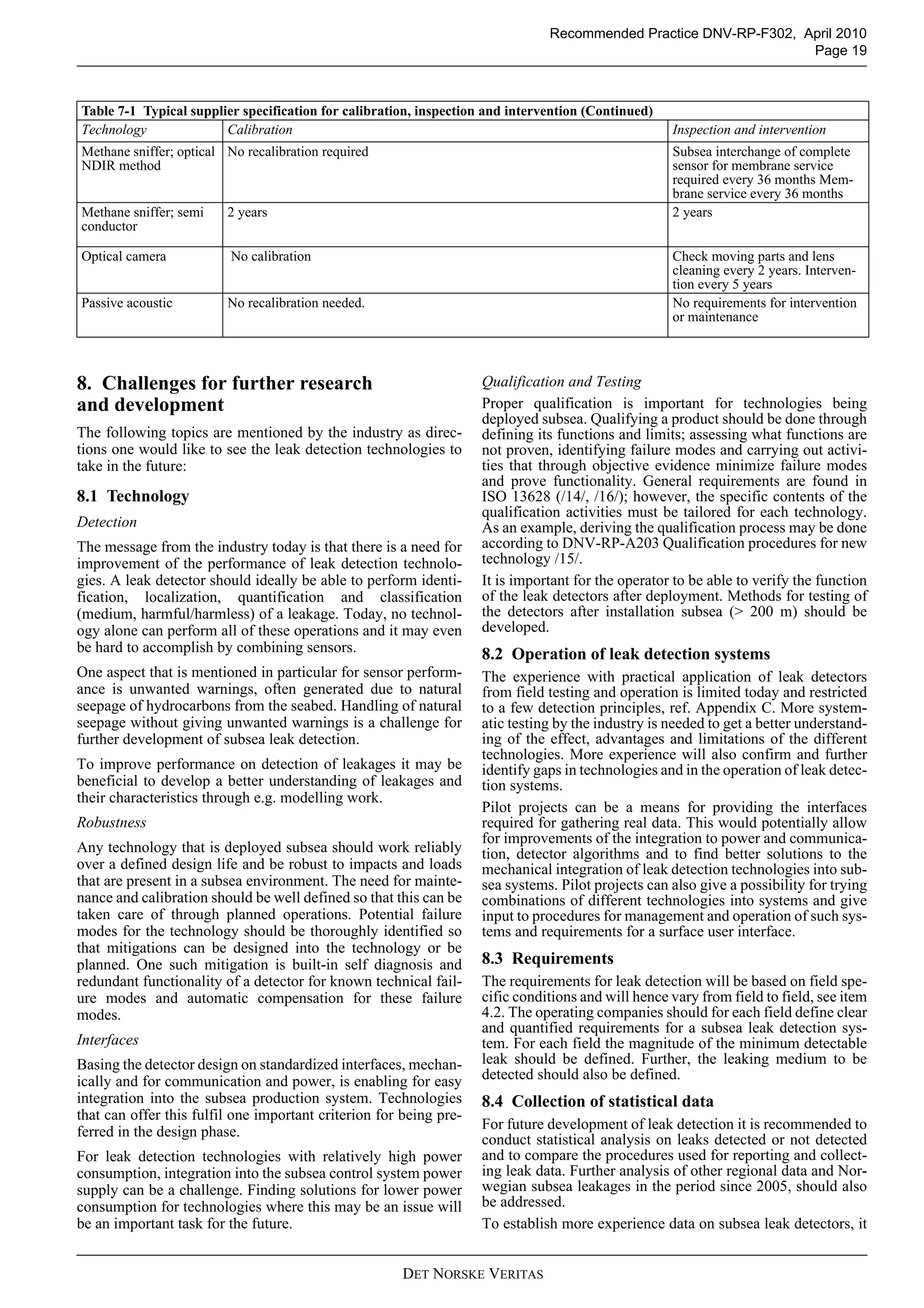

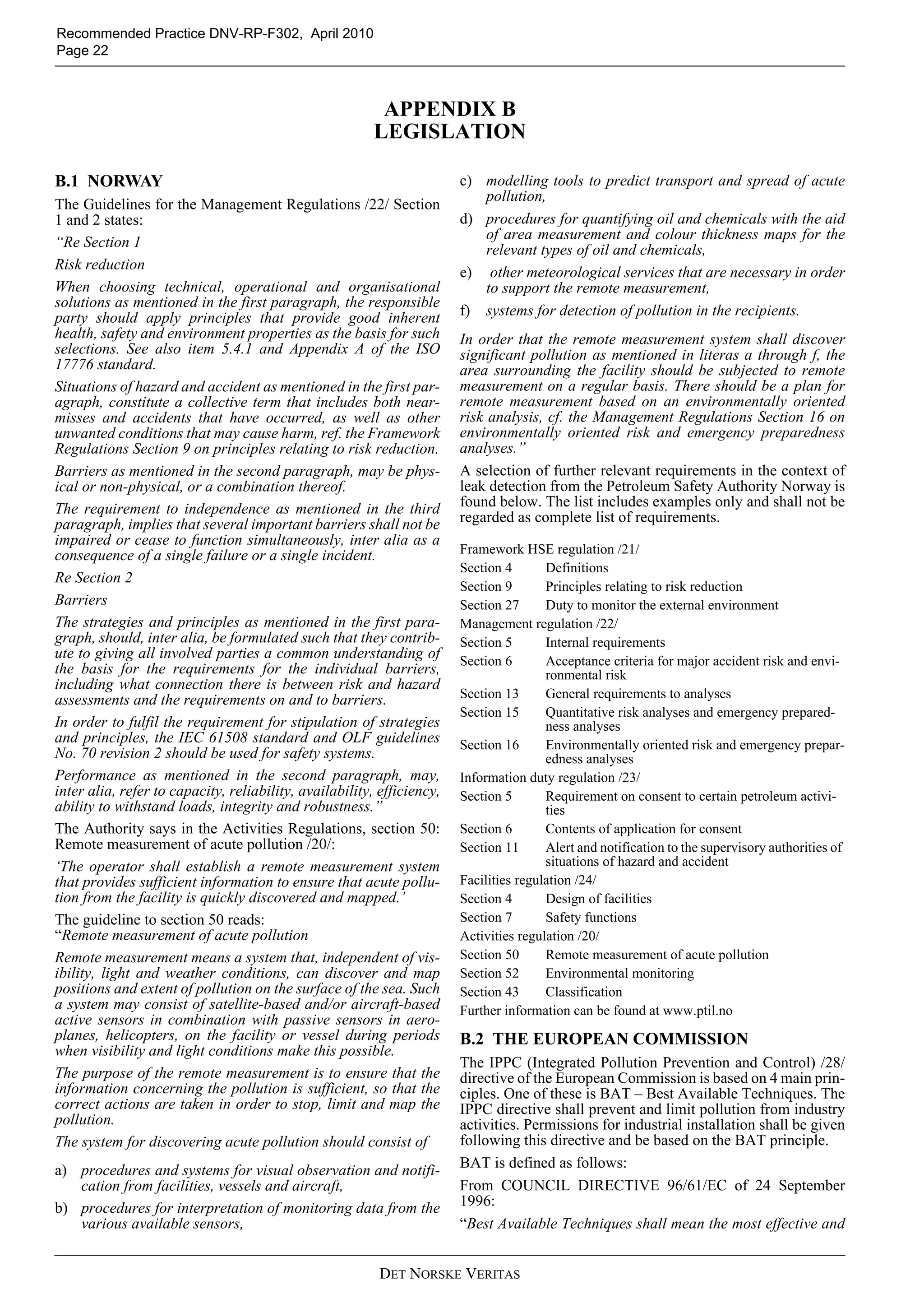

![Recommended Practice DNV-RP-F302, April 2010

Page 32

DET NORSKE VERITAS

APPENDIXD

SUBSEALEAKDETECTORSSUPPLIERTECHNICALDATA

TableD-1Detectors-SupplierTechnicalData

Tech-

nology

Calibra-

tion/

Re-cali-

bration

Mainte-

nance

Mechani-

calinter-

face

Weight

[kg]

DimensionsConnec-

tionto

power

andcom-

munica-

tion

Power

need

Band-

width

need

Maturity1Detectablerelease

limitorotheraccu-

racyinformation

Detectable

media

Detection

range

Reliabil-

itydata2

Design

life

[years]

Water

depth

[m]

Tem-

pera-

ture

[°C]

Active

acoustic

Calibra-

tiondur-

ingSea

Accept-

anceTest

3-5

years

interval

Mounted

onROV

skidor

directlyto

template

structure.

Willbe

designedto

beROV

retievable.

Receive

array9.6

(dry),

subsea

bottle

24.8

(dry),

transmit

array4.5

(dry),

Receiver:

102x496x

131mm

Transmit-

ter:240x86

x99mm

Subsea

Bottle:

530.9x

174mm

48V,

Ethernet

40W-

100W

High,

develop-

ment

goalis

1-

10Mbit

ethernet

interface

Baseline

offshore

product:

Commer-

ciallydeliv-

ered.

Subseaver-

sion:Con-

cept

Smallgasleakages

(0.35mmnozzle,2

barpressurediffer-

ence)detectedat

about30meters.

Fluidleakfrom5mm

nozzlewith15bar

pressuredifference

detectedat50m

Notdepend-

entonchem-

ical

compoundas

longas

acoustic

impedanceis

differentto

thatofsea-

water.

dependson

leaksizeand

media.Small

gasleaksseen

upto125m

range.Fluid

seenupto50m

range(maxi-

mumtestrange

todate

NA*NA*400

and

6000

ver-

sions

avail-

able

-5to40

(opera-

tion)

-30to

55

(stor-

age)

Cali-

brates

automati-

callyat

installa-

tion.No

recalibra-

tion

needed.

Deep-

ening

on

water

depht

from4-

8years

interval

ROV

mountable

onXmas

tree,nopre

installation

required

<11kg

com-

plete

unit

(dry)

226x62x

154mm

15-36V

100Mb/s

Ethernet

16Mb/s

RS-485

Typ:

15W

<30W

-

depend

enton

require

d

updat-

ingrate

Depend-

entom

requier-

ment

and

infroma-

tion,can

below

9600

Baud-

system

spesific

PrototypesAngularresolution<

0.75°

Rangeresolution<

10mm

Notdepend-

entonchem-

ical

compoundas

longas

acoustic

impedanceis

differentto

thatofsea-

water.

Anglehorizon-

tal90°or120°

Anglevertical

20°

Range1to<

100m

NA*25300or

3000

-20-60

Biosen-

sors

Calibra-

tionafter

installa-

tion

Replace

mentof

biosen-

sor

module

Installedin

asensor

rackinte-

gratedorin

proximity

ofthemon-

itored

structure

Biosen-

sormod-

ule:2-3

(inair)

Prototype

racksare2

mx0.4mx

0.4m(phys-

ical,chemi-

caland

biological

sensor

array)

Con-

nectedto

subsea

control

system

viacable.

RS-485

orEther-

net

approx

.10W

LowPilots

installedfor

shallow

water.Con-

ceptfor

deepwater

<0.06ppmon

hydrocarbons(raw

oil)

Notdepend-

entonchem-

ical

compound,

specification

willdepend

onselected

biosensor.

Dependingon

leaksize,

mediaandsea

current

(upstream/

downstream

approach)

NA*NA*100

(500

from

2012)

Ocean

temper-

ature

range.](https://image.slidesharecdn.com/rp-f3022010-04-150513092724-lva1-app6891/75/Rp-f302-2010-04-32-2048.jpg)

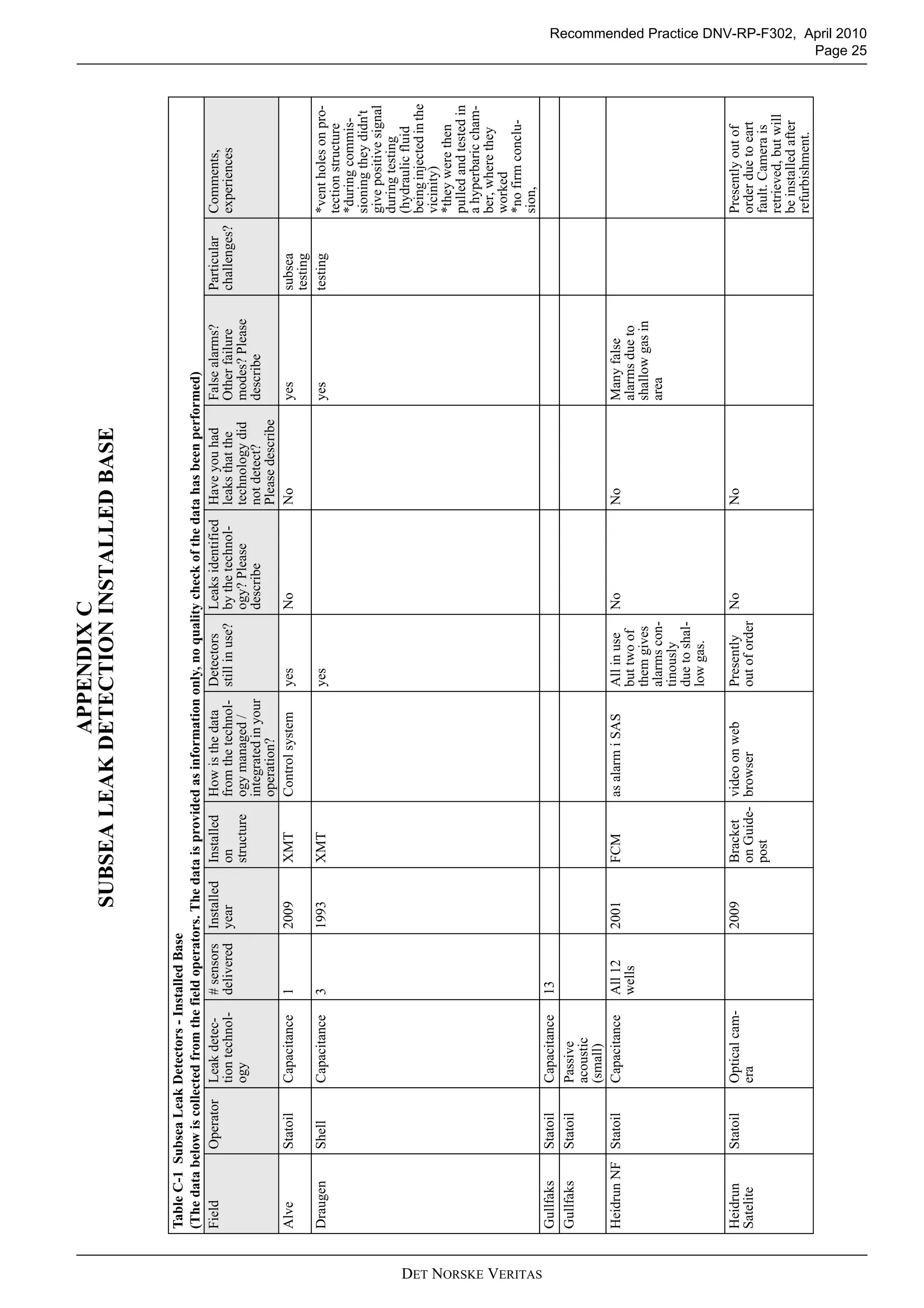

![Recommended Practice DNV-RP-F302, April 2010

Page 33

DET NORSKE VERITAS

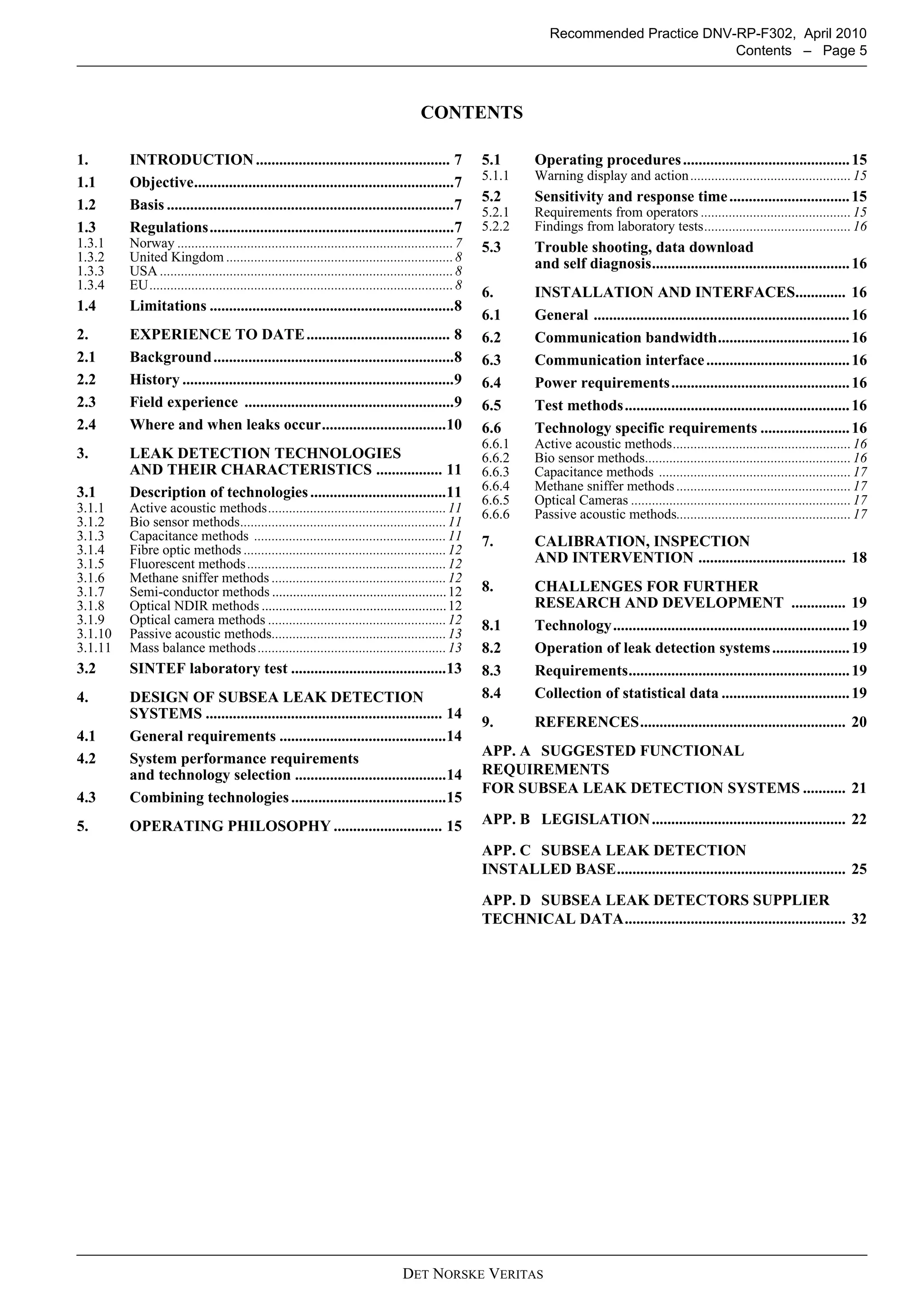

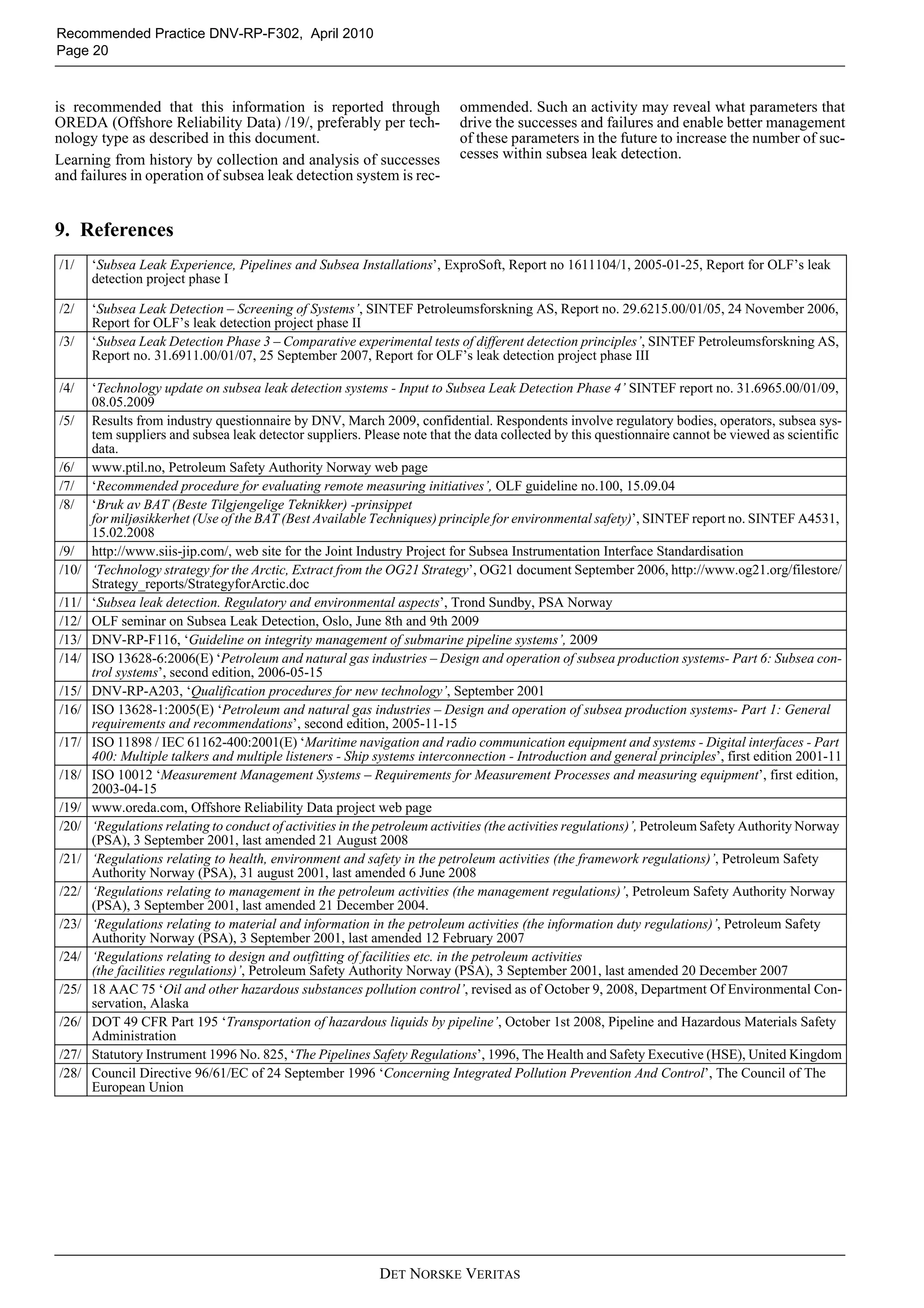

Capaci-

tance

Norecali-

bration

required

Clean-

ing.

Usinga

hydro-

jet

should

beOK

Boltedon

tocover

aboveleak

point.

<5<1000ccm

=1l

4-20mA

and

CANBus

24V,

0.5W

LowCommer-

ciallydeliv-

eredand

qualified

Evensmallleaksare

detected.

Allhydro-

carbons

Dependingon

overallsystem

design.

Approx.

300units

deliv-

ered,no

returns

andno

reports

offailure

after

installa-

tion.

254000,

deepe

rif

requir

ed.

Allsea

temper-

atures

OK.

Fiber

optic

Nocali-

bration

2YearsSystem

Specif

20kg-

surface

equip-

ment

56x45x15c

ms

Ethernet

atsur-

face

240/

110v

300w

at

surace

System

spefic

Concept

tested(top-

sidefor

pipelines)

Gasbubbleat1Hz

detected.Lowpres-

surethreshold

approx2bar.No

upperlimit

Notdepend-

entonchem-

ical

compound,

detects

vibrations

causedbya

leak

Dependenton

energy,but

typically5m

NA*204000+5to

+50

(opera-

tion)

Fluores-

cent

Norecali-

bration

required

Possi-

blelens

clean-

ing

every

3-5

years

Boltedon

toXTand

SPS

10-15in

air

Ø200x200m

m,

100x200x20

0mm

4wire

Tronic/

Canbus/

4-20mA

24V,

<10W

LowInusewith

ROV.Con-

ceptversion

forsubsea

Widedynamic

range.<100ppm

@4m

Crudeoil.

Production

fluidswith

fluorescent

markers

3-5mNA*NA*NA*NA*

Meth-

ane

sniffer;

optical

NDIR

method

Norecali-

bration

required

Mem-

brane

service

every

36

months

ROV

mountable/

inter-

changea-

blebywet-

mateable

plugsand

ROVhan-

dle

5,2inair

2,7in

water

Diameter

90mm,

length

700mm

wet-

matea-

bleplug

3Wlowcommer-

ciallydeliv-

ered

verysmallleaksMethaneNA*Stability

3years.

Newver-

sion5

years

106000-4upto

50

Meth-

ane

sniffer;

semi

conduc-

tor

2years2yearsadaptable

tofitappli-

cation

0.5kgin

water

Ø49mmx

200mm

wet-

matea-

bleplug

1WLowBaseline

product

commer-

ciallydeliv-

ered.

Concept

versionfor

subsea

verysmallleaksMethanelowerrange

limit1nM

(oceanicback-

ground)

lifetime

5years

540000-30

TableD-1Detectors-SupplierTechnicalData(Continued)

Tech-

nology

Calibra-

tion/

Re-cali-

bration

Mainte-

nance

Mechani-

calinter-

face

Weight

[kg]

DimensionsConnec-

tionto

power

andcom-

munica-

tion

Power

need

Band-

width

need

Maturity1Detectablerelease

limitorotheraccu-

racyinformation

Detectable

media

Detection

range

Reliabil-

itydata2

Design

life

[years]

Water

depth

[m]

Tem-

pera-

ture

[°C]](https://image.slidesharecdn.com/rp-f3022010-04-150513092724-lva1-app6891/75/Rp-f302-2010-04-33-2048.jpg)

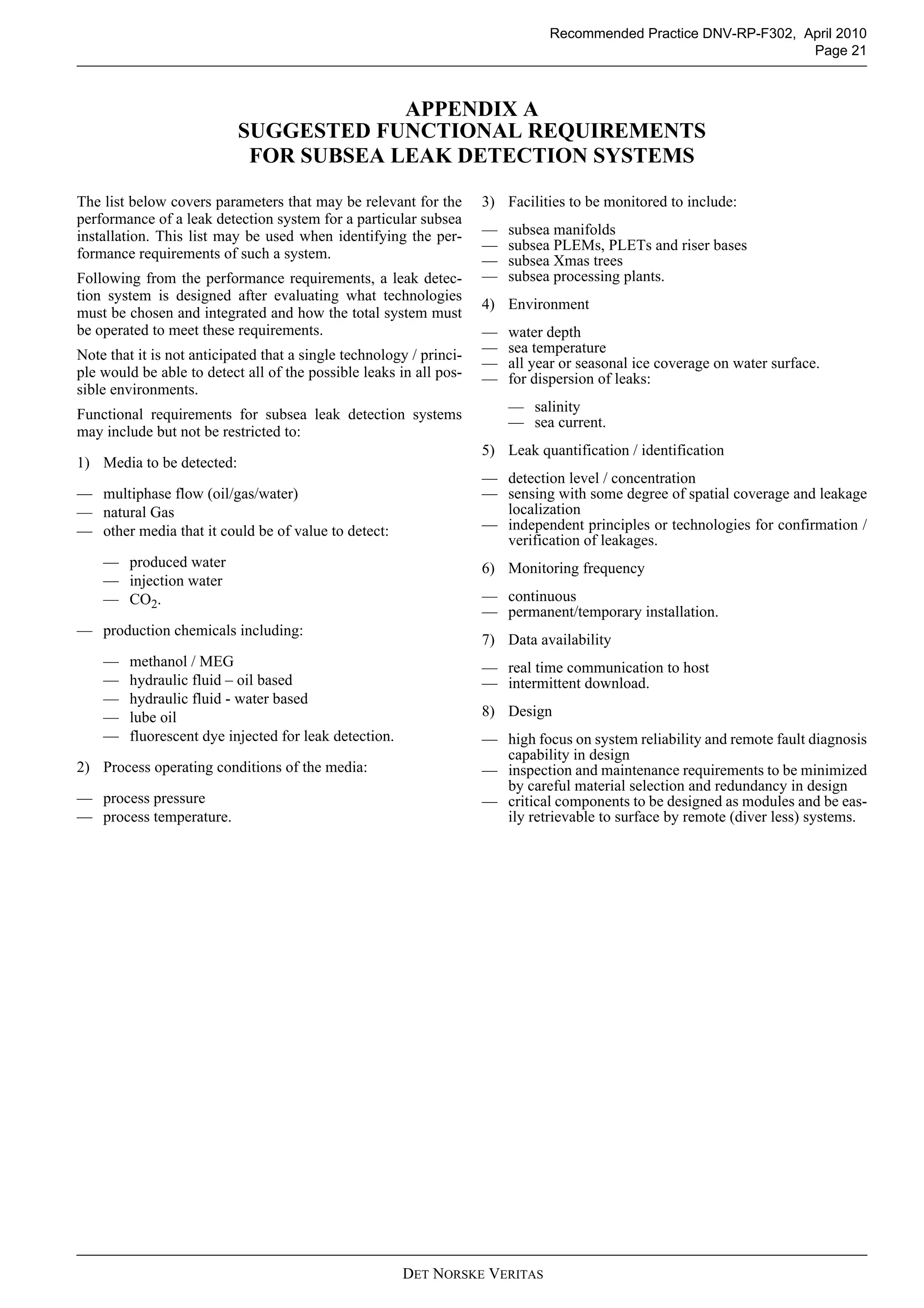

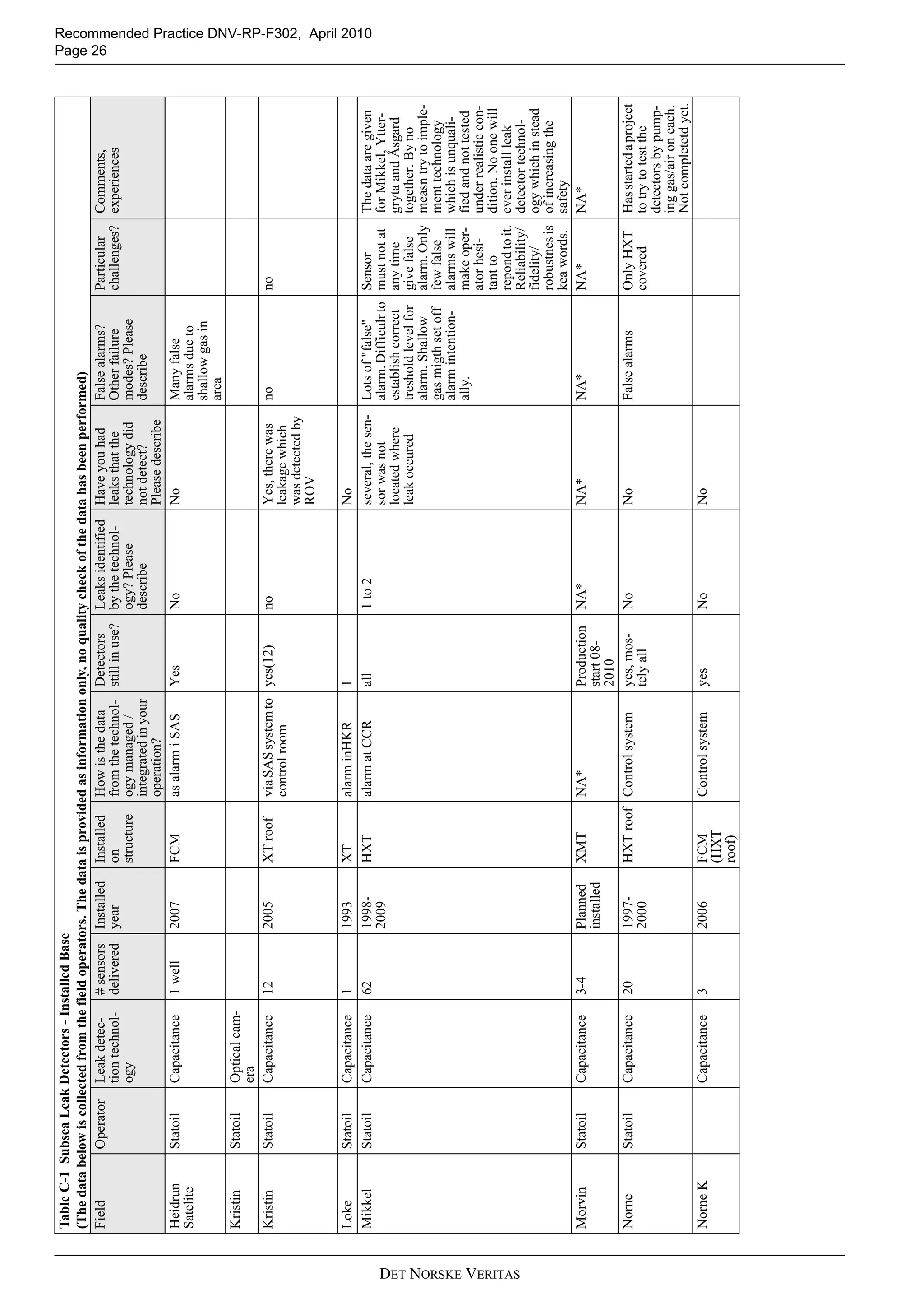

![Recommended Practice DNV-RP-F302, April 2010

Page 34

DET NORSKE VERITAS

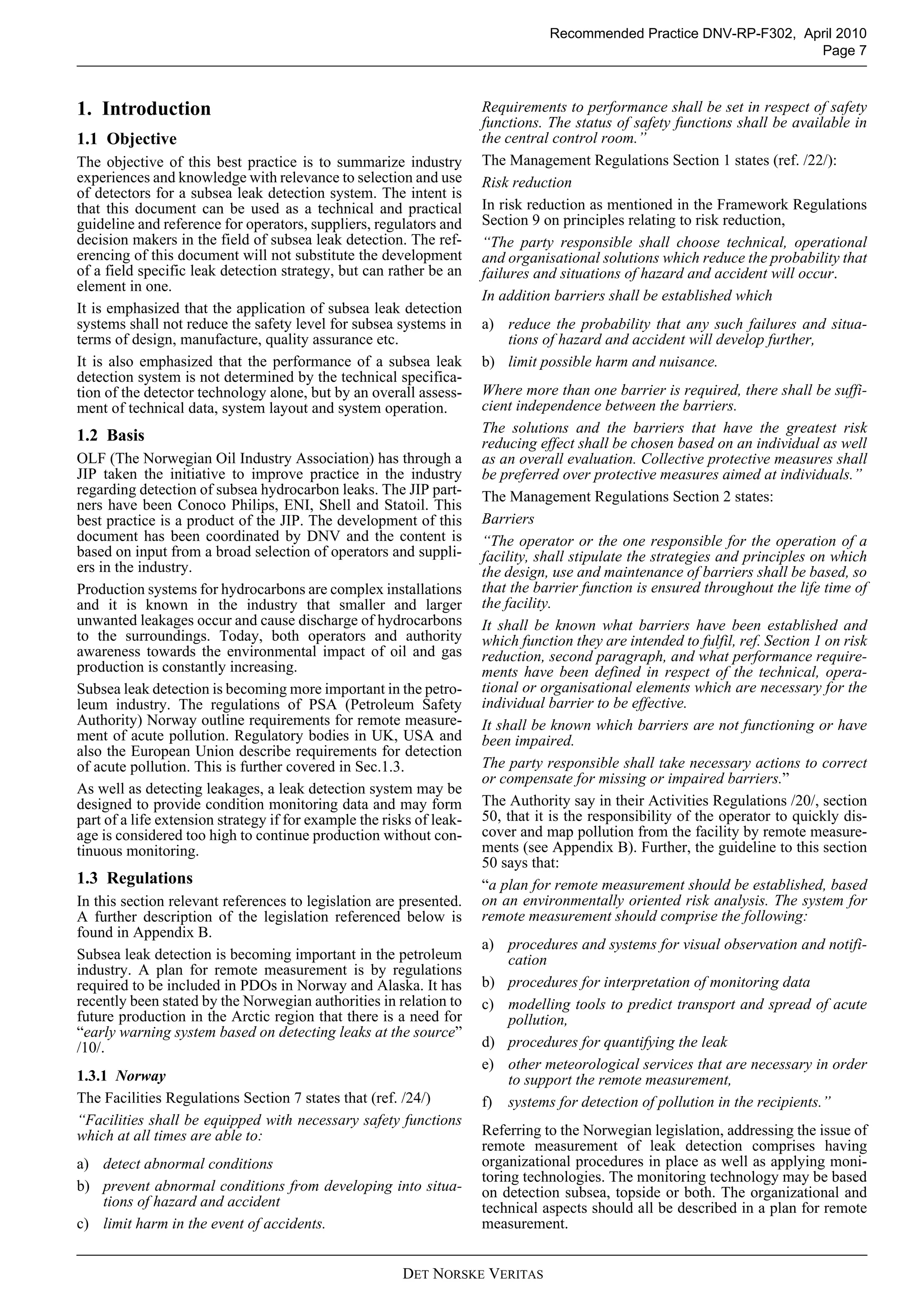

Optical

camera

NoCheck

mov-

ing

parts

and

lens

clean-

ing

every2

years.

Inter-

vention

every5

years

ROV

mountable

onXmas

tree,nopre

installation

required

camera

3.2in

air.

Light

4.1in

air.

ø100x200m

m.

880*550*45

0

4wire

tronic.

Commu-

nication

via

power

line.

96WMedium

.Com-

munica-

tionon

separate

lineor

viasub-

seacon-

trol

system

Firstproto-

typewith

patternrec-

ognition

readyin

2006

NotdefinedAll

hydrocar-

bonsand

injected

chemicals

10metersNA*251000

made

inalu-

min-

ium

3000

made

intita-

nium

Passive

acoustic

Adaptsto

back-

ground

noiseat

installa-

tionsite.

Norecali-

bration

required

NonROV

mounting,

forlarger

typeofsys-

temsaspe-

cialconeis

required

Smaller

type2-3,

larger

type250

inair

Smallertype

ø64x

357mm,

largertype

ø1x1.8m

NA*Larger

type:

25W

Depend-

entom

process-

ingsub-

seaor

topside.

Process-

ingtop-

side

requires

more

band-

width

Commer-

ciallydeliv-

ered,both

largerand

smaller

type

Smallertype:5liter/

min@25Bardiff

pressureat2mdis-

tance.Detection

range50mwith

increasedleakage

rate.Largertype:5

liter/min@5Bar

diffpressureat5m

distance.Detection

range1000mwith

increasedleakage

rate.

Notimpor-

tant,allleaks

asdescribed

under

'Detectable

releaselimit'

Seedetectable

releaselimit

25.8year

calcu-

lated

MTBF

basedon

data-

heets,

EPRD-

97and

MIL-

HDBK-

217F.

5for

small

type

and25

for

large

type.

2500opera-

tional

insea

water:-

5-+30.

Onshor

etest

temper-

ature-

20-

+70.

Stor-

age-40

-+70

Cali-

brates

automati-

callyat

installa-

tion.No

recalibra-

tion

needed.

NonROV

mountable

onXmas

tree,nopre

installation

required

<7kg

sensor

unit

(dry)

<15kg

funnel

(dry)

324x

ø90mm

Con-

nectedto

subsea

control

system

via

RS485,

CanBus,

Profi-

bus,

Modbus

orEther-

net

0,8W,

12-38

VDC

mini-

mum

1200

baud,

upto115

Kbaud

Commer-

ciallydeliv-

ered

Minimumforliquid:

dP>3bar,min.leak-

agerate0.1l/min

Minimumforgas:

dP>1bar,min.leak-

agerate0.1l/min

instrumenttobe

closetoleaksource-

mechanicalonto

structureorvalves

Shortarea

coverage

withinradius

of3meters-

leaksneedto

belargertobe

detected

beyondthis

area

Deliv-

eredin

several

versions

-more

than

1000

systems

installed

subsea

MTBF

calcula-

tions>

140

Years

+304500-20-215

TableD-1Detectors-SupplierTechnicalData(Continued)

Tech-

nology

Calibra-

tion/

Re-cali-

bration

Mainte-

nance

Mechani-

calinter-

face

Weight

[kg]

DimensionsConnec-

tionto

power

andcom-

munica-

tion

Power

need

Band-

width

need

Maturity1Detectablerelease

limitorotheraccu-

racyinformation

Detectable

media

Detection

range

Reliabil-

itydata2

Design

life

[years]

Water

depth

[m]

Tem-

pera-

ture

[°C]](https://image.slidesharecdn.com/rp-f3022010-04-150513092724-lva1-app6891/75/Rp-f302-2010-04-34-2048.jpg)

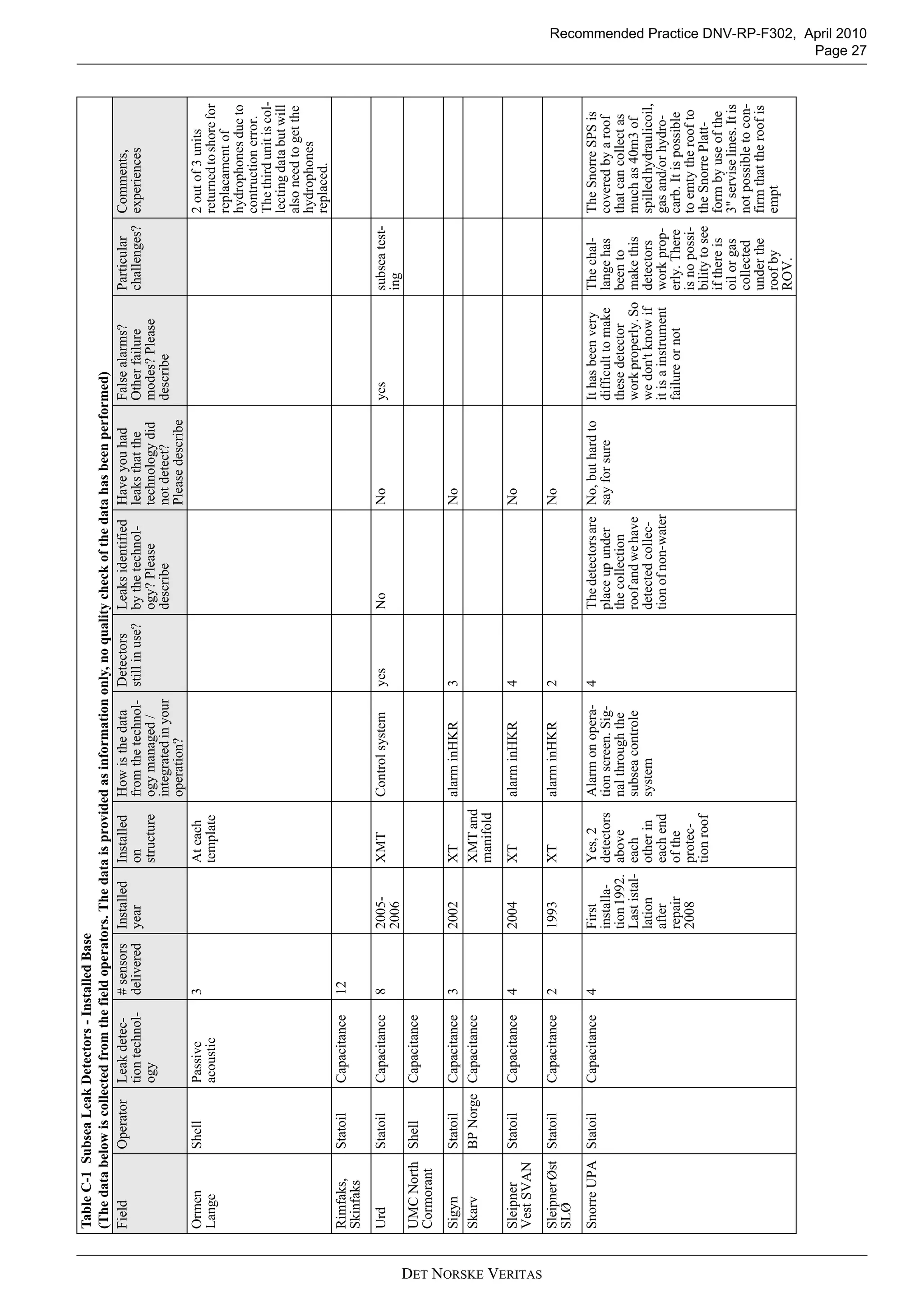

![Recommended Practice DNV-RP-F302, April 2010

Page 35

DET NORSKE VERITAS

Note1:Thedatabelowarecollectedfromvarioussuppliersofleakdetectors.Forsomeofthetechnologies,morethanonesupplierisavailableandhavebeengivinginputtothedatabelow.Whenconsidering

aspecificproductforagivenapplication,objectiveevidenceshouldbecollectedfromthesuppliertoverifytheperformancespecificationsforthatspecificproduct.

Note2:Othersuppliersthanthosethathavegiveninputtothistablemayexist

1Maturityclassesareforthistabledefinedasfollows:Concept,ConceptTested,PrototypesorPilotstested,Commerciallydelivered,Commerciallydeliveredandqualified

2Reliabilitydatamaybecalculatedfromfieldexperiencedataormaybecalculatedbyapplyingareliabilitymodel.Inbothcases,thereliabilitydatashouldbespecificandgiveninhardnumbers

*NA=NotApplicable

TableD-1Detectors-SupplierTechnicalData(Continued)

Tech-

nology

Calibra-

tion/

Re-cali-

bration

Mainte-

nance

Mechani-

calinter-

face

Weight

[kg]

DimensionsConnec-

tionto

power

andcom-

munica-

tion

Power

need

Band-

width

need

Maturity1Detectablerelease

limitorotheraccu-

racyinformation

Detectable

media

Detection

range

Reliabil-

itydata2

Design

life

[years]

Water

depth

[m]

Tem-

pera-

ture

[°C]](https://image.slidesharecdn.com/rp-f3022010-04-150513092724-lva1-app6891/75/Rp-f302-2010-04-35-2048.jpg)